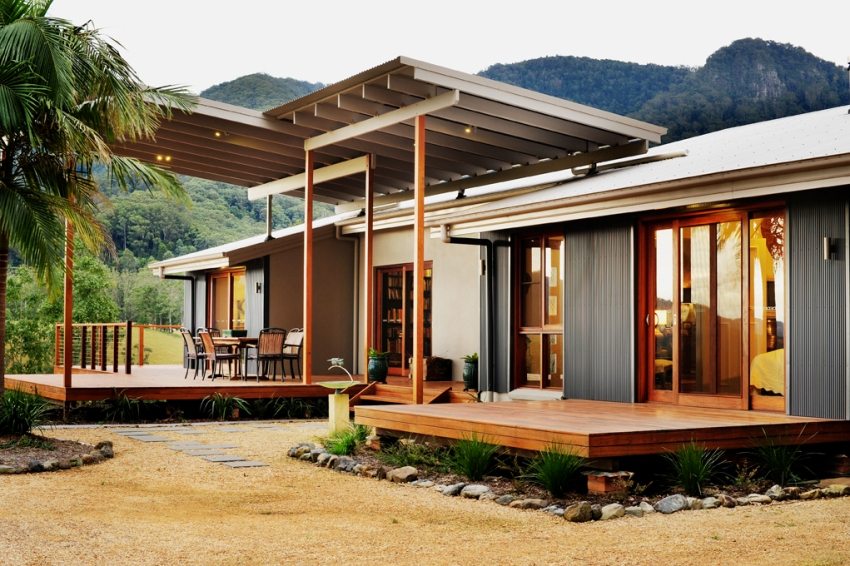

Country housing in the modern sense is a combination of privacy, tranquility and closeness to nature. A place for a recreation area is immediately laid in the project of a good cottage. It could be a patio alcove or a canopy attached to the house: photos of canopies can be viewed in our gallery. Ancillary structures of this kind decorate the estate and expand the usable living space.

Content [Hide]

Materials for building canopies

Frames for attached structures are mainly made of timber or profiled steel pipes. But often for these purposes are used brick, stone, asbestos-cement pipes, filled with reinforced concrete. It all depends on the destination canopy and the expected load on the frame.

The canopy attached to the house (the photo can be found on the Internet) adjoins the wall, taking on the weight of the snow rolling down from the roof. To withstand such severe loads, the base of the extension must be strong enough.

The roof of the annex is usually covered with slate, professional sheet, galvanized iron. But today the construction market offers a more interesting alternative - a polycarbonate canopy attached to the house. Photos of similar structures confirm that fiberglass is ideally combined with frames made of any materials. For awnings cellular sheets with a thickness of 6-8 mm are used.

The main advantages of polycarbonate:

- strength. Plastic is 200 times stronger than glass. He is not afraid of hammer blows, hail, stones;

- light weight. The material is 20 times lighter than glass. This allows you to create voluminous, but lightweight structures, reduces the complexity of work and the cost of construction;

- transparency. Thermoplastic of different thickness transmits from 80% to 95% of natural light;

- flexibility. Cellular polycarbonate is the only translucent material that can be bent at low temperatures. The main thing here is to take into account the permissible bending radius and the direction of the internal channels.

Polycarbonate canopy over plastic doors

It is also important that the transparent polymer is easy to process. It can be drilled, cut with a saw, grinder, jigsaw.

Helpful advice! Dfor awnings, you need to take polycarbonate with UF-protection, otherwise the material under the sun will quickly become cloudy and lose flexibility.

Canopy attached to the house: photos of structures

The awnings attached to the house (the photo is on specialized resources) are divided into two groups: canopies on consoles and awnings installed on capital supports.

Cantilever models can be as long as you like along the facade of the building, but they should not exceed 2 m in width so that the wind does not pull them out of the wall. The purpose of such products is to protect doors from the sun and precipitation, as well as to improve the appearance of the building. Forged and carved canopies in an ensemble with an entrance group can transform the facade.

Support sheds are designed for the following purposes:

- arrangement of a place for summer vacations;

- protection from precipitation of the site in front of the entrance, pool, walkways around the house;

- car placement;

- awning over the barbecue area;

- sheds for household needs.

The use of polycarbonate allows you to create roofs of various configurations - single slope, gable, pyramidal, arched, concave and convex with a small bending radius. The canopy design can be improved by using colored or tinted fiberglass.

Project development

When planning the installation of a canopy attached to the house, photos of finished projects must be viewed in advance. The choice of design depends on several criteria:

- purpose and intended size of the object;

- total area of the site;

- wind and snow loads;

- annual precipitation;

- depth of snow cover;

- the condition of the walls and foundation of the building;

- house construction;

- availability of materials, tools and fasteners, as well as construction skills, if the work will be carried out on their own.

Next, they make a drawing of the canopy attached to the house (photos confirm this), putting down the real dimensions of the height, length and depth of the structure. Based on this, the amount of material for creating the frame and roof is determined.

Standard sizes of a carport:

- 250 × 500 cm for a machine up to 4 meters long;

- 350 × 660 cm for SUVs and cars longer than 4 m.

