Polymer and composite materials, due to the ease of processing and the ability to give them the desired properties, are actively included in any technological field of activity. New materials are also appearing in construction, especially in the field of "small engineering". One of these materials is polyvinyl chloride, and many other plastics. Gradually, plastic ventilation is replacing ventilation systems made of traditional materials.

Content [Hide]

Benefits of using plastic in ventilation systems

For any pipe communications, including for ventilation ducts, air ducts and ducts, during construction they usually used:

- Concrete, as the most reliable and inert to the environment.

- Asbestos, as the most easily processed.

- Metal, which, with its strength, makes it easy to give parts to any shape.

However, concrete and asbestos are brittle and have a non-linear thermal expansion coefficient, which leads to rapid thermal degradation. The metal is not cheap and too heavy, but in all other respects it is ideal if the environment is not aggressive.

In modern household ventilation systems, it is still impossible to completely exclude metal, however, with the advent of cheap and environment-resistant polymeric materials, plastic pipes for ventilation take off 10 to 20% of communications.

Good to know! Many people believe that plastic is perfectly impervious, flexible and durable, but this is only true in laboratory conditions. Under the influence of the environment, microcracks form in plastic, which expand with temperature drops - polymer fibers break, and plastic ventilation ducts gradually become fragile and fragile.

Polyvinyl chloride (PVC)

It is the cheapest, lightest and most durable option, easily processed both industrially and at home.Under normal climatic conditions, it is practically eternal and harmless: it decomposes, if not hundreds, then certainly tens of years, so that ventilation ducts and various products from it will survive the house itself.

But there is one hard usage limitation. This plastic contains chlorine, and the decomposition temperature of PVC (160-180 ° C) is lower than the plastic temperature (200-220 ° C). Therefore, it cannot be formed with a burner and, moreover, used where relatively high temperatures are used.

Important! In everyday life, steam can easily reach a temperature of 200 ° C, that is, the use of PVC plastic ventilation boxes in a sauna is definitely excluded.

Decomposition will release chlorine compounds and, first of all, HCl. This gas with moisture forms hydrochloric acid itself, therefore it is dangerous for the eyes and respiratory tract, although otherwise it is simply unpleasant or almost invisible.

Thus, polyvinyl chloride is an ideal plastic for ventilation, partially excluding the kitchen, water heater, fireplace and those places where temperatures above 120 ° C can occur (it is considered that this is the "upper bar" for human safety).

Polyurethane

This plastic differs little from PVC, but it can withstand temperatures up to 280 ° C without problems. At temperatures above, decomposition begins with the release of nitrogen compounds, which is many times more dangerous than chlorine compounds.

Its high cost is considered to be a relative disadvantage, but it combines two seemingly incongruous factors: plasticity and wear resistance. The ductility of polyurethanes is superior to the resistance of granite and steel to fracture stresses. The finished polyurethane product can be bent an infinite number of times - it will not crack and will retain its original shape as soon as the tension disappears.

Polyurethane is ideal for household temperature parts, especially where shears and distortions are possible: coupling rings, all kinds of pipes and areas where there may be high household temperatures.

Polypropylene

This plastic is ideal for molding. Already at 180 ° C, it is surprisingly plastic, so that any pipe can be twisted, even just in hot steam, and it can be bent at any angle with a burner. At the same time, it is durable, and at high temperatures it does not emit anything dangerous in itself (impurity dyes or special additives can be dangerous). It is located in the middle price category, but sufficient to make from it not only components of plastic ventilation systems, but also heating batteries.

Polypropylene is a relatively expensive but versatile safe plastic.

Interesting! Recently, the ABS / PLA family of plastics has been gaining popularity, which is used for 3D printers. For household needs, these plastics are absolutely safe, and with the help of a printer you can independently produce all non-standard parts. Including those that use plastic ventilation: from "turn signals" with non-standard angles to components such as valves.

