Landscape construction is an effective way to ennoble the territory of a suburban or suburban area, to make it unique. Many owners of private houses use various tricks, starting with the design of paths, ending with green hedges. To date, the most popular method for arranging the territory is do-it-yourself gabions: the step-by-step instructions are so simple that you can start building the structure yourself.

Content [Hide]

- 1 What are gabions: general definition and description

- 2 Diy gabions: step-by-step construction instructions and its features

- 2.1 Required materials for construction

- 2.2 The choice of material for the walls of conventional and welded gabions

- 2.3 The choice of material for creating a welded mesh gabion

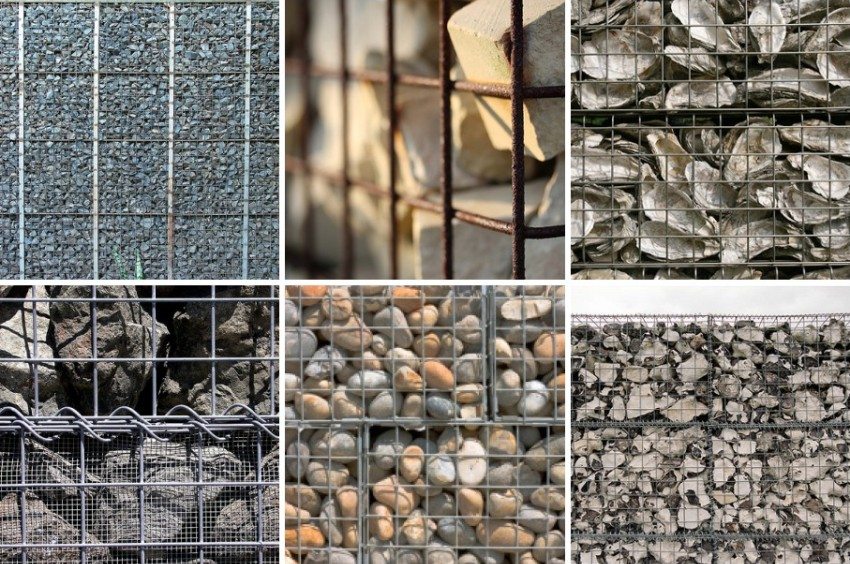

- 2.4 The choice of filler: stones for gabions

- 2.5 Do-it-yourself technology for creating a fence from gabions

- 2.6 Features of filling structures with stones

- 3 Additional recommendations for creating and photo gabions

What are gabions: general definition and description

Gabions are containers made of metal wire. The gabion device involves the construction of a frame, inside which a certain material is placed.

The filling material can be:

- wood;

- crushed stone;

- a rock;

- cobblestones;

- gray pebbles.

Helpful advice! It is recommended to use fine chippings to mask the empty spaces that form between larger pieces.

