For those who decide to equip a personal plot with a greenhouse, manufacturers offer various types of greenhouse structures. They can be installed permanently or have a collapsible design. The frame is made of various types of profiles, the only question is the price. Or you can assemble a light and inexpensive greenhouse structure yourself. For small household plots, a greenhouse or a greenhouse made of plastic pipes with your own hands would be appropriate. Due to the low price, lightness and ease of assembly, do-it-yourself greenhouses made of plastic pipes are becoming more and more popular among gardeners.

Content [Hide]

- 1 The advantages of plastic pipes for building a greenhouse with your own hands

- 2 Do-it-yourself molds and materials for covering greenhouses from plastic pipes. Photos of structures

- 3 DIY greenhouse model made of polypropylene pipes. Photo of greenhouses covered with foil

- 4 Do-it-yourself greenhouse assembly from plastic pipes and polycarbonate. Step by step instructions

- 5 DIY greenhouse from plastic pipes: assembling a frame from HDPE pipes

The advantages of plastic pipes for building a greenhouse with your own hands

Such qualities of plastic pipes as strength, low weight, resistance to mechanical, temperature and weather influences have made it possible to widely use them in construction. These characteristics have become the main advantages in the construction of do-it-yourself plastic pipe greenhouses. Giving preference to such greenhouses, owners of personal plots receive a design with the following advantages:

- resistance to corrosion - the frame of the greenhouse made of plastic pipes does not rust, unlike the metal profile, it is not afraid of moisture when compared with wooden frames;

- pliability PVC pipes processing, ease of assembly - they can be easily cut, bent, creating various forms of construction. They are easy to install: quickly assembled and disassembled if necessary;

- light weight - they are easy to transport, it is possible to transfer the structure without resorting to disassembly to another place;

- durability of plastic pipes - the period of operation reaches 50 years;

- resistance to temperature extremes is a refractory material that is difficult to ignite and stops burning as soon as the high temperature is eliminated;

- wear resistance - over time and under the influence of natural factors, the composition of the pipes does not change its structure;

- strength - the frame made of plastic pipes is stable and withstands strong gusts of wind;

- low price - allows you to assemble a greenhouse using the minimum amount of funds;

- no need for additional surface treatment of plastic pipes after installation;

- attractive appearance of self-assembled greenhouses made of PVC pipes.

Do-it-yourself molds and materials for covering greenhouses from plastic pipes. Photos of structures

