Due to a blockage in the sewer system, a situation may occur when all of its contents begin to move through the pipes in reverse order, pouring out of plumbing fixtures. This problem often arises in apartments on the first floors of high-rise buildings. In a private house, this is possible in the event of an overflow of the well. To avoid such a nuisance, a sewage check valve should be installed. You can learn how to choose a device from this article.

Content [Hide]

- 1 What is a check valve for: purpose of the device

- 2 The device and principle of operation of the check valve for sewage

- 3 Check valve for sewage: device design options

- 4 Valve Types: Wafer and Lifting Features

- 5 Automated check valves for sewage

- 6 How to choose a check valve for sewage 50 mm or more

- 7 Material for manufacture and location of the check valve

- 8 What is a sewer air valve

- 9 Rules for installing a check valve for sewage

What is a check valve for: purpose of the device

Before considering the purpose of the valve, it is necessary to understand how the sewage system works. The pipeline system operates on the principle of communicating vessels. When a blockage occurs in one of the sections, the drains in the pipes will look for ways to get out. Feces through pipelines will rise and flow out of plumbing fixtures, creating unpleasant conditions for residents of an apartment or house.

To eliminate this situation, a sewer check valve is installed. Its main purpose is to block the return flow of wastewater through the pipeline in the event of a blockage in the system. This takes place in horizontal pipes that are in the basement. Wastewater begins to move upward in search of an accessible outlet. The valve closes the lumen in the pipes.

Devices are mainly installed on taps for connecting plumbing fixtures on the first and second floors of any multi-storey building. Such a double measure is simply necessary, since the drains, not finding an exit on the first floor, will rise to the second. Wastewater does not reach above this level. The drain will already be able to push through the plug and move freely along the sewer pipe.

However, in the event of a strong blockage of the network with foreign objects, situations sometimes occur when fecal water can be poured out of plumbing fixtures located on higher floors, depending on the location of the plug.

In a private house, which is connected to a centralized network, a non-return valve is mounted on the inside of the sewer well before discharge. This device should also be installed for autonomous drainage systems, where wastewater accumulates in a drain pit.

Useful advice! A check valve in a private house acts as a barrier for rodents and other animals that can enter the room through the sewer pipe.

The device and principle of operation of the check valve for sewage

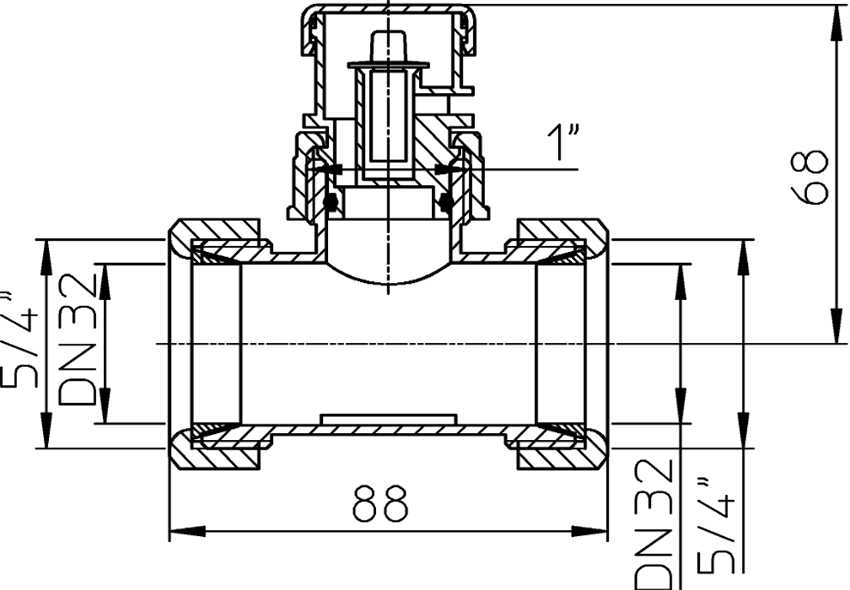

The check valve has a hexagonal body, in which the internal cavity is divided into several compartments: a receiving area, a stopper with a locking element fixing system with an inspection window function and an outlet part.

