Correct arrangement of the ventilation system in the kitchen is the key to a healthy indoor climate. The system consists of an exhaust device and an air duct made of different materials. Due to their low cost, ease of installation and durability, plastic boxes for ventilation are the most popular. Everything you need to know about this product is detailed in the article.

Content [Hide]

What are plastic ventilation boxes?

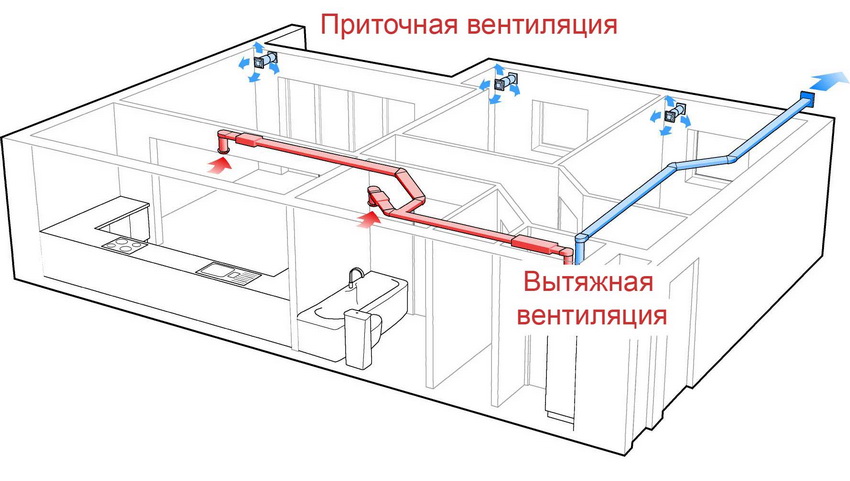

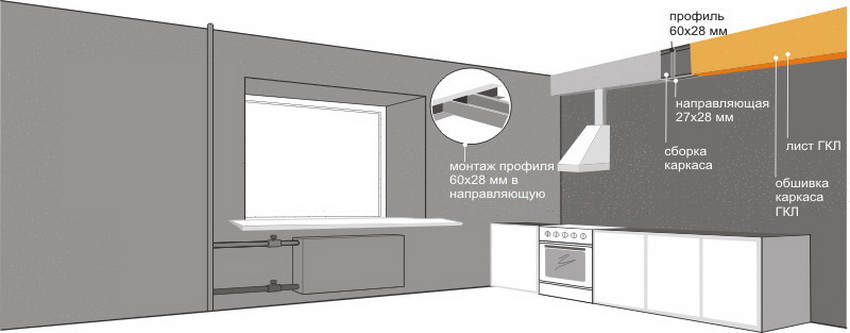

Each modern apartment has natural ventilation, which is provided by a common ventilation duct running through all floors of the building. Kitchens with a ventilation duct in the corner are very common. In this case, the design of the room should be correctly designed so that this element is practically invisible and fits perfectly into the overall concept of the interior.

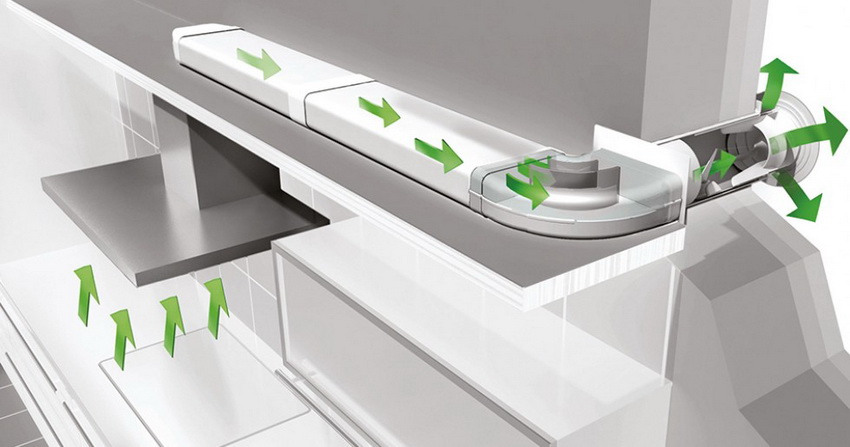

Often the capacity of the ventilation system is not enough to provide the required air exchange in the room. This is especially true for kitchens. To organize a favorable, healthy microclimate in a room with high humidity, it is important to equip a forced ventilation system. It is able to continuously purify the air from smoke and odors that are formed as a result of cooking. This system consists of a hood and a metal or plastic air duct. It connects to the ventilation duct in the kitchen.

