Air exchange in the ventilation system occurs due to the movement of the air flow through the air duct network. Depending on the application of ventilation systems, ventilation ducts can be for industrial and domestic purposes. Their effectiveness is determined by the stiffness, shape and diameter of the sections. The design of air ducts can be flexible and rigid. To ensure maximum performance of ventilation systems, you should familiarize yourself with the calculation, methods of installation and maintenance of air ducts for ventilation.

Content [Hide]

Air ducts for ventilation: forms of structures and materials of manufacture

Air ducts for ventilation are pipe system of various diameters and sectional shapes interconnected by shaped elements. The correct selection of air ducts for a particular ventilation system depends on the design features of the performance and design parameters, taking into account the compliance with building and sanitary standards.

Materials for the manufacture of ventilation ducts

Air ducts for ventilation, taking into account the use of materials for their manufacture, are divided into groups:

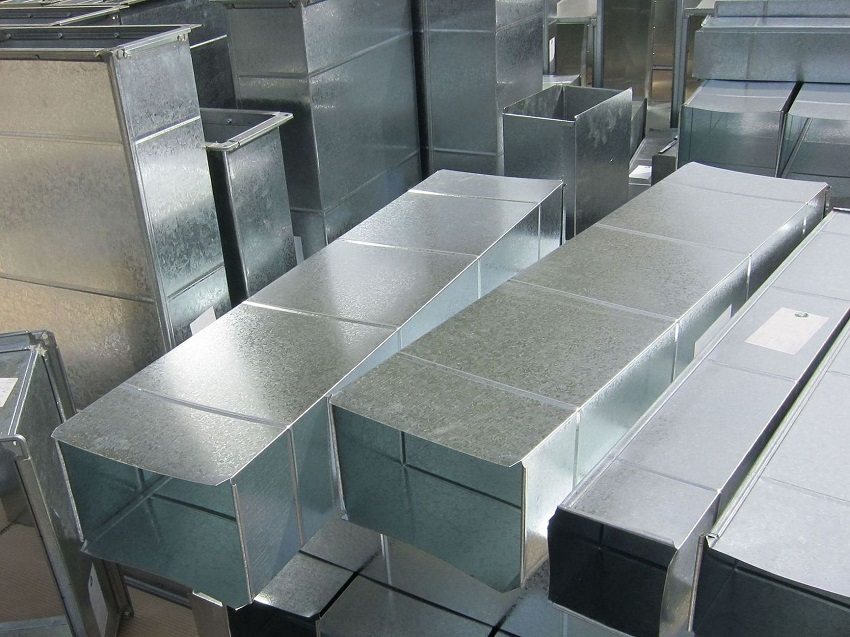

- metal. For their manufacture, galvanized or stainless steel is used. Their advantages include low weight, high degree of thermal stability, corrosion resistance, ease of installation;

