Everyone has come across a situation when, being in their apartment, you can accurately determine which dish is being prepared by your neighbors or, even worse, you smell tobacco. This occurs due to the ingress of foreign odors into the apartment through the ventilation duct during reverse draft. To prevent this from happening, it is recommended to install a check valve for ventilation, which blocks the air flow in the opposite direction and helps to effectively remove the exhaust air from the room.

Check valve adjusts the direction of air flow through the vent

Content [Hide]

Check valve for ventilation: device and classification of mechanisms

Let's take a look at how the reverse ventilation valves work. The design of the ventilation check valve is quite simple: the valve blades are located on the same axis so that air can flow in only one direction. If the direction of flow changes, the valve closes. In addition to the function of blocking the reverse flow, the valve can be used to regulate the supply air volume by changing the section of the air duct.

Air check valves for ventilation are distinguished by the following characteristics:

- material for manufacturing - valves made of plastic or galvanized steel are used in various air ducts;

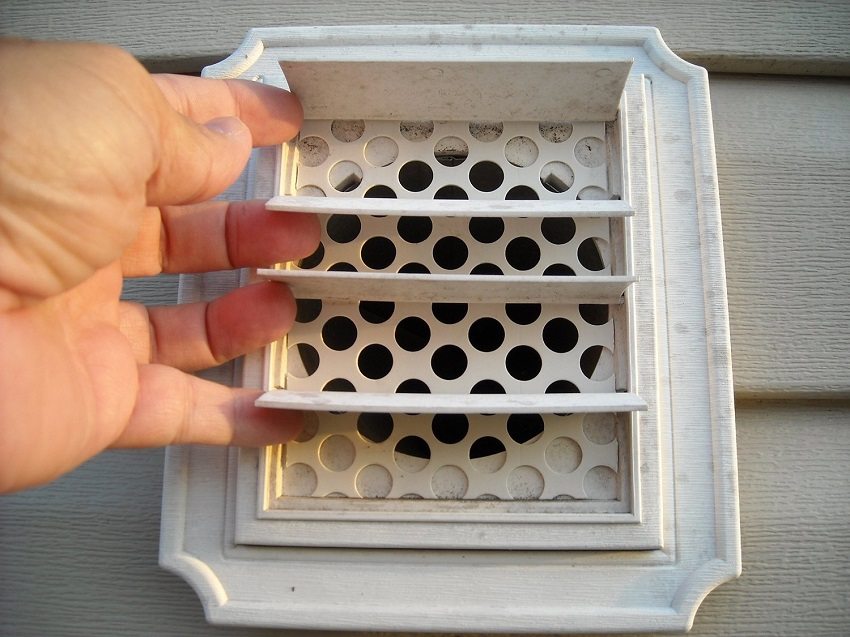

- by design - lattice, butterfly, petal or membrane. In the device of the grill with a check valve for ventilation, louvers are provided that open under the pressure of air only in one direction, which eliminates the reverse flow. Such grilles with a check valve can have various shapes and designs and are installed at the inlet or outlet of the ventilation duct. The butterfly valve resembles a butterfly valve made of two plates fastened by a spring. The diaphragm check valve is a thin flap that deflects even with a slight air flow and sticks to the ventilation grill when the flow changes direction. It is used, as a rule, with natural ventilation. The flap check valve is similar in principle to the diaphragm valve, but it is made in the form of a rigid damper fixed on an axis, which turns under the pressure of air and opens or closes the channel, depending on the direction of flow;

- in shape - rectangular or round. They are chosen depending on the shape and size of the duct section, where the check valve will be installed.Round valves for domestic needs are produced with a diameter of 100 mm, 120 mm, 125 mm, 150 mm and above. Check valves used in industrial ventilation systems have a diameter from 150 mm to 1000 mm.

