Drinking water from an unverified source is strictly prohibited. If a one-time rash step can lead to a short-term disruption of the state of the body, then the constant use of water with unwanted impurities can significantly affect human health. Well water purification filters, correctly selected and installed, will make the drinking source not only safe, but also useful.

Content [Hide]

Possible types of contamination of drinking water from underground sources

The composition of well water depends on the depth of the formation and the types of soil through which it passes. It is not enough to focus only on taste, color and smell when determining quality. Chemical analysis of water in laboratory conditions is mandatory. The main types of pollution and indicators of non-compliance with sanitary standards can be considered:

If the water has an elevated level of iron, hydrogen sulfide and nitrates are present, then it should not be drunk

- Increased iron content. This is a problem for almost all shallow sources. The water may have a reddish color and a metallic taste. But even in seemingly pure water, the concentration of this trace element may be excessive.

- The presence of hydrogen sulfide. A significant excess of this substance in the composition of the water produces an unpleasant odor. But even if the amount is small, this chemical compound can be toxic.

- High level of mineralization. This is the salt content. Their excess gives the water a salty taste. Such water poses a serious threat to health, especially for people with hypertensive diseases.

- Rigidity. The content of calcium and magnesium together gives this indicator. Causes the formation of stones in the human body, scale on heating devices.

- Concentration of nitrates. Not determined by taste, has a detrimental effect on the cardiovascular system. Children are especially vulnerable.

- Mechanical impurities. May get caught during well installation.This is crumbling soil, the remains of synthetic materials used for sealing and lubrication.

- Bacteria and Viruses. They arise as a consequence of the decomposition of biological materials. It is also possible that they penetrate the water while drilling a well.

Helpful advice! If laboratory studies have shown the presence in the water of an increased amount of certain trace elements or the presence of harmful bacteria, cleaning is mandatory. Neglect of this rule during prolonged use of liquid can cause serious harm to health, up to irreversible processes.

Water filters for wells: basic types and principles of operation

The filtration system is installed depending on the type of well and surrounding soil. The latter determines the material used to create the filter frame. It can be steel, polyethylene, polypropylene, etc. For the cleaning process to be effective, it is necessary to calculate the duty cycle. This is the value that is obtained by dividing the area of the holes by the area of the working surface and multiplied by 100%. The resulting number should not be less than 25%.

There are several types of filter systems. The main ones are the following:

- mesh;

- tubular with slotted or round perforations;

- gravel;

- wire (frame-rod and tubular).

Mesh filters are installed in wells drilled in unstable, unstable rocks. They are made mainly of steel, installed directly at depth. Depending on the particles to be filtered, the meshes can be single-layer, multi-layer, with square cells, etc. The disadvantage of this system is fast clogging. However, the screens are fairly easy to remove for cleaning or repair. The range of mesh sizes is 0.12-3 mm².

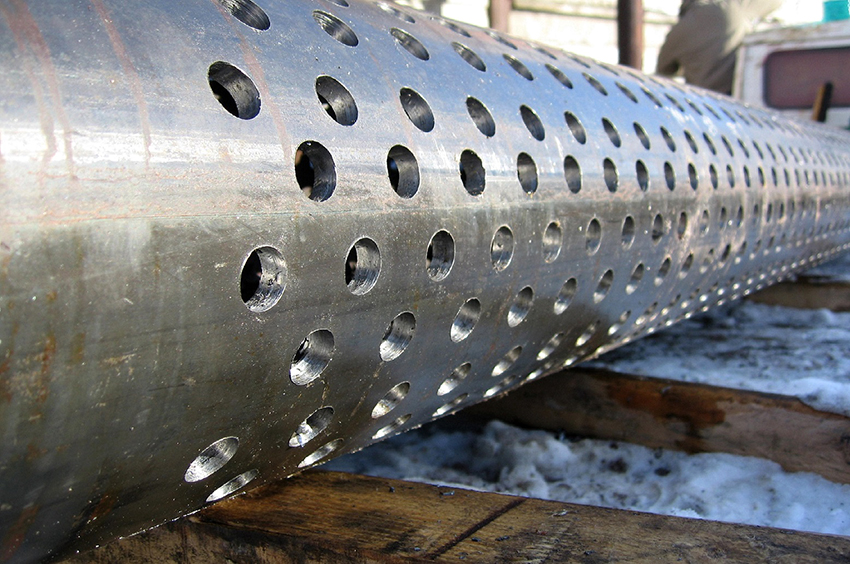

Tubular slotted and round devices are best used in cases where water is pumped out of pebbles and gravel rocks. The filter is a pipe with round perforations or multiple slots, which can retain particles up to 10 mm in size.

