One of the most pressing problems for owners of country houses is the arrangement of a water supply and sewerage system. And this is natural, because in the absence of centralized water supply, everyone has to solve this problem on their own. Consider one of the most popular methods for this: a plastic caisson for a well. We will try to figure out what its advantages are over the others, and whether it is possible to carry out the installation on our own.

Content [Hide]

Plastic caisson for a well: what is it and why is it needed

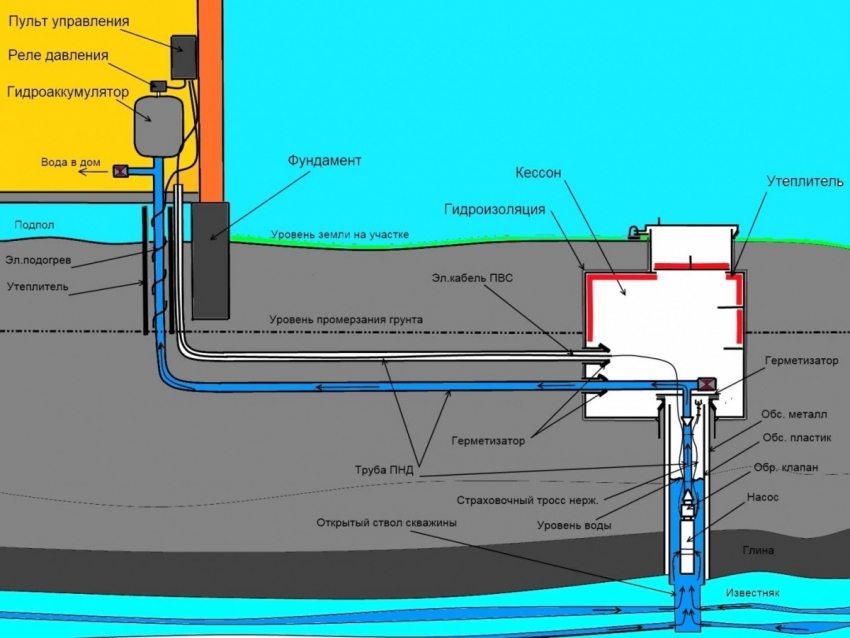

The correct arrangement of the well is the main condition for its stable operation throughout the entire calendar year. That is why we must not forget that in our climatic zone in winter the temperature drops significantly below 0 ° C, which leads to freezing of water. Therefore, when installing plumbing equipment, it is necessary to think over how to protect it from freezing.

At great depths, where the aquifer lenses are located, there is no frost, but closer to the surface of the earth, where the pumping equipment is located, serious temperature drops can lead to its malfunction. Freezing water inside the pipes can cause them to burst and the entire aquifer system will require repair. In order to avoid this, caissons are used.

The caisson is a special thermal container with a lid, which is required for almost every well. The only exception is the case when it comes to a heated building. Although this option is quite rare, since, despite all the amenities associated with maintaining the system, it is very noisy inside the building. Therefore, most owners of country houses give preference to arrangement wells using a plastic caisson.

The composition of the plastic caisson includes the following components:

- a pump that supplies water;

- filtration equipment;

- fittings designed to shut off the flow;

- expansion tank;

- several instruments that measure the pressure inside the system;

- automation.

The caisson is installed on the casing pipe at a depth of 1-2 m, which protects the system even from the most severe frosts.

Useful advice! Additional installation and outlet of the branch pipe allows you to connect a hose for watering the garden and vegetable garden.

Plastic caisson: advantages and disadvantages

Until recently, it was believed that plastic equipment is too fragile and not suitable for use in such harsh operating conditions. But modern technology has made it possible to create plastic caissons that are great for installation in wells. And today, plastic is one of the most popular materials used for this purpose.

The plastic caissons include polyethylene, PVC-U, polypropylene and fiberglass. All of these additives provide the container with added strength and reliability. Let us consider all the advantages and disadvantages of using named caissons from this material.

Pros of using plastic caissons:

- easier maintenance and repair work. If you have a ladder, you can easily check the condition and functionality of all the constituent elements;

- plastic caissons boast a decent service life - about 50 years;

- the thermal insulation performance of plastic is quite high, which makes it possible to avoid additional thermal insulation of equipment in regions with temperate climates. But even if additional insulation is needed, it is quite simple to do this - you can simply equip an insulating shelf;

- plastic is one of the most inexpensive materials today. That is why the use of plastic equipment will cost you several times cheaper than products made of any other material;

- plastic retains all its properties throughout its entire service life, while it does not undergo rotting and corrosion processes;

- during the installation of a plastic caisson, you do not have to worry about waterproofing;

- plastic is lightweight, which allows the installation of equipment without the participation of special equipment and without involving specialists for this;

- modern plastic caissons have no seams and joints, which makes them more durable and significantly reduces the risk of damage during use.