The receiving compartment is located in front of the shut-off element. It connects the inlet to the sewer line. The limiter ensures the free movement of fecal waste exclusively in one direction. In the event of their reverse movement, this element closes the valve.

The outlet area facilitates the smooth flow of the drain from the restrictor compartment. It is the connecting link between the device and the return line.

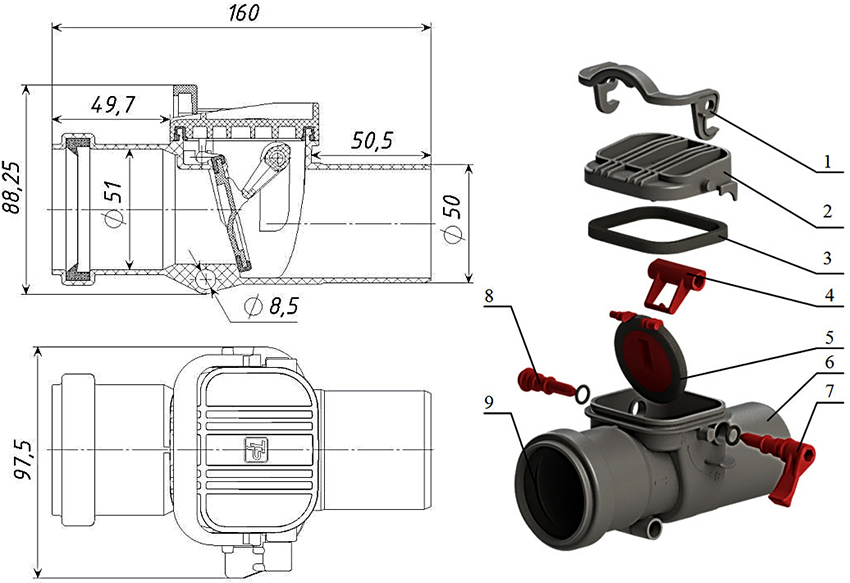

1-handle-lock; 2-cover; 3-cover seal; 4-pusher; 5-damper with O-ring; 6-building; 7-semi-major axis; 8-semi-minor axis; 9-socket outlet gasket

Important! All working zones of the valve can have a different design depending on the type of device, however, the principle of operation is the same for all models.

How does a sewage check valve work? The principle of operation of the device is based on stopping the reverse flow of waste masses by blocking the pipe section with a gate element. This occurs at the moment of stopping the free movement of liquid through the sewer pipe. At this time, the pressure in the inlet and outlet nozzles is equalized. The shut-off element obstructs the section under the action of gravity, thus closing the valve.

The non-return valve can be controlled automatically or mechanically. The nominal diameter of the manufactured devices of the connecting pipes is 50-300 mm. The valve, depending on the design, can be installed vertically or horizontally at the pipe connection. Moreover, it can be mounted on a common drain pipe or on the branch of each plumbing fixture. In the first case, a device with a diameter of 110 mm or more is selected, and in the second - 50 mm.

Important!The non-return valve for pipes 32 and 40 mm must have a diameter of 50 mm; special adapters are used for connection.

Check valve for sewage: device design options

Check valves for sewage are classified according to the type and principle of operation of the shut-off element. There are petal, ball, wafer and lifting devices.