Varieties of ventilation systems

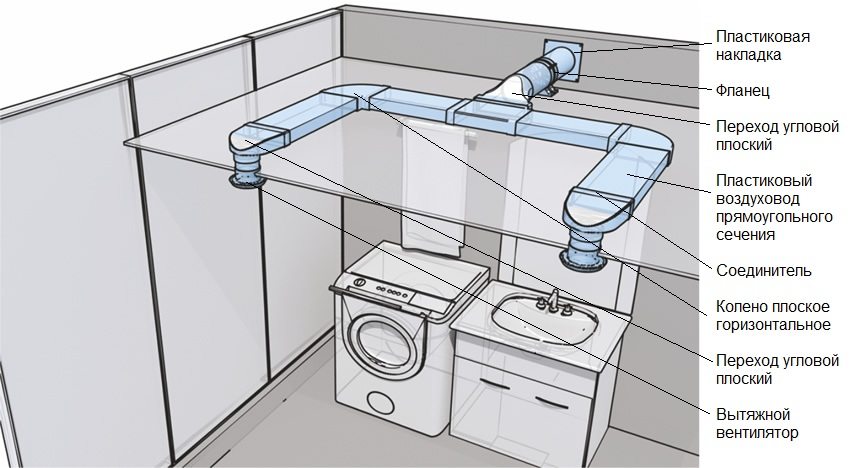

After the boom in plastic windows, almost the entire industry began to use PVC for any pipes and plastic ventilation parts (round and rectangular), replacing metal where possible. Accordingly, gratings, nozzles, adapters, rings and pipes and ducts themselves of any size and cross-section - both round and rectangular - can be found everywhere. They are assembled by hand in minutes and, in fact, simplify the installation of even the most complex ventilation systems.

Related article:

Types of ventilation, advantages and disadvantages of ventilation systems, their design.

Significance and types, advantages and disadvantages, main parameters, main components of ventilation systems.

Natural ventilation

PVC can be used everywhere except (partially) in two areas: kitchen and fireplace / water heater. Since in the kitchen you can turn on all the burners at once to the maximum, the temperature of the air entering the hood is simply impossible to predict. The air itself has a microscopic heat capacity, but a couple of hours of frying may well warm up the plastic outlet to a critical temperature. It is better to use the longest possible metal outlet - the longer, the better, since the metal will easily give off heat to the room air and the already acceptable temperature of the outlet stream will reach the plastic. Only metal can be used to equip the fireplace hood.

In case of water heater you can get by with a small piece of metal pipe, and then plastic. It is convenient for the primary condensate to settle on the metal and flow back, and then the steam is no longer dangerous for PVC, since the temperature of boiling water and steam will not exceed 100 ° C.

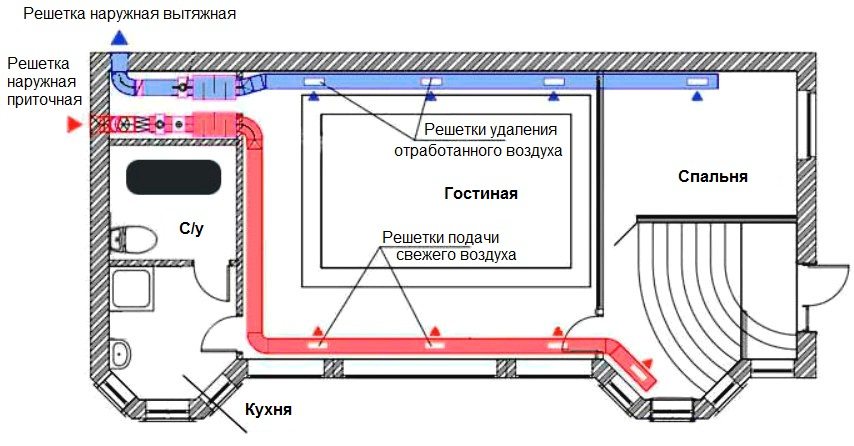

With natural ventilation, air enters the room through open windows and is removed through exhaust vents

However, there are water heaters under pressure, which are used for mini-saunas. Here the use of any plastic is excluded, even polyurethane, which will simply "flow".

