Comfort is not increased exactingness, it is conditions that contribute to a positive effect on the psychophysical state of a person. In order not to languish from the heat during cooking and to prevent the spread of odors to other rooms, an air vent is needed in the kitchen. For aesthetics and in order to protect it from unwanted influences, its parts are placed in a hood. About what boxes can be and how to install them will be discussed in this article.

Content [Hide]

- 1 Principles of functioning of forced ventilation systems

- 2 Forms of ventilation ducts and basic installation methods

- 3 Materials used for the manufacture of hoods

- 4 Kitchen hood duct: the right location

- 5 How to correctly calculate the dimensions of a plastic box

- 6 Features of mounting a plastic ventilation duct

- 7 How to choose and which one to buy a hood for the kitchen

- 8 Hood box in the kitchen: design options for non-standard situations

- 9 Do-it-yourself kitchen hoods

- 10 Reasons for clogging and the procedure for restoring the ventilation duct

- 11 Hood box: rules of operation and use of accessories

Principles of functioning of forced ventilation systems

The ventilation of kitchens has become a prerequisite for the normal functioning of the room. In general, the kitchen exhaust system has the following elements:

- engine;

- fan;

- filters;

- pipes.

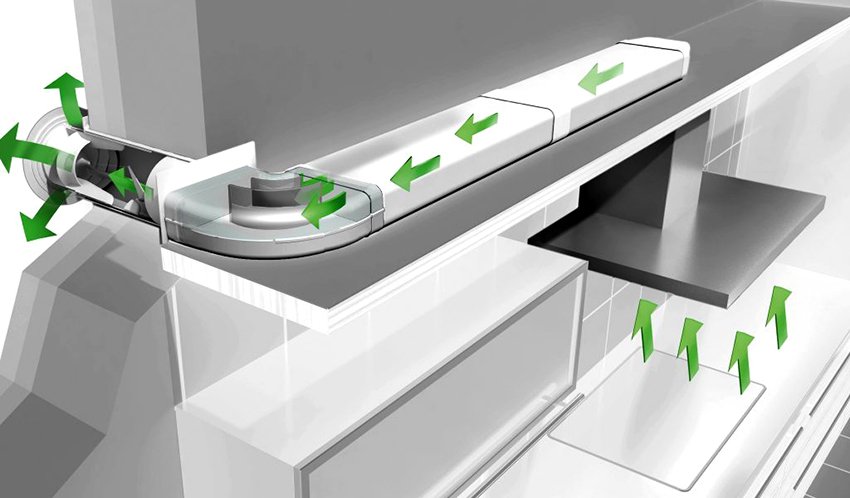

The engine provides the operation of the fan, which feeds contaminated air flows to the filters, where grease and burning particles are retained, then the flows enter the duct - into the piping system for ventilation. There are two types of exhaust systems functioning:

- circulation;

- inline.

The circulation system involves the intake of contaminated air with a fan, passing it through several filters, where fumes and grease first settle, and then the air flow itself is filtered, and the purified air is returned to the room. This is an expensive system, it is difficult to operate, since there is a frequent need to rinse and replace filters.

They resort to using such an air cleaning system most often in cases where the connection to a common ventilation duct is complicated (relevant for apartments) or the external ventilation outlet turns out to be on the facade of a private house building. Systems with in-line cleaning are very popular, when dirty air, having passed through a filter, is discharged outside. These systems have several advantages:

- more efficient air purification;

- easy care;

- affordable cost.

But such a system requires a ventilation duct. Consequently, the installation is somewhat complicated, where the placement of the common ventilation duct will be of great importance. In addition to solving technical problems, there is a need for the right design choice: a kitchen with a ventilation duct should be cozy and aesthetic.

Forms of ventilation ducts and basic installation methods

The installation process of this system is carried out in the presence of one of two circumstances:

- the installation site was laid down in the construction (or repair) project, while all

- preparatory work;

- it is necessary to integrate the system into existing conditions.

The production of a large number of types of hoods, the parameters and technical characteristics of which differ depending on the location, allows you to choose the appropriate option. Ventilation systems can occupy the following positions:

- built into a furniture wardrobe;

- fasten to the wall;

- be located in the corner;

- hang from the ceiling along the wall;

- take any overhead position (island hoods).