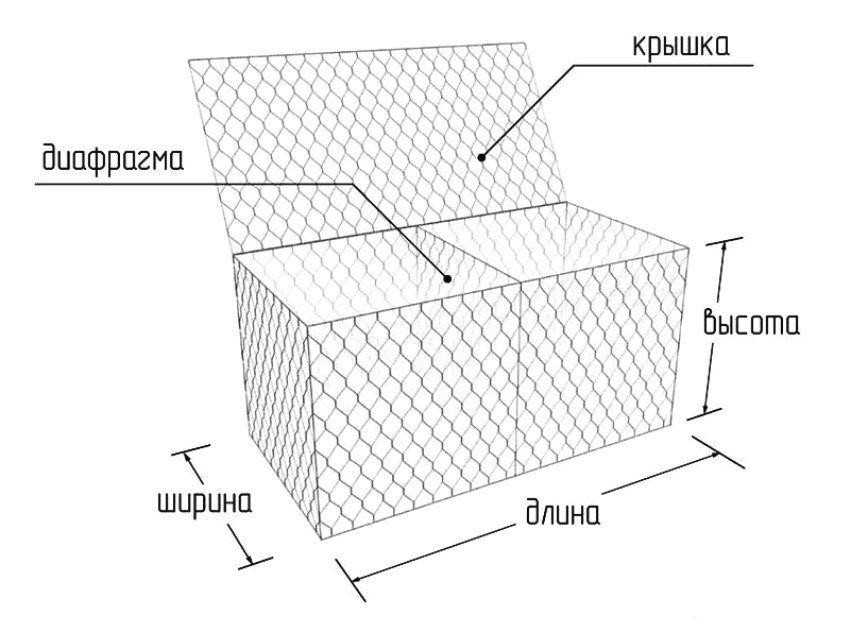

The structure is large in size and is made of twisted wire and mesh. With large dimensions, additional installation of sectional compartments is performed. They will not allow deformation of the walls under the mass of stones that fill the metal frame.

DIY construction of gabions is inexpensive, which is why they are so popular among owners of suburban areas. Such a product does not require much effort in terms of maintaining it; it is equipped with a lid on top.

One of the advantages of gabion structures is their attractive appearance, as evidenced by photos of gabions in landscape design. Thanks to the wide variety of fillers for the mesh frame, a unique appearance can be achieved. These designs are reliable and durable.

Scope of constructions

Gabions were widely used as fortification structures on the battlefields. In a literal translation, the name of such a structure means "a stone in a grid".Today the technology of building gabions in landscape design is successfully used.

Structures are installed as:

- foundations for creating furnishings on the site and in the patio (the formation of outdoor chairs and benches, tables and chairs);

- framing for vegetation;

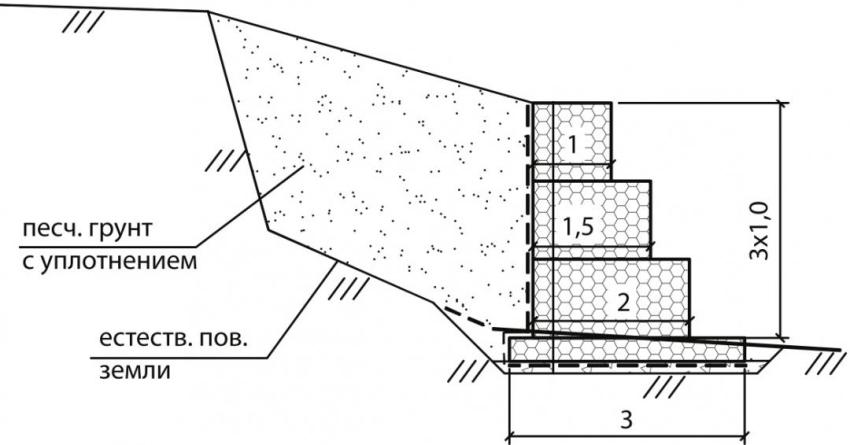

- retaining walls to strengthen hangars;

- building material for lawns and stone gardens;

- bases for the formation of partitions, arches, durable flower bed with a vertical type of placement;

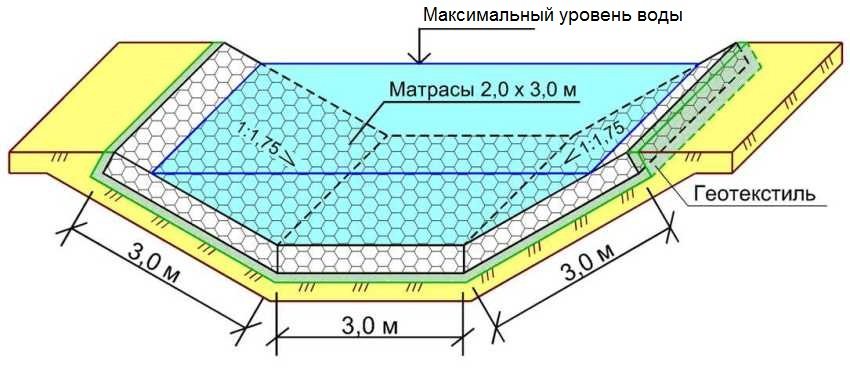

- strengthening structures for fixing the soil of the coastal zone of lakes and rivers located near the site or house;