Wire filters are divided into two types: frame-rod and tubular. Frame-rod devices have rods made of bar steel, nozzles made of casing pipes and casing belts made of iron. Wire is wound on such a frame. Wire wrapped tubular barriers have a perforated tube frame and stainless steel wire wrapped. A spiral wire is wound around the frame, creating long slots through which sand and gravel particles are filtered. Wire filters are highly efficient. However, there are a number of disadvantages: the equipment is expensive, it is rather difficult to clean it from accumulated mechanical particles.

The most reliable and inexpensive cleaning devices are gravel filters. They are a layer of gravel or coarse sand in contact with a water reservoir. Such filters can be run ready-made into the well. Gravel is poured into the annular space. The finished filter must have a layer of at least 30 mm, with filling - at least 50 mm. This system is durable, easy to clean and highly environmentally friendly.

Helpful advice! It is better to install any type of filter system with the participation of a specialist who will correctly assess the soil of the aquifer.

Well water filtration systems: targeted focus

Depending on the chemical composition of the water, it may be necessary to use not one, but several filters, that is, to create a filtering system.Each cleaning device fulfills its task and occupies a certain place, taking into account the cleaning sequence as a whole. There are many filters that differ in their focus.

Reverse osmosis filters. The pressurized stream of water is directed to a low-permeability membrane that only conducts pure water. In this case, harmful substances do not penetrate into the water. At the heart of filters for deferrization of water from a well, it is the reverse osmosis system that is used. Iron precipitated in the form of rust is retained as it passes through the membrane. A common problem is the need to remove lime (calcium salts) from water. This impurity in excess is extremely harmful to the human body. Filters for water purification from lime also work using a membrane system.

Iron removers. At the heart of this cleaning system is backfill. It accelerates the chemical reaction in which iron and manganese are oxidized and precipitated without entering the water supply stream. Such a cleaning process can be mechanical, but there are also automated methods.

Reagent-free iron removers. It is based on the electrolysis process. This is one of the most effective water filters against rust, but it is quite expensive. Apart from this, its installation is quite problematic.

Softeners. These are filters for softening water hardness. The cleaning process is based on ion exchange. The water passes through the resin, which changes the magnesium and calcium ions into sodium ions. The ion exchange resin is regenerative.

Carbon filters. Coal performs a sorption function. After passing through the coal layer, the water comes out clear, odorless. In this way, water can be purified from hydrogen sulfide and mechanical impurities.

Coarse filters. Coarse water filters for a well or any water supply system work according to the same principle: various particles of debris and metal sediments are retained using a mesh.

UV filters. Destroys bacteria and viruses. UV water filters are a housing with UV lamps placed inside. The flow of water passing through such a system is disinfected and becomes safe.

Helpful advice! It makes sense to install this filtration system if iron is the only substance to be removed. In other cases, this method will be unprofitable.