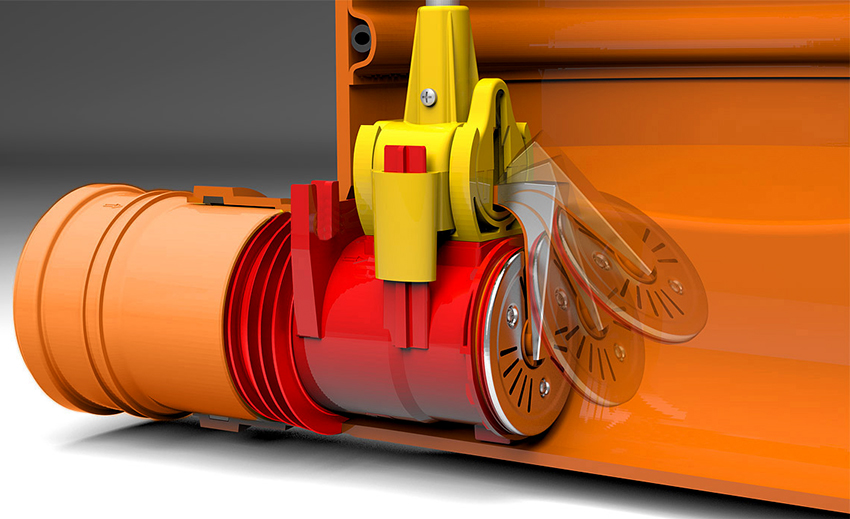

Rotary (petal) check valves have a spring-loaded, circular diaphragm that attaches to the upper interior of the body. At the moment of free movement of the masses along the drain pipe, it is lifted up. When a reverse flow of liquid occurs, the tray rotates and presses against the rim of the inner surface of the outlet pipe, sealingly and tightly overlapping the pipe section. Some devices can be equipped with a manual shutter, which is represented by a second membrane, which is controlled by a button.

The check valve has more overall dimensions in comparison with the sewer pipe. When installed, it creates narrowed and expanded zones, which are ideal places for blockages. A removable cover located at the top of the device case will help to eliminate such troubles.In this regard, it is not recommended to install a rotary type check valve (40 mm) for sewerage.

The ball check valve is equipped with a ball locking device. In this regard, such models have a specific internal structure. In the upper part of the body there is a special recess where the ball is located at the time of the unhindered flow of fecal fluid through the pipeline. When the movement of the waste masses stops, it rolls out and blocks the gap in the pipe, preventing the return flow of the waste.

Important! Such a valve does not exclude the possibility of drainage in the opposite direction, which occurs due to the loose fit of the ball to the side wall of the body.

Both 50 mm diameter options are the most common in the system. The devices are able to withstand the high pressures that are typical for a multi-storey building system.

Valve Types: Wafer and Lifting Features

The wafer tool is characterized by a small size, relatively simple device. The check valve consists of a body in the form of a hollow cylinder, in the inner part of which there is a rotary valve. The element can be in the form of a small disc attached to the wall of the housing by means of a spring, or it can consist of two flaps that are attached to a rod passing through the center of the device.

The casing is equipped with sealing elements on both sides, thanks to which additional gaskets are not required when installing the device. The disadvantages of such a device include the impossibility of performing household cleaning. To get to the inside of the device, you will need to completely disassemble the connection. Such devices are available in diameter from 160 mm. They are used on large drainages or sewer systems of industrial enterprises.

Useful advice! The wafer valve can be selected even when space is limited for installation.

At the lift check valve, the shut-off element is lifted up when the waste fluid moves freely in the system. This is due to the pressure exerted on the plate, which is pressed against the top of the housing. At the moment of stopping the movement, the spring is expanded, the plate overlaps the lumen, which is achieved due to the non-linear shape of the body.

The lift check valve is the most reliable type of device, but tends to clog frequently. To clean the interior, remove the cover by unscrewing the four bolts. This type of fixture is most commonly used as a ground floor toilet seat check valve.