It is very important that the common channel is working properly. Otherwise, in order to ensure effective ventilation in the apartment, it will be necessary to restore the ventilation duct. That will require additional costs for attracting specialists. The efficient operation of the supply ventilation system depends on a properly selected hood and proper installation of the air duct.

Ventilation ducts differ in material of manufacture, size and shape of section, flexibility and degree of elasticity. Plastic air ducts are considered the most popular for the arrangement of a household ventilation system. Unlike bulky galvanized ventilation ducts, they can successfully complement any kitchen interior.They are made of high-quality polymeric materials such as polyethylene, polyvinyl chloride and propylene, without impurities harmful to human health.

The production of ventilation boxes from polymers is carried out using a simple hot pressing technology, which makes it possible to obtain a product of various shapes and sizes. Using, for example, flat boxes, it is possible to create an almost invisible ventilation system that is hidden behind the canvas of the false ceiling or the top wall of the hanging kitchen cabinets.

Varieties of plastic ventilation ducts for hoods

Today, manufacturers produce various variations of polymer air ducts that provide normal air circulation and fit into any interior.

Polymer ventilation ducts are divided into:

- rectangular products;

- round boxes;

- oval products.

The most popular are rectangular plastic ventilation ducts, which fit well into any interior. Such an air duct can be hidden under a stretch ceiling or placed inside a kitchen cabinet. It can also be revetted with finishing materials or painted in a suitable color. Installation of rectangular boxes is quite simple, even in hard-to-reach places, and does not require special skills.

The cross-section of polymer air ducts is selected based on the capacity of the ventilation system. Manufacturers mainly produce plastic rectangular ventilation ducts with dimensions of 110x55 mm, 120x60 mm, 204x60 mm with a wall thickness of 3-4 mm.

For a large ventilation system, you can buy a ventilation box for a rectangular hood with a size of 220x90 mm and a round shape with a diameter of 200 mm.

For laying long ventilation systems, mainly round ventilation ducts of 50-150 mm are used. Here, due to the fact that the circle, as a geometric figure, has the smallest perimeter, the internal resistance in the duct is minimized, which has a beneficial effect on the performance of the entire ventilation system.

Useful advice! It is better to perform long sections of the ventilation system from flexible boxes of a round or rectangular shape, which are 15-20 m long.

Advantages of plastic ventilation ducts for hoods

Today many people prefer kitchen design with a ventilation duct made of polymers. Plastic boxes have become a worthy alternative to bulky, unattractive metal items. They have a number of undeniable advantages, which makes them more demanded by consumers:

- high operational and technical parameters;

- durability of the product;

- wear resistance;

- increased resistance to mechanical damage;

- products are not subject to deformation;

- resistance to temperature fluctuations and aggressive substances;

- light weight, which simplifies the installation of the product;

- have an attractive appearance;

- the presence of various color variations;

- low cost of the product.

The ventilation system made of plastic boxes is very easy to install according to the pipe-socket principle. Thanks to such a simple wiring diagram, the structure can later be easily disassembled for maintenance and cleaning, and reassembled. Moreover, the number of such cycles is not limited.

Among a wide range of plastic fittings, you can select the necessary composition of components, with the help of which you can lay an air duct of any configuration and length without using welding machines, rolling devices or soldering irons. Numerous photos on the Internet show how to beat the ventilation duct in the kitchen so that it fits perfectly into the interior of the room.

Due to its low weight, the polymer air duct can be easily fixed to the ceiling or wall using ordinary dowels.

If it is necessary to assemble a ventilation system that will collect and remove hot air saturated with vapors, then it is advisable to use a ventilation box made of galvanized steel. It is able to withstand high temperatures and not lose shape. A plastic box, on the other hand, can quickly deform and lose its tightness.

The polymer has good heat insulating properties, which reduces the risk of water condensation and reduces the oiling of organic vapors on the inner surface of the plastic box. And thanks to the smooth, polished plastic surface, unimpeded removal of polluted air containing fats, organic compounds and soot, which does not settle on the walls of the box, is ensured. These characteristics reduce the risk of accumulation and development of pathogens in the ventilation system.