The sequence of the drinking water purification process

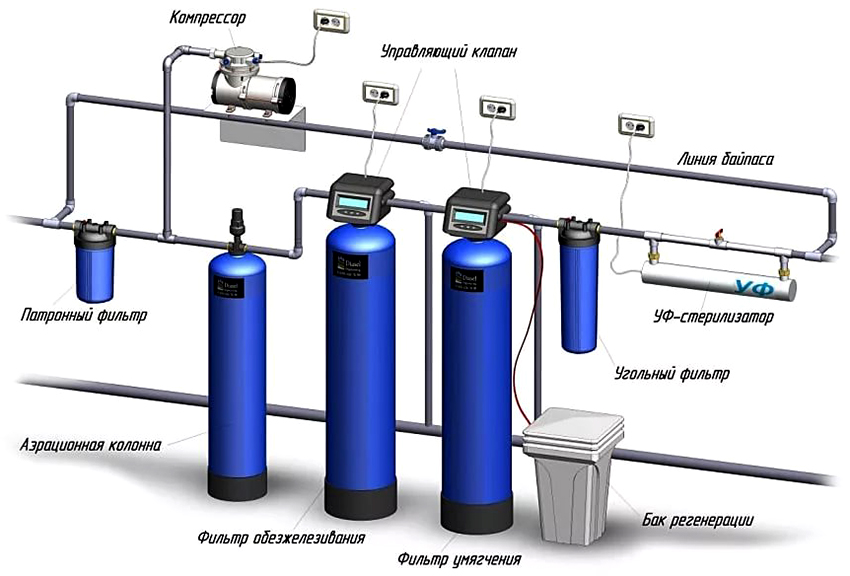

With rare exceptions, water needs to be purified from several elements at once, so the installation of a step system will become reliable and giving the desired result. In the process of its action, several stages are distinguished:

- Chemical analysis of water, which gives a general idea of the composition and degree of concentration of harmful substances and organisms. The level of mineralization, hardness is established, the organoleptic component is determined.

- A coarse cleaning is carried out, during which various particles (grains of sand, pieces of scale) are removed, which can harm the operation of other types of filters.

- Metals are removed, the presence of which can also be harmful to health and the operation of other filters.

- Salt removal - water softening, during which the liquid is purified from magnesium and calcium salts.

- Fine cleaning, the purpose of which is to remove organic impurities, improve taste.

- Disinfection - destruction of bacteria and viruses.

Helpful advice! Failure to comply with at least one of the purification steps makes the water unsuitable for human consumption.

How to choose the right water filter from the well

There are two main reasons why it is required to install filters for water from a well:

- Bringing water composition indicators to a state corresponding to high-quality consumption standards.

- Protection of equipment used for feeding and cleaning from damage by harmful impurities.

Therefore, in order to buy a filter for a well that meets the conditions of correct operation and the requirements for obtaining high-quality water, these needs must be based on. The primary task is the intended purpose: from what and in what way to cleanse. The second, no less important problem when choosing a cleaning device: it should be taken into account whether the conditions for its maximum effective work will be provided. There are general objective characteristics that any filter must meet:

- Anti-corrosion qualities. The conditions in which any filter is placed are conducive to corrosion. Therefore, you should pay special attention to the material from which the filter unit is made.

- High throughput. It depends on the nominal technical characteristics of the purifier and the correctness of calculations for matching the filter to the well size.

- Strength. It is ensured that the quality and features of the filter assembly match the conditions of its operation.

Helpful advice! When choosing a filter, you must follow the rules of reasonable selection. For example, an expensive and durable wire mesh filter will not work as a sand well filter. It will last a long time but will need constant cleaning.

Stages of water purification from a well in a country house

When implementing a water treatment plant in a country house, you must follow the traditional algorithm:

Related article:

Water purification from iron from a well: chemical and mechanical methods

The need for analysis. Features of cleaning wells and wells. Removal of sand and silt. Do-it-yourself cleaning.

- deep analysis of the chemical composition of water;

- identification of substances, the concentration of which exceeds the norm;

- system selection and design;

- approbation of equipment operation.

The installation of water filtration in a private house can be considered in the following example. For example, the amount of chlorine, hydrogen sulfide and dissolved (bivalent) iron in the water is exceeded. It is necessary to buy a filter for purifying water from a well that performs coarse water treatment. Then you need an aeration column to saturate the water with oxygen, accelerate the oxidation reaction, as a result of which the iron will become trivalent and precipitate. The filter material placed in the column will cleanse gases dissolved in water.

This level of purification will make the water suitable for technical purposes, safe for household equipment. If it is necessary to bring the composition to compliance with food standards, additional filters will need to be installed.