The built-in hood is installed in a wall cabinet. This is a convenient option that does not entail special design requirements. The retractable lower part, which is most often found in such models, automatically starts the engine, brings the system into operation. The ventilation box becomes part of the furniture, in which the connections are hidden, which greatly simplifies installation.

The wall hood is an open part of the kitchen, therefore, in addition to technical requirements, it must have a certain appearance. The box is hidden by a common body, on a flat rectangular surface there is a control and lighting panel.

In small kitchens, corner hoods are installed. The cut corners of the body reduce the overall dimensions of the structure, which is important for small rooms: the exhaust system does not seem bulky.

Suspended hoods are fixed to the ceiling. Special requirements are imposed on the appearance of the box, which remains open. This design does not take up much space and makes it easier to perceive the working wall.

Island hoods are usually installed in kitchens with a large area, when the hob is not located near the wall, but is located in the center (or offset to one side) of the room. Such a hood, in addition to its functional purpose, is one of the main components of the interior.

Exhaust systems traditionally come in two forms: rectangular (square) and round. Built-in and wall-mounted models most often have a rectangular ventilation box, plastic or metal. Suspended and island hoods are round, metal, although rectangular suspended options are quite common.

Useful advice! Round ventilation ducts for the hood visually seem to be smaller than rectangular ones and are successfully combined with other interior items of a similar shape, for example, with rounded backs of chairs or glass of an oven, microwave oven, with rounded table top edges.

Materials used for the manufacture of hoods

The part of the hood, where the motor, fan and filters are located, is always closed and has an aesthetic appearance. But as for the connection to a common ventilation duct or to the outlet of air flows to the outside, there are models that are already equipped with boxes, but there are also those that need to be independently equipped with these devices or made them.

For the production of boxes, two main types of material are used: plastic and metal. Outwardly, both options look presentable. With regard to performance, both types have both advantages and disadvantages. Finished models are most often equipped with metal boxes. They often make plastic air ducts for kitchen hoods on their own.

Modern models of plastic hoods

One of the main positive qualities of a plastic hood for a kitchen hood is affordability. But not only this advantage makes these products popular. Such air vents are easy to install. The assembly principle is the pipe-to-socket method. With the correct calculation, installation is not difficult. The material features also make such a box acceptable. The inner surface is smooth, fatty deposits and burning residues do not accumulate on it so intensively. Therefore, there will be no need for frequent cleaning. With proper operation, manufacturers give a 50-year warranty for such products.

The material is not subject to corrosion, condensation does not accumulate on it. During operation, especially if the box has a considerable length, the issue of noise generation is usually acute. Plastic models, unlike metal ones, have a low noise level. This indicator is important in ensuring comfort. As a positive quality, it is worth noting the presence of a large number of variations of components, which allows you to choose a model for any technical conditions. Summing up the above, we can say that the main advantages of plastic boxes are:

- low price;

- long service life;

- technical qualities of the product ensuring ease of use;

- low noise level.

With the constantly increasing quality level of polymers, plastic, nevertheless, remains a vulnerable material for mechanical damage and high temperatures. If exposed sunlight falls on the outer surface, then over time it becomes rough. This leads to the accumulation of fatty deposits in the pores and complicates the cleaning process. Scratch marks become more visible, the overall aesthetic level is significantly reduced.

Metal hoods for hoods: practicality and durability

A metal product is a more reliable design. Stainless steel hoods are especially popular. Their main operational advantage is relatively easy cleaning. Traces of burning, grease can be washed off with any detergent. The material is resistant to mechanical stress, does not corrode.

We can especially note the visual qualities: style, showiness, presentability. Highlighting these advantages, it is worth paying attention to the fact that this type of box is not suitable for any room. The structure looks cumbersome, therefore, the dimensions of the surrounding furniture and the room as a whole must correspond to it. This option must be correctly entered into the interior of the kitchen.

The disadvantage of the metal box is the high noise level.In addition, fingerprints easily remaining on the surface cause problems - you will have to make an effort to keep the hood clean. The metal structure is more difficult to assemble. It should be attributed to the disadvantages and monotony of color, as this contributes to the limited use.