- control method - valves according to their device are manual and electric. The manual ventilation check valve is manually adjustable by a lever or a slide. The electric valve functions in conjunction with other supply and exhaust ventilation devices and automatically regulates the air flow;

- installation method - the device can be mounted vertically or horizontally, depending on the design of the air ducts;

- throughput - the volume of air passing through the valve per unit of time can be different.

Louver louvers with gravitational mechanism of action are lowered under their own weight in the absence or change of the direction of the draft

Use of check valves for different ventilation systems

Regardless of the type of ventilation, whether it is a natural supply and exhaust system or a mechanical system, reverse draft is possible in it.

For natural ventilation, where ventilation ducts are used, check valves are used, which are especially sensitive to changes in the direction of air masses. For high-quality air exchange, it is better to install a check valve for ventilation simultaneously with the installation of ventilation ducts.

Installation of a non-return valve for ventilation in an apartment, where natural air circulation is carried out, is carried out in the walls between rooms. Usually, holes in the walls of an apartment are made near the doors and check valve grids are installed in them, which control the air flow.

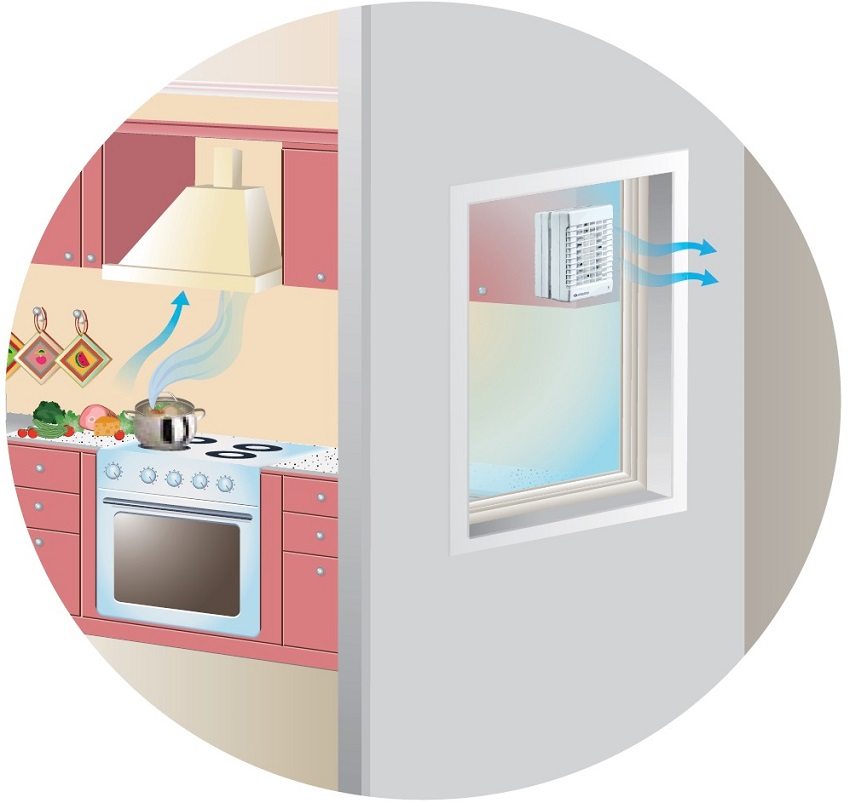

Supply ventilation, the design of which consists of an air duct built into the outer wall, equipped with a grate for air intake from the street side. The filter cleans the outside air, and the check valve device regulates the supply air volume and helps to maintain the room temperature. At the same time, the installation of a check valve for supply ventilation makes it possible not to resort to additional ventilation of the rooms where plastic windows are installed, the air exchange will be sufficient.

