Any private territory or personal plot needs a fence, which, in turn, must have a gate. There are many different types of doors, differing in material, type of construction and other characteristics. On the Internet you can find everything you need to create a metal swing gate with a wicket: photos, instructions, drawings and detailed advice.

Content [Hide]

- 1 Benefits and design features

- 2 Types of structures

- 3 What the gate consists of and what tools are used for installation

- 4 The choice of profile sheet, materials for the frame and pillars

- 5 Installation procedure

- 6 Installation of automation on the gate

- 7 Wrought iron gates: photos and instructions for making

- 8 Metal swing gates with a wicket: photos and nuances of work

Benefits and design features

Swing gates equipped with a wicket are not only an excellent protection of your territory from unauthorized entry, but also a very convenient design that allows guests and equipment to pass through. Each type of this design has a number of advantages:

- to create, you can use a large number of modern metal profiles, which opens up a wide scope for you to realize your design fantasies;

Openwork gates and a wicket made of metal are harmoniously combined with the design of the building and the adjacent territory

- all elements of the metal structure are made with a special polymer coating that protects it from corrosion, temperature extremes and other negative influences;

- the wicket is fixed with special 3-section overhead hinges, which increases the strength of the entire structure;

- metal swing gates have no visible fastening elements, making them very difficult to break.

In addition, sketches, designs, drawings, diagrams of swing gates with your own hands can be created according to an individual project, using forged elements, automation for opening the gates and much more. Thus, your construction will not only be reliable, but also unique in terms of design.

Types of structures

All types of these gates consist of two or one leaves, which are attached to the frame with hinges. Depending on the type of sash, the following types of structures are distinguished:

- frame with a mesh - this type of gate is well suited where you need to fence off an area with plants, or simply prevent constant shading. At the same time, the mesh is quite cheap, easy to install, does not need constant care and boasts a number of other advantages;

Forged gates and the gate look elegant and luxurious

- with corrugated board - a photo of a gate made of corrugated board with forging or other elements shows that such a structure looks attractive and reliably protects the territory. The corrugated board itself is distinguished by its great durability and reliability, as well as a wide range of colors. It is not surprising that it is this type of structure that has been increasingly popular lately;

- with a welded lattice frame - this type of construction has a stylish look and is used, most often, for decorative purposes. But do not underestimate the strength of such a frame, it tolerates mechanical damage well;

- with insulation - most often they are installed in garages to protect the car from severe frosts. As insulation, you can use polypropylene plates or ordinary wooden boards. In this case, the metal shell can be double or single.

Helpful advice! When choosing a structure, also consider the type of fence to which it will be attached. For example, if your fence is made of corrugated board, then the gate should be made from it.

By the number of flaps, the following classification can be made:

- single-leaf - are characterized by high weight and require a reinforced support post. This type of construction is not very popular, since not every hinge can withstand the weight of a solid metal sheet, and it is difficult to mount it. The advantages include greater strength, and the disadvantages are the need for a reinforced foundation and holders, as well as the need for a large amount of free space for opening and closing the gate;

- bivalves are the most common option. Installation of hinged metal gates with a wicket made of corrugated board is perfect for a garage, warehouse or industrial premises. The main advantages are simplicity of design and ease of operation and maintenance;

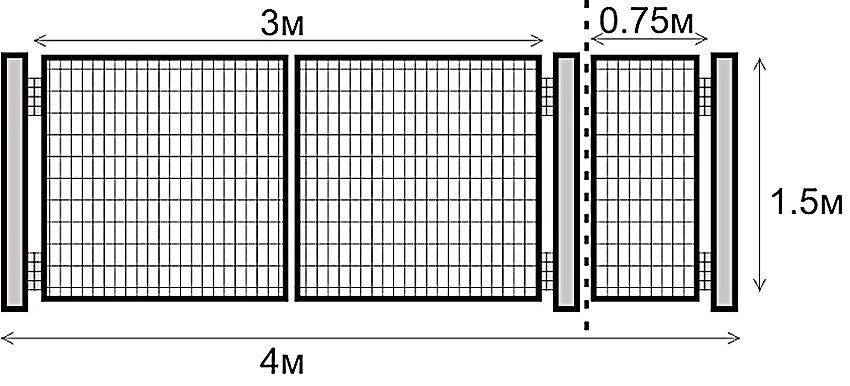

- bivalves with a wicket are the most convenient and frequently used option. The wicket allows people to freely enter the territory without having to open the main doors.

