The presence of a well in a suburban area is often a prerequisite for creating comfort. Many people prefer to have an independent source even with a centralized water supply. The absence of this makes it necessary to extract water from the bowels. The state of the art has greatly expanded the drilling capabilities. But a do-it-yourself water well remains a reality and an inexpensive way to provide it.

Content [Hide]

- 1 Diy wells: possible types

- 2 The main methods of drilling wells under water

- 3 Manual drilling of a well under water

- 3.1 Impact method

- 3.2 Rope percussion drilling

- 3.3 DIY tools used in drilling water wells

- 3.4 Turnkey water well price

- 3.5 Water supply of a private house from a well: layout of the main elements

- 3.6 Well pumps: key features

- 3.7 Basics of correct well operation

- 3.8 Do-it-yourself water well: possible problems and solutions

Diy wells: possible types

Providing water is the primary task in the arrangement of any living space. Today, there are several ways to extract water:

- well;

- Abyssinian well:

- sand well;

- artesian well.

Arrangement of a well is a laborious and therefore expensive process.

Its disadvantage is also the fact that water is drawn from the upper layers, which creates a high probability of contamination, both external and entering through the upper layers of the soil. The amount of water is limited, the average flow rate is 0.5 cubic meters per hour. The well requires constant cleaning and repair, all these processes are carried out manually.

A well is a more modern, reliable, durable and affordable way of producing water. You can drill a well for water on any land plot. Depending on the depth of the aquifers, the type of structure is selected: Abyssinian well, sand or artesian well. If the aquifer is located at a depth of 12 m, an Abyssinian well is drilled. If this figure is 50 m, water can be produced using a sand well. Artesian is necessary if the water is at a depth of up to 200 m.

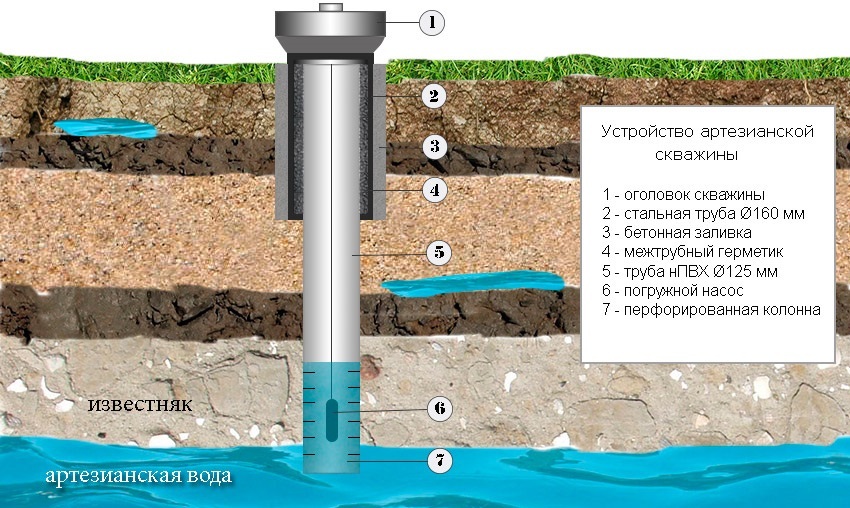

The Abyssinian well has a small diameter, surface dirt and dust do not get into it. A cheap and reliable option for moderate water use. The sand well has an average flow rate of 1.5 cubic meters per hour. This is a filter view, i.e. put on the water-bearing sand filter made of polymers or stainless steel. The artesian well is filterless, the water is supplied clean, without impurities.The flow rate ranges from 5 to 100 cubic meters per hour.

A diagram of the principle of operation of a well for water (sandy appearance) gives a visual representation of its internal structure.

Choosing a well type is an extremely important and responsible process.

Helpful advice! If there is no information about the depth of the water layer, it is not worth determining the type of well without preliminary exploration. This can lead to unplanned additional costs and unexpectedly low production rates.