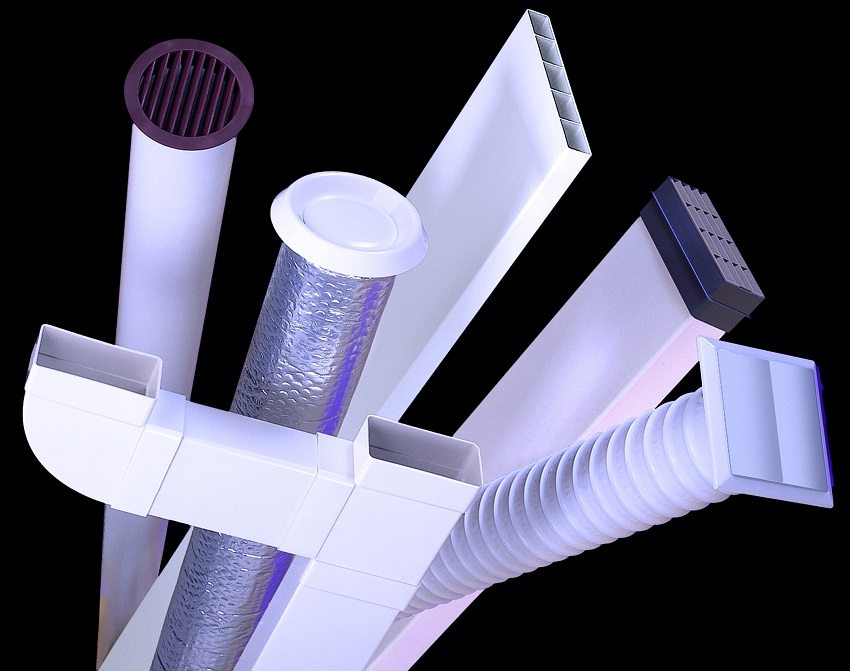

Plastic air ducts various shapes and sizes

- plastic. In the manufacture of such pipes, polypropylene, polyurethane, polyvinyl chloride are used as an air duct. Among their advantages are absolute harmlessness, perfect tightness, ease of installation and maintenance. They are easy to clean and wash quickly;

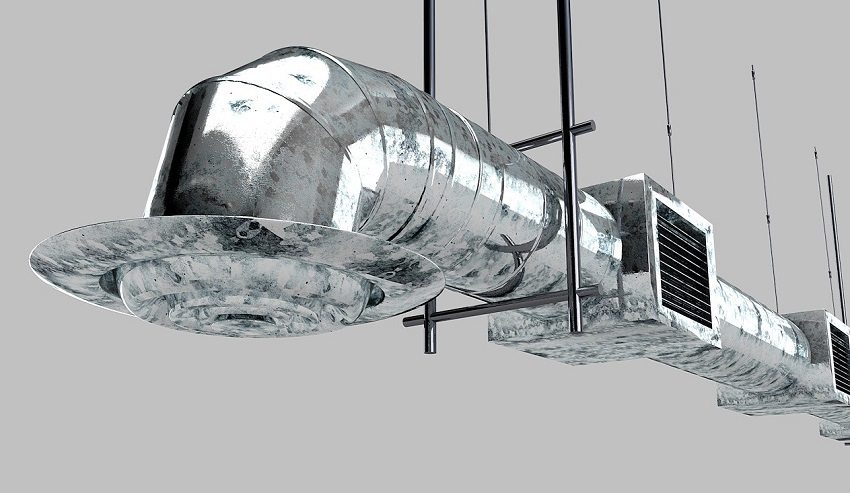

- corrugated aluminum. Ventilation ducts made of corrugated aluminum pipes are widely used due to their ability to compress and stretch in any direction and at the required angle. The design of flexible corrugated pipes is such that they retain their rigidity and cross-sectional shape. The advantages of flexible ventilation ducts are the absence of numerous connections, ease of installation and long-term operation;

- textile.The material for the manufacture of these ventilation ducts is synthetic fabric (polyester). Fasteners are also made of textiles. The fabric prevents the formation of condensation on the surface of the duct and does not require insulation. Among the advantages are the light weight of the tissue system, quiet operation, maneuverability, simple assembly and disassembly. Cleaning of fabric systems is carried out by means of washing.