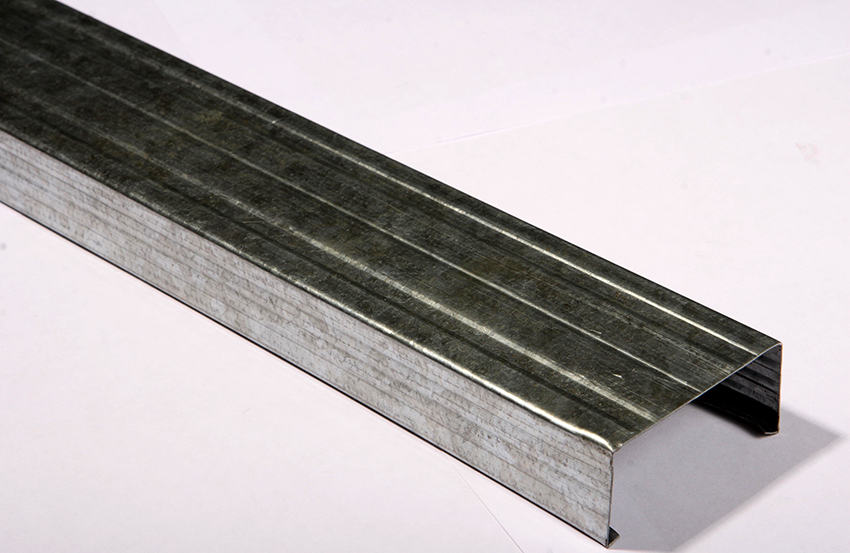

Galvanized ventilation ducts are often installed in kitchens. The material is based on zinc-coated metal. This is a fairly strong connection, which is protected from corrosion, in installation it is much easier than stainless steel, and also has a lower cost. In terms of durability, galvanized steel is inferior to stainless steel. But the variety of modifications of galvanized boxes makes them more acceptable.

Useful advice! When choosing a metal box for a hood, you need to be confident in the material. Sometimes galvanized steel is given for a stainless steel product (especially if it has not been subjected to a mirror finish). It is worth carefully examining the box: galvanizing has characteristic spots - a crystallization pattern.

Kitchen hood duct: the right location

A vent box in the kitchen is an important subject in all respects, so its operation should be considered in two directions:

- technical functionality that creates a microclimate in the room by removing air contaminated with vapors, fumes and fatty particles;

- design functionality, which consists in filling the interior with aesthetics and originality.

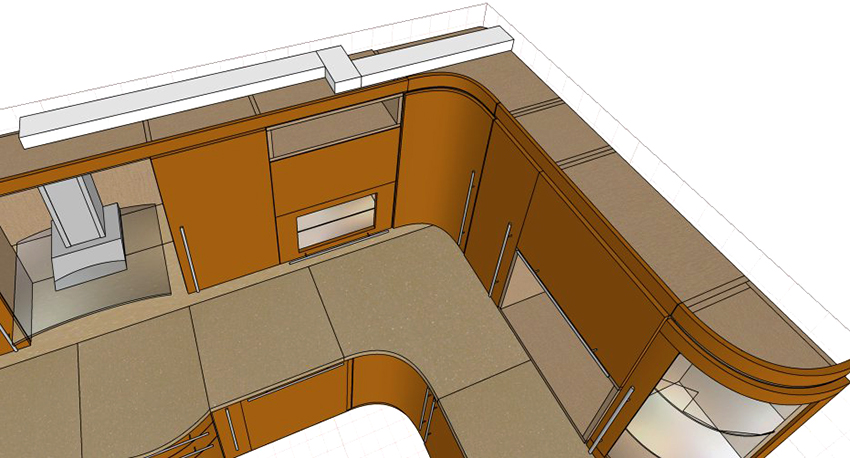

The conditions necessary for the good operation of the ventilation system are interrelated, and it is only necessary to solve the problem of their creation as a whole. To meet the design requirements, you need to choose the appropriate shape, size, color, etc. However, the best choice can only be made taking into account the location that provides the correct connection. If the ventilation box needs to be pulled through the entire kitchen, it is impossible to maintain aesthetics and ensure a sufficient intensity of air flow extraction, and a rather extensive part of the kitchen space is involved. It is necessary to determine the location of the air outlet depending on the conditions:

- places of passage of a common ventilation shaft;

- technical characteristics of the hood;

- layout and way of furnishing the room.