What the gate consists of and what tools are used for installation

Any swing gate with a wicket consists of the following elements:

- frame - the base of the gate, which is attached to the posts or to the fence;

- sheathing is the material with which the frame is filled;

- hinges with which the frame is attached to the support posts;

- pillars;

- locking mechanism - a lock or bolt with which the gate is closed.

Also, for the installation of the structure, a large number of consumables are used: bricks, crushed stone, sand, cement, primer and ordinary paint, nails or dowels. Directly when creating a gate with your own hands, you will need a building level, a grinder with various discs for cutting and grinding metal (you can also use a special grinder for grinding), a spray gun, a roller or brushes, a welding machine.

The choice of profile sheet, materials for the frame and pillars

Before you start making a fence and gates for a private house from corrugated board (photos of which can often be seen on the network), you should decide on the type of profile sheet. The following options are distinguished:

- "C" - wall profile sheet made of small thickness galvanized steel. Characterized by lightness and strength, it is most often used for self-production of gates;

- "NS" - sheets with a large wave height and large thickness, characterized by increased strength, but also high weight;

- "H" - a bearing profile sheet of great thickness and weight, is used to create hangars and garages.

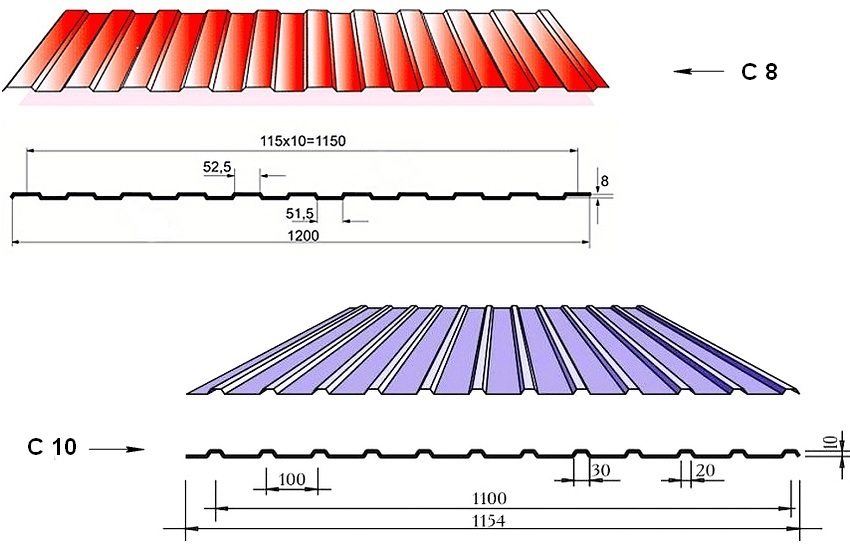

For creating gate two types are best suited: C8 and C10. The thickness of the first sheets is 0.4-0.6 mm, and the wave height is 8 mm. A square meter of such a sheet weighs up to 5.5 kg, that is, one standard sash measuring 2x2.5 m will weigh about 25 kg. С10 is made of steel up to 0.8 mm thick, wave height - 10 mm. It is very heavy, one sash can weigh up to 40 kg.

The gate frame can be made of rolled iron or wooden beams. The first option is preferable, since the tree must be constantly protected from decay and other adverse effects that the metal transfers much more easily. The following frame types are also distinguished:

- welded structure is the most durable and reliable option, which can withstand heavy weight well. The only drawback is that the welded frame can be too heavy to create automatic gates;

- aluminum frame - used only in combination with lightweight sheathing materials. Ideal for automatically opening gates due to its low weight;

- bolted frame - it is easier to construct than welded, but cannot boast the same reliability and durability.

Helpful advice! If you are still going to use wood for the frame, then a high-quality wooden beam with a section of 10x10 is best suited for these purposes.

The iron frame is assembled from a profiled tube with a square or rectangular section. The optimal size is 40x20 mm.

