Wood-fired sauna stoves with a water tank are installed in the house in cases where there is no possibility of connecting the electrical network or gas pipeline. This multifunctional equipment attracts consumers with its simple installation scheme and economy. The market offer offers a variety of designs of various types and power levels.

Modern wood burning stovesare mainly made of metal

Content [Hide]

- 1 Wood-fired sauna stoves with a water tank: design features

- 2 The principle of operation of wood-burning cast-iron stoves for a bath

- 3 Types of cast-iron stoves for wood-fired baths (by type of tank placement), their characteristics

- 4 Wood-fired sauna stoves: how to choose the optimal design

- 5 Construction of a wood-burning stove for a summer residence made of brick and metal

Wood-fired sauna stoves with a water tank: design features

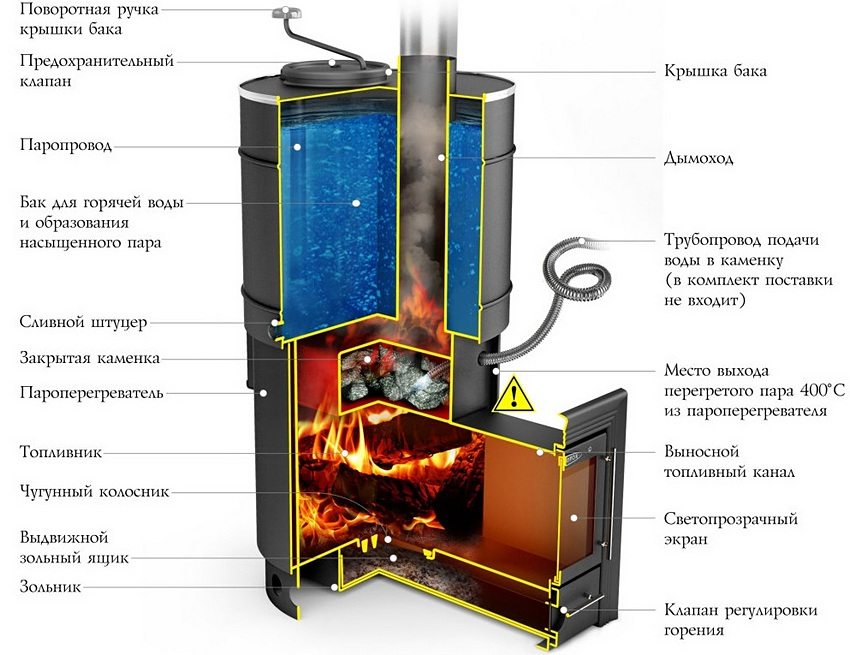

Furnace designs have several components. The body includes a grate, a firebox, a chimney and a space for placing stones, called a stove.

Wood-fired sauna stoves with a water tank of the modern generation are made of metal, sometimes of brick. But the leading positions are occupied by structures made of stainless steel.

The material for the manufacture of the grate is usually cast iron. It has excellent performance, is able to withstand severe temperatures, and is durable. To close the firebox, a sealed door is provided in the design.

Note! In some models, you can find a door with glass. It is sufficiently thick and has heat-resistant properties.

Most models can offer a wide range of functions. Therefore, consumers have the opportunity to buy inexpensive wood-fired sauna stoves with advanced functionality (for example, from the manufacturer of sauna stoves Teplodar, or another brand).

This list may include the ability to:

- carry out work within several modes;

- regulate the working time;

- control the duration of heating the bath rooms;

- set parameters in relation to steam quality;

- adjust the temperature inside the tank and steam room.

The principle of operation of wood-burning cast-iron stoves for a bath

Fuel is loaded into the equipment in several ways. This point depends on the type of wood-burning sauna stove with a water tank. In the process of burning firewood, ash and soot are formed. These fuel residues are poured into the ash pan through the grate.The ash pan is manually cleaned of soot and ash. The chimney is designed to remove gaseous combustion products that arise during the combustion of wood.

As a result of fuel combustion, heat is generated. Heated air is several times lighter than cold air, so it rises up the stones. The stones heat up, giving off heat to the steam room, where comfortable temperature conditions are formed.

The ability to create an optimal temperature regime is possessed by wood-burning stoves for a bath with a water tank with a remote firebox. In such structures, the fuel is loaded into the chamber from a room adjacent to the steam room. Waste gases give off heat, and the water heats up quickly.