Automated check valves for sewage

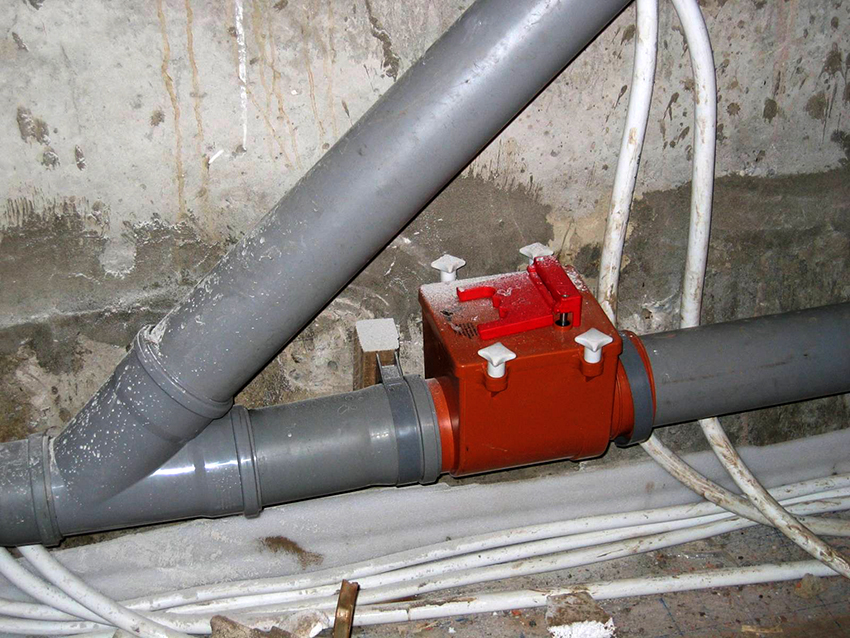

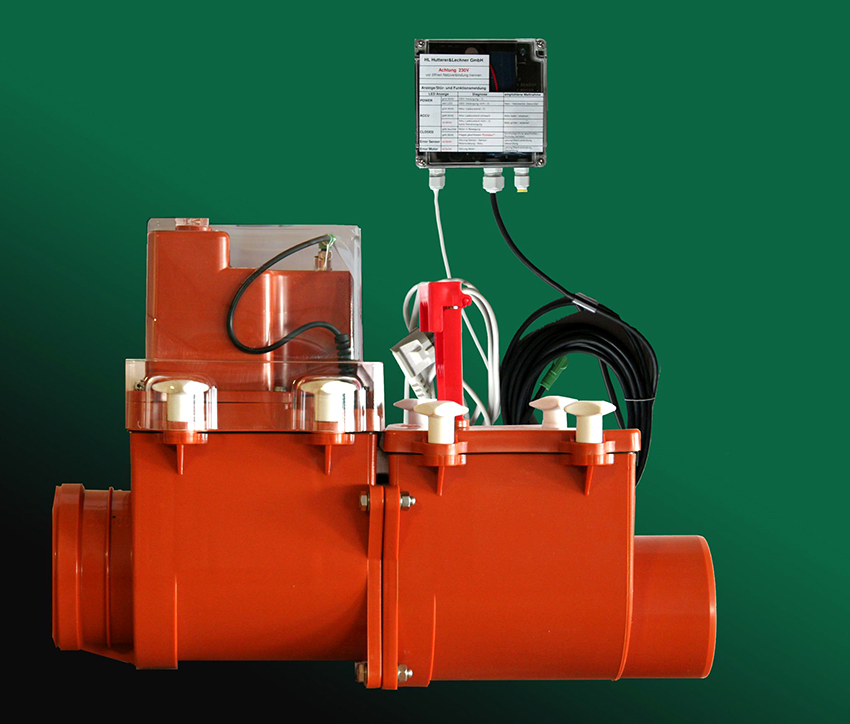

Many manufacturers today are using new technologies to improve the performance of the sewer system. Among the popular achievements is the automatic operation of the sewage check valve. The device is installed on a pipeline and connected to a 220 V network.

The automated valve is powered by the mains, while it is equipped with a battery in case of a power outage

In the event of a power outage, the automated non-return valve will be able to operate smoothly, performing its functions, thanks to the built-in battery. You should periodically check the charge level of the device. Manufacturers produce automated both horizontal and vertical check valves for sewage.