Support pillars, which can be seen in the photo of forged gates and wickets, can also be made of different materials:

- wood is the cheapest, but far from the most durable material for supporting pillars. The advantage is ease of processing;

- brick - lasts longer than wood, looks quite attractive and can withstand a lot of weight. The ideal use of bricks is to cover metal structures with it. In this case, hinges and other structural elements must be welded to the iron core;

- concrete is one of the most durable and easy-to-work materials for support pillars. Due to its massiveness, it easily withstands the weight of a large structure, easily lends itself to cosmetic repair;

- asbestos - the middle option between metal and wooden poles;

- metal - the pillars from it are easiest to install (they are simply dug into the ground), they can withstand many natural and mechanical influences. A very good option for supporting pillars for all types of structures is metal pillars with a concrete or brick base.

Installation procedure

Making a gate from a profiled sheet with your own hands is a rather complicated, lengthy and laborious process. Let's consider it in detail.

The initial stage of building a gate is drawing up a detailed drawing of the future structure, which can be made from scratch or taken from the Internet. In any case, it is necessary to carry out a certain number of calculations and measurements. DIY drawings, photos and videos of swing gates can be found on any specialized construction site, so you just have to choose the design option that suits you.

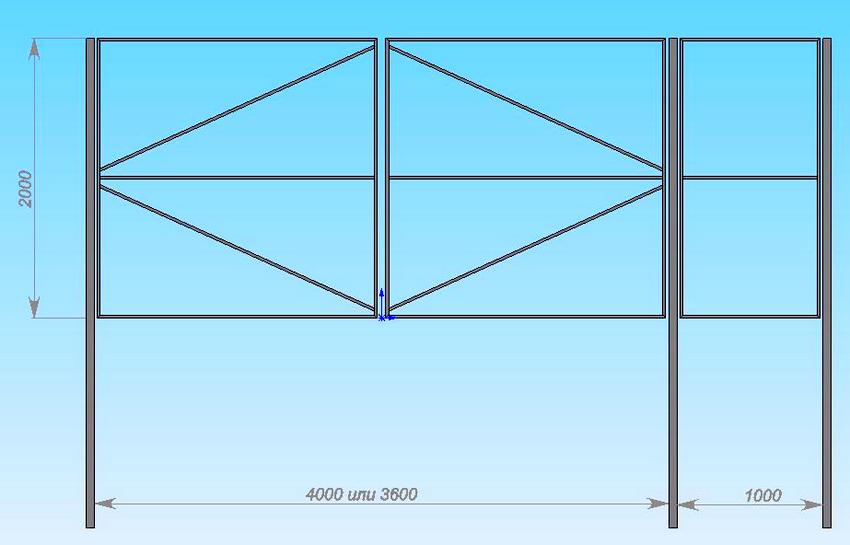

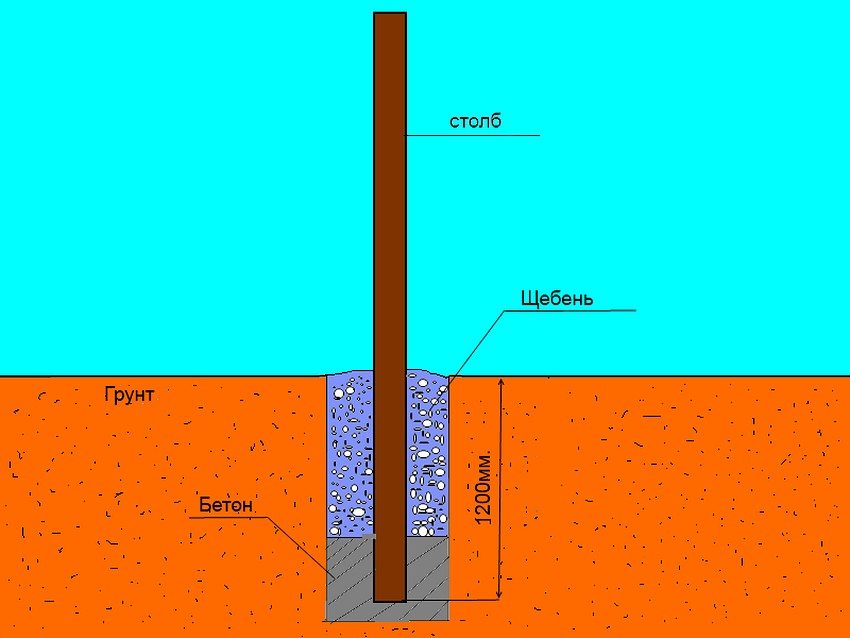

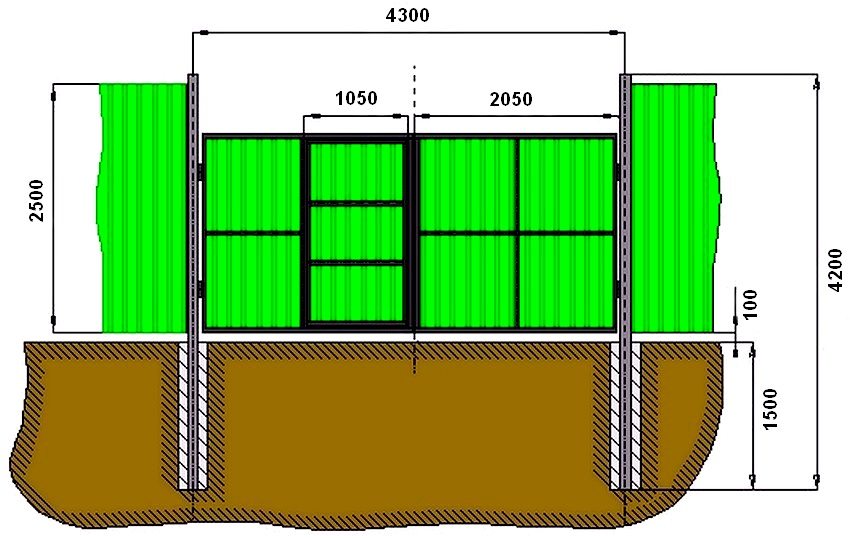

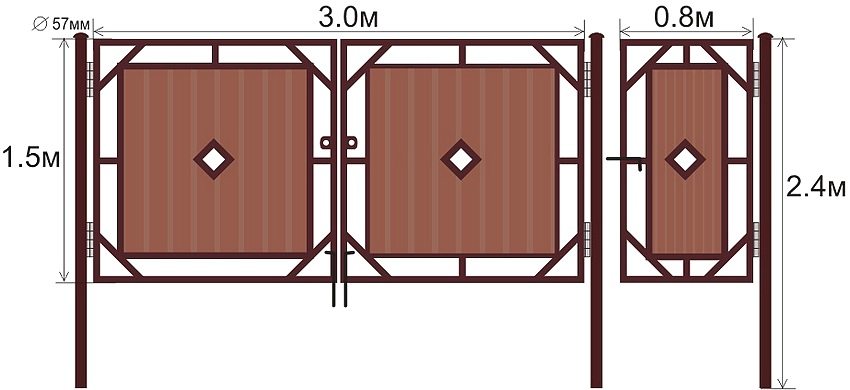

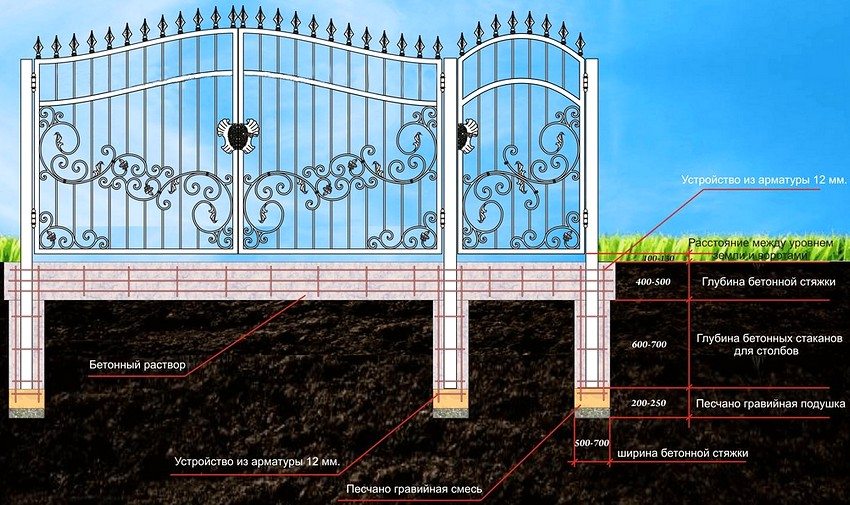

An important point is to correctly determine the depth of the pits for the support pillars. If your gate is 2 m high, then the depth of the pit should be at least 1 m, and the diameter of the recess should be 10 cm larger than the diameter of the support pipe.The classic dimensions of the gates made of corrugated board with forging elements are 3-4 by 2.5 m. In this case, you need to take into account the dimensions of the wicket, and if you are limited in the size of the site, then it can be cut into one of the leaves.