The hood is always installed above the hob. Sometimes it can be difficult to find a compromise between a convenient location of the cooking area and meeting the technical requirements for the proper functioning of the air outlet. The consumer characteristics of the hood are not lost if the length of the ventilation box is 120-150 mm. Each subsequent 50-70 mm reduce the intensity of air passage by 10-12%.

Useful advice! If the air exhaust duct is more than 200 cm long, it is necessary to purchase a hood with a capacity exceeding the optimum for the kitchen area by 100-200 m³ / h.

How to correctly calculate the dimensions of a plastic box

For the full functioning of the kitchen ventilation system, it is necessary to correctly select the hood power and calculate the air exhaust parameters. The main indicator when choosing a box is its inner section. The throughput of the system as a whole will depend on this size and on the power of the engine.

Related article:

Exhaust corrugation: ease of installation and ease of use

Advantages and disadvantages, application. Materials of manufacture and classification, advice on selection. Features of installation. Care recommendations.

There are no documents in any way regulating the flow rate. In the domestic version, the average speed is 3-7 m / s.The size of the cross-section is traditionally chosen equal to or slightly larger than the dimensions of the air outlet at the hood. Sometimes, if it is practically not planned to turn on the hood at full power, the channel cross-section is chosen less than at the exhaust outlet.

You can calculate the cross-section of the air outlet using the formula P = S * (M / N), where S is the cross-sectional area of the branch pipe, M is the volume of conducted air during the planned mode, N is the volume of outgoing air when the hood is operating in maximum mode. The resulting P is the required section size. If the cross-section of the box is chosen less than the recommended dimensions, the following consequences are possible:

- the load on the fan and the motor increases, which can lead to breakdown of these mechanisms;

- the intensity of air circulation in the room itself decreases;

- the noise level in the ventilation duct increases;

- vibration occurs, which negatively affects the condition of the mounts.

The increased (relative to the dimensions recommended by the instructions) channel cross-section does not negatively affect the operation of the ventilation system.

Useful advice! When installing a ventilation duct of a larger size than recommended for the hood model, it should be understood that this will not increase efficiency, but will lead to unnecessary financial costs and installation problems, since it is more difficult to mount large elements.

The dimensions of the most common commercial round plastic ventilation ducts are as follows:

- 80 mm, cross-sectional area - 50.3 cm²;

- 100 mm, sectional area - 78.5 cm²;

- 125 mm, cross-sectional area - 122.7 cm²;

- 150 mm, cross-sectional area - 176.7 cm².

The dimensions of ventilation rectangular plastic boxes used for domestic purposes have the following indicators:

- 110x55 mm, cross-sectional area - 60.5 cm²;

- 120x60 mm, sectional area - 72 cm²;

- 204x60 mm, cross-sectional area - 122.4 cm².

The above are traditional indicators, but there are also non-standard sizes. Before planning the installation of a ventilation duct of special dimensions, you should make sure that such products are manufactured and can be purchased.

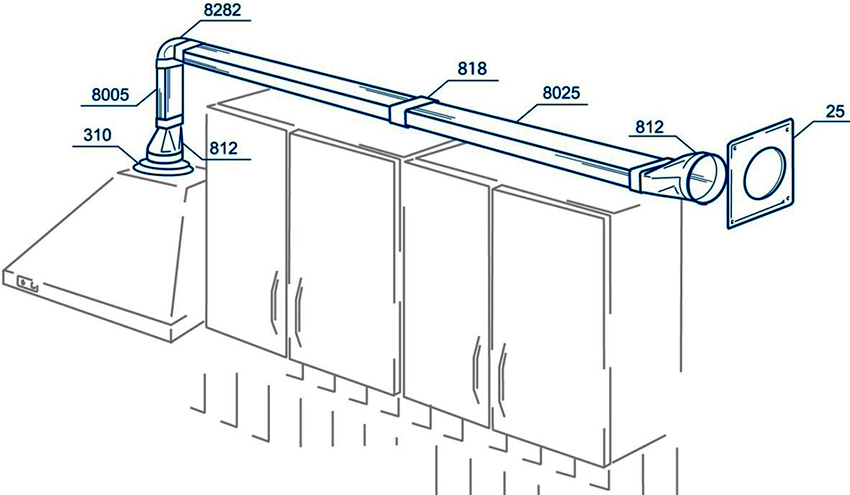

Features of mounting a plastic ventilation duct

Installation of a plastic air duct for the hood is carried out in several stages, including the design part and the installation itself.