Features of the choice of a polymer ventilation duct for ventilation

Before you buy plastic boxes for ventilation, you should decide on the purpose, type and capacity of the ventilation system. Polymer air ducts are selected based on the exhaust power, the specifics of the layout and design of the room. The efficiency of the entire system depends not only on the correct installation in accordance with all the main criteria, but also on the correct choice of the cross-sectional area and shape of the channel.

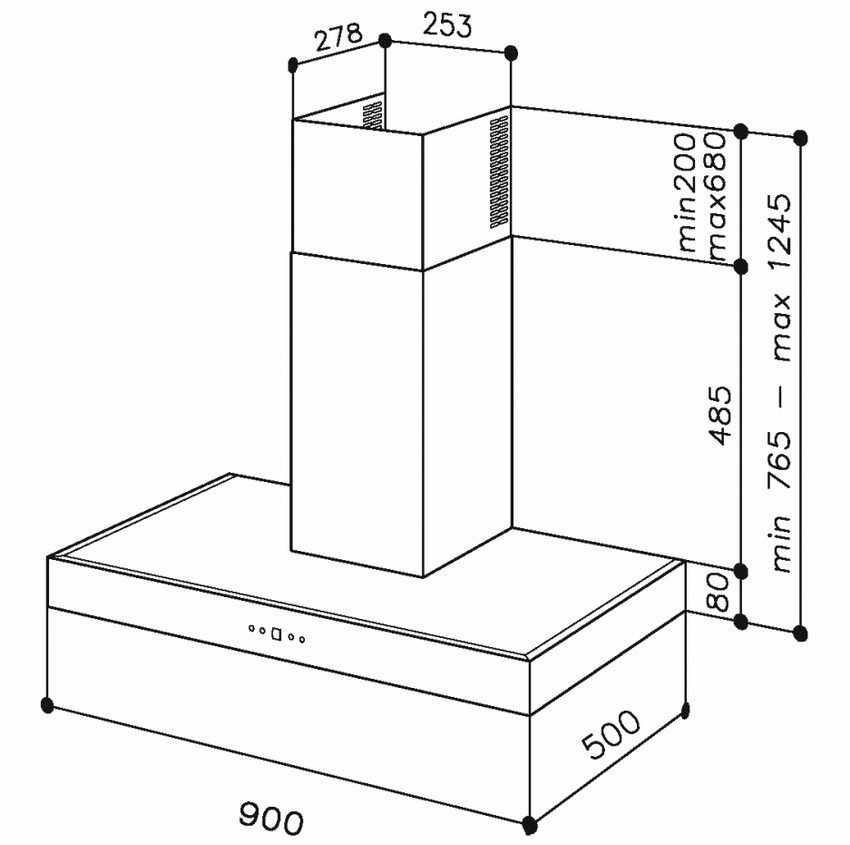

Cross section pipes for a plastic box it is selected based on the maximum volume of contaminated air that must pass through the system at a speed of 3-7 m / s. This value should be equal to or slightly larger than the size of the exhaust outlet.

Plastic size diagram hoods

If the cross section is selected too large, a working ventilation system will create an extra hum. In addition, this will lead to an inappropriate financial investment and laborious installation work.

In the case of a small duct cross-section, the extraction performance will be reduced due to the increased load on the mechanism. This will lead to a decrease in air exchange cycles in the room, the occurrence of vibration in the system and an increase in energy costs.

The choice of the shape of the ventilation duct depends on personal preference and kitchen design.

Important! Round air ducts provide a quieter ventilation system.