- decorative elements to decorate the territory (installed at the entrance to the courtyard, in the area of the stairs);

- material for the construction of ladders designed to descend to the water.

garden furniture from stone gabions

Useful advice! Gabion mounting technology can be effectively used for space zoning. These structures are used not only as external fences (fencesseparating the adjacent territory from the street and neighbors), but also to divide the total area into areas, for example, a recreation area, a place for installing a stove, barbecue, grill, an area for placing a summer shower, etc.

The advantages of installing gabions on the territory of a suburban area

Most often, people are interested in information on how to make a gabion with their own hands in order to create fortifications on the site, because they have a number of advantages.

Benefits of reinforcing structures:

- there is no need to use specialized construction equipment, so the process of erecting gabions does not harm the surrounding landscape forms;

- products have a high throughput, due to which air and water flows freely penetrate through them. Thanks to this, a high level of environmental friendliness of buildings is achieved. The constant access of air contributes to the normal growth of plants, and the structures themselves do not have a negative effect on the landscaping of the site;

- mesh cells for gabions do not hinder the germination of grass. As a result of this, a beautiful merging effect is obtained without such negative consequences as deformation of the building or disruption of its functions;

- stones inside the frame are not fixed, due to which the filling of the partition remains mobile, which reduces the level of hydrostatic pressure;

- seasonal soil displacement cannot harm the products. Even with significant changes, the structure will not lose its integral forms, only slight deformation is possible;

- due to the plants that grow more and more between the stones every year, the strength of the structure increases.

General classification of gabion structures

Within the framework of the general classification, the following types of products are distinguished:

- box type;

- flat;

- cylindrical type.

Box gabion designs are called Jumbo. The grid in them forms hexagonal or rectangular cells. This version of the structure is the most dimensional, since the products can be about 2 meters wide. Their length is 6 meters, and their height reaches one meter.

Note! Given the fact that Jumbo structures are so variable in size, their frames are necessarily supplemented with partitions. During construction, not only the mesh method of forming the frame can be used, but also the welded one.

Scope of Jumbo:

- protection of soil from erosion;

- manufacturing of retaining walls from gabions;

- monitoring of soil conditions.

Products of a cylindrical shape are called gabion bags. With the help of them, foundations located under water are equipped. This type of design offers increased flexibility.

Flat products have a height of 17 to 30 cm. They are called Reno mattresses and are laid out on top of uneven surfaces, since they have the ability to adapt to them.

Diy gabions: step-by-step construction instructions and its features

To simplify your work, you can purchase ready-made designs. Modern stores offer a wide range of products for forming gabions. But the finished parts of the frames do not always correspond to the required dimensions. In some cases it is easier to create a gabion with your own hands. The first stage of construction involves the design of the future composition and the calculation of the required amount of materials. If you want to make a design with your own hands, photos of gabions can be used for inspiration and design for your own unique project.

Related article:

Geotextile: what it is and how is it used in construction

Fields of application, types of geotextiles and their distinctive features. How does the density of geotextiles affect its application?

The design is carried out according to the following scheme:

- Taking measurements from the territory.

- Marking.

- Transferring the markup to paper (layout plan of structures).

- Drawing up drawings for each object.

- Selection of fillers and materials.

- Calculation of the required amount of materials.

Useful advice! Materials should be purchased with stock. The calculation result needs to be increased by about 10-15%.

To achieve high strength, it is recommended to purchase a double twist mesh. It has a flexible structure, is easy to store and transport, durable and resistant to the negative effects of external factors.

Required materials for construction

Before making a gabion with your own hands, you should take care of the availability of the necessary tools, basic and consumables.

Consumables include:

- staples designed to connect adjacent walls, or spiral-shaped wire;

- geotextile;

- pins made of steel (used to fix products in the soil);

- steel braces (designed to tie the walls with the opposite type of placement in relation to each other).