Using a check valve in the kitchen and bathroom

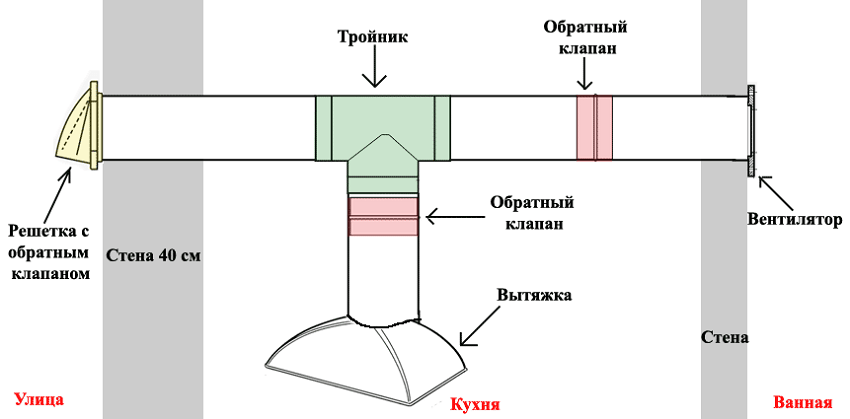

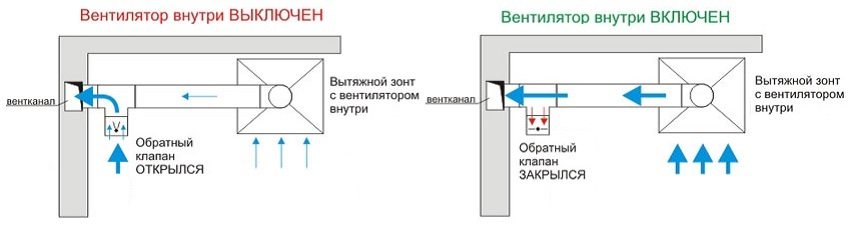

Installation of a check valve for ventilation in the kitchen allows you to block even when it is turned off hood the intake of foreign odors with a reverse draft, but at the same time it does not prevent the removal of exhaust air from the kitchen into the ventilation channel.

To keep the ventilation running, the air ducts are equipped with ventilation grilles with a check valve for natural ventilation with openings through which the exhaust air is removed without the use of an exhaust hood. In recent years, the demand has been for a hood with polluted air discharge directly to the street. On the outside, the air duct is equipped with an exhaust ventilation check valve, which does not allow cold outside air to enter the room.

Even when the appliance is turned off, exhaust ventilation in the kitchen is carried out using a non-return valve

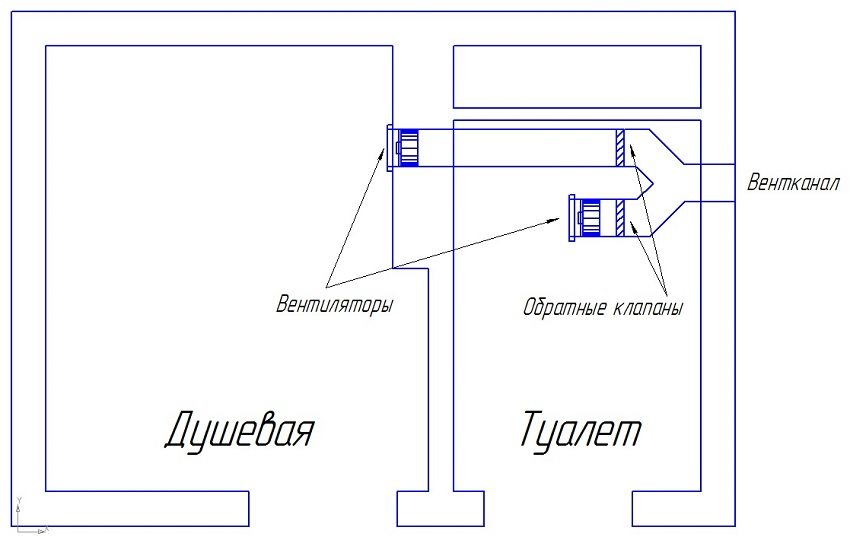

In the bathroom, mold and persistent damp odors are common. This is due to ineffective ventilation. A bathroom premise primarily needs high-quality removal of moist air and prevention of odors from other apartments. And given that the bathroom can be used by neighbors for smoking, tobacco smoke with poor air exchange can get through the ventilation shaft and into your bathroom, and therefore into the apartment. Installing a check valve for ventilation in the bathroom will solve the problem of foreign odors getting there.