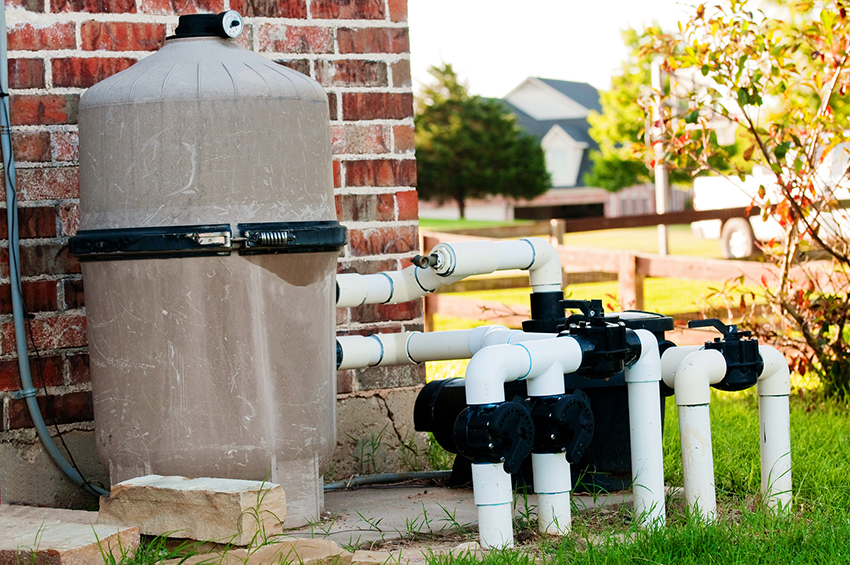

The water purification system from a country well does not fundamentally differ from the water purification system of a country house. For giving, a coarse water filter is also required, since without it a further filtration system is impossible. Its absence can affect the operation of the pump, contribute to breakdowns and equipment wear. The rest of the filters for water from a well for a summer residence have standard technical characteristics (depending on the purpose).

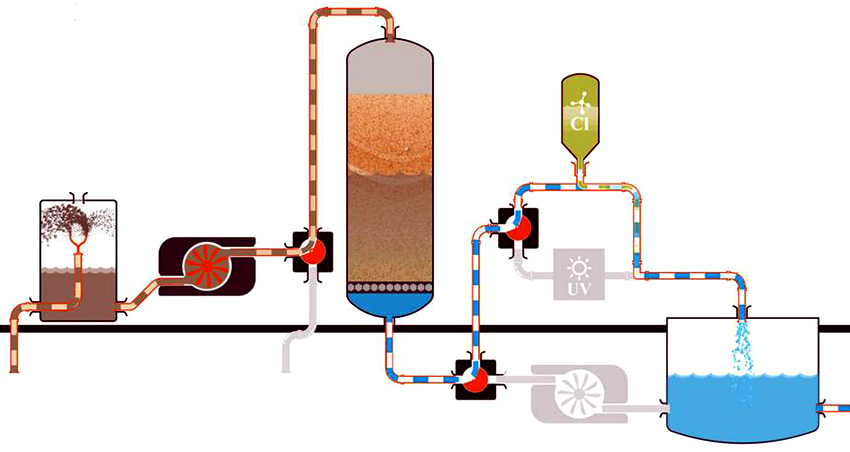

They are actively used in summer cottages as water treatment facilities. The principle of operation of such filters for giving is as follows: water moves into the tank (by means of the upper supply) down the pipe.She reaches the shield under the pipe, and with its help changes the direction of movement - rises. When passing over the edge, the water already has a purified state, since the polluting elements remained at the bottom, having precipitated.

The bottom of such a tank often has the shape of a cone, less often it is pyramidal, since in the latter, dirt is clogged into the corners, as a result of which fermentation begins, it flows worse through the sludge pipe.

Helpful advice! In order for the water sump to function normally, it is imperative to monitor the condition of the filtered substances and their entry into the collection point. Manual cleaning is sometimes necessary as the waste can condense.

Diy well filter: materials and sequence of execution

The complexity of installation and the high price of ready-made filtering equipment often lead to the desire to understand how to make a filter for a well yourself. This is not difficult. In addition, a self-made cleaning device has a number of advantages:

- available materials are used;

- the system does not require special physical costs;

- does not need large financial investments;

- qualitatively cleans from large impurities;

- removes substances that create unpleasant odors and tastes.

The main disadvantage of homemade water filters is the impossibility of biological disinfection. Such water must be boiled.

Uncomplicated and efficient home construction

How to make a water filter? For this you will need:

- charcoal;

- a flap of cotton fabric;

- plastic bottle with a screw cap.

A filtering layer is created as follows: activated carbon is prepared - it is crushed to particles of 4-5 mm, then boiled in water for 5-7 minutes, cooled down and placed in a bottle (filled by a third) .A hole with a diameter of about 3 mm is made in the cork, in the neck of the bottle the fabric is laid, the bottom is cut off. This filter is whipped up, but the water flows from it is clear.