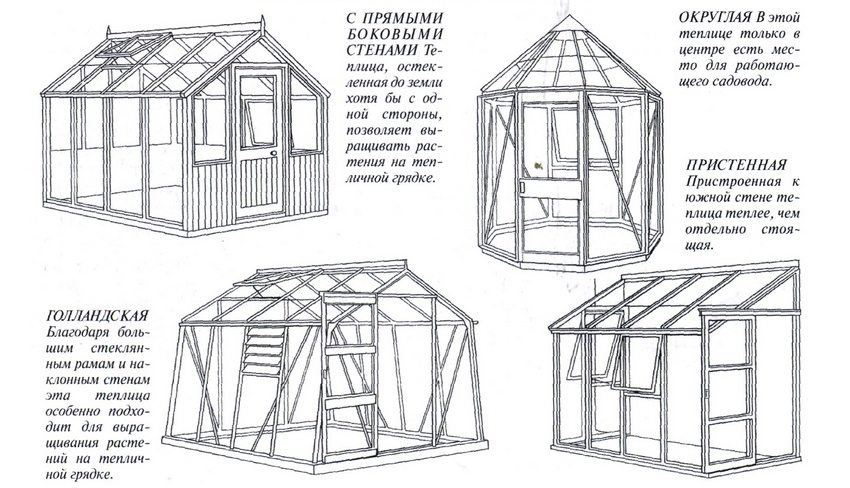

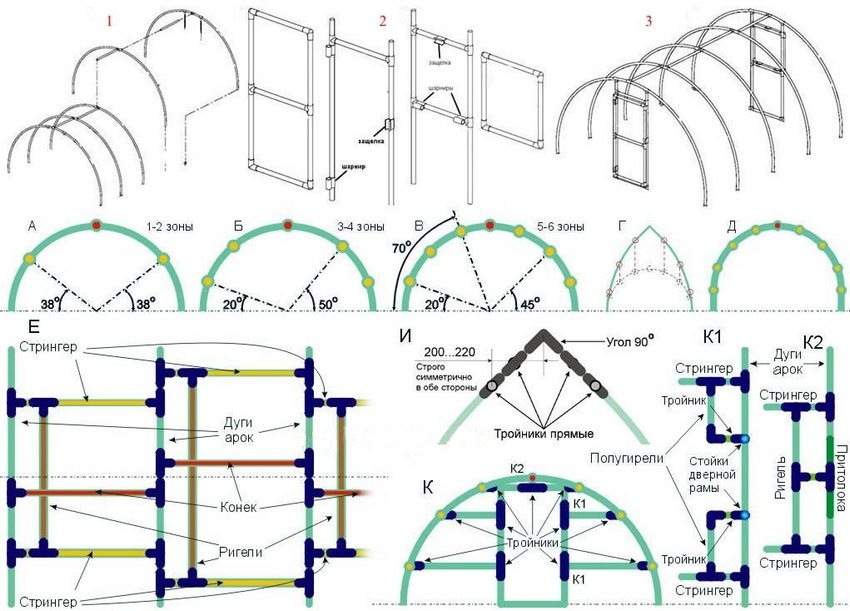

You can assemble a greenhouse from plastic pipes with your own hands (photos of various models are presented on the network) of any size. Taking into account the high flexibility, the different pipe lengths and diameters, the various mounting methods, it is also possible to shape the greenhouse into any desired shape. The most relevant are the following designs:

- arched greenhouse shape;

- rectangular single-slope construction;

- rectangular gable structure;

- there are models of greenhouses attached to the house, where one of the sides protrudes

wall of an existing building.

Useful advice! The shape of the greenhouse structure and its size largely depend on what crops will be grown in it.

Greenhouse made of PVC pipeshandmade

Some craftsmen build unique greenhouse structures in the form of a tent or dome on their sites. The main thing is to strictly adhere to the parameters indicated in the drawings of greenhouses made of PVC pipes with your own hands.

Plastic pipes used to make greenhouses can be purchased in sizes from 2 to 7 meters. By choosing a long pipe, additional connections can be avoided. The pipe diameter and wall thickness are selected taking into account the size of the structure. For medium-sized household plots, small greenhouses made of PVC pipes, which are quickly and easily assembled and disassembled, will be appropriate. Photos of greenhouses made of PVC pipes with their own hands clearly demonstrate the variety of forms of structures.

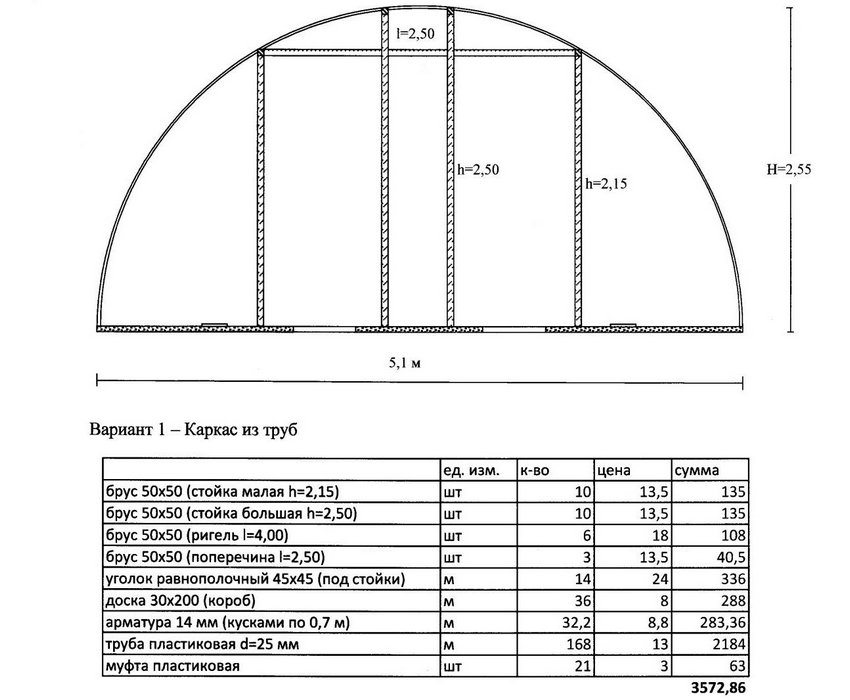

Calculation of materials for the greenhouse. The length of the structure is 12 m, the width is 5.1 m, the height is 2.55 m.The calculated distance between the arcs is 60 cm.The length of the arc (pipe) is 3.14 x R = 3.14 x 2.55 m = 8 m

