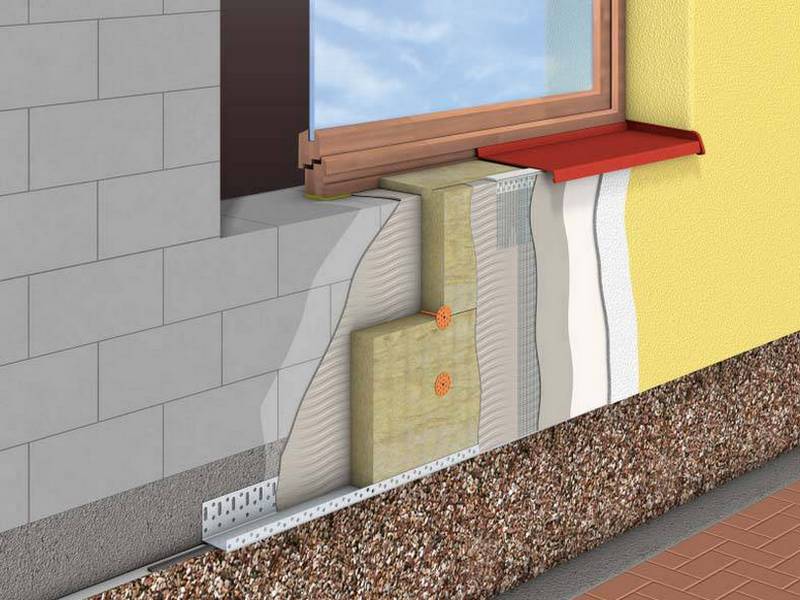

For insulation of facades, polystyrene foam plates are often used or, in another way, penoplex. This is a high-quality material that allows you to keep the heat accumulated in the room and significantly increase the energy efficiency of the house. The question is quite relevant: how to glue such plates, and which glue to choose for expanded polystyrene for outdoor work.

Among the huge number of existing adhesives, it is necessary to choose one that would meet the following requirements:

- provides good adhesion to any surface;

- resistant to temperature and other atmospheric extremes;

- easy to use and does not form drips;

- does not contain poisonous, toxic substances.

Helpful advice! When working with expanded polystyrene, it is impossible to use mixtures containing aggressive solvents. They destroy the material.

Content [Hide]

Glue for expanded polystyrene for outdoor use: varieties

The adhesive mixture can be produced in different forms. These can be special formulations that must be diluted on their own or ready-made solutions. Penoplex glue should not contain strong solvents such as acetone, gasoline. Such compounds can dissolve insulation, burning large holes in them. Also, they should not contain:

- formaldehyde;

- drying oils;

- diethyl ether;

- toluene;

- kerosene;

- xylene.

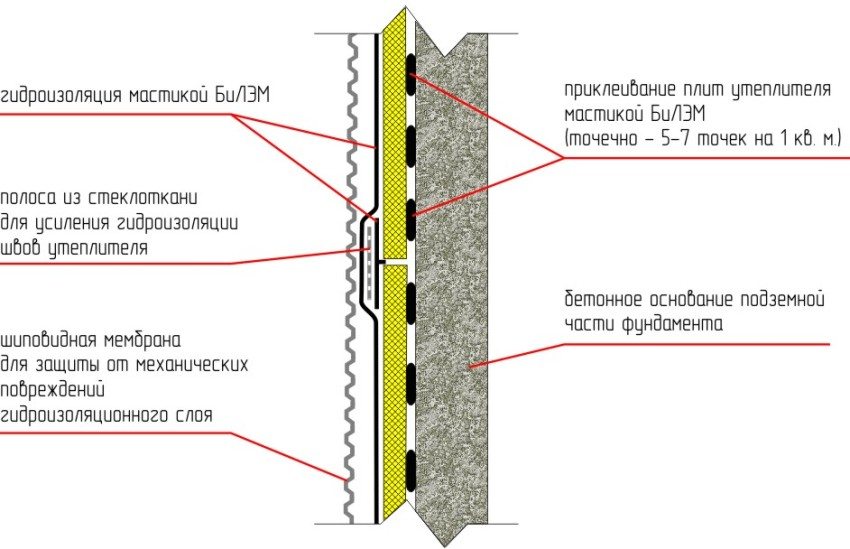

Bituminous glue

Such adhesives consist of a special light solvent that does not affect polystyrene foam, plasticizer and bitumen itself. These mixtures are quite popular, they are sold ready-made in small buckets, which makes them much easier to use.