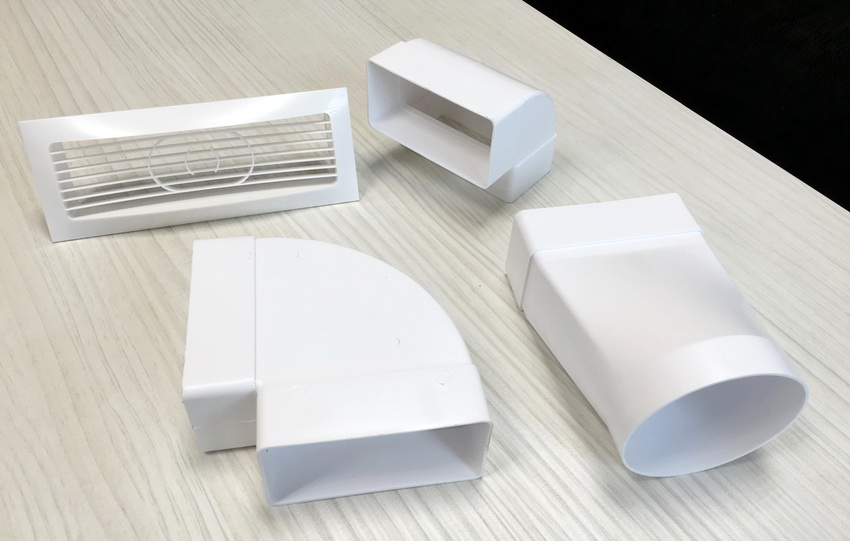

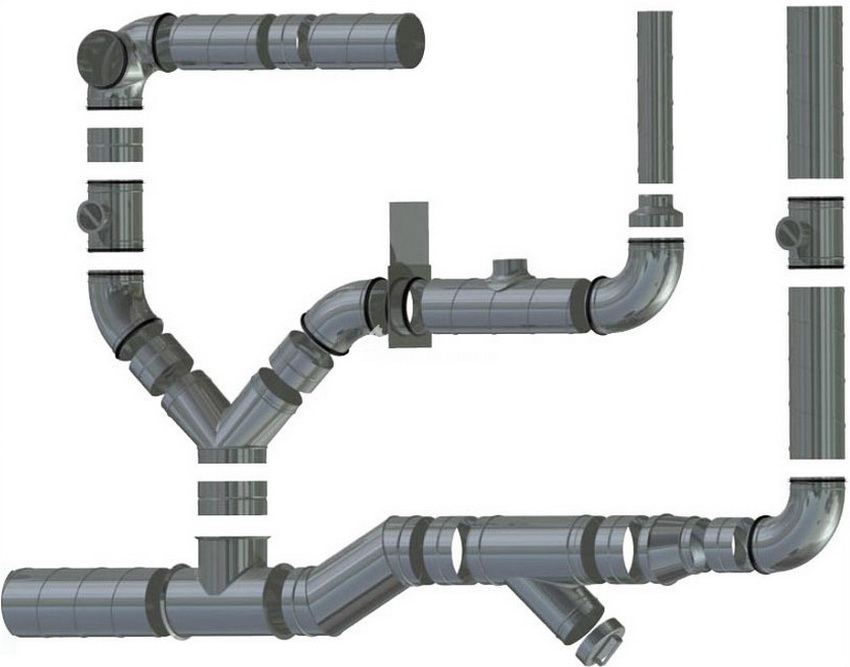

Plastic fittings for hoods

The arrangement of the ventilation system should begin with drawing up a drawing indicating the types and sizes of parts and points of attachment of elements to the wall or ceiling. Depending on the design of the room and the location of the furniture, the ventilation box can have a different configuration. This is done with the help of special plastic fittings, which are connected to the straight sections of the ventilation duct through the "landing flange - bell" system.

Today you can buy ventilation ducts of round or rectangular cross-section with a length of 0.35 to 2 m. You can cut off a section of the required length using a grinder or a hacksaw. If the length of the straight section exceeds 2 m, it can be mounted using several elements of standard length, connecting them together using special elements for polymer channels.

Rotation of the air duct by 45º or 90º is carried out using the knee. If a rectangular box is used, the direction change can be performed both horizontally and vertically.

Useful advice! If the air duct needs to be turned by an amount not multiple of an angle of 45º, a multi-angle elbow should be used, in which one of the sides, depending on the required angle, is cut off.

If it is necessary to change the shape of the box from rectangular to round, special adapters are used. Products can be straight or angled.

Manufacturers produce the following types of transitions:

- from a section diameter of 100 mm to the size of a rectangular box 110x55 mm;

- from a cross-sectional diameter of 100 mm to the size of a rectangular box 120x60 mm;

- from a cross-section diameter of 125 mm to a rectangular box size of 204x60 mm.

To make the transition to a plastic box of a different size, reducers should be used. A special universal adapter is used for polymeric products of circular cross-section of any standard size.

Related article:

Built-in hood for the kitchen: the best solution for air purification

The need for installation and features of the device. Installation options for built-in hoods. Popular hood manufacturers.