Next comes the installation of supports. The thickness of the support pipe is selected depending on the weight of the entire structure. The pipe is laid in a pit, then covered with crushed stone or broken brick and filled with mortar (cement with sand in a ratio of 1: 3 and 25% water). If the structure is too heavy or you just need additional reinforcement, then the pillars at the base can be overlaid with bricks.

Making the gate itself is a separate process that should be described in detail.

Installation of corrugated doors with forging elements: photos and instructions

When manufacturing a gate, first of all, it is necessary to mount a frame that will be installed in the opening. For this, metal corners are arranged in the shape of a square or rectangle, and the joints are welded using a welding machine.

Helpful advice! For greater strength, it is recommended to make two frames - on the outer and inner sides of the opening. Metal plates need to be welded between them. The more secure the fastening, the better the frame will support the weight of the doors.

When manufacturing sashes, metal profiles are laid out on a flat surface in accordance with your drawing, and then the contact points are welded. The resulting sheets should be reinforced with longitudinal or transverse iron beams. The frame for the wicket door is made in the same way.

After that, the coating is welded to the frame part. The recommended sheet metal thickness is approx. 2 mm. Thicker sheets may not support the support legs, and metal that is too thin can be easily damaged.

Particular attention should be paid to the hinges, since it is on them that the whole structure rests. You should not save on this element of the gate, otherwise you risk getting an extremely unreliable design. The hinges are welded to the support posts and sash using a welding machine.

After that, the gate and wicket are installed on the hinges, locks and bolts are mounted, the structure is coated with paint to protect it from corrosion.