Homemade affordable water treatment system for a well

Optimal and affordable design - bottom filter. For its arrangement you need:

- river pebbles of medium size;

- crushed stone;

- gravel;

- sand;

- black stone - shungite;

- zeolite as a sorbent.

It is necessary to make a shield from wood or other suitable material (stainless metal, polypropylene), wrap it with geotextile fabric and lower it into a well. If the bottom is clayey, then a direct filter is needed, for a sandy bottom - a reverse one. When installing a direct filter system, first coarse fractions are stacked, then smaller ones. The finishing layer is sand. The return filter starts with sand and ends with a stone.

The thickness of each layer for any of the two filters must be at least 20 cm, while there must be at least three layers. Despite the simplicity, ease of installation and efficiency of use, these filters have a drawback: they need to be cleaned almost annually. It is better to replace all layers, but if this is not possible, then you will definitely need to lay new sand, and the stones must be thoroughly washed and disinfected with boiling water.

Helpful advice! Construction crushed stone is an easily available material, but it is not recommended to use it, as it needs serious cleaning.

Creation of a device for cleaning well water

When creating a treatment system for a well, you will need the following materials:

- pipe, preferably polypropylene with thick walls;

- wooden plug;

- mesh with small cells.

The only time-consuming process when creating a well screen is perforation. The holes are made with a drill and drill at an angle of 60 °, staggered at a distance of 2-3 cm. The perforation should take up a quarter of the pipe. The lower part is wrapped in a net, which must be firmly fixed, as exposure to water can damage the structure. The pipe is closed from above with a stopper. Passing through such a filter, large particles fall into the sump, small ones are retained by the mesh. Such a filter for water from a well from sand works most effectively.

Well water filters: manufacturers and prices

You can buy a filter for water from a well from different manufacturers, the market is quite saturated. The right decision when choosing is to rely on products, the quality of which has been tested by time. The leader in the production of filtering devices in the world market is Honeywell. This is an American trademark used by manufacturers in many countries, including Russia and China. The products are distinguished by their resistance to corrosion processes and durability.

Filters produced by the Israeli company Arkal are worthy of competition. They are environmentally friendly, easy to install. In addition, the company has a well-organized repair service.

The products of the domestic company Rusfilter are also competitive. The filtering functions of the products are quite high, the products are of high quality. Both coarse and fine cleaning are carried out. There is a difficulty in maintenance and repair.

The cleaning systems of the joint Russian-Italian production Valtec are popular. The line is represented by a variety of products, including oblique, self-cleaning, large and small filters. The use of high quality alloys (brass, bronze, stainless steel) prolongs their service life.

The assortment of the Three Wells online store includes water filters of foreign and domestic manufacturers. Lime water filters for wells include softeners, iron removers, coal, ultraviolet, aeration plants, and complex systems.

The price of well water filters depends on the quality of the material used and the manufacturer. The cost of single-functional species ranges from 20,000 to 40,000 rubles. When filters of two types of cleaning are performed, the price increases by a third - 27,000-55,000 rubles. The cost of complex systems reaches 100,000 rubles. Some foreign-made installations exceed this price level.

The main reasons for the unsatisfactory operation of filters for water purification from a well

Unfortunately, there are often cases when after using the purification in the water unnecessary impurities remain, and the taste leaves much to be desired. The reasons for this result can be different. Among the most common are the following:

- the types of filters are incorrectly selected;

- insufficient number of them;

- mistakes when choosing sizes;

- the sump is not tightly closed;

- the individual parts of the filter used are made of material that does not resist corrosion.

The filter must be of the right size and correctly installed, then the water from the well will be clean and useful

Helpful advice! When choosing a filter, it is necessary to take into account all the conditions and parameters of the well - and it is better to do this with the participation of a specialist. Certain types of filters cannot be removed for repair without damaging the casing. In such a situation, you will have to spend a lot of effort, money and time to restore the functioning of the source.

How to reduce the hardness of water, make it clear, tasty and safe for consumption - these are the tasks for filtering installations. But even the most modern equipment with the most precise electronic control cannot cope with work without human intervention. The ability to correctly, correctly use the filter is the key to success in the process of water purification. Human health directly depends on the quality of the water used.