Types of duct cross-sections

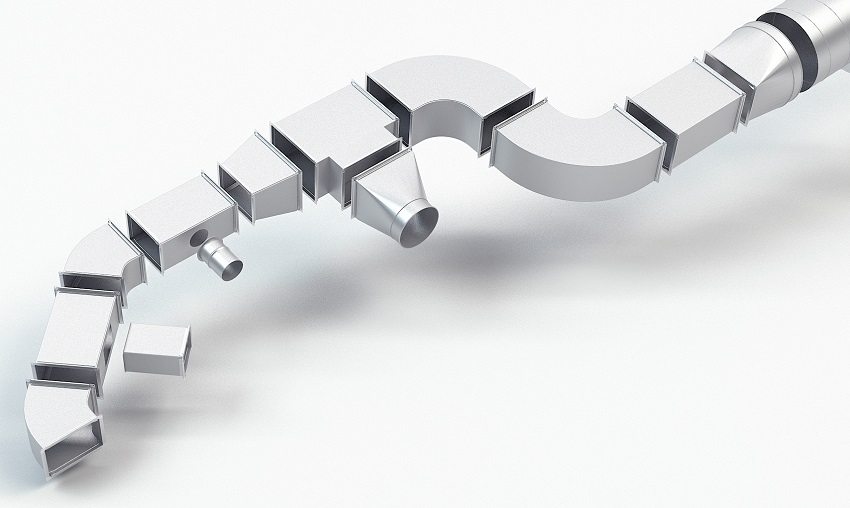

The generally established forms of cross-sections of air ducts are rectangular and circular sections. If the design of the ventilation system has restrictions on the shape and dimensions of the section, flat-oval (elliptical) sections are used for air ducts.

The material for manufacturing rectangular ventilation ducts is galvanized steel. The wall thickness is used depending on the size of the section and is regulated by SNiP. Rectangular air ducts are connected with and without flange elements. The standard length is 1.25 m, the maximum length is 2.5 m. Due to their compact form, rectangular structures are built into spaces with limited height (for example, under a suspended ceiling).

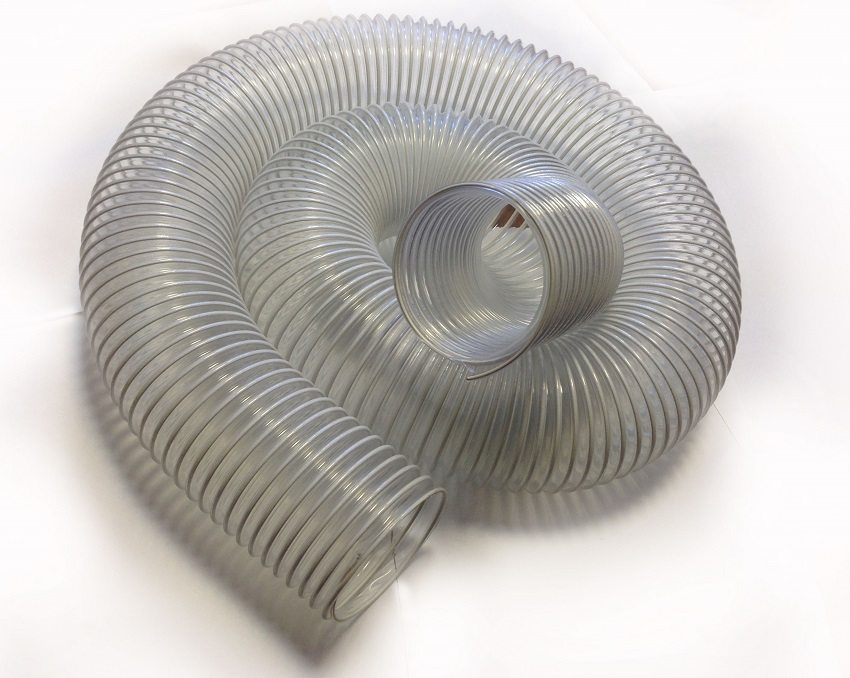

The material for circular air ducts can be galvanized steel, plastic, metallized polyester tape with a spiral frame, PVC with a spiral frame, aluminum foil. The cross-section diameter varies from 100 to 1250 mm. The joints of flexible corrugated ventilation ducts are tight-fitting. For convenient transportation, corrugated flexible air ducts can be compressed 5 times.

Plastic corrugated air ducts retain the shape and rigidity of the section when bending and stretching

Helpful advice! The choice of an aluminum corrugated duct for use in the ventilation system can significantly reduce the cost of purchasing fittings and installing the duct itself.

Possible multiple changes in the shape of flexible corrugated air ducts do not violate their qualities. Spiral flexible structures are connected using flange elements and gaskets. They do not need additional insulation. The scope of application of flexible air ducts is air supply and exhaust in residential and industrial premises.