Among the disadvantages of this type of equipment, only one significant disadvantage can be distinguished - plastic is prone to deformation. However, this can only happen when the groundwater is too close to the surface of the earth. If you had to face such a situation, you can solve the problem by pouring a 10 cm layer of concrete around the tank.

Note! Some modern structures are designed to take into account the possibility of groundwater running close to the surface of the earth and have a special field for pouring concrete.

Reinforced concrete or metal caisson for a well: which is better

In addition to plastic caissons, you can find products made of metal or reinforced concrete on sale. What advantages do they have and how to make the right choice, equipping your own well for water with a caisson, we will consider further.

Concrete caissons are extremely rare today. This is due to the fact that the disadvantages of their operation significantly outweigh the advantages. They are very expensive and at the same time require a complex installation procedure, which is associated with a large structure weight. Here you cannot do without the help of specialists, as well as calling for special equipment, which also entails additional costs.

In addition, due to their weight, concrete structures put a serious load on the ground, which often leads to its subsidence, and as a result, damage to the water supply system. In addition, such caissons require high-quality waterproofing and a very reliable foundation.Photos of caissons made from this material can be seen on the Internet.

The advantages of metal tanks include the fact that you can make such a caisson for a well with your own hands. How to make and install a metal structure - you can see in the video or photo instructions. It will be easier to buy a metal caisson, but before doing this, you need to weigh all the pros and cons.

This solution has one significant drawback: most of the cheap and medium-cost materials are corrosive. Those models that are resistant to almost any external factors have a very considerable cost. Also, the prices of metal caissons for a well can vary significantly depending on the manufacturer.

Well caissons: prices and characteristics of popular models

The most popular in the domestic market are plastic caissons Triton... Depending on the size, their cost can range from 18.5 to 80 thousand rubles. You can get acquainted with the current pricing policy of other manufacturers from the table below:

| Manufacturer | Specifications | Dimensions, mm | Weight, kg | price, rub. |

| Metal rolling plant (Russia) | Rectangular metal caisson with built-in ladder. The lid is additionally insulated | 2000x1000x1000 | 280 | 23000 |

| Round metal caisson with built-in ladder. The lid of the container is insulated | 250 | 19230 | ||

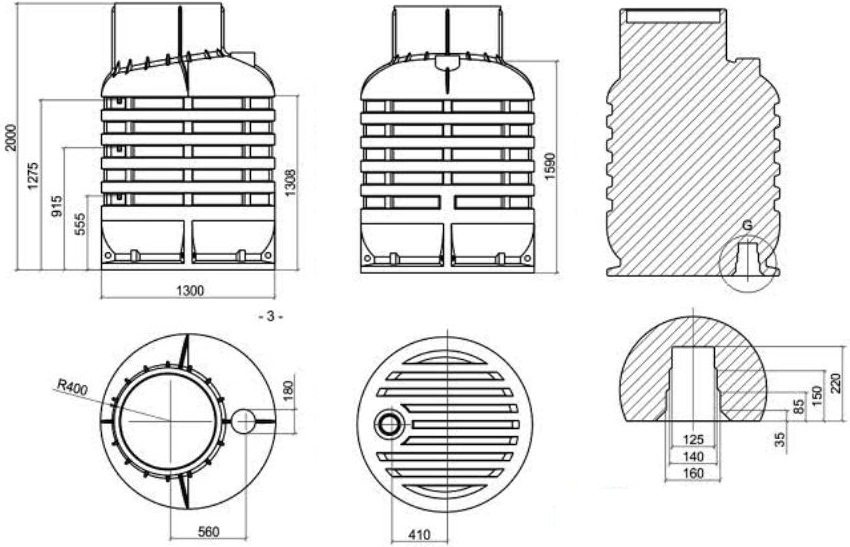

| Termit 2000 (Russia) | Plastic caisson. Allows installation of several holes for pipes of different diameters | 1440x2100 | 85 | 31500 |

| Alta Group (Russia) | Plastic box with 8 mm base. Equipped with an internal ladder and a shelf for insulation | 1000x1000x1630 | 44 | 25100 |

Installation of a caisson on a well: the cost of work

Buying a caisson for a well is only half the battle. After it is delivered to the site, it must be installed. However, not everyone wants to do this on their own. Most prefer to turn to professionals and order the installation of a caisson under the well from a company that specializes in this.

Some companies offer their customers free installation of equipment, provided that you have to buy a plastic caisson from them. However, this can be found infrequently, and the products they offer will have a cost that is several times higher than other similar offers.

Consider the average price range for the installation of the caisson in the well:

- Digging a pit for a caisson will cost about 12,000 rubles.

- Installation of the device inside the well - 9,000 rubles.

- Installation of the pump will cost about 8,000 rubles.

- Work related to digging trenches, as well as laying a cable - 1600 rubles per 1 running meter.