To secure your actions and reduce the time of work, you need to use additional tools.

The list of related tools includes:

- mount;

- pliers;

- plumb line;

- shovel;

- a hammer;

- hand protection gloves made of high density material.

Designers often give the natural landscape of the territory interesting and unique relief forms. This type of structure is so strong that it can be used to form hills and valleys.

On top of the landscape, you can create flower beds from gabions with your own hands, as well as waterfalls, artificial reservoirs, fountains And so on.

The choice of material for the walls of conventional and welded gabions

Wire mesh is used when the gabion project is based on Renault mattresses. Most often, the need to use such products arises when the intention is to build an object with a complex configuration on the site.In this case, Reno mattresses are located along the bending lines. They can be installed in an arc or placed on separate sections of the structure where it is necessary to turn or bend the frame. Flower beds or fountains are finished with this type of material.

Useful advice! Taking into account that the structure will be placed not indoors, but outdoors, it is recommended to buy a gabion net with a special protective coating. Under outdoor conditions, common material will corrode and become unusable very quickly. Galvanized mesh can last almost 100 years.

For the construction of gabions, it is necessary to choose a mesh with a thickness of at least 2.7 mm

For the manufacture of gabions, it is not recommended to use a material whose thickness is less than 2.7 mm. The table shows the prices for products made of galvanized steel with a thickness of 3 mm.

Average net price for gabions:

| Product parameters (width / length / height) | Cell size, cm | Price, rubles |

| 1x1.5x0.5 | 10x8 | 800 |

| 1x2x0.5 | 1600 | |

| 1х4х0.5 | 2100 | |

| 1x1.5x1 | 1300 | |

| 1x2x1 | 1540 | |

| 1х4х1 | 2990 |

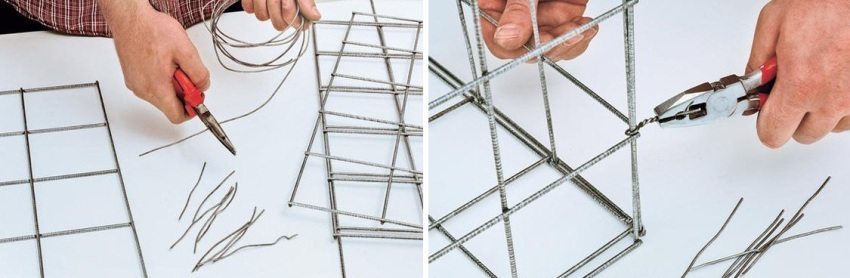

The choice of material for creating a welded mesh gabion

In welded structures, the mesh is created from thick rods. These elements are laid perpendicular to each other, and their intersections are connected by welding.

The section of the rods is selected based on the purpose for which the object is created. In most cases, it is recommended to choose a material with a large thickness. Moreover, it should not exceed 0.8 cm.

The installation of such structures is carried out in those areas where Reno mattresses will be subject to significant weight loads. They are very convenient for filling with coarse sized samples.

Welded elements are used to create:

- grounds;

- retaining elements;

- supports.

They are much stronger than reinforcing elements, but their installation is accompanied by certain inconveniences. The walls of gabions, made of double twisted mesh, are interconnected with a wire. But in the case of a welded frame, this method will be less reliable and more time-consuming. It is better to use a welding machine to connect all the elements of such a structure.

Note! Good welding skills are required to perform well on the welding machine. If you are not confident in your abilities, use a different version of the material or order a gabion installation service from professionals.

The choice of filler: stones for gabions

Almost any material can be used as a filler. When choosing a filling, one should be guided by:

- your own preferences;

- budgetary possibilities;

- type of object placement (underwater or surface).

Designers mainly use stones of natural or artificial origin. They can be rounded or crushed, but always large. The colors can be very diverse. The shade depends on the type of stone and its composition.