Before applying bituminous glue, the surface of the walls must be thoroughly dried, sanded and primed. There should be no dust, dirt, rust or other stains on the base. A special comb-type spatula is used to apply the composition. With its help, a thin continuous layer in wavy lines is laid on the wall, after which the slab is glued. The adhesion of expanded polystyrene to the surface occurs in the first 20 minutes, therefore, during this period, additional fixation with props or some kind of load is required.

Such glue is resistant to gasoline, various oils, acids, ultraviolet radiation. It provides additional moisture insulation for the entire insulation system.

Cement-polymer adhesive

A similar composition can be used both indoors and outdoors.Cement-polymer adhesive for expanded polystyrene for outdoor use is ideal for laying foam on concrete, cinder block or brick walls. This type of glue adheres to polystyrene boards quite firmly, but requires a fairly deep priming of any surface. They are sold mainly in the form of a dry powder, which requires dilution according to the attached instructions.

Various polymers are added to the Portland cement available in the mixture, which allows the finished glue to be quite plastic and convenient for application. The resulting solutions are resistant to high humidity, low temperatures and do not deteriorate over time.

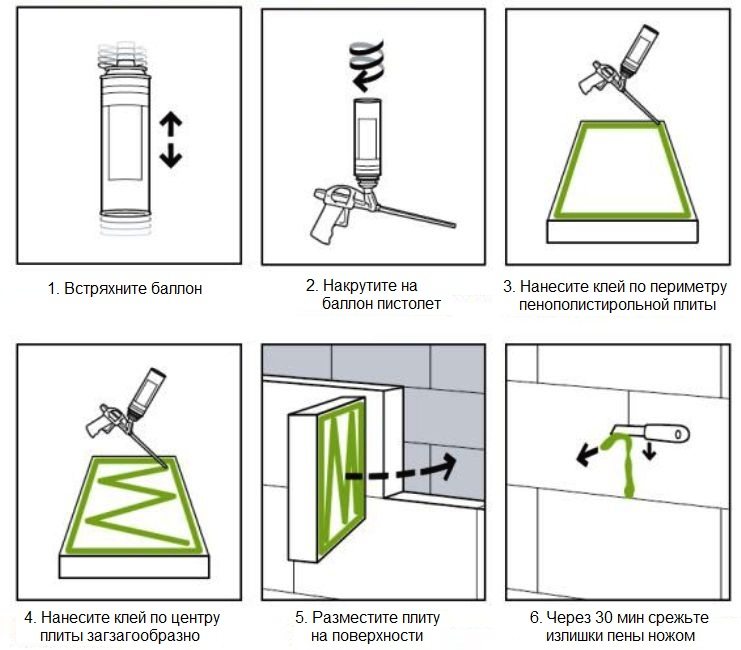

Polyurethane foam adhesive

This type of adhesive composition is fundamentally different from the above. It is sold in cylinders and used as a regular polyurethane foam... Polyurethane glue for polystyrene for outdoor use has high adhesion properties, and also has a number of other important advantages:

- easy to use;

- dries quickly;

- has an economical consumption;

- not affected by various weather disasters;

- does not spread;

- has high frost resistance.

The quality of gluing foam when using foam glue for polystyrene for outdoor use much higher. There is no need for constant monitoring of the correct preparation of the composition, as well as compliance with the recommended proportions. Such an adhesive mixture does not need to be kneaded. Full strength is gained in about 2 hours, while bitumen and cement mortars require at least 6. One cylinder of such glue replaces more than 25 kg of dry mix.

Foam glue does not require continuous application, which is why it is economical. It is applied directly to the polystyrene foam board along the edge around the entire perimeter and at several additional points for a stronger adhesion. It also requires application to the joints in order to fix the foam sheets together.

Helpful advice! The glue foam must be applied with a special construction gun. With its help, you can glue the resulting gaps between the plates.

Consumption of adhesives

Before buying the selected glue for expanded polystyrene for outdoor use, in order to determine its amount, it is necessary to calculate the future consumption of the composition. It is, of course, impossible to calculate exact figures, since they may depend on the material of the wall, its absorbency, but approximate data can be obtained by consulting the instructions from the manufacturer.

Average consumption of various formulations:

| Adhesive composition | amount |

| Dry mixes | 500 gr. / m² |

| Bituminous compositions | 800-1000 gr. / m² |

| Polyurethane foam adhesive | 1 cylinder for 8-10 m² |

The health of the building and the people living in it primarily depends on high-quality thermal insulation. The choice of the glue used for external insulation is an important task. After reviewing the description of the main adhesives for expanded polystyrene, as well as with the methods of their application, you can choose the ideal composition suitable for a specific surface.