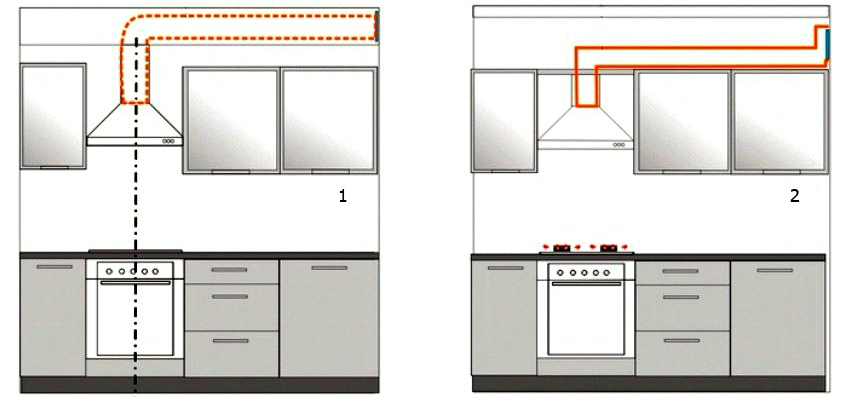

Scheme development. To correctly calculate the required number of air outlet elements, it is necessary to draw up a diagram of the ventilation duct installation. A variety of plastic construction elements allows you to perform almost any variation of the box. For the hood to work normally, the following conditions must be met:

- reduce the length of the box as much as possible, since when lengthening, the intensity of the removal of the air flow is lost;

- use a minimum number of installation elements that contribute to a change in the trajectory of the air flow (constrictions, bends, etc.), since they increase resistance;

- refuse to rotate the structure by 90 °. Such areas maximize resistance and contribute to the adhesion of pollution particles in these places;

- remove the box from the heating riser. If this is not possible, then it must be thermally insulated so that the temperature of the device does not exceed 50 ° C. The insulating material will help suppress noise;

- according to the developed scheme, the exhaust duct is assembled.

Installation of a check valve and grate. The valve is an indispensable element of the ventilation duct. In its absence, the air will simply return to the room. It is installed at the end of the air outlet.It is supplemented with a grate and equipped with a mesh so that small animals, birds and insects do not get into the ventilation system from the street or from a common mine.

Placing and securing the air outlet. The way of fastening directly depends on the placement of the box. If the product is installed in a cabinet, then it should be attached to the back wall using clamps. The box laid over the cabinets can be fixed to them by means of holders and self-tapping screws. Fixing to a wall or ceiling should be done using holders and clamps and positioned at intervals of at least 70 mm.

Leakage control. When assembling the plastic ventilation duct, it is necessary to ensure that all joints are fitted, that there are no gaps and gaps. It is impossible to check the box for tightness before starting operation, therefore, mistakes made can result in the penetration of polluted air into the room and increased noise.

During installation, it is necessary to clearly adjust all joints so that the structure becomes absolutely tight

Useful advice! Having opted for a plastic box, it is worth buying parts from one manufacturer, since individual elements may differ in quality and even in size with, at first glance, appropriate marking.

