Self-leveling floor has recently been very popular due to its ease of installation, presentable appearance, high strength and durability. In addition, without any special problems, you can arrange a self-leveling floor with your own hands: there are step-by-step instructions for this on many specialized sites. With the right approach, you will get a beautiful and durable floor covering with relatively little effort and time.

Content [Hide]

- 1 Varieties of self-leveling floors

- 2 Self-leveling floors with your own hands: video, advantages and disadvantages

- 3 Tools required for styling

- 4 Do-it-yourself self-leveling floor: step-by-step instructions and manufacturing steps

- 5 Self-leveling floor 3D: photos, prices and installation technology

- 6 Price per square meter of self-leveling floor and recommendations for maintenance

Varieties of self-leveling floors

If you want to know how to fill self-leveling floors with your own hands, then you should understand that there are several main types of coating. It can be mineral or polymer. The first option is a mixture of various mineral fillers, cement and modifiers that make the mixture viscous. Polymer floors are a fully synthetic type of flooring that has found application in industrial premises.

Polyurethane coating is considered to be the most durable and is used for various types of premises.

There are also 4 groups of coatings:

- polyurethane - has a high resistance to mechanical damage, elasticity and durability. In addition, polyurethane flooring boasts high resistance to chemicals, temperature extremes and many other adverse influences. Therefore, this type of flooring is popular in factories, industrial premises, unheated warehouses. Another advantage of this type of coating is that it is very easy to wash it both manually and automatically;

- epoxy - characterized by resistance to high humidity and shock resistance. It is most often used in closed rooms, in which flooding often occurs or simply working with water. If you want to fill the self-leveling floor with your own hands, a video with the corresponding instructions can be easily found on construction sites. Such a coating is cleaned using an automatic or manual wash;

- epoxy-urethane - combines the positive features of urethane and epoxy coatings. Differs in increased shock and abrasion resistance, as well as good elasticity. Scope of application - metro platforms or closed parking lots;

- methyl methacrylate - cannot boast of such high performance characteristics as the previous varieties, but it has one significant advantage. This type of flooring can be used just 2 hours after installation. The filling itself must be done in a well-ventilated area, since the composition has a sharp unpleasant odor. This kind of floor can be smooth, non-slip or rough.

Helpful advice! When choosing the type of coverage, be guided first of all by what type of room it will be used in. An option that works well for a living space may be completely unsuitable for a production space.

Self-leveling floors with your own hands: video, advantages and disadvantages

Like any other coating, self-leveling floors have their strengths and weaknesses. The benefits include the following:

- able to level any surface, which is especially important in rooms with uneven floors;

- do not have seams in which germs and dirt could accumulate;

- are characterized by a long period of operation, and also do not lose their attractive appearance even after several years;

- practically immune to the effects of aggressive chemical environment;

- do not crack under mechanical stress, withstand shock and fall of heavy objects;

- resistant to fire, do not emit harmful substances when heated;

- they are environmentally friendly, so they can be used in medical institutions or premises for children.

Before you make a self-leveling floor with your own hands, you should also know about its shortcomings:

- relatively small selection of design options compared to other types of flooring;

- before pouring the self-leveling floor, the surface must be carefully and for a long time to be prepared, leveled and the level of humidity must be reduced;

- it is very difficult to dismantle the self-leveling floor, which takes a lot of time and effort;

- some types of self-leveling floor coverings may turn yellow when exposed to direct sunlight;

- price per sq. m of self-leveling floor is higher than for other types of flooring, as is the cost of installation;

- repairing a self-leveling coating is difficult and expensive;

- the material itself is also not distinguished by its low cost.

As you can see from all these factors, before installing the coating, you should carefully consider how appropriate it is. The price for a 25 kg bag of self-leveling floor can depend on the type of material, manufacturer and other parameters and vary in a very wide range.

Tools required for styling

In order to install a self-leveling floor covering, you do not need special construction skills or specialized tools. It is enough to take the following things:

- the container in which the mixture will be kneaded;

- tape or thread for marking;

- a special attachment for a drill or construction mixer for stirring the solution;

- a set of spatulas;

- needle roller for even distribution of the mixture over the surface;

- level and rule;

- personal protective equipment, special footwear and clothing.

If you use a self-leveling coating for pouring, then it spreads evenly over the surface itself, so you can not use the roller. But it is imperative to put on personal protective equipment, since aggressive chemicals may be included in the mixture.

Related article:

Floors in the apartment: what to make and how to choose. Parameters that can influence the choice. Properties of various materials. Features of the floor in different rooms. Additional floor modifications.