In all other parts, PVC can be used with absolutely impunity: pipes, ducts, valves, valve grids. The cross-sections and dimensions of plastic pipes for ventilation are reduced to several generally accepted standards. Just do not try to form, for example, a bent pipe with a burner. Better to buy an extra adapter.

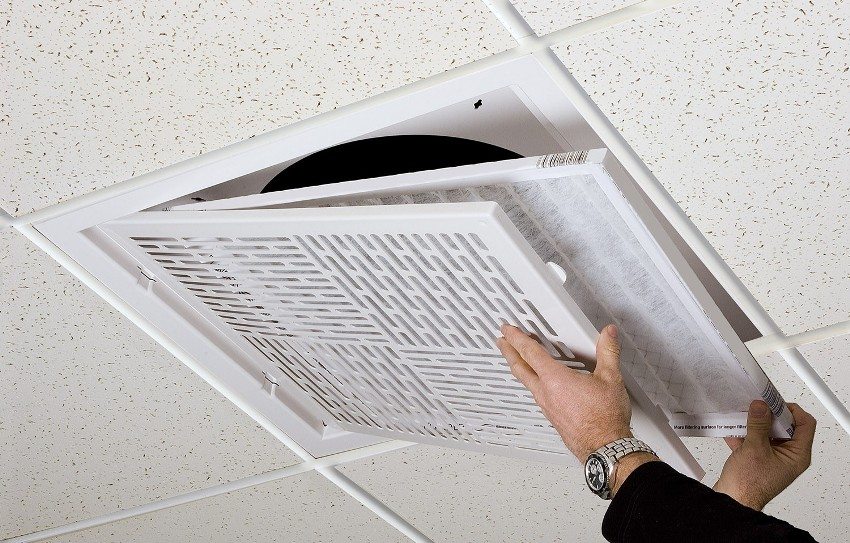

Outlet valves that use ventilators, as well as plastic ventilation grills, are sold in several standard sizes, so choosing plastic ventilation parts with rectangular or circular cross-section is more like choosing parts for a children's construction set. Insofar as PVC pipe can be cut even with a knife, then the entire installation of the system will be reduced to a trip to the store.

Forced ventilation

This method involves the use of high power fans, recuperators, heaters and other sources of vibration and temperature changes.

All these devices, especially those that come in contact with plastic air ducts for ventilation in the kitchen, it is best to connect through small pieces of metal pipes, the interfaces of which with plastic must be securely fixed. Due to the constant exposure to temperature changes and vibrations, plastic becomes brittle: polymer fibers break off, and in order for them to "adhere" again, a viscosity temperature is required.

Unlike polyurethane and polypropylene, this "number will not work" with PVC - the viscosity temperature of PVC is higher than the decomposition temperature, so it will not be possible to get rid of a couple of minutes of heating with a gas mini-burner. In a few years, it will be useful to change those pipe sections that are directly connected to the equipment of an active plastic ventilation system.

When installing a plastic duct for a kitchen hood, it is recommended to use a connecting piece from a metal pipe

Ventilation system for plastic windows

Plastic windows have special requirements for the ventilation system. The simplest ventilation system is natural channelless, in which air circulation in the room is ensured by opening the vents, transoms or windows as a whole. However, this method is too expensive for middle and northern latitudes, especially during the cold season.

Supply ventilation for plastic windows

A more correct approach in this case is to use a supply ventilation valve for plastic windows. This fixture mounts horizontally at the top plastic window and can be installed by hand. You will need a few simple tools: a screwdriver, a tape measure, a stationery cutter and the valve itself.

Valve supply ventilationinstalled on a metal-plastic window

The main advantages of using a ventilation valve for plastic windows:

- the natural flow of air into the room is restored;

- drafts do not appear;

- sound insulation is not violated;

- the light opening does not decrease.

It is much easier to arrange ventilation of plastic windows with your own hands than to install a valve or similar device for wooden or aluminum windows.