For complex structures, where several hoods are connected, a tee is used, which can be round, rectangular or combined. A check valve is used to prevent backdraft during stopping the hood. It can be built into the connecting element of the plastic channel or its function is performed by the louvers of the ventilation grill.

Features of mounting a plastic box for the hood

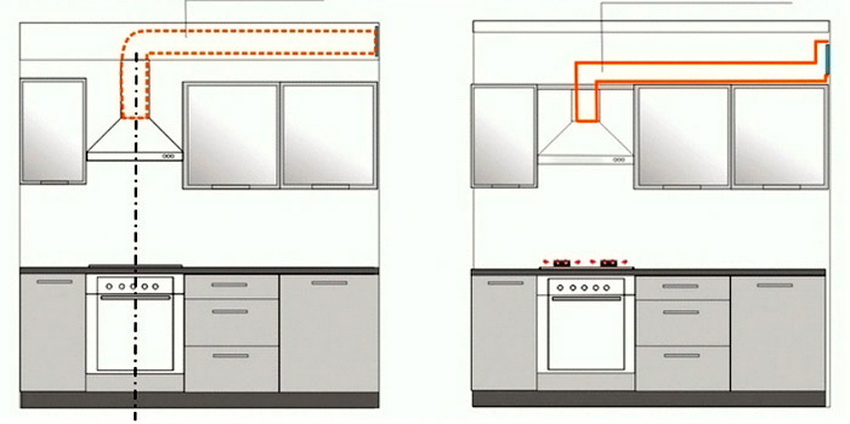

Installation of a plastic box is easy to do on your own, without the involvement of specialists. However, for the effective operation of the system, it is better to use the services of professionals. When performing installation, it is important to follow certain rules. First, in order for the ventilation system to operate at maximum performance, the length of the duct section should be minimal. The optimal distance is considered to be no more than 3 m. It depends on the location of the ventilation duct, which is located along one of the walls or in the corner of the kitchen, and the location of the hood relative to it.

The most common option is a kitchen with a ventilation duct in the corner, the photos clearly demonstrate this. Here it is advisable to place the hood close to the duct, which will eliminate the need to install long air lines and reduce the power loss of the hood.

Secondly, in order not to create excessive aerodynamic drag within the system, it is desirable to use a minimum number of shaped elements to change the direction of the air flow. The more 90º elbows are installed on the site, the higher the resistance in the system will be, which will create additional noise during the operation of the hood. This will also lead to excessive accumulation of grease and dust on the inner surface of the air box.

It should be remembered that polymer boxes have a low degree of fire resistance. Products are capable of withstanding temperatures not exceeding 50 ° C. Therefore, if it is necessary to mount an air duct near a heating riser or other heat source, thermal insulation should be laid between them to prevent irreversible deformation of the plastic.

Useful advice! To create thermal insulation, it is better to use foam that has a low thermal conductivity, which will not create additional noise when the plastic box vibrates.

Sections of the polymer duct from the hood to the ventilation duct can be fixed in different ways. It depends on their location in relation to walls, ceilings and cabinets. Here all the nuances should be taken into account in order to avoid the appearance of noise from vibrations, deformation and sagging of the ventilation duct with possible depressurization.

The plastic box, which is located inside the kitchen cabinets, is attached to their back wall with clamps. The places where the box passes through the walls are fixed with expanded polystyrene or foam inserts, which prevents noise during the operation of the system.

If the air duct is located above the cabinets, it is fixed using special holders or small wood screws. The fixing of the product to the ceiling or wall is carried out with the help of holders located at a distance of 1 m from each other. Fixation is carried out using special clamps, which are selected according to the size and shape of the ventilation duct.

If the ventilation box is closed by a suspended or stretch ceiling, it should be securely fixed without taking into account the visual perception of the structure's appearance and check the reliability of the mounting system at maximum hood operation.

Useful advice! Despite the fact that all plastic elements of the ventilation system fit tightly to each other, it is better to treat all joints with acrylic or silicone sealant, which will prevent the ventilation duct from depressurizing after a while.

Plastic air ducts in the apartment are not only convenient, but they can be stylishly beaten by creating a unique design

Plastic air ducts are a good solution for a reliable, highly efficient system supply ventilation in a house or apartment. And correctly selected fittings, fasteners and sealant give the structure not only an attractive appearance, but also significantly extend the service life of the system.