Do-it-yourself self-leveling floor: step-by-step instructions and manufacturing steps

As already mentioned, this type of flooring is relatively easy to install. For a successful filling, you must adhere to a clear scheme, then your floor will be as attractive as possible and will serve you for more than one year.

Preparation of various types of substrate

The flooded floor can be mounted on a concrete, wooden or tiled base. Each case has its own characteristics that must be taken into account.

Helpful advice! Ensure that the surface is level before pouring the mortar. This is done using a spirit level and the maximum tolerance is 4 mm.

If you are pouring the solution onto a concrete base, then you need to do this in the following sequence:

- the moisture content of the surface is checked. It should not exceed 4%;

- compressive strength and tear strength are tested. The first parameter should be at least 20 MPa, and the second - 1.5 MPa. For verification, special measuring instruments are used;

- if the base has recently been laid, then at least 28 days must pass before the self-leveling floor is installed on it;

- the old concrete base must be thoroughly cleaned of the previous coating. This includes removing traces of glue and paint, oil stains and other contaminants;

- then the surface is cleaned of dust, chips and cracks are sealed in it. To do this, you need to use a regular mortar mixed with resin. If the cracks are small, then building glue can be used. Small irregularities are removed using a grinder;

- the horizontalness of the concrete base is checked.

The video "how to pour self-leveling floors on a concrete base with your own hands" will help you avoid common mistakes, do everything quickly and correctly.

If we are talking about a wooden base, then the following steps must be performed:

- just as in the case of a concrete base, the moisture content of the surface is checked. In this case, it should not exceed 10%;

- removed old skirting boards, since after pouring the coatings, new ones will be installed;

- wood is cleaned of paint, varnish, glue and other contaminants with a spatula and a grinder;

- cracks open, and their edges are smoothed with sandpaper for better adhesion to the mortar;

- using a construction vacuum cleaner, dust is removed from the surface, and the plane itself is degreased with a cleaning agent;

- mortar or concrete screed is poured into the cracks.

If you decide to pour a self-leveling coating on a ceramic tile, you need to check it for strength. Elements that do not adhere well must be removed, and the gaps must be putty. After that, the coating is degreased with an organic solvent, and a primer is applied on top.

Self-leveling floor can only be applied to firmly fixed tiles, all poorly adhered tiles will have to be removed

How and why to apply a primer

The base primer is necessary in order to increase the level of adhesion of the self-leveling coating to it. If the base is characterized by high porosity and surface roughness, then it must be primed several times. For this, special primers with high viscosity values are used.

Helpful advice! When priming the substrate, the temperature in the room must be constant. Otherwise, you risk getting bubbles.

Apply the primer with a roller or wide brush, or if you have an airless sprayer, you can use it. After the first layer has dried, the second is applied, and so on, until the required thickness is obtained. On an already primed surface, it is highly discouraged to allow dust to settle, this may impair the adhesion of the self-leveling coating.

The video "how to make self-leveling floors with your own hands" clearly shows that you only need to start laying the coating on a clean primer a day after it dries.

Preparing the solution and checking it for spreading

When preparing the mortar, it is very important to maintain the correct consistency. It is achieved if you follow the manufacturer's instructions, which indicate the desired proportions. First, water is poured into a previously prepared container, into which the dry mixture is poured. The resulting solution must be mixed for 10 minutes using a construction mixer or a drill with a special attachment.

In order to make sure that the solution spreads well, there is a fairly simple test. For this, a plastic ring is taken, the diameter and height of which should be about 5 cm. As such a ring, you can use, for example, the lid from a can of shaving foam. The bottom of the lid is cut out, then it is installed on a flat surface and the ready-made solution is poured into it. In this case, the lid is lifted, and the mixture spreads over the surface. The optimum consistency is when the diameter of the spreading mixture is no more than 18 cm. If it is less, then water should be added to the solution, if more - dry mixture.

When preparing the solution, it is also important not to overdo it with water, otherwise the coating will not be strong enough, cracks may appear in it from mechanical stress.

Before starting work, you need to find out how to make do-it-yourself self-leveling floors in stages. One of the important points to consider at the first stage is the indoor microclimate. The temperature should be between 15-25 ° C, and the humidity should not be more than 80%. If these conditions are met, you can get a floor covering with a perfectly smooth surface, but excessive humidity, for example, will lead to the formation of condensation on the surface.

Price for a bag of self-leveling floor, consumption and filling technology

The cost of a mixture depends on its type, manufacturer, and many other factors. If you decide to install colored or patterned flooring, the price will be even higher. In this case, it is not recommended to save money, since the price usually determines the quality of the finished coating. The cost of a bag of mix for a self-leveling floor will be about 200-500 rubles.