Helpful advice! Long burning stoves are capable of efficiently performing work for 6-10 hours. Having chosen the optimal design model, you can forget about constant monitoring of the stove - it will be enough just to replenish the supply of firewood in the firebox twice a day.

Types of cast-iron stoves for wood-fired baths (by type of tank placement), their characteristics

Most of the manufacturers produce constructions made within the framework of strict design. Decorative glasses for observing the flame are equipped only with fireplace stovesinstalled in living rooms.

Wood-burning stoves are considered the most traditional equipment option. When wood burns in the room, a pleasant aroma of a Russian steam room is created.

Ready-made structures can have a different type of placement of the water tank:

- in the furnace building (built-in tank);

- on a pipe that removes smoke (it is recommended to purchase ready-made structures of this type, since the device of chimneys in a bath for wood-burning stoves with your own hands requires serious knowledge and skills);

- separate from the structure (these furnaces have a built-in heat exchanger, which acts as a connecting element between the structure and the tank outside of it);

- hinged type (attached to the body).

There are a number of popular designs for those who intend to buy a wood-fired sauna stove.

Average prices for furnace models with different designs:

| Model name | Tank placement type | Cost, rub. |

| Tunguska | on the chimney | from 10000 |

| Helo (Finnish) | built in | from 25000 |

| Sahara | hinged | from 12000 |

Before buying a wood-burning stove, it will be useful to familiarize yourself with consumer reviews, which are presented in large quantities on the network.

Features of stoves for a wood-burning bathhouse with a built-in or hinged tank

The water tank is a metal container. The design option with a tank suspended from the outside or built into the furnace body is considered very inconvenient.

The built-in type of placement of the water tank does not allow you to control the liquid level in it. In this case, water undergoes constant boiling, so it will be necessary to additionally organize a system for removing steam.

Hinged cisterns are characterized by rapid boiling, which is ahead of the moment when the steam room begins to heat normally. A negative phenomenon called "cold steam" is formed. Such steam increases the humidity level in the room, which creates serious obstacles to the formation of acceptable and comfortable conditions in the bath.

Advice! It is recommended to use birch logs, alder firewood. Efficient fuel is coal and peat briquettes. The wood must be dry in order to warm up the room quickly. It is better to refuse the use of coniferous wood. When burned, a large amount of soot is formed, clogging the chimney.

In the attached tanks, part of the heat is spent on heating the water, which increases the heating time of the steam room. Hot water must be drained and diluted with cold water, which creates additional inconvenience.

Related article:

The best photos of finishing the bath inside and a description of the stages of work. Recommended materials and installation rules. The sequence of actions when decorating a bath. Waterproofing and wall insulation.