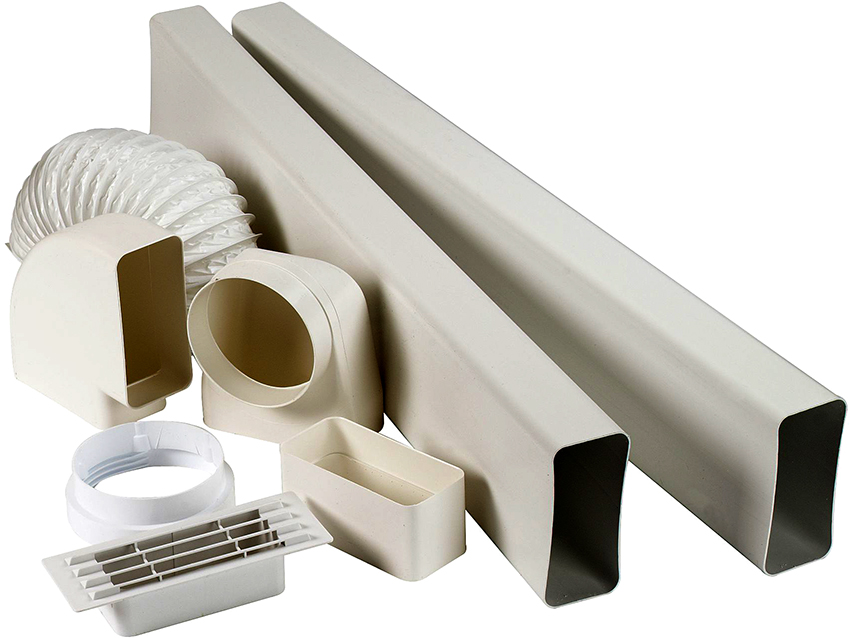

Special elements used when installing hoods in the kitchen

Kitchens in private houses and apartments have different layouts, which sometimes seriously complicate the installation of the ventilation system. In such situations, you cannot do without special elements. Traditionally, ventilation ducts are straight parts of a round or rectangular (square) shape. The length of these products is 35, 50, 100, 150 and 200 mm. If necessary, using a hacksaw, you can cut off a section of the desired size. When there is a need for a length of more than 200 mm, an element from several standard products is mounted using a plastic connector. The connector is positioned so that the overall length does not increase.

Quite often, during installation, it is required to rotate the air outlet. This usually occurs when you have to bend around the protrusions. For these purposes, the so-called knees are used. The rotation angle can be 45 and 90 °. Direction is changed horizontally and vertically. For situations where the angle of rotation is not a multiple of 45 °, multi-angle bends are used. The required degree of rotation is achieved by cutting off one side of the connector.

If it is necessary to change the shape of the box from rectangular (square) to round (and vice versa), adapters for the hood are used. A frequently occurring problem, solved by using adapters, is that a rectangular box must be attached to the round hole of the hood. These elements are available in both straight and angular shapes. Standard indicators - from a diameter of 100 mm to a size of 110x55 mm; from a diameter of 100 mm to a size of 120x60 mm; from a diameter of 125 mm to a size of 204x60 mm.

All of the above items are used exclusively for plastic products. The technology for installing metal boxes for the hood is completely different. Joints are made by welding or gluing with a special compound.

Useful advice! Despite the large number of additional elements, it is necessary to strive for a minimum number of their use, so as not to reduce the potential of the hood.

How to choose and which one to buy a hood for the kitchen

What should you pay attention to when choosing a ventilation duct for the kitchen? First of all, on the recommendations of the instructions for the hood. If it is not possible to fulfill the requirements, it is worth relying on independent calculations and the following tips:

- The round ventilation box takes up a lot of space visually and physically. It is worth giving preference to it only if the room has a high ceiling, a rather large area and is not cluttered with furniture.

- If you want to hide the ventilation duct as much as possible, a rectangular shape is suitable. Such a box can be placed on furniture and made it almost invisible. The rectangular design is appropriate for low ceilings and small kitchen sizes.

- It is better to use a square shape with a small box length, since large dimensions add to the bulkiness. The kitchen should be quite spacious for this model to fit organically.

If we evaluate the structure from the point of view of the material of manufacture, then plastic ventilation ducts for the hood are much easier to install, especially when there are difficulties with the straightness of the ventilation duct. Installation can be done independently without the help of specialists. When choosing elements from high-quality plastic, the color of which will correspond to the range of shades used in creating the kitchen design, the device becomes not only an air outlet, but also an interesting part of the interior.

A correctly technically installed metal box is an attractive design dominant. Choosing this option, one should take into account the high price, the need to ensure the reliability of fasteners and constant care of the product to maintain aesthetics.

Useful advice! If you plan to make a metal box part of the interior, it is better to choose stainless steel. Even before use, galvanized metal does not look very attractive, but during operation it quickly fades and loses its appearance.

Hood box in the kitchen: design options for non-standard situations

The location of the common ventilation shaft, especially in older houses, is often a problem to be solved in the quest to rationally locate the air cleaning system. If the shaft is located in the corner and protrudes 40-50 cm, then there is practically no other way to beat the ventilation box in the kitchen, making it an element of furniture.