Corrugated fabric polyester air ducts do not require additional insulation, as they do not attract condensate

How to calculate ventilation ducts with natural air exchange

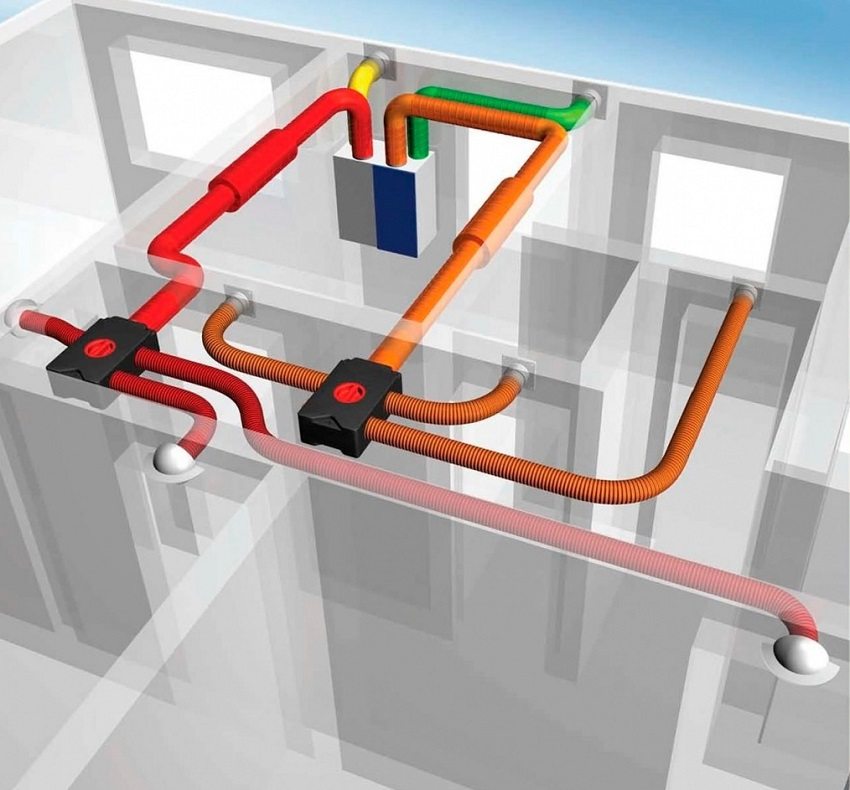

To correctly calculate the diameter of the ventilation duct, it is required to draw up a diagram of the entire duct system. It should contain the dimensions of all rooms with an indication of their purpose. The required amount of air exchange is calculated in m³ / h. The air speed in the natural ventilation system is up to 1 m / s.

To correctly calculate the diameter of the ventilation duct, it is required to draw up a diagram of the entire duct system

We calculate the dimensions of the ventilation of air ducts:

- air exchange rate (L) - for the kitchen this value is 90 m³ / h, for the toilet and bathroom 30 m³ / h;

- the average air flow velocity (V) is 0.3 m / s;

- the calculation of the approximate dimensions of the duct is made according to the formula:

F = L * V * 3600 (the number 3600 is used for the relationship between seconds and hours);

- to calculate the diameter, we use the formula:

D = 2AB * (A + B), where D is the section diameter, A and B are the height and width of the duct.

Air ducts for ventilation are a system of pipes of various diameters and cross-sectional shapes, interconnected by shaped elements

Calculation of the cross-section of ventilation ducts:

- we calculate the area of a circular cross-section according to the formula:

S = π * D² / 400, where

S is the actual cross-sectional area (cm²);

D - duct diameter (mm);

- calculation of the area of a rectangular section:

S = A * B / 100, where

S is the actual cross-sectional area (cm²);

A, B - the height and width of the rectangular duct (mm).

Features of installation of ventilation ducts

Competent installation of air ducts provides for the following actions:

- correct calculation of the cross-sectional area of the duct;

- selection of an acceptable method for connecting elements of the ventilation duct;

- calculation of the number of fittings;

- provide for a method of insulation and their sound insulation.