Features of ovens with a portable water tank

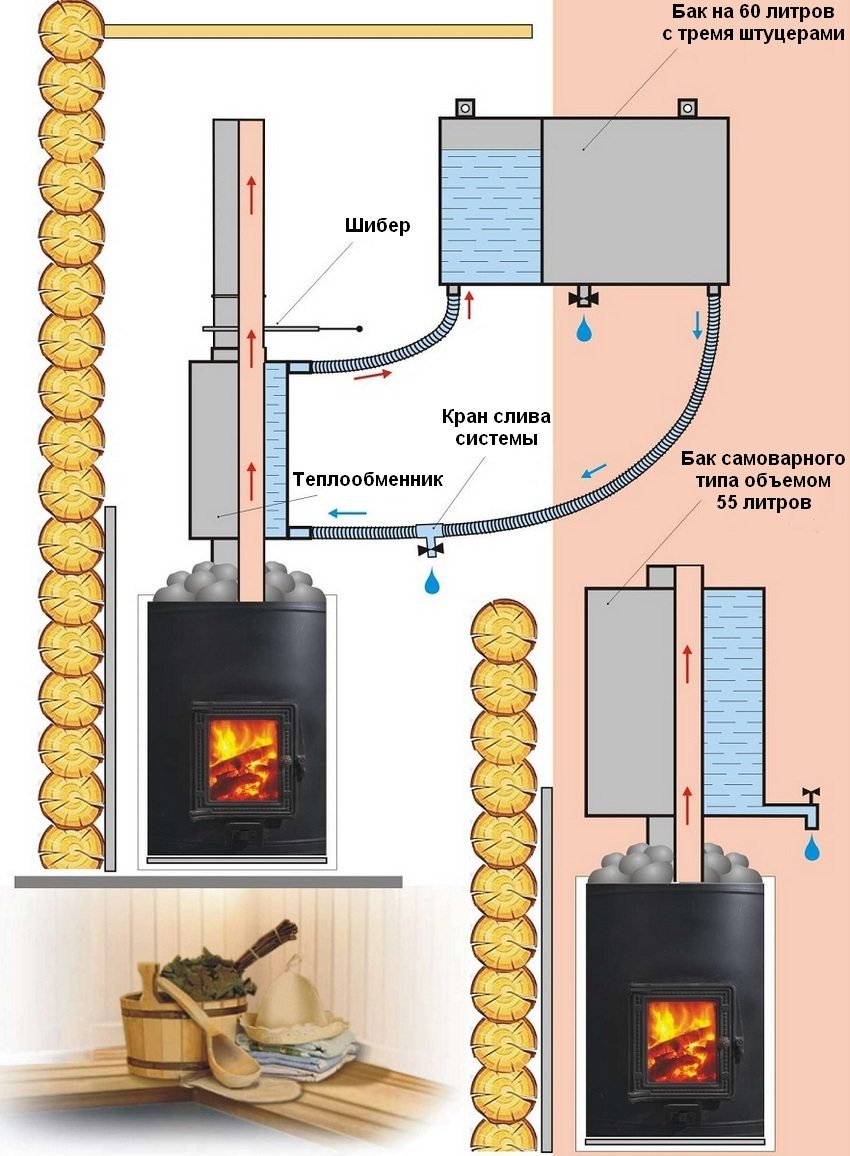

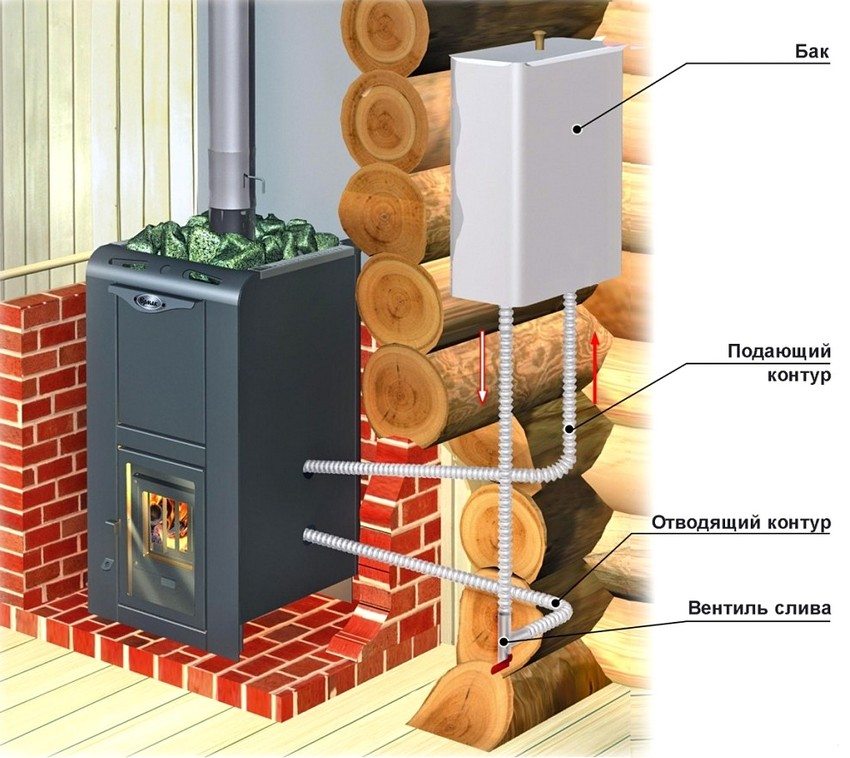

The portable water tank is heated in two ways: from the chimney or from the firebox. When it comes to heating by means of a firebox, in metal or brick ovens, the coil is installed directly into it. Such a coil is equipped with a pair of pipes. They go outside, where a remote tank is mounted, which must be located near the heat source. The maximum distance allowed is 3 meters.

This requirement is due to the fact that the circulation inside the circuit will be carried out in a natural mode. The tank is hung on the wall from the inside or outside of the steam room. It must be placed above the level of the combustion chamber.

This makes it possible to:

- control the temperature regime;

- control the liquid level;

- install a shower or mixer directly to the cistern.