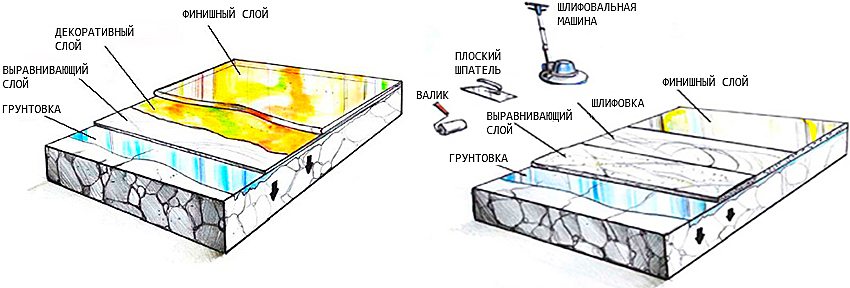

The step-by-step installation of a self-leveling floor is as follows:

- The solution is poured onto a previously prepared and primed surface. Each next portion is located next to the previous one; a spatula is used for leveling. The layer thickness can be monitored with a squeegee.

- In order to remove air bubbles from the solution, a special needle roller is used.

- Thus, the entire floor is poured in several approaches.

- After the work is over, the floor is covered with plastic wrap. This is done so that dust does not fall on the surface, and the solution solidifies evenly.

- On top of the hardened solution, you can apply polyurethane varnish. This will give the coating an attractive sheen and improve its appearance.

Helpful advice! The solution should be poured from the edge of the room opposite to the entrance.It is worth completing the fill in the entire room at one time, so you will avoid height differences.

A video on how to make self-leveling floors with your own hands will help you follow the above instructions more accurately, and will also clearly show how to use certain tools.

You can use a self-leveling coating after a week, after pouring it, and walk on it after 12 hours. It can be used as a base floor, or it can be laid over carpet, parquet or laminate. If you are making flooring in a living space and want to leave it as a finishing option, then it is better to use decorative or 3D self-leveling floors.

Self-leveling floor 3D: photos, prices and installation technology

A three-dimensional image on the floor is a great way to give a room a stylish and original look, show your design talents and surprise all guests. You can make such a coating with the help of qualified specialists, or you can do it yourself. The second option will take you much more time and effort, but it will allow you to put any picture you want on the floor. Of course, the cost of 3D flooring will be much higher than usual, for a m² you will have to pay from 5500 rubles. But the aesthetic qualities will differ significantly from a simple smooth surface.

The simplest option for a voluminous floor is small objects poured into it, for example, pebbles, shells or coins. The second most difficult is the photorealistic image. The most difficult thing is to make an optical illusion on the floor, but the showiness of such a floor will be at its best.

Choosing a picture for the floor

It is worth starting the installation of a self-leveling floor with a volumetric pattern by choosing a picture. It can be an image from the Internet, a still from a movie, or even your own creation. When downloading a picture from the network, make sure that it has sufficient resolution - at least 300 dpi.

Pictures with depth effect look best on the floor. It can be an abyss, a descent, a body of water. The water theme is generally very popular, as it looks beautiful in any room, has a calming effect on the psyche and has a volumetric effect.

It is not recommended to use as an image for a self-leveling floor:

- pictures with monsters or grinning predators. Aggressive drawings can put pressure on the psyche and cause not the most pleasant sensations;

- images with dynamics. They can have a bad effect on people with a weak vestibular apparatus;

- too bright and bulky pictures, flashy colors and aggressive color combinations. It will be difficult to relax in such a room, and the abundance of bright colors (especially red) is a strong irritant to the psyche;

- little things enlarged to a huge size. It will look not only tasteless, but also get bored very quickly.

After the image is selected, you can proceed to the next steps.