It is possible to manufacture structures with less standard filling in the form of:

- broken tiles;

- solid or broken bricks;

- cut pipes made of propylene;

- wood cuts with a different pattern of tree rings;

- aluminum cans;

- car tires cut into pieces;

- glass bottles;

- large cones;

- pieces of bark, etc.

Important! The size of stones or particles of other filler must be larger than the mesh size, otherwise the inside will spill out. The minimum stone size is usually 25 cm. For structures placed under water, the filling should exceed the mesh size by 50%, for surface products - 30%.

Do-it-yourself technology for creating a fence from gabions

A gabion fence takes up much more space than a regular fence fence... But there is no need to create a basement, because the installation of the fence is carried out directly on the ground.

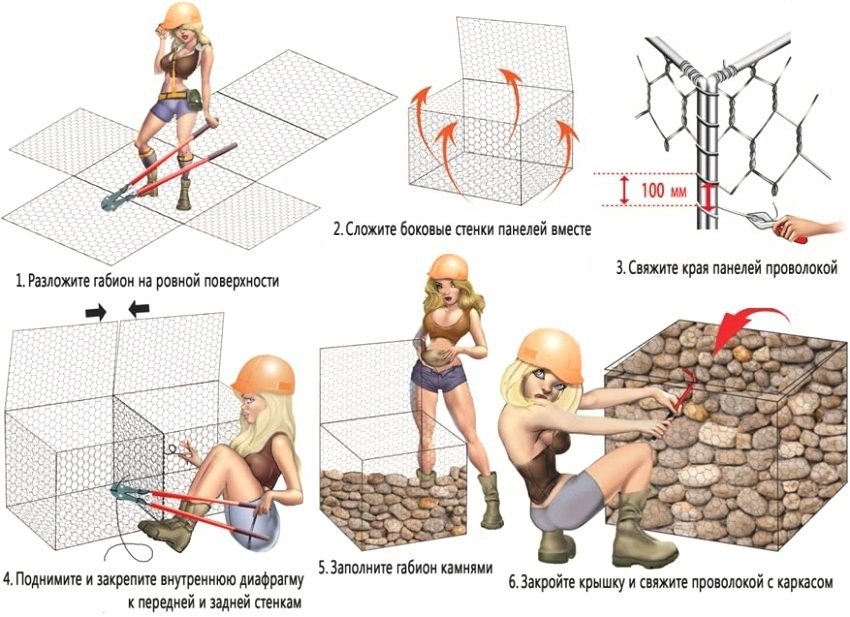

Step-by-step instructions for implementation:

- Cleaning the surface from plants, stones and roots, leveling the soil.

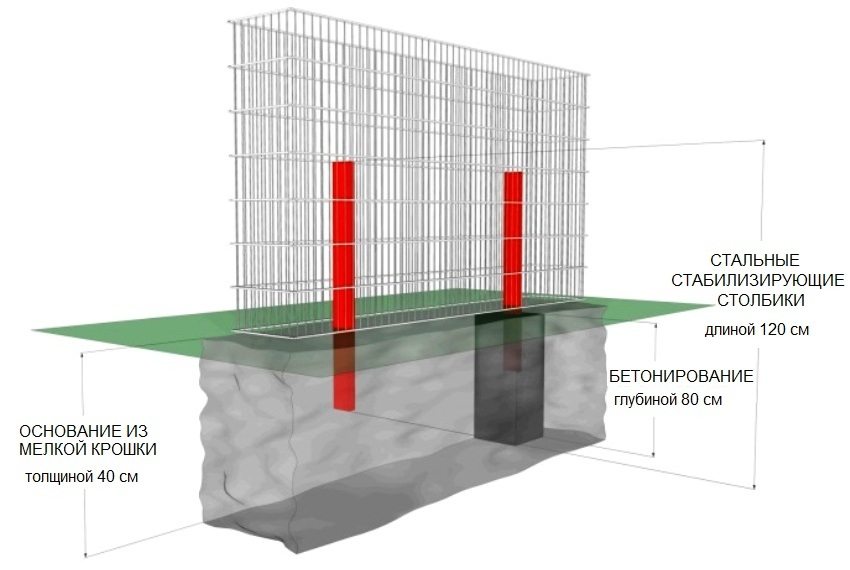

- Formation of holes for the installation of pillars (depth about 0.4-0.5 m).