Such ovens also have disadvantages. During the warming up of the room, part of the heat from the firebox goes to warming up the water. You cannot do without this, because pouring the system after heating the steam room is prohibited, since liquid boiling can occur in hot pipes, provoked by sharp cooling. This can be followed by impact and destruction of the heat exchanger.

Wood-burning stoves with water tank (heated from chimney)

The most advantageous option is considered to be stove structures in which the water tank is powered by the energy of the flue gas. Combustion gases are very hot. Therefore, the efficiency of the furnace will not be reduced if part of the heat from the gas duct is taken to service the hot water supply.

Helpful advice! The heating process can be organized in several ways at once. It is allowed to build a tank with a large volume into the chimney, the liquid in it will be heated directly from the combustion products of firewood. It is possible to install a small tank on the chimney, complete with two nozzles. A portable container with a large volume is mounted to them.

The use of heat from combustion products to heat water is the best way to organize the system, so consumers have the opportunity to buy wood-fired sauna stoves of this and other modifications in a wide variety.

Prices for popular domestic models:

| Model name (manufacturer) | Cost, rub. |

| Angara (Termofor) | 18000 |

| Compact (Termofor) | 15000 |

| Tunguska (Termofor) | 17000 |

| Sahara (Teplodar) | 12000 |

| Rus (Teplodar) | 11000 |

| Siberia (Teplodar) | 12000 |

There are no unambiguously good or bad designs. The optimal oven is selected based on the conditions of the room where it is planned to be installed and the requirements of the individual buyer.

Wood-fired sauna stoves: how to choose the optimal design

If you are planning to purchase a wood-burning stove for a bath, a number of parameters that you should pay attention to will help to facilitate the choice:

- the level of thermal power - depends on the size of the steam room (a model with a high power rating in a small room will provoke overheating, and a low-power stove in a large bath will break down very quickly due to a high load);

- a type of firebox, which can be remote or built-in. In the first case, the oven is served from the dressing room;

- material - most models consist of multilayer metal, which eliminates the appearance of burns due to accidental contact with the furnace body;

- type of oven - with frequent use of the bath, it is recommended to install a closed structure that retains heat for a long time.Open versions of stoves are mounted in steam rooms, which are very rarely used;

- volume of stones - a large number of stones contributes to a longer retention of heat, and, consequently, a decrease in firewood consumption;

- trademark - the products of leading manufacturers are distinguished by high efficiency and extensive functionality.

Note! Some models are faced with ceramic tiles or natural stone.