To cover the frames of greenhouses made of plastic pipes, polyethylene film or polycarbonate sheets are used. Greenhouses intended for growing seedlings in the spring season are traditionally covered with foil. For stationary durable structures that function throughout the year, a cellular polycarbonate coating is used. Such a coating is able to protect plants from wind, cold and ultraviolet radiation. On the network, you can see the video of greenhouses made of PVC pipes with your own hands to get an idea of this type of structure.

The base for greenhouses made of plastic pipes can be boxes made of timber and boards. Many people mount the frame on metal rods driven into the ground along the perimeter of the structure.

Useful advice! In order for a do-it-yourself greenhouse from a plastic pipe to be sufficiently durable, it is recommended to use a shallow or columnar tape foundation under its base.

For the construction of foundations, brick, blocks, stone or concrete mortar are used.

Small greenhouses from arcs

DIY greenhouse model made of polypropylene pipes. Photo of greenhouses covered with foil

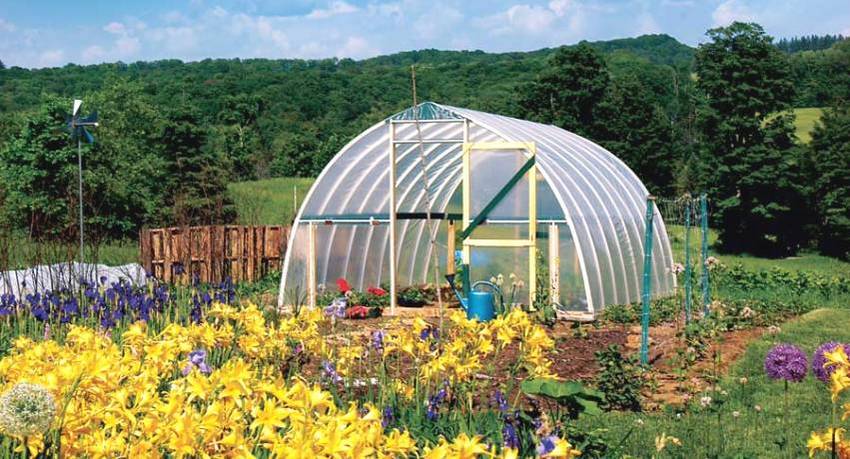

Arched frames for greenhouses and greenhouses can be purchased in specialized stores or ordered on the relevant sites. The set includes ready-made marked frame elements made of pipes and fasteners. Such structures are assembled quickly and easily: the foundation is not equipped for them, but only the place on the site is leveled.

Arched frames for greenhouses and greenhouses can be purchased in specialized stores or made by yourself

Do-it-yourself installation of a greenhouse made of polypropylene pipes allows you to get a structure made according to individual sizes and drawings. An arched greenhouse is equipped with windows and doors at the ends of the structure. For budget coverage, use plastic wrap.

Choosing a place for a greenhouse

When choosing a place to install a greenhouse made of polypropylene pipes with your own hands, you must consider the following points:

- the greenhouse should not be under the shade of garden trees or other buildings on the site;

- a convenient approach to the structure should be provided for caring for plants;

- it is necessary to take into account the prevailing wind direction in your area. The location of the greenhouse with this factor in mind will reduce heat loss.

Before starting construction, the area for the greenhouse is leveled. If the surface of the ground is not smooth enough, the leveling is carried out without excessive compaction, so as not to disturb the structure of the soil. Then they make accurate markings, observing the correct angles, which will provide the frame with stability.