To accurately calculate the diameter and length of the air ducts, it is better to contact a specialist

Mounting options for ventilation ducts

The installation of duct systems involves the use of various fasteners. Depending on the types of air ducts (round, rectangular, flexible), the required number is calculated.

Related article:

|

As fasteners and connections there can be: inserts, adapters, bends, crosses, plugs, swivels, etc.

Helpful advice! To avoid additional costs for fittings and air duct fasteners, it is recommended to use the help of a ventilation installer for the calculation.

Round air ducts:

- during installation, a coupling and a nipple are used to fasten round air ducts. The two elements of the duct are connected by means of a piece that is inserted inside or mounted outside the duct;

- the connection of parts of the air ducts with a flange is made by means of a spring mechanism or using screws. The use of a spring mechanism simplifies and shortens the installation of systems and ensures reliable sealing. If there are flanges on the parts of the air duct, then additional fixation is not performed;

- less commonly, the method of fastening with a bandage is used (a device that is put on the flanged ends of the air duct). This method is characterized by simplicity and a high level of tightness. But due to the expensive manufacture of bandages, it is not popular.

Helpful advice! To reduce noise during the operation of the ventilation system, when installing the air ducts, it is necessary to use as few turns and transitions from one diameter to another as possible.

Rectangular ducts:

- rectangular ventilation ducts are suspended by means of clamps and traverses. The clamps are made of a metal strip, the traverse is made of angle steel;

- flange connection technology is similar to the connection of round air ducts, but in order to avoid subsidence of the sides, the flanges are fixed with rivets;

- connection using a bus is made using a porous gasket, pulling the fastener with a lock. With such a connection, it is necessary to seal the gaps with a sealant.

Methods for insulating ventilation ducts

To keep warm air in the room, it is recommended to insulate the air ducts. In industry, insulation is used with foam insulation, which protects air ducts from heat loss and serves as soundproofing... For insulation of household outdoor rectangular air ducts, foam plastic, basalt wool in slabs, and expanded polystyrene are used. Insulation is carried out using special glue and additionally using reinforcing foil tape.

Roll materials are used to insulate round air ducts: isolon, isover. These materials have good soundproofing properties and fire safety. For insulation, you can also use mineral wool by wrapping the duct in two layers.

Methods for cleaning ventilation ducts

The efficiency of ventilation depends on the regularity of cleaning the air ducts. Typically, the cleaning procedure does not require dismantling parts of the system. There are mechanical and chemical cleaning methods. The cleaning method is chosen depending on the type of air duct (flexible, semi-rigid, rigid) and the type of pollution.

The chemical method is characterized by the use of special aerosol formulations. They are used to clean the air ducts of the kitchen and industrial catering premises from fatty deposits. Sometimes they resort to the method of cleaning by means of granules, which, passing through the air duct, form a microexplosion, coming into contact with a coating of fat. With the chemical method of cleaning air ducts, complete tightness of the structure is required.

Hydromechanical devices and vacuum pumps are used for mechanical cleaning of ventilation ducts. A vacuum pump is connected to the ventilation outlet, and a manipulator and brushes are placed in the initial hole. During the operation of the pump, the air duct is mechanically cleaned with rotating brushes, and all contaminants are collected in a special pump filter. Mechanical cleaning is a difficult, but most effective way to clean air ducts in case of intense pollution.

Measures for disinfection of air ducts of ventilation systems

After completing the cleaning steps, the air ducts are disinfected. Disinfection is carried out to protect against pathogenic bacteria, dust mites, etc. For disinfection, special formulations (powders, liquids, aerosols) based on hydrogen peroxide are used. Not only duct systems are disinfected, but also all elements of the ventilation system. You should also take into account the purpose of the premises in the air ducts of which disinfection is carried out. These or those reagents can be approved for use for disinfection in the air ducts of industrial premises and prohibited for use in schools and childcare facilities.

As a rule, organizations providing ventilation system maintenance services offer a full range of diagnostics, cleaning and disinfection of air ducts.

An attentive and responsible approach to the installation, operation and maintenance of air ducts is a guarantee of a long and trouble-free operation of the ventilation system.