The specifics of Finnish wood-fired sauna stoves from popular manufacturers

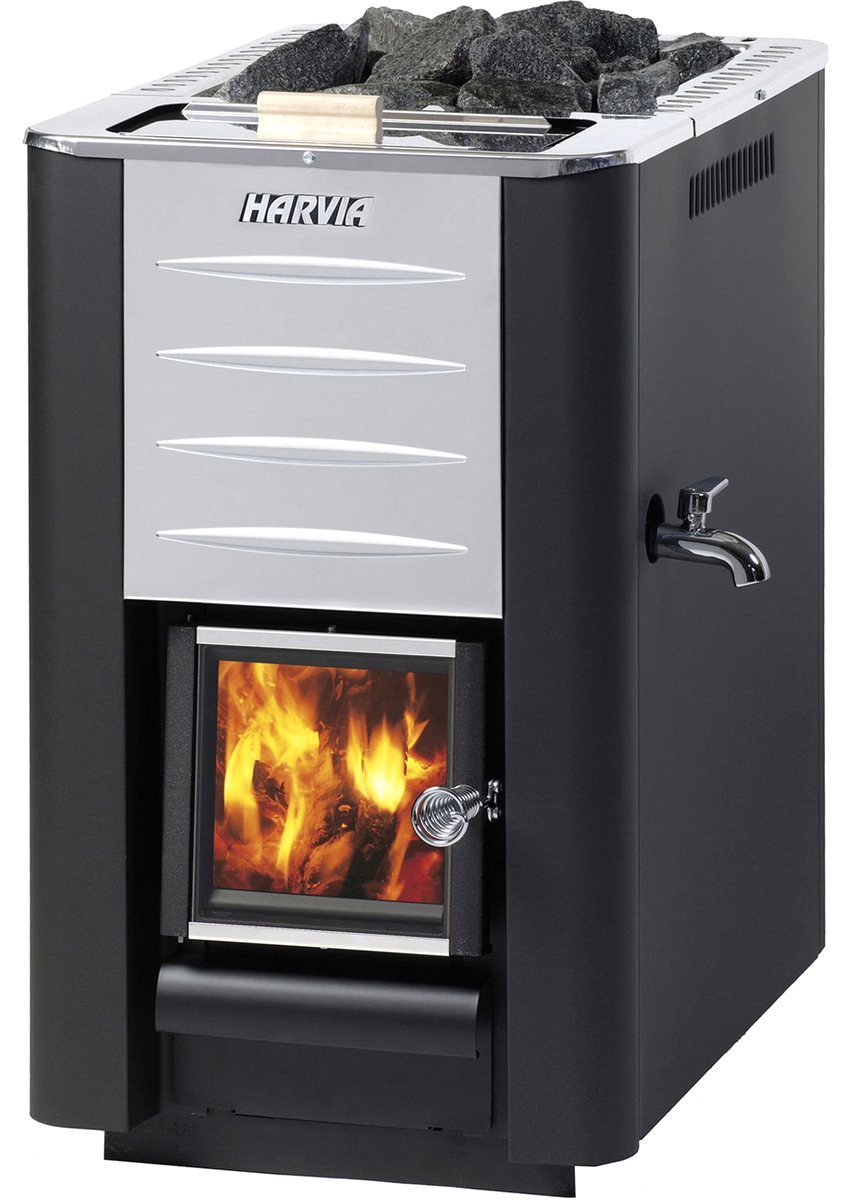

Finnish stove constructions are associated by consumers with the concept of reliability and comfort. The cost of products is an order of magnitude higher than domestic ones. But the advantageous characteristics of Finnish products justify the high price.

Popular brands:

- Kastor - heating is carried out due to thermal radiation coming from stones and walls of the case. The design is based on the principle of convection. The most advantageous characteristics of the products are the high quality of materials used in the manufacture of ovens, an attractive external design, a special air exchange system and doors made of glass;

- Helo - the model range includes modifications for domestic use in home baths (low power and price) and structures for public saunas (wide functionality, high efficiency);

- Harvia - brand products are distinguished by long effective service life, durability, environmental friendliness and high speed of heating the room. The ovens are economical;

- Narvi - the company's equipment offers consumers ease of use, simplicity and high heating speed.

Average cost of Finnish stoves:

| Manufacturer | Cost, rub. |

| Kastor | 23000 – 38000 |

| Helo | 35000 – 40000 |

| Harvia | 21000 – 38000 |

| Narvi | 37000 – 45000 |

Construction of a wood-burning stove for a summer residence made of brick and metal

Brick structures are made by hand. For high-quality and fast construction, you can resort to the help of specialists.

Helpful advice! At the initial stage of work, the organization of the foundation is carried out. Unlike steel or cast iron construction, placing a heavy brick oven directly on the floor is not permitted.