It is recommended to cover the greenhouse frame with a film at a temperature of 16-18 ° C, which will help eliminate material sagging

Assembling the frame

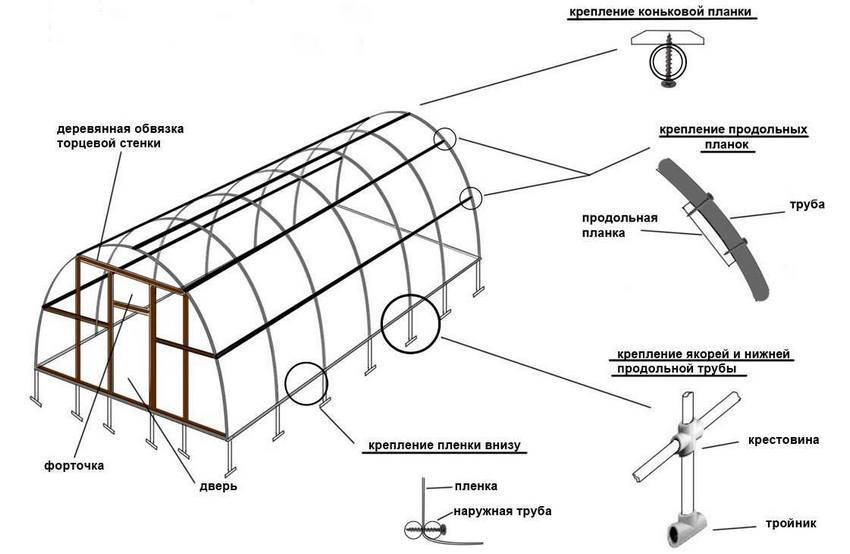

To assemble the greenhouse frame, all the necessary materials should be prepared:

- polypropylene pipe, fasteners;

- clamps for fastening the polyethylene cover;

- tees, corner adapters, a set of self-tapping screws;

- metal reinforcement rods 0.8 m long.

Metal rods are driven in along the long sides of the marked rectangle. The distance between the reinforcement bars should be from 0.5 to 0.9 m. The closer the bars are, the more stable the structure will be. The reinforcement should enter the ground by 0.4 m. At this stage, it is important that the rods on one side are clearly positioned against the rods on the other side. In this case, the greenhouse will turn out without distortions.

Further, pipes of the required length are put on opposite reinforcement rods - thus, even arcs are obtained. When all the arcs are installed, a pipe is laid horizontally along the upper points of the arches and fastened to the arches with the help of anchors. For a more rigid structure, the horizontal supports can be fixed in several places.

DIY greenhouse made of polypropylene pipes: video

Greenhouse covering with polyethylene

When the frame is ready, they begin to cover the structure with a film. It is recommended to perform this work at a temperature of 16-18 ° C to avoid sagging of the material. The polyethylene is fastened with clamps. Such fastening allows, if necessary, to pull the film and remove the sag. In the place of contact of the film with the ground, it can be dug in with earth or weights (board, brick) can be laid on it.

Useful advice! In order for the plastic wrap to last longer, choose to cover greenhouses reinforced or a multi-layer material with high strength, tightness and wear resistance.

It should be noted that greenhousescreated with plastic wrap are not durable enough. They are designed to operate for one or two seasons, after which the film will need to be changed. In addition, the film coating does not provide adequate thermal insulation.

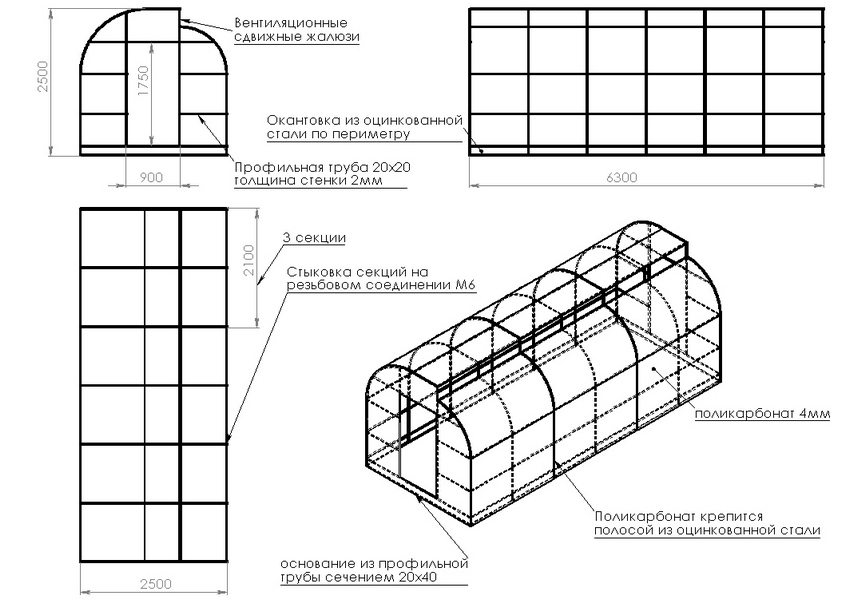

Do-it-yourself greenhouse assembly from plastic pipes and polycarbonate. Step by step instructions