Installation of automation on the gate

The auto-drive design is a very convenient and functional option that will save you time and effort. For this, it is not even necessary to have specialized equipment, but you can use the rotary mechanism, which is used in the satellite dish. This option will not only be effective and inexpensive, but also safe, since the motor from the satellite system can be combined with a step-down transformer.

Two drives from satellite systems with the longest stems are attached to the gate leaves from the inside of the site. A universal control panel is also bought for them. It also does not hurt to connect a current relay to the system, which will return the sash to its original position if a stone or other obstacle falls under it. If such relay will not, the automatic gate opening mechanism may fail as a result of hitting the road in front of the structure, even a small obstacle.

Related article:

Do-it-yourself gate. Drawings, photos and videos. Advantages and disadvantages of swing and sliding gates, features of their installation. Video of the installation process of various types of gates.

Wrought iron gates: photos and instructions for making

As mentioned above, wrought iron gates are a great option that will show all guests your good taste as well as financial well-being. In order to make this type of construction with your own hands, it is not at all necessary to be a professional blacksmith. A large number of all kinds of forged items are sold in modern hardware stores, you just have to purchase them and include them in your sketch.

There are several options for wrought iron gates:

- Metal - this type is completely made of decorative elements, iron rods, corners. It looks very stylish and beautiful, but it will be very expensive.

- Combined - structures made of various materials, decorated with metal forged elements. They cost several times cheaper. The combination of materials depends on your imagination and needs, but the most popular option is corrugated gates with forging elements.