It is most appropriate to make a false case out of the box. If the furniture is of two colors, then this design should be made dark: it will divide the corner furniture visually into two zones, which in practice can have different purposes: for example, a work wall with a hob and a sink on one side of the room and household appliances on the other.

Extending the common duct by less than 40 cm expands the design possibilities for a kitchen with a ventilation duct in the corner. The upper and lower parts can be closed, respectively, with a wall cabinet and a curbstone. This will increase the working surface, and the furniture elements will be functional. It is recommended to decorate the open parts of the channel with the same material that is used over the entire countertop. Or you can organize a separate area where kitchen utensils or interior items should be placed.

In the proposed photos of kitchens with a ventilation duct in the corner, there are ideas that will help you choose an option that allows you to make an interesting design element out of the problem of a protruding channel.

In a situation where the common ventilation duct is located in the wall and protrudes slightly, it is possible to resort to creative solutions, arranging an electric fireplace or a rock out of it, only if the dimensions of the room are at least 16-20 m². With a smaller area, it is better to decorate the ledge with a material common to the walls and decorate with non-volumetric interior items. Alternatively, you can place a TV on it.

Decorative hoods for kitchen interiors

The desire to decorate ventilation ducts is quite natural. After artistic processing, the simplest construction of regular geometric shapes acquires an aesthetic appearance and complements the design. The main materials for the manufacture of decorative boxes are:

- wood;

- metal;

- drywall.

Wooden boxes go well with classic kitchen furniture with front parts made of wood or imitating this material. Such a box retains its style, organically fitting into the overall interior. Wooden structures are quite heavy, they require strong fastening.

Until recently, metal boxes served both as a decoration and an air outlet. Most modern metal products are covered with corrugated pipes or telescopic systems placed inside, used in suspended structures. Metal baskets harmonize well with similar or glass hobs. Perfectly complement the modern interior in modern and high-tech styles.

By themselves, drywall boxes cannot perform the function of an air outlet. They only hide the pipes through which the air flow goes. Typically, this device is used in cases where it is necessary to close the channel in a hard-to-reach place or the designed box has an irregular shape. The advantage of this model is the variety in the choice of options, allowing you to show the most daring imagination. The inability to clean the air vent without damaging the fragments of the plasterboard structure can be attributed to serious disadvantages.

Useful advice! When choosing or manufacturing a decorative ventilation duct, the dimensions must be correlated, first of all, with the parameters of the room as a whole. Otherwise, he can obsessively dominate or, conversely, get lost in the interior as an unnecessary addition.

Do-it-yourself kitchen hoods

You can make a hood for the kitchen with your own hands. Thus, money is saved and ideas are implemented that allow you to create the ideal option, taking into account the characteristics of the room. Consider a wireframe model. Required materials for its manufacture:

- galvanized U-shaped profile, 15 mm wide;

- finishing material (plastic, plywood, chipboard, galvanized metal);

- dowels, anchor bolts;

- corrugated plastic or metal pipes.

The algorithm of actions is as follows:

- A 35x45 cm frame is attached to the profile ceiling.

- Then, a frame is assembled from the same profile, corresponding to the dimensions of the hob. One side is fixed to the wall 70 cm above the slab. To prevent the frame from falling apart, you need to substitute wooden blocks under the other sides.

- The upper (ceiling) and lower frames are connected by vertically exposed profile segments. The result is a solid, rigid structure.

- Using any material (optional or available), the frame is sheathed.

Useful advice! When making your own hood, it is better to position it so that the ventilation hole is inside the frame. Then there will be no need to additionally mount the box.

You can also make a metal hood with your own hands. Thin galvanized sheets are most suitable for this purpose. Blanks for the walls should be cut with metal scissors, and it is recommended to use special glue as a connection. The back wall of the structure must be attached to the wall in several places to increase rigidity.

Similar actions can be used to make a ventilation box out of galvanized steel. It is only necessary to take into account that it must be equipped with an inspection hatch, which can also be constructed from metal fragments, or it is better to buy a ready-made swing door. It will allow for the prevention of air venting without violating the integrity of the duct structure.

Reasons for clogging and the procedure for restoring the ventilation duct

Any operating system after the expiration of time requires the repair of individual elements or the complete replacement of all components. The ventilation system is no exception. The main signs indicating a decrease in the level of duct efficiency are:

- musty air;

- mold and mildew on the walls;

- the accumulation of condensation on the windows;

- odors are not removed;

- ventilation results are noticeable for a short time.