In order for the construction of a greenhouse made of plastic pipes to be more reliable and serve for more than one season, it is recommended to use polycarbonate sheets for covering. This material has a number of properties that make its use suitable for such purposes.Polycarbonate perfectly tolerates significant temperature fluctuations, has good thermal insulation, is not flammable, and a special film coating protects plants from ultraviolet radiation.

Polycarbonate greenhouse scheme and polypropylene pipes

Choosing a place on the site, the type and size of the greenhouse

When choosing a place for installation, it is important that the area for the greenhouse is flat and well lit by the sun. In addition, you need to immediately decide how the greenhouse will function. If you plan to grow crops in the winter, you need to consider a heating system.

The dimensions of the structure are determined based on the following parameters:

- type of foundation for the greenhouse;

- the form of the structure;

- seasonality (whether the greenhouse will be used in winter);

- types and number of crops planted in the greenhouse.

It is not recommended to build a greenhouse that is too large, since it is quite expensive in such a room and it will be difficult to maintain the required microclimate. Traditionally, the height of the greenhouse is taken equal to two meters. The width is determined based on the number of planted plants, the path between beds, a sufficient distance to equip the door, which is allocated at least 60 cm.

Base device

The wooden base is made of a bar with a section of 10 cm. To prevent rotting, the bars are treated with an antiseptic compound. Connect the bars to the frame using staples.

First, prepare a trench for wooden beams. For this, with the help of pegs, markings are made and the cord is pulled along the perimeter of the base. To make sure the corners are correct, the cord is pulled diagonally. If the lengths of both diagonals are the same, then the markings are correct.

Polycarbonate perfectly tolerates significant temperature fluctuations, has good thermal insulation and protects plants from ultraviolet radiation

The trench is dug in such a way that the timber located in it is half buried. The bottom of the trench is covered with a layer of sand. Before lowering the beams into the trench, they are covered with a layer of waterproofing material, usually with roofing material. This is done in order to avoid contact of the wooden surface with moisture from the soil. Roofing material sheets are overlapped. After that, they fall asleep and tightly tamp the remaining space in the trench.

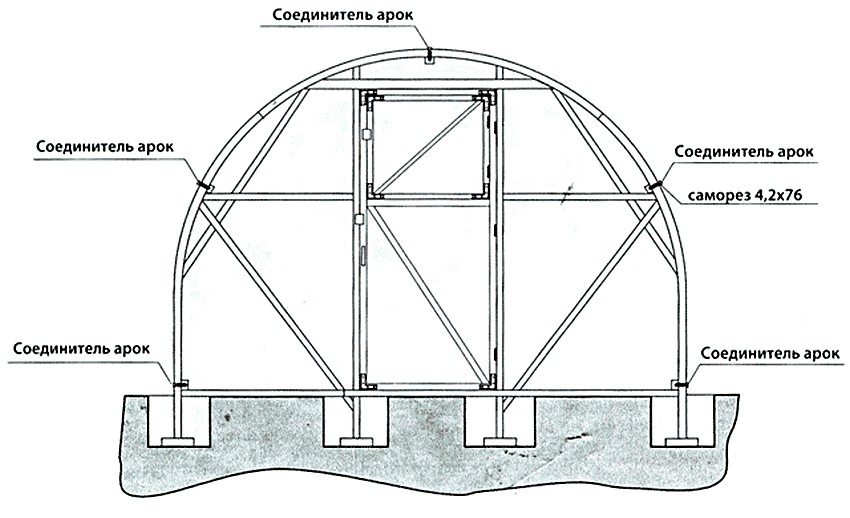

To assemble the greenhouse frame with your own hands from plastic pipes and polycarbonate, it is necessary to cut the reinforcement rods into pieces 75-80 cm long.Along the long side of the wooden base, the rods are driven into the ground to a depth of 35-40 cm.The distance between the reinforcement rods should be no more than 60 cm , and it is important to ensure that it is the same on both sides of the base.