What to be guided by when choosing a check valve

To determine which check valves are better for ventilation, you need to have an idea of the main selection criteria:

- the device should work even with small air movement, which is typical for natural ventilation. The thrust force with such air exchange is small, therefore, for effective air exchange, it is better to install an exhaust fan complete with a ventilation grill and a check valve;

Important! It should be understood that if the check valve model is incorrectly selected, air exchange in the room can deteriorate, up to a complete cessation.

- check valve parameters must correspond to the characteristics of the selected fan: for example, if the valve is 150 mm in diameter, then the fan must be of the same diameter. The fan power must be sufficient for the air flow to be created to open the valve petals;

- environmental conditions. Some check valve devices are not capable of operating at low temperatures. Therefore, they are only mounted indoors;

- features of the ventilation system. If the air duct of the system has a rectangular shape, then for ease of installation, a check valve for ventilation of a rectangular section is provided. Dimensions are also selected taking into account the section of the box. For domestic needs, air ducts and check valves for ventilation of 100 mm are more often used.

Element plastic duct rectangular section with built-in petal check valve

Helpful advice! To be sure of the quality and compliance of the device with the characteristics, it is necessary to purchase check valves from reputable manufacturers.

The Leroy Merlin hypermarket chain offers a wide range of ventilation equipment from trusted manufacturers. You can familiarize yourself with and order a suitable model of a check valve on the official website of the Leroy Merlin company. In Leroy Merlin stores, you can directly consult with specialists and purchase check valves of various models and sizes.

Popular models of check valves for ventilation offered by the Leroy Merlin network:

| Name | Brand | Diameter | Device type | Cross section | Material |

| Check valve for ventilation 100 | Vents KO 100 | 100 mm | membrane | round | plastic |

| Check valve for ventilation 120 | Vents KO 120 | 120 mm | petal | round | plastic |

| Check valve for ventilation 125 | Vents KO 125 | 125 mm | petal | round | plastic |

| Check valve for ventilation 150 | Vents 150 | 150 mm | petal | round | metal |

In addition to check valves, the Leroy Merlin network offers a large selection of ventilation grilles, both internal and external, of various shapes, sizes and colors, thanks to which they can additionally serve as a decoration.

Diy installation of a check valve for ventilation

In order to properly install the device with your own hands, first of all, you need to determine what place the check valve will take on ventilation scheme.

Related article:

|

A ventilation grill with a check valve is installed at the inlet or outlet of the ventilation duct. Such an installation is very simple to do with your own hands: the ventilation grill is fastened as tightly as possible to the wall with self-tapping screws or with the help of "liquid nails", completely closing the air duct opening.

When the check valve is installed in the ventilation shaft behind the fan, the fan is dismantled first. Then a valve is inserted into the ventilation hole and markings are applied to secure the device. After pulling out the case, holes for fastening are drilled in the marked places. After that, the body is installed in the channel and through the holes made, places for fastening are outlined already on the concrete wall itself. With the help of a bolt, holes are made at the designated places, where the dowels will then be hammered. Then the valve is mounted in the ventilation duct.

Helpful advice! If, when installing the check valve with your own hands, there are gaps between the wall of the ventilation shaft and the body of the device, they are filled with silicone sealant.

After installing the check valve, the fan is mounted in its place. If the installation is correct, check valve will prevent the return air from entering the room.

A ventilation check valve is a simple but effective device that promotes high-quality ventilation and a healthy indoor climate.