Basic ways drilling wells for water

Drilling wells do it yourself is quite realistic and affordable if you have the necessary hydrogeological information. Having chosen the method of drilling a well for water, you should correctly determine the place for its installation. There should be no sewerage system, drain pits, or other communications that can pollute water nearby. It is also necessary to take into account the distance from the housing where it is planned to supply water.

There are a lot of types of manual drilling, using various mechanisms, devices, complex equipment: from the simplest hammering to hydraulic drilling.

Drilling methods for water wells differ depending on the technology used to destroy the rock. There is drilling:

- shock;

- rotational;

- mixed type.

Auger drilling

This method is used for sand wells. Typically, auger drilling of water wells is carried out in relatively soft, loose or frozen soil. The auger is a pipe wrapped in a metal tape. By rotation, the screw-shaped device deepens, giving out the selected soil to the surface. Often, with this technology, a casing is lowered behind the auger screw, which clogs the walls and prevents the earth from crumbling. This method has several advantages:

- good speed;

- no need for flushing;

- borehole walls are compacted.

If auger drilling is carried out in an area with soft or loose soil, then the bit blades should be positioned at an angle of 30 to 60 degrees relative to the bottom. If wells are drilled with this method on denser sediments, based on gravel and pebbles, then the blades should be at an angle of 90 degrees relative to the bottom. It is necessary to determine the angle during work depending on the hardness of the soil with which it is supposed to work.

The depth of auger drilling of the well is carried out by the size of one rod, which then rises upward and is increased by an additional rod. After that, drilling can be continued. The diameter of the screw hole ranges from 6 to 80 cm.

Rotary drilling method

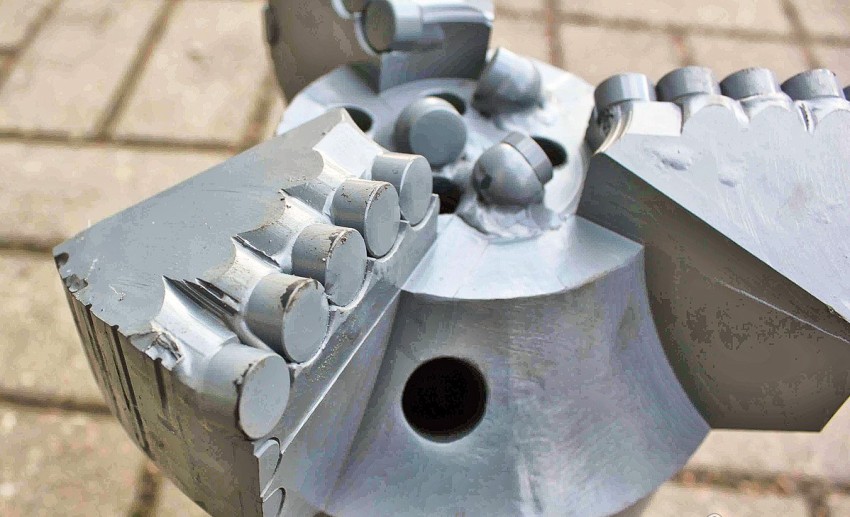

Rotary drilling refers to rotary methods: a rotor located on the surface drives a bit that is lowered into the well. The bit is additionally weighted (“loaded”) with pipes to increase the degree of soil crushing.

Using this technology, you can destroy almost any rock in terms of hardness. This is an expensive method used for artesian wells.

With rotary drilling, flushing is mandatory. This process quickly removes the waste rock while keeping the well clean so that the casing can be inserted smoothly.

There are two types of flushing: direct and reverse. Direct flushing is performed with a clay solution, which quickly removes waste rocks and strengthens the walls, since the clay excludes clogging of the formation. Backwash with water is used to remove slag from the annulus.