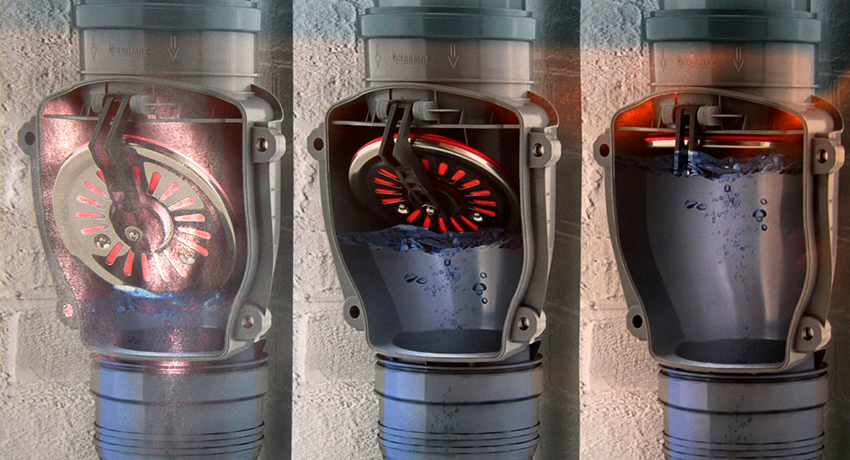

The principle of operation of an automated check valve is as follows. At the moment of free flow of sewage through the pipeline, the valve of the device is fully open.This prevents the formation of mud ridges, which can subsequently lead to incomplete closure of the valve in the event of backflow of fecal water.

At the moment of the return flow of waste water, thanks to a probe built into the check valve, an alarm is triggered when the pipeline reaches 70% fullness. At this time, light and sound accompaniments are turned on, warning of a blockage in the sewer system. At the same time, the damper blade closes hermetically, ensuring high reliability.

How to choose a check valve for sewage 50 mm or more

When choosing the type of device, one should be guided by the features of the sewer system. Depending on this, the size of the check valve for the sewage system, the material of manufacture and the diameter of the socket are selected.

When choosing a specific model, you need to make sure of the reliability of the device, which must be made of a durable material that is resistant to the negative effects of an aggressive environment. The check valve must be easy to install and easy to maintain. The best in this regard are models with a removable cover, which is necessary for cleaning the body elements.

The reliability of the automatic mechanism for closing the cross-section of the pipeline at the time of the reverse flow of the liquid is a guarantee of the durability of the device. Preference should be given to models with the possibility of manual adjustment in the event of an accident.

The socket diameter is selected based on the size of the pipeline. You should not choose a larger or smaller size of the device section, since you will need to use adapters. This will disrupt the smooth functioning of the entire system, reducing the throughput of the pipeline. However, a 32 mm check valve for sewage is selected with a diameter of 50 mm, the necessary adapters are selected for it.

Material for manufacture and location of the check valve

The material for the manufacture of the check valve must be the same from which the pipeline itself is made. Depending on this, the product can be made of plastic, steel, cast iron or bronze. The most affordable are plastic devices. The price of a check valve for sewage PP 110 mm is 420 rubles, and a cast-iron valve is 700 rubles.

Important! If the non-return valve and the sewer line are made of different materials, special adapters are used to install the device.

Valve dimensions are determined by the place of its installation. It should be borne in mind here that there are models for horizontal and vertical mounting. For flushing toilets and baths, the first option is mainly used. For this, a non-return valve for sewage systems of 50, 60, 100, 110 and 160 mm can be used, which is determined by the diameter of the waste pipeline. The second type of device is used to drain wastewater from sinks and washing machines. For this, a 50 mm vertical sewer check valve is installed.

A high-quality product has an arrow on the upper part of the case, which indicates the direction of movement of wastewater, in order to eliminate errors during installation of the device.

Related article:

Sewer trap: an important element of plumbing equipment

Description of the device. Varieties of siphons. Materials for manufacturing. Siphon installation. Troubleshooting.