When one of the signs appears, it is necessary to check the condition of the box, ventilation as a whole, that is, the functioning of the engine, the condition of the filters. If no problems are found in the residential part, you need to contact the specialists with a request to examine the condition of the general ventilation shaft. Often, signs of poor functioning of ventilation ducts appear due to the following reasons:

The main signs of poor functioning of the hood are a decrease in the section of the air duct, clogging or complete blocking of the channel.

- channel clogging;

- reducing the section of the air outlet;

- complete channel overlap.

Channel clogging can be caused by gradual accumulation of dirt on the walls. Sometimes the residents themselves, when carrying out repair work, dump construction waste into the ventilation shaft. A decrease in the section or complete overlap is often the result of illegal redevelopment in apartments, when communications are built into the ventilation duct, or it is dismantled at the level of one apartment, and thus the air outlet is completely blocked.

Only specialists who have a certificate for the implementation of this activity have access to the survey and performance of works on cleaning the channels.

Useful advice! Be sure to ask the specialists who carried out the survey an act reflecting the condition of the ventilation shaft. This, in addition to compliance with the rule of law, will help determine the next steps.

If the reason for the failure of the general ventilation shaft is the illegal activity of residents, the restoration is carried out at their expense.

Dismantling of ventilation ducts, quotation in the estimate

Degraded ventilation ducts need repair or complete replacement. Often it is the dismantling stage that becomes problematic due to the difficulty of accurately determining the volume of labor costs and their cost. In order to correctly outline the types of work for disassembling the system, you need to conduct a thorough examination and determine the degree of damage and the number of failed components. Then you need to analyze how many people will be needed to work, what equipment will be involved, what materials will be required for replacement. Only then can the dismantling price be calculated.

In the event that the shaft structure is to be replaced completely, the price for dismantling will increase significantly, because it will be necessary to disassemble the box and remove all air vents and louvered grilles.

Prices for dismantling works can be found in GESNr-65- (28-32) and FERr-65- (28-32). The cost of labor should also include garbage disposal and waste disposal. The use of reduction factors relative to the direct costs of dismantling works (according to MDS-37 clause 3.2) is carried out as follows:

- if the equipment after dismantling will be used, then, taking into account the dismantling and conservation for the purpose of preservation, the applied coefficient will be 0.7;

- if the equipment will be used, but the work on disassembly, conservation and storage is not performed, a coefficient of 0.6 is used;

- if the equipment is not subject to use, but is disassembled and cut into parts, a coefficient of 0.5 applies;

- the equipment is disassembled, cut and discarded - the coefficient will be 0.3.

Drawing up estimates for dismantling works is a complex and painstaking process, it requires special education and certain skills.

Hood box: rules of operation and use of accessories

The cooker hood can be classified as one of those types of household appliances that, if properly used, work reliably for several years. To a large extent, the durability of work depends on the condition of the ventilation duct. During its operation, the following requirements must be observed:

- installation in accordance with the provisions of the instructions;

- before the initial start-up, it is mandatory to check the operation of the ventilation ducts;

- providing access to preventive actions (cleaning, checking the tightness) to maintain the normal state of the air outlet;

- cleaning the outer surface of the box;

- timely replacement of filters.

If the above requirements are met, the functionality of the ventilation system is maintained for a long time, but external surfaces remain vulnerable. They give out the “age” of the device.

Useful advice! If the hood works fine, but traces from constant cleaning, minor damage and faded color haunt you, there is no need to buy a new model, you can simply purchase a hood for the hood separately.

The old plastic ventilation box, covered with a modern stainless steel metal casing, will radically change the place of the hood in the kitchen design. Often the problem of the appearance of the structure arises when replacing kitchen furniture. Changing the color and shape with this accessory will bring harmony to all interior items.

The desire to turn off the hood as soon as possible in order to get rid of the noise will most likely be associated with an incorrect design of the air exhaust duct, with a discrepancy between its dimensions and the hood power. A kitchen with a ventilation duct, the design of which violates the overall perception of style, also does not contribute to a comfortable feeling. The exhaust system, installed taking into account all technical requirements and in accordance with the characteristics of the interior, will provide not only clean air, but also comfort.