Rotary drilling advantages:

- the power of the equipment used, which allows breaking rocks of any hardness;

- the durability of the drilled well (wall strength);

- the ability to drill in a limited area due to the small size of the drilling rig.

The disadvantages of this technology can be considered the complexity of work at sub-zero temperatures and low drilling speed.

Helpful advice! If the rotary method is used on the site, it should be borne in mind that backwashing contributes to a more complete penetration of the aquifer and an increase in the well flow rate.

Manual drilling of a well under water

Drilling a well by hand only for an unprepared person will seem to be an extremely difficult process that requires large physical costs. With certain knowledge and preparation, making a drill for a well with your own hands is realistic and feasible. Depending on the conditions of groundwater occurrence, you can use several methods of self-drilling wells.

To carry out drilling operations, specialists are usually invited, but if desired, they can be performed independently

Impact method

In this way, the simplest needle-hole is installed - the Abyssinian well. This method is actively used by home craftsmen, punching a well for water in the country. The "rig" design is a borehole made up of pipe sections and a tip that cuts through layers of soil. The hammer is a weighty woman, which rises and falls with the help of ropes: when pulled, a kind of hammer rises to the top of the structure, when loosening it falls onto the podbabok - a device of clamps arranged symmetrically. After the trunk enters the ground, it is built up with a new section, the cap is attached to the new part, and the hammering continues until the tip enters the aquifer by 2/3 of the formation.

The trunk-pipe serves as a hole for water to exit to the surface.

Important! The Abyssinian well raises the uppermost aquifer, which contains many impurities. Water from such a well can only be used for technical purposes. It is suitable for drinking only after deep cleaning.

The advantage of this well is that it can be drilled in a basement or other suitable room. This creates ease of use. The price is also attractive, it is inexpensive to pierce a well for water in this way.

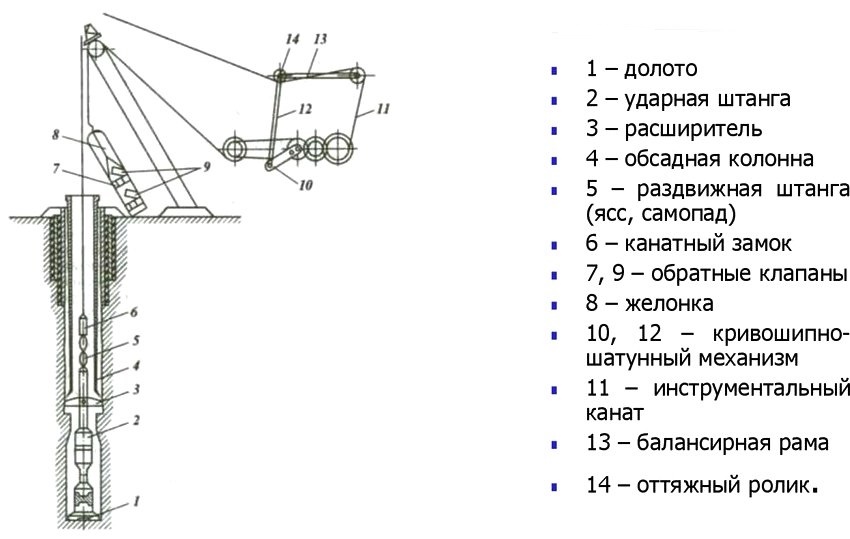

Rope percussion drilling

The most commonly used method. This method involves breaking the ground by lowering a heavy drilling tool from a two-meter height. The structure used in this type of drilling consists of the following elements:

- a tripod, which is placed over the drilling site;

- block with a winch and a cable;

- hammer-in glass, rods;

- bailers (for passing through loose soil layers).

The glass is a piece of steel pipe, beveled inward, with a strong lower cutting edge. An anvil is placed on top of the driving glass. A barbell hits it. The lowering and raising of the driven nozzle is carried out using a winch. The rock that enters the glass is held in it by friction. In order to penetrate as deep as possible into the ground, a shock bar is used: it is thrown onto an anvil. After filling the glass with soil, it is lifted up and then cleaned. The operation is repeated until the required depth is reached.