Thus, you will have to pay a considerable amount for the complete arrangement of the system, especially if you take into account the additional equipment of the irrigation system and other trifles. This makes one think that the price of a plastic caisson for a well should not be too low. Since it is simply impractical to install a cheap low-quality tank for that kind of money.

Do-it-yourself caisson from concrete rings for a well

Despite the quite affordable prices for ready-made caissons, many tend to try to make them on their own, using the materials at hand. One of these options is a do-it-yourself concrete caisson. If you decide to give preference to this option, then you need to familiarize yourself with some of the features of this process:

- The main difficulty is to ensure an accurate tight connection between the rings. Therefore, the installation process should be given special attention.

- The diameter of concrete rings can be anything, but you should not choose too large - they complicate the installation process and often do not justify themselves.

- Don't forget about quality waterproofing.For this purpose, use bituminous mastic.

- Take care of creating a solid foundation: use concrete mortar for formwork.

The construction of a caisson for a well made of concrete rings is a rather complicated process, which is practically impossible to carry out without the involvement of special equipment. The structural elements are too heavy to be manually lowered into the excavation. Repairing a caisson made of concrete rings is also difficult, but if holes appear between the rings, it is necessary.

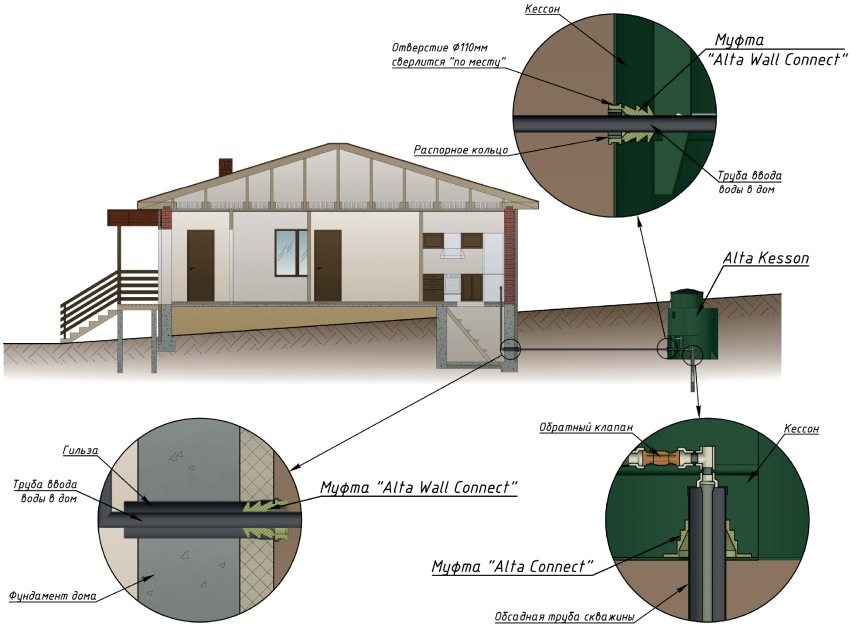

How to install a plastic caisson for a well with your own hands

Before proceeding to the direct installation of the caisson on the well, it is necessary to prepare a reliable base for it, i.e. pit. Its dimensions must necessarily be about 20-30 cm larger than that of a plastic tank. At the same time, at the bottom of the pit, you need to additionally make a small depression that will help fix the container. You can do this by following simple guidelines:

- it is necessary to pour some sand on the leveled bottom of the pit;

- then an even layer of fine gravel;

- to ensure the rigidity of the structure, a reinforced frame is installed on top;

- after that, it remains only to pour the concrete and wait until it dries completely.

Competent installation of a plastic caisson for a well is a guarantee of a long and flawless service in the future

In the process of work, it is important not to forget that if the system is equipped with a hydraulic accumulator, then the hole for the pipe should be located slightly to the side. In this case, the ideal option is if the casing will protrude above ground level. This will make the system installation procedure much easier.

Particular attention should be paid to the process of attaching the plastic caisson to the pipe. This will require attention and accuracy. Some of the more recent models are equipped with concrete cavities. If the system provides for the presence of a hydraulic accumulator, then all equipment can be tied to a previously prepared base. After the caisson takes its place in the pit, the remaining gaps are covered with dry earth.

As mentioned earlier, if the water table is too high, then the remaining gaps must also be filled with concrete to prevent damage to the tank. In addition, you can use reinforcement for this. This is a more reliable way to protect the well. Before pouring concrete, it is important not to forget that all cables and pipes must be routed outside.

Note! Be sure to wait until the concrete is completely hardened, otherwise you will have to start all work from the very beginning.

If we talk about the choice, then buying a plastic caisson for a well is the best solution. This type of product is devoid of the shortcomings of its predecessors and allows you to carry out all the work on your own. That is why plastic caissons for wells are deservedly popular and, in most cases, are preferred for purchase. And although the price of a metal box may be slightly less, all the advantages of using plastic in this case are obvious.