What is a sewer air valve

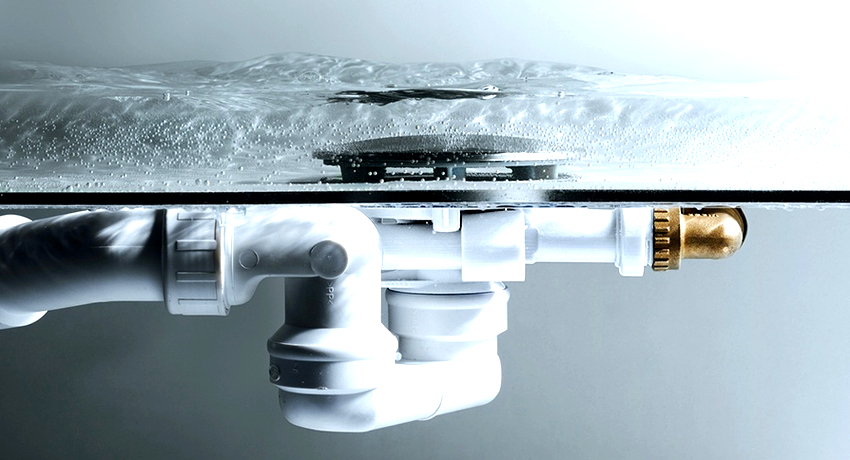

The air valve is installed in the waste pipe. It is used to let air into the sewer network and prevent it from coming back out, which is an obstacle to the appearance of an unpleasant odor in the apartment. It also reduces the noise level when the water flows down the system.

The principle of operation of the device is as follows. During the descent of water through the sewer, a vacuum occurs in the network. From the outside, air must flow into it. If the system is ventilated, there will be no problem. In its absence, air will come from the plumbing fixture with the smallest water seal.

When discharging, the valve membrane opens, and when the pressure in the network stabilizes, it closes. Thus, air enters only the sewage system, and does not get back into the room. For the manufacture of the air aerator, as well as for the check valve, high quality plastic is used.

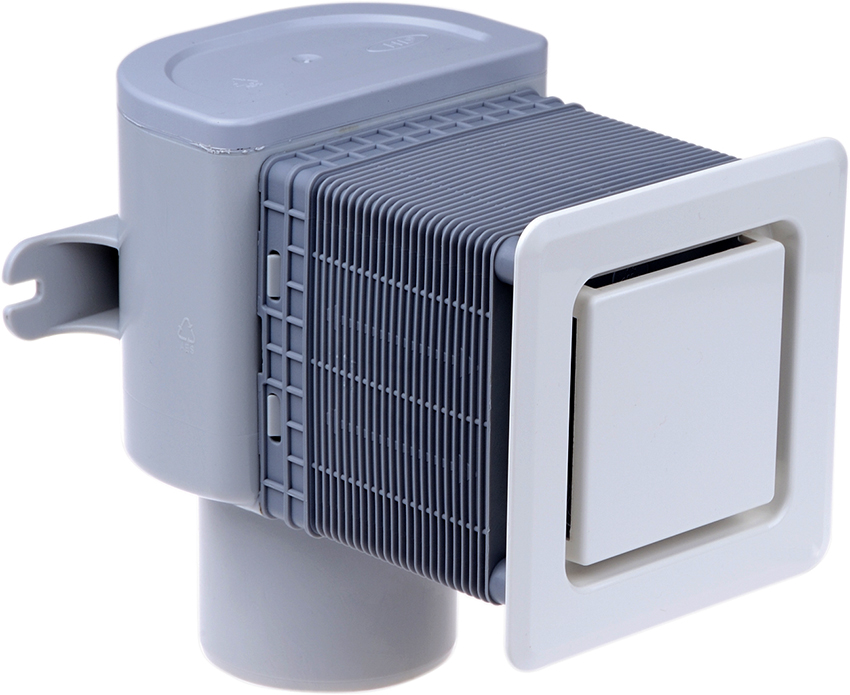

An air valve must be installed in all buildings that are more than 2 stories high. It is installed in a place where the temperature will not be below 0 ° C. If a floor drain is installed in the room to drain water, then the device is fixed at a height of at least 35 cm above the floor level. When there is no drain, the valve is located above the highest pipe in the sewer pipe that connects to the plumbing fixture.