Well drilling on loose soils is carried out using a thief. The latter is a steel pipe, at the lower end of which a stop cap is installed. After the thief enters the soil, the valve opens, as a result of which the soil enters the pipe. When the structure is lifted, the valve closes.After being removed to the surface, the thief is cleaned, the actions are repeated again.

Helpful advice! In rope-hammer drilling, it is necessary to carefully monitor the verticality of the well. At the slightest deviation, the installation of casing may become impossible. To prevent the problem, do not use a glass less than 2 m high.

The screw method described above is also effectively used for independent drilling. How to drill a well with your own hands using an auger, it makes no sense to explain additionally – the basic principle remains.

The advantages of hand drilling:

- economical way financially;

- repair and maintenance of a hand drill is easy to do;

- the equipment is not bulky, so there is no need to use heavy equipment;

- the method is applicable in hard-to-reach places;

- effective, does not require a lot of time.

The main disadvantages of manual drilling can be considered lowering to a shallow depth (up to 10 m), where mainly formations pass, the water of which requires cleaning, and the inability to crush hard rocks.

The manual drilling of a well for water watched on the video will help to avoid typical mistakes when choosing a location and method of drilling

Related article:

Plastic caisson for a well: how to choose and install yourself

Appointment of the caisson. Prices and characteristics of the most popular models.

Tools used when drilling water wells with your own hands

When arranging a water well with your own hands, the correct selection of tools is of great importance. It determines the speed and quality of work.

The drilling tool must be made of a strong and wear-resistant material, preferably steel. You can buy it in a store, or you can make it yourself and be sure of its quality. The main tools used when self-drilling a well:

- the spoon. It consists of a steel hollow cylinder, which has a threaded head in the upper part for connecting to the rods, and in the lower part there is a cutting edge. The body has a longitudinal slot with one edge bent inward, and the second is sharpened and can work like a blade when rotating. A drill spoon can be crafted in a workshop that has a lathe and a forge. These fixtures have diameters of 70,140 and 198 mm. This size of the spoon should be 10 mm larger than the diameter of the pipes lowered after drilling;

- chisel. The wellbore is rounded by turning the bit 15–20 degrees after each stroke. The tool is made by forging from one piece of ductile steel. Its sharpening angle is 90 degrees. Chisels have a diameter of 74, 108, 147 mm. Small fixtures can be made in workshops where there is at least a small forge, as well as lathes and planers;

- bailer. Its body consists of an iron or steel pipe, to the top of which a fork with a tapered thread is attached for hanging from a rope or attaching to working rods. In the lower part, the pipe is equipped with a steel cutting shoe with a valve. The thief body can be made of casing or gas pipe 1–2 m long;

- screw. It has flat spirals with rapid pitch. At the end of the tool there is a hammer that breaks the rock, and flat spirals bring it to the surface. The efficiency of the auger can be increased by using a small motor to rotate, for example, from a saw, a motor plow, etc .;

- glass. It is a conventional pipe with pointed bottom ends. Working with it consists in lifting and dropping it from a height of 2-3 m to the bottom. Sharp ends cut the rock and tear it away from the face;

- barbell. It is used for percussion and rotary drilling. On it, a tool is lowered to the bottom of the hole, while it rotates, drilling is carried out, with its help, destroyed rock is extracted to the surface. The rods are subjected to compressive, tensile, bending and twisting loads. As this tool, you can use square or round steel rods, as well as water pipes with a reinforced wall.

Flexible augers are characterized by simplicity of design, reliability and manufacturability of maintenance

Turnkey water well price

The cost of a turnkey water well, the price per meter of drilling, is a complex value influenced by a number of circumstances. First of all, it depends on the location of the object and the specifics of the area. Geological sections in the territory of one region are heterogeneous, the distribution of aquifers is different. As a result, drilling water wells costs differently in each area. In addition, soil composition and landscape matter.