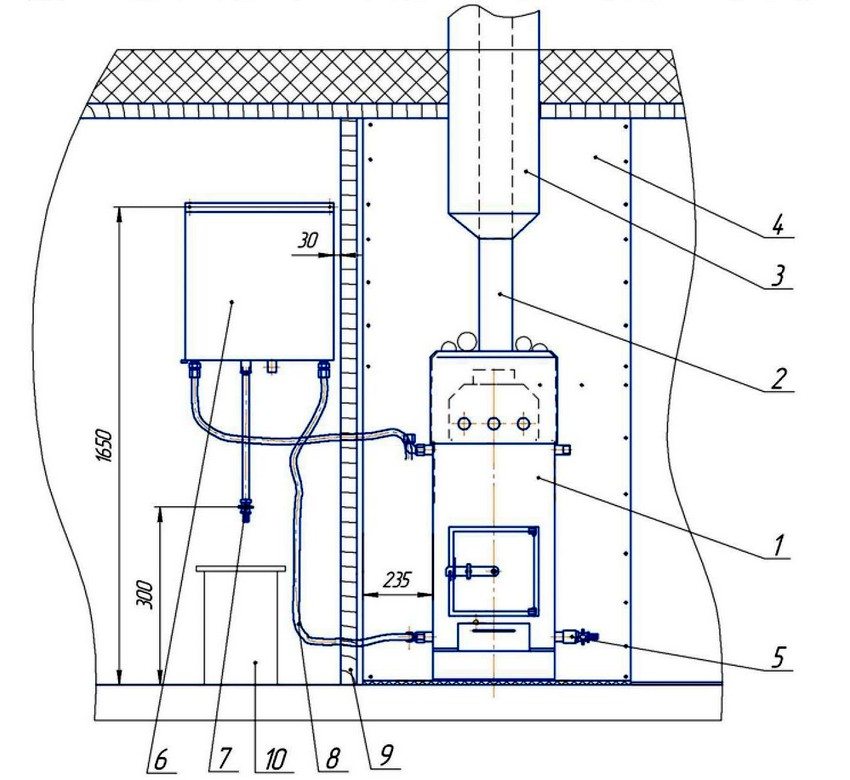

Placement of a metal stove and a water tank in the bath: 1 - stove-heater with a water-heating jacket; 2 - stainless steel chimney (115 mm); 3 - chimney cutting; 4 - non-combustible wall covering; 5 - drain valve; 6 - hot water tank; 7 - hot water analysis tap; 8 - heat-resistant pipes; 9 - partition; 10 - bench for a basin

Step-by-step instruction:

- pit formation (depth - 0.3 m, dimensions by 0.1 m exceed the dimensions of the furnace on each side);

- compaction of soil;

- formation of a crushed stone cushion (layer thickness - 0.1 m);

- sand layer formation and compaction (thickness - 0.1 m);

- installation of wooden formwork;

- the formation of a frame from reinforcement (with a diameter of 12 and 8 mm);

- pouring with concrete mixture (thickness - 0.1 m);

- drying for 3 weeks (the formwork can be removed before final hardening);

- installation of waterproofing, thermal insulation layers (steel sheet or asbestos cardboard);

- laying bricks using clay mortar.

Organization of small metal stoves for a bath with your own hands, drawings, photos

Metal structures are less inert than brick ones. They cool down as quickly as they heat up. For small steam rooms, a small-sized version of the product with a tank placed above the chamber is suitable. steam stones.

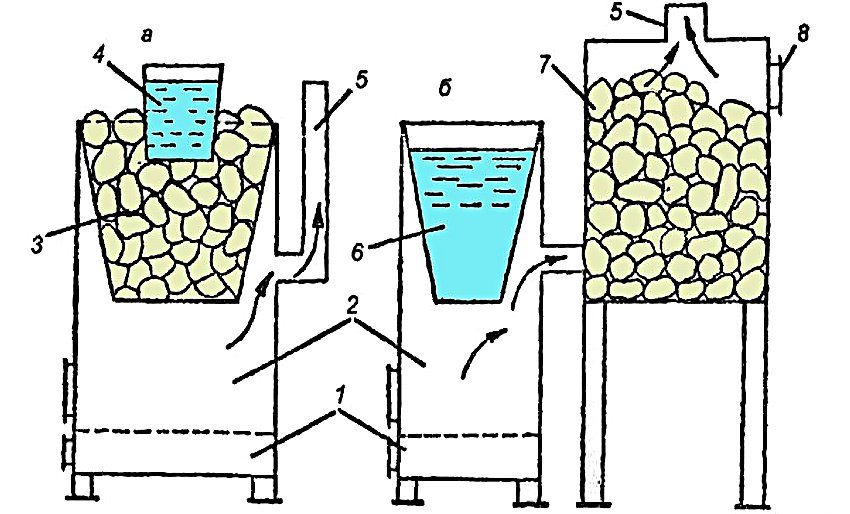

Compact stove-heater for a bath with a water tank (a - continuous heater; b - batch heater): 1 - ash pan; 2 - firebox of the washer-oven; 3 - tank filled with stones; 4 - a bucket of water; 5 - outlet chimney; 6 - bucks with water; 7 - a barrel filled with stones; 8 - steam door

For self-manufacturing of the case, you will need sheet steel with a thickness of 3-5 mm. Large diameter steel pipes or barrels can be used.

In the upper area of the body there are chambers for stones. A door is mounted in the side part through which steam stones will be irrigated.

Next, a lining is made, folded of refractory bricks for the firebox, as well as for the chamber with stones.

During the operation of such a furnace, hot gases and fire will pass through the stones and heat them together with water. To remove gases, a chimney should be arranged from the middle of the tank. The use of sandwich pipes is recommended.

Do-it-yourself construction of a furnace structure has many advantages. However, without the appropriate skills and knowledge, it is better to resort to the help of specialists or to purchase a ready-made structure made of cast iron or metal.