The air valve is made of polyethylene. It consists of a body, stem or diaphragm that reacts to the occurrence of overpressure in the network, a rubber gasket that restricts the movement of the stem, making it work properly, and a cover that protects against contamination. For connection to the sewer pipe, there is a side hole on the device body.

There are three types of vacuum valve. For a separate plumbing fixture, an automatic air valve with a small capacity can be installed. The anti-vacuum or kinetic model, which can operate at low pressure, is characterized by a greater flow capacity. There is a combined type of valve that combines both options of the device.

The air valve is installed in the socket joint. For one drain point, a device with a diameter of 50 mm is used, and for a common riser, a 110 mm vacuum valve for sewage is mounted.

Rules for installing a check valve for sewage

Check valves equipped with a spring-loaded shut-off element can be mounted in any position on the pipeline. Appliances that do not have springs must be positioned exclusively vertically.

Important! A strainer should be installed in front of all types of check valves except the ball mechanism to ensure that the unit is protected from large debris in the drain.

The installation site is selected based on easy access to the device, which should not take up torsional, bending, compressive or tensile loads from the attached pipes. The position of the valve is selected based on the direction of flow indicated on it, since the device works to pass the drain in only one direction.

There are two options for protecting the premises from sewage flooding. The first one involves the installation of one 110 mm sewer check valve on the main pipe and is used mainly for apartments in a multi-storey building. In the second option, the installation of devices is carried out for each drain source, which is typical for the private sector.

For installation, you will need a tape measure, tow and sealant. The first step is to turn off the riser water supply using a valve at the inlet. This must be done to eliminate the likelihood of unauthorized water ingress into the sewer system circuit.

After selecting the installation site, a section of the pipe is cut out in the pipeline, the size of which must correspond to the length of the valve. The PVC check valve is mounted by putting a socket on the free edges of the pipes and sealing with sealing rubber bands. For greater reliability, butt joints are pre-treated with a sealant.

The cast iron model is installed using bolts tightening the mounting plates and sealing rubbers. If a model with sockets is chosen, it is mounted traditionally using tow and by filling the seam with silicone. After the completion of the work, the water supply is resumed. A check valve for a pressure sewage system is installed according to the same principle.

Important! The check valve should be regularly serviced to ensure reliable, efficient and long-term operation.

The sequence of installing a vacuum valve for sewage

The valve is mounted exclusively in a vertical position on the drain. It is necessary that it be located in a place that is above the connection point of plumbing fixtures. The room should be well ventilated with easy access to the maintenance of the device. In an apartment, this device is mounted in the bathroom, and in a private house - in the attic. It is located after a toilet check valve or other plumbing fixture.

Important! The valve diameter and material must match the pipe parameters. Otherwise, special adapters with a rubber seal are used.

After choosing the installation site, turn off the water supply. Next, the sewer pipe is cut, and the burrs are cleaned on it. A tee is mounted in place of the cut. The center hole of the product acts as a seat for the vacuum valve. Most models of fixtures are characterized by a socket connection.

All elements of the system are connected using silicone-lubricated rubber cuffs. Reliability of sealing joints is ensured thanks to the rings. On the new sewer network, shaped inserts should be provided. After the completion of all work, the water supply is resumed.

Flush mounting of the valve requires the use of special device models. In the event that the riser is in the pipe or protective box, a ventilation hole is made according to the dimensions of the aerator mesh. The valve body should be recessed into the wall. The fastener must be adjusted so that the outer surface is flush with the wall. Only the grille remains visible, which is fixed with self-tapping screws.

Important! There are models of aerator that can be used as a hole for cleaning the sewer network, which occurs after removing the valve mechanism from the pipe with the introduction of the cable.

The non-return valve is an important and necessary element of the sewer network, which prevents the room from flooding with sewage in the event of a blockage in the system. The choice of model depends on the installation location, material and pipe diameter. Thanks to the simple design, you can easily mount a sewage check valve with your own hands, following a certain procedure.