Further, plastic pipes are put on the reinforcement rods, forming arched arcs. Each pipe must be fixed to a wooden base. This can be done using metal clamps (brackets). To give the structure rigidity and stability from above (along all arcs from one end of the frame to the other), a pipe (stiffener) is attached. It is fixed under the arcs on plastic clamps.

The next step will be the lathing device. To do this, it is necessary to install at both ends four racks of wooden blocks measuring 2 x 4 (cm). The distance between the central pillars is selected taking into account the width of the future door and window opening. The racks are connected with each other by transverse strips.

To thoroughly familiarize yourself with the installation steps, use the video "DIY greenhouse made of plastic pipes" presented at the end of the article.

Polycarbonate and polyethylene film are used as a covering for a greenhouse with a frame made of plastic pipes.

Covering the frame with polycarbonate plates

In order to properly work on covering the frame with polycarbonate sheets, you should know some of the features of working with this material:

- the spacing of the mounts is 45 mm;

- sheets are stacked end-to-end and connected with a special bar;

- holes for fasteners are drilled 1 mm larger than the diameter of the screws;

Related article:

DIY polycarbonate greenhouse from a profile. Construction drawings. Types of polycarbonate and profile for greenhouses. Foundation device. Assembling the frame. Greenhouse heating methods.

- when fastening with self-tapping screws, thermal washers are used, which contribute to the tightness of the connection;

- the sheets are laid so that the channels of the cells are located as vertically as possible;

- the protection film is removed only after the installation process is completed;

- corner lines are held together with a special corner profile.

To make the construction of a greenhouse made of plastic pipes more reliable and serve for more than one season, it is recommended to use polycarbonate sheets for covering

Useful advice! If polycarbonate sheets were purchased long before installation, they should be stored in a dry room to avoid moisture absorption.

Before laying the polycarbonate sheet on the arched frame, the ends are closed with punched tape, and then with an end profile. This profile provides drainage and ventilation of the sheets, which will allow the condensation formed in the channels to drain freely. In no case should you glue the ends with tape or leave them open.

Installation of polycarbonate panels is carried out with a protective film upwards. If this condition is neglected, polycarbonate will undergo rapid destruction.

DIY greenhouse from plastic pipes: assembling a frame from HDPE pipes

Quite often you can find do-it-yourself greenhouses from HDPE pipes. Such pipes are produced in coils of 100 m or in ready-made sections of 12-13 meters, which can facilitate the implementation of a structure of any length. The technology for their assembly is quite similar to the installation of a frame from other types of plastic pipes. Here are some of the benefits of such pipes:

- the price is much cheaper than metal analogues;

- the shelf life is quite long - up to 50 years;

- resistance to chemical attack, corrosion;

- high frost resistance allows you to operate greenhouses in the cold season.

Foundation device

For this greenhouse, a strip foundation is arranged. A trench half a meter deep and 30 cm wide is dug along the perimeter of the future structure.Crushed stone (1: 1) mixed with sand (1: 1) with a thickness of about 10-12 cm is poured into the bottom of the trench.We put the formwork from boards, make a frame of reinforcement and fill it with mortar. The solution is prepared at the rate of cement - 1 portion, sand - 3, crushed stone - 5. We bring the mixture to the consistency of thick sour cream with water. After the final setting of the mortar, the greenhouse frame can be installed on the foundation.

Assembling the frame from HDPE pipes

For the base of the frame, a frame structure is made of pipes with the width and length according to the drawing. The pipes are fixed in the frame with self-tapping screws. Every meter, transverse arches are attached to the finished frame. The pipe is first fixed on one side of the frame, then carefully bent and fixed on the opposite side of the frame. Further, pipes are attached longitudinally, protruding with stiffeners. It is advisable to install at least three such pipes: one runs along the top point and two on the sides of the structure.

A doorway is assembled at the end of the frame made of pipes - it looks like a U-shaped structure. It is attached to the base pipe and fixed from above on the end-piece arcuate pipe.The door is assembled according to the drawing from four pipe sections.

The finished frame is fixed to the foundation by means of dowels, after which the greenhouse is sewn up with polycarbonate.

Assembling a greenhouse from any type of plastic pipes can be carried out within one to two days. This does not require special knowledge and skills. Considering that plastic pipes have an acceptable cost, and the structure itself can last for several years, an increasing number of gardeners prefer such greenhouses and greenhouses.