To calculate what the price of a well for water will be, the following factors must be taken into account:

- development area;

- the technique used;

- fare;

- the depth of the aquifers;

- installation of equipment;

- direct work on drilling and pumping a well for water;

- type of well, features of its technical arrangement.

First, a qualified study of the soil is carried out, as a result of which the technology and equipment are selected. Since all the work of drilling a water well is carried out by one company, you can save time and effort by getting water in the shortest possible time.

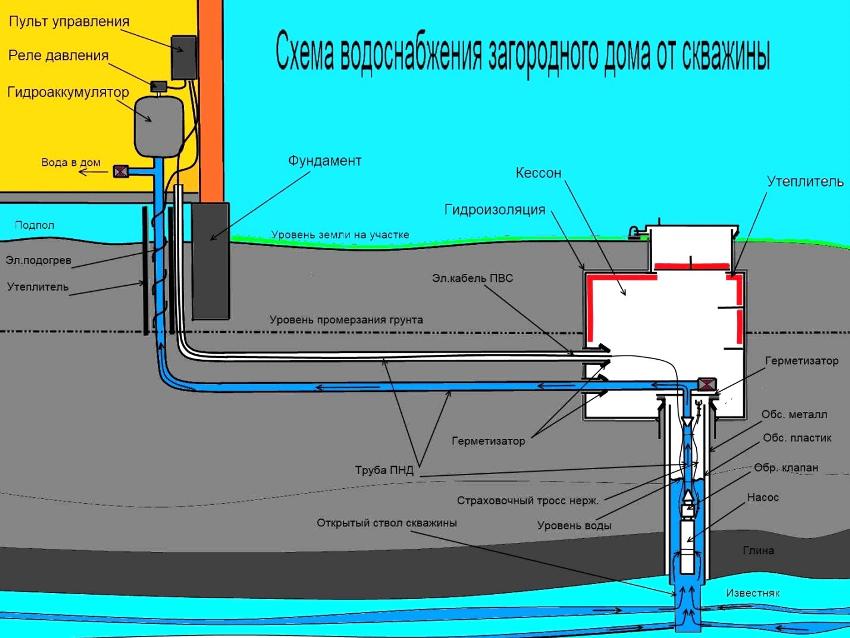

Water supply of a private house from a well: layout of the main elements

The installation of a water well in a private house and connecting a water supply to it will not cause difficulties if you draw up a diagram correctly and purchase high-quality equipment. The water supply scheme for a private house from a well contains 3 main components:

- source (well);

- pumping station;

- pipeline.

These main components are equipped with additional:

- well caisson;

- automation;

- cleaning filters;

- water heater.

To connect the water supply to the house, pipes must be laid. If you do not plan to arrange insulation in the form of a cement tunnel (which is troublesome and time-consuming), you need to dig a trench that will lower them below the freezing point. Another option for insulation can be fiberglass foil materials.

Raw materials for pipes are used in different ways: there are several types of metal and an even greater variety of non-metal, polymer products.

Helpful advice! When replacing or laying water pipes, remember that contact with water and the formation of condensation will necessarily lead to corrosion on metal products. Plastic pipes are not subject to corrosion.

Well pumps: key features

When arranging a pumping station, one of the main mechanisms is a pump. The choice of this unit is extremely important.

By the way they work, pumps are divided into 2 types:

- superficial;

- submersible (deep).

Surface pumps pump water out of wells, the depth of which does not exceed 8 m. They are installed on the surface, the installation method is quite simple.