Helpful advice! A machine with a load on top must freely drive under the canopy. But if the roof height exceeds 230 cm, precipitation will inevitably fall on the car. There is a way out - you need to change the angle of inclination of the roof.

Preparatory work

If all of the above aspects are taken into account, you can start preparing the site for construction. The marked area is cleared, trees and bushes are uprooted. The existing sod is removed to the depth of root germination. The cleaned area is leveled by adding sand or fine gravel, and tamped.

Related article:

|

Under the supports of the canopy attached to the house (the photo clearly demonstrates this), pits are drilled with a section of 20 cm, 50-60 cm deep (up to dense soil). At this stage, it is necessary to provide for laying the cable under the lighting fixtures. The spacing of the supports depends on the area of the extension, as well as on the material of the frame and the weight of the roof. The heavier the structure, the more often the pitch of the posts (on average, after 1-1.5 m). The advantage of such a foundation is that it does not need to be joined to the main foundation of the building.

Asymmetric design canopy over the porch of the house

A bucket of rubble is poured into the finished recesses, vertical racks are installed in them and poured with concrete. Each post is level. The second option - embedded parts with brackets are concreted in the pits, and the pillars are already fixed in them.

Materials should also be prepared before installation: the wood is impregnated with an antiseptic, drying oil or painted in the selected color. Lumber is chosen dry and always sanded, otherwise woodworms will quickly start under the bark.

Helpful advice! EIf the house is in a lowland, the ends of the wooden supports are additionally waterproofed (wrapped with a polyethylene or roofing felt jacket, poured with hot bitumen).

Metal posts must be coated with a primer containing zinc phosphate. And it is better to immediately purchase a galvanized or aluminum profile.

While the concrete in the pits is gaining strength, it is possible to arrange a floor covering for the shed. Options:

- pour concrete screed;

- lay paving slabs or a board;

- cover with sand or gravel.

Installation of a polycarbonate canopy attached to the house

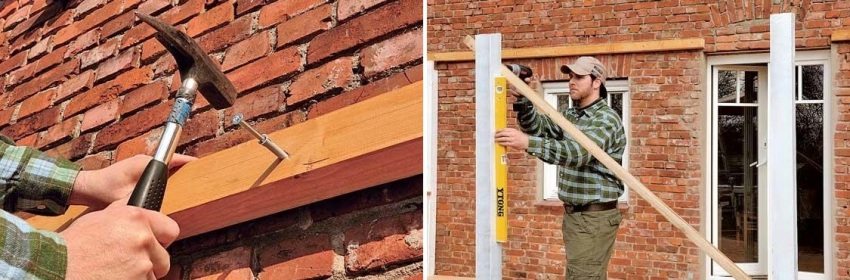

Having sustained a certain time for the concrete to set (10-15 days, depending on the air temperature), we begin the assembly of the structure. First, to the outer wall of the house, where it will adjoin polycarbonate canopy, several brackets are attached. A load-bearing transverse beam is mounted on them.

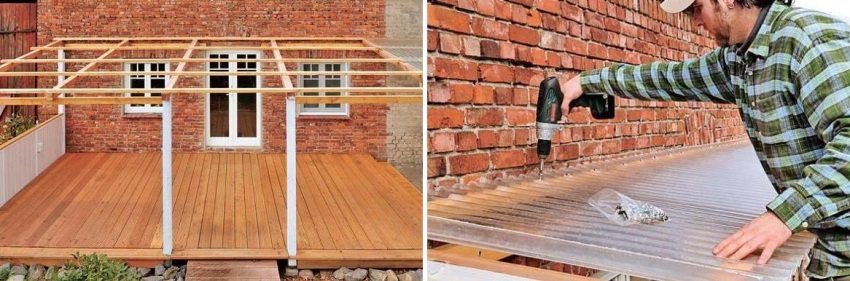

Canopy lathing

Next, the top strapping is made. The ends of the concreted vertical pillars are connected first to the transverse beam, then to each other. This is done using parallel-laid profiles. If the frame is metal, the parts are welded, if it is wooden, they are pulled together with steel corners... Weld seams are cleaned, primed and painted.

The rafters are attached to the crossbeams in 60 cm increments. The connection to the structural beam attached to the wall is made using steel corners... The lathing is laid across the rafters, with a distance of 30 cm, and is fastened with self-tapping screws. The diameter of the timber for the frame:

- Racks - 120 × 120 mm.

- Cross beams - 100 × 100 mm.

- Rafters - 70 × 70 mm.

- Lathing - 50 × 50 mm.

Section of the steel profile for the frame:

- racks - 40 × 60 mm;

- rafters and lathing - 30 × 50 mm.

Roof installation

Fiberglass sheets are cut to size and screwed to the crate, after having drilled holes for fasteners in them. In this case, it is necessary to ensure that the plastic cells are directed downward - to drain condensate. Self-tapping screws must have a rubber thermal washer. The sheets themselves are interconnected by an H-shaped profile.

Overlapping the polycarbonate canopy attached to the house (the photo can be seen in various magazines), you must follow the rules for pairing compression seams. Simply put, you need to leave small gaps between the panels so that the polymer can expand without hindrance when heated. The dimensions of the holes for fasteners should also have a margin of 2-3 mm. Remove the protective film from the sheet after installation.