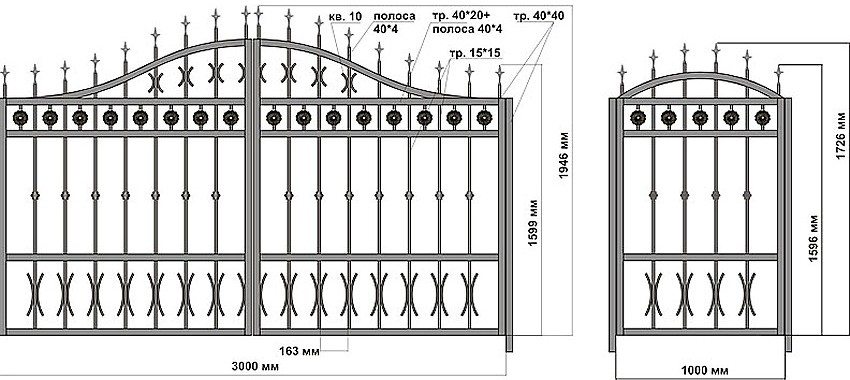

Forged structures are made in almost the same way as from corrugated board. First, a sketch is made, on which the forged elements are applied. By the way, on the Internet you can see a large number of design options for finished products, on the basis of which you can create your own unique style. Then all the parts are assembled on a flat horizontal surface and fastened together by welding.

An example of mounting swing wrought iron gates and wickets

Helpful advice! In the drawing of a forged gate, it is very important to take into account the exact dimensions of the elements so that gaps do not form between them in the finished product.

If the gate is forged, the photo will show that all the seams between the elements are carefully cleaned and processed. This can be done by hand using an emery cloth, or using a special sander. It is also somewhat more difficult to paint a forged structure than one made from a profile sheet. It is best to use a special spray gun or a set of brushes for this if you have a lot of free time.

It is also necessary to choose options for the location of forged elements on the profile sheet. In this case, the decor may not cover the entire surface of the sheet, but only part of it. This can save you money while still creating a beautiful and expensive looking fence.

Advantages and disadvantages of wrought iron gates

Like any other type, the forged design has its advantages and disadvantages. Advantages:

- durability - metal can last more than a dozen years with minimal maintenance, and artistic forging will never go out of fashion;

- environmental friendliness - the metal of forged products is absolutely safe for human health. In addition, its appearance goes well with garden and backyard decorative elements.

Disadvantages:

- difficulty in manufacturing - if you forge such a gate with your own hands, it will take a lot of time and effort. Fortunately, now all forged items can be purchased ready-made in a specialized store;

- high price is a disadvantage that logically follows from the previous paragraph.

Care of forged structures

This type of fencing does not require special maintenance, especially if all elements are painted with a special anti-corrosion paint. From time to time, the elements need to be cleaned of dirt and tinted, and the moving parts should be lubricated. It is best and most convenient to clean the forged structure with a powerful jet of water.

According to the drawings, photos and videos of forged gates with your own hands, you can see that the abundance of openwork elements can lead to a number of difficulties in the process of painting them, but a good spray gun will save the situation.Please note that to touch up discolored parts mounted on top of a profiled metal sheet, paper should be placed on the latter.

Metal swing gates with a wicket: photos and nuances of work

Regardless of which of the swing gate options you choose, there are a number of important points to consider:

- the concrete around the support pillars must dry properly before frame work is carried out. If you make pillars with a straight cut into the ground, then the ground around them must be watered abundantly, tamped thoroughly, and then allowed to dry;

- it is best to carry out work on laying the foundation for the gate (if required) and support pillars in the warm season, when the soil is not frozen yet, but not too wet;

- if you do not want the metal gates to suffer from precipitation, then they should be closed on top with a small visor;

- the metal frame and pillars must be opened with a special paint to protect against corrosion. This must be done before the start of installation work;

- the posts must not have holes at the top. Therefore, if you make them from hollow pipes, then the holes must be welded.

Remember that high-quality and reliable gates are a guarantee of the safety of your territory. Therefore, you should not save on consumables, and also be inattentive to the assembly and installation process of the structure. Today, specialized sites on the Internet contain a huge amount of detailed and accessible materials, a careful study of which will help avoid the most common mistakes.

Metal swing gates with wickets are one of the most popular types of gates. They are quite simple to manufacture and operate, are inexpensive and will serve you for many years.