- Installation of supports and concrete pouring.

- Installation of the frame around the supports (after the concrete solution has hardened, the drying period is 3-4 days).

- Fixing the frame to the posts using bolts, nuts or clamps.

- Processing the end part of the wire with protective agents or zinc paste.

- Filling the mesh frame.

- Install and fix the top cover.

To form the frame, cut six pieces from a roll of mesh of the appropriate length. One of them will fall on the bottom, others will become the front and back walls fence, lid and sides. After laying the bottom, the side walls are attached, which are fixed with a spiral wire. Then they are fixed in the soil with metal pins.

The lid is mounted and secured only after the containers have been filled and the filler has shrunk. A metal profile can be used to reinforce the corner parts of the frame.

Features of filling structures with stones

The stage of filling the mesh frame is specific. You should adhere to certain rules when working with stones or other types of filling for gabions.

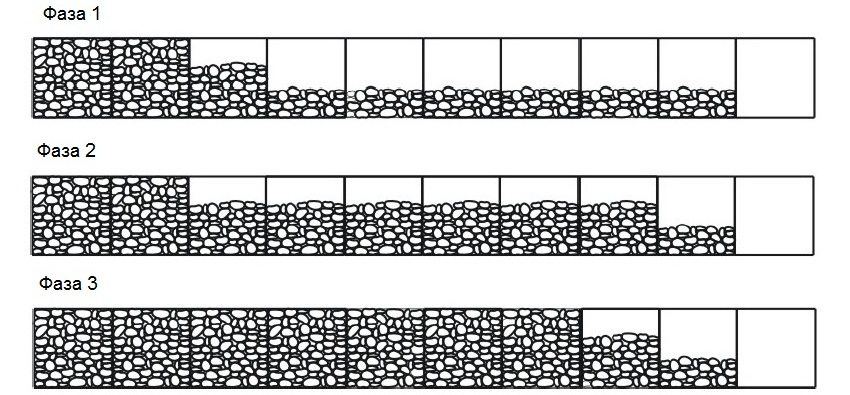

Rules for filling structures:

- It is not recommended to fill the frame immediately. To begin with, it is worth filling half the space inside the gabion.

- After that, the walls of the product, which have opposite placement in relation to each other, are pulled together. At the same time, it is very important to achieve strict parallelism. To fix the walls in the desired position, braces are used made of thick wire. The installation area of the braces is determined based on the size of the stones, as well as the structural features of the gabion.

- The next stage of construction is full filling of the product with stones to the very top.

- The upper sections of the sides are again pulled together with metal cables or wires.

Useful advice! If the width of the gabion is large enough, in order to save money, large particles of material should be laid along the outer walls. The remaining interior space can be filled with debris or fines. But you should not load the braces too much, they can bend under the mass of the stone and deform the frame.

Additional recommendations for creating and photo gabions

If the object is made from reinforcement, there is a way to economically use filling material and simplify installation work. For this, the intervals between the rods are increased, and a mesh-netting is laid on top of them. It will prevent material from spilling out.

Gabions, used as decorative elements to improve the external aesthetics of the territory, are recommended to be domesticated. In the upper part, natural or fake diamond, tile.This allows you to mask the mesh and thereby improve the design of the structure.

Large objects are divided into compartments. This will increase the strength of the entire structure. The material for creating partitions, called diaphragms, can be a mesh or a rod.

If small fractions were used to fill the inside, geofabric can be used to prevent small elements from spilling out through large stones.

By combining materials of different types, sizes and colors, you can create an unusually beautiful composition. During construction fences partial combination of gabions with other materials (wood, concrete, brick, etc.) is allowed. This also applies to other objects that can be located on the territory. Design fantasy can only be limited by budget.