For greater depths, submersible pumps should be chosen. They are of several types:

- centrifugal. They work due to the centrifugal force created by the paddle wheel blades when the shaft rotates;

- screw (or screw). The pumping of liquid occurs due to its movement along the axis of the screw in the chamber formed by the helical grooves and the surface of the body;

- vortex.The basis of the design is a wheel with blades, placed in a housing and attached to a shaft. Powered by centrifugal vortex force;

- vibrating. They work due to vibrations of the membrane, from which a pressure difference arises, and the liquid is pumped into the water supply system.

The main parameters that should be considered when choosing a pump for a well:

- performance;

- power;

- well depth, flow rate and diameter;

- cost.

The price of submersible pumps for water wells is much higher than surface pumps. This is due to their greater power, performance, design and installation features. Among submersibles, the most productive and expensive are centrifugal pumps, among which screw types are popular. They have high technical characteristics, good performance and reasonable price.

If it is necessary to deliver a small volume of water in a short time, it is better to give preference to a vortex pump. A vibration device is more often used with a target orientation - to shake the well. Prolonged exposure to vibration can damage the downhole structure closest to the pump.

Helpful advice! When deriving well parameters, some indicators are relative values. Therefore, when buying a pump, it is worth choosing a suitable model with a performance margin.

You can buy a hand pump for water from a well. It requires physical effort, but it is much more reliable, much cheaper, easier to repair and more durable in operation. Hand pumps are of several types:

- vane. Principle of operation: under the influence of a hand lever, the wing rotates, actuating the suction element;

- piston. The pressure is generated at the outlet;

- rod. They act on the same principle as piston ones. The piston is significantly elongated, resembles a barbell, hence the name;

- membrane. The operation is based on the reciprocating movements of the membrane.

When choosing a hand pump for water from a well, it is necessary first of all to take into account the depth of the water reservoir. The deepest of the hand pumps is piston (up to 30 m), diaphragm effective up to 8-10 m. All types of hand pumps can fully replace the surface.

Basics of correct well operation

The cost of repairing a well for water is always high, since this process is complex and labor-intensive. It is not always possible to do this on your own. In order for the well to supply water for a long time and fully, the following rules must be followed when it starts:

- It is necessary to turn on the pump smoothly for the first time. It is necessary to turn the valve on the head, starting from the minimum value of the water intake, and bring it to the optimal value.

- The duration of the first water withdrawal must be at least two hours.

- During operation, it is necessary to avoid excessively short-term switching on of the pumping station.

- A systematic and significant water withdrawal in the first months of operation will ensure a constant flow of water and full functioning of the well.

A prerequisite for a long period of use of water supply is timely maintenance and correctly selected well operation mode.

Helpful advice! At the beginning of using water from a well, it is imperative to take a sample for chemical analysis of the composition. This will allow you to be confident in the beneficial properties of water used as drinking water, and will also make it possible to properly operate the water supply system as a whole.

Diy water well: possible problems and ways to solve them

Even with the payment of the required cost of a turnkey water well, when the work was performed by professionals, it is not always possible to avoid troubles during use. The most common problems during well operation:

- silting up:

- contaminated water;

- weak flow.

If the well is not used systematically, but only in the summer, silting is almost inevitable. There is no need to flush the structure in such a situation, but intensive pumping is needed.

Contaminated water can become due to the ingress of soil, intermediate waters. The most common cause is casing leakage. Repair is needed, it can be significant if casing replacement is required, and not just patching up individual sections.

Helpful advice! When purchasing materials for the arrangement of casing pipes for a water well, the price of which belongs to the budget, it is not worth choosing: the efficiency of the most expensive pumping station can be reduced to zero precisely because of the problems of depressurization. Plastic rings are reliable and convenient for mounting the casing.

Weak flow can cause filter clogging. The solution to this problem is to clean or replace the entire filter.

To figure out how to make a water well with your own hands, or order it on a turnkey basis, accepting the conditions and cost of a water well already in the finished version - everyone decides for himself. Price cannot be a priority, and neither can a manufacturer of equipment. The main thing is that the output has the quality and quantity of water, which is necessary for daily consumption and life support.