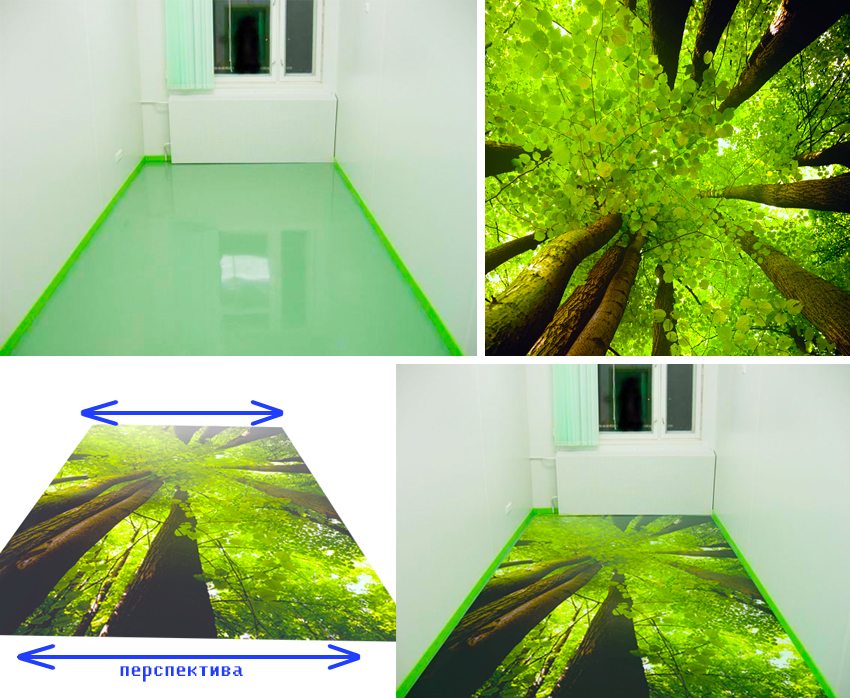

Changing the perspective of an image

In order for the picture to appear three-dimensional, you need to do the following:

- the room in which it will be applied to the floor should be photographed from the desired angle. It is important to take into account that some cameras move away or zoom in on objects in the photo, so the distance should be chosen so that in the photo the room looks like you see it from the threshold or from the desired point;

- in a graphics editor, the picture you have selected is applied to the floor photo as you are going to place it in reality. This will create an optical illusion;

- in the figure, everything is cropped except the floor itself, with the image superimposed on it. As a result, you should have a trapezoid extended downward, as the human eye sees the floor;

- the trapezoid is transformed into a regular rectangle using the appropriate tools in Photoshop or another graphics editor;

- the resulting image must be saved and printed in high resolution.

Helpful advice! If you do not know how to use graphic editors, then hire a designer for this or use the services of friends. The price of a photo of a self-leveling floor with a volumetric image made in this way will still be lower than when contacting a specialized company.

Printing a picture on a banner fabric

In order for the picture applied to the self-leveling floor to not lose its appearance upon contact with polymers or transparent varnishes, you need to use a special banner fabric for printing. It is designed for use in difficult weather conditions, so it will transfer the fill to the floor well. Banner printing is carried out by specialized firms.

To be sure that the selected image is correct, you can first print it in regular black and white and lay it on the floor to make sure the image looks as you intended.

The banner should be printed with colors that do not fade in the sun, as the floor will be constantly exposed to direct sunlight. In addition, the polymers that will cover the banner can heat up when mixed, which can also negatively affect the picture.

How to prepare the base

In the do-it-yourself 3D self-leveling floor video, you can see that the most common self-leveling floor covering acts as the base, the installation process of which is described in detail above. The main requirement for this is the absence of spots and irregularities. If the drawing is applied to a new freshly laid floor, then no problems should arise at all, but the old base will have to be cleaned and leveled.

Irregularities can be removed with a milling machine or conventional hand sanding. Particularly neglected contamination must be removed using special compounds. If it turns out that nothing can be done with a small spot, then you can try to organically include it in the picture.

Banner sticker

The finished banner with a picture is glued to the self-leveling coating. The final stage of the step-by-step instructions for the self-leveling floor with your own hands will be the application of a finishing layer over the drawing. A special plastic lens is poured onto the finished picture, and a wear-resistant layer is applied on top, which increases the operational properties of the surface. If you need a special optical effect, then many advertising agencies can order a special super-transparent lens.

It is best to fill the drawing with polyurethane varnish. It does not tarnish over time, boasts strength and increased abrasion resistance. Experts advise to give preference to varnishes and coatings of foreign production, as they are characterized by durability and resistance to mechanical damage.

Remember that when you apply a photo yourself, the price of a self-leveling floor for an apartment will be much lower than when contacting a specialized construction company.

Price per square meter of self-leveling floor and recommendations for maintenance

The cost of a self-leveling floor depends on its thickness, binder composition and other factors. The average price of a screed per m² is 210-350 rubles.

The finished floor is highly durable, but it also requires regular maintenance. Usually it consists of a banal dry or wet cleaning. The polyurethane coating is dust-repellent, so cleaning is not particularly difficult.You can use a regular vacuum cleaner or water and detergent for this.

The main requirement for the maintenance of self-leveling flooring is not to allow heavy objects to fall if you are using decorative flooring. Other types of coatings are well tolerated by mechanical and natural influences.