Choosing technology and material for building a house, many owners give preference to houses from a bar. This decision is due to several positive aspects, including the ability to independently carry out all the necessary work. Consider how the construction of houses from a bar with your own hands should be carried out, so that in the end you get a beautiful and reliable building.

Content [Hide]

- 1 DIY construction of houses from a bar: the rules for choosing wood

- 2 Diy log house: which is better, solid, glued or profiled timber?

- 2.1 Construction of a wooden house from a profiled bar: advantages and disadvantages

- 2.2 Construction of a wooden house from a bar: the advantages of using a solid bar

- 2.3 Features of the construction of houses from laminated veneer lumber

- 2.4 Glued laminated timber house: reviews and recommendations of the owners

- 2.5 Wooden houses from a bar: preparation for self-construction

- 3 On what foundation should you build a house from a bar: selection rules

- 4 How one-story houses are built from a bar: step-by-step instructions for building walls

- 5 How to build a house from a bar: features of installing the roof and floor

- 6 Features of finishing a house from a bar: photo examples

- 7 Turnkey log houses: examples, projects, prices and descriptions

- 8 Finnish houses made of laminated veneer lumber: what they are and how they differ from the rest

- 9 Rules for caring for a house from a bar: how to extend the life of a wooden house

- 10 How to build a house from a bar on your own: video instruction for beginners

DIY construction of houses from a bar: the rules for choosing wood

Choosing the right quality wood is the first and one of the most important aspects that determines the success of a construction. And since wood, like any other material, has its own characteristics and advantages, it is worthwhile to take a responsible approach to its choice and purchase.

Thanks to the use of laminated veneer lumber for construction, the building will be strong, reliable and durable

The first characteristics that you should pay attention to when choosing wood are its density and strength. For different types of wood, this indicator is different and there are even those that are in no way inferior to metal. Therefore, in the selection process, it is important to pay attention to this, since even a small house from a bar should be built so that it can withstand serious loads without problems.

Here are the basic requirements that a good log house must meet:

- walls must be strong, reliable and durable;

- the level of heat and sound insulation should be high enough;

- the project must be designed in such a way that the loads do not provoke subsidence and deformation of the walls.

If you decide to build a house from a bar, then achieving these indicators is more than realistic. And, nevertheless, with some shortcomings of wood you still have to put up. So, for example, a timber has an extremely low level of fire safety. In addition, it tends to react negatively to precipitation, partially deformed as a result of their impact.

The quality of wood for building a house determines the duration of the service life of the entire building

Important! The process of sedimentary deformation is especially relevant for the first few years of house operation. In the future, if this will be observed, then to a much lesser extent.

It is best to build a house from a bar from coniferous trees. Thus, you will receive several advantages at once: the service life of such a bar is quite long, while it is maximally resistant to decay processes, has a low weight, which has a positive effect on the foundation and does not crack over time.

Thus, the choice of a suitable material is no less important issue than compliance with the prescribed construction technology. In the buying process, you should pay attention to the quality of the purchased wood, choosing only the best material that can serve for many years.

In order for the building to have all the necessary characteristics, it is worthwhile to familiarize yourself in advance with the advantages and disadvantages of timber as a material for construction

Diy log house: which is better, solid, glued or profiled timber?

There are two types of timber: solid and profiled. Both options are used to build houses, but in order to make a choice in favor of the most suitable option, it is worth considering the advantages and disadvantages of both.

Construction of a wooden house from a profiled bar: advantages and disadvantages

In the case of using a profiled beam for the construction, a profile is definitely required. In this case, these can be spikes or crown grooves. With their help, the bar is fastened along the entire length, after which it is polished. Usually, timber for construction is sold already in a completely finished form, so the owner only has to assemble the structure from the elements provided. Here are the advantages of such a solution:

- resistance to deformation of such buildings is extremely high;

- with this technology, the costs of construction are significantly reduced;

- the construction technology of such a house is somewhat simpler than in all other cases;

- the surface of the walls is flat, which eliminates the need to additionally sheathe them;

- rain and melt water will not collect inside the walls, so the level of protection against decay can also be called quite high.

Important! In the production process of high-quality profiled timber, certain calculations are made to prevent precipitation from entering the seams between the joints.

The clear and beautiful shape of the material allows you to carry out all the necessary construction work as quickly and efficiently as possible. In addition, these houses are characterized by a high level of thermal insulation and have an attractive appearance.

After the house from the profiled house is settled, there is no need to waste time and effort to seal the walls. Natural wind protection of the walls of such a house will be quite sufficient, and the thermal insulation also turns out to be quite decent due to the high density of the crown joints.

Of course, like any other material, the profiled bar has its drawbacks.For example, it does not tolerate any atmospheric influences. In addition, the material ignites extremely easily and actively supports combustion. In order to somehow reduce these negative factors, wood must be treated with a special protective impregnation.

Important! Due to the influence of natural atmospheric humidity in warm weather, the timber often cracks. Therefore, it is worthwhile to attend to the search for such a material, the moisture content of which was initially reduced to at least 20%. This is done using chamber drying technology.

Another important aspect is that the thickness of the walls made of profiled timber is not enough for comfortable living in the rather harsh climate of our country. Therefore, it is best to resort to additional external insulation.

Construction of a wooden house from a bar: the advantages of using a solid bar

Of course, you should pay attention to the construction of houses from a solid bar. Despite the fact that its appearance is significantly inferior to the first option, it is widely used in construction and has some advantages. One of the main ones is cost. Another important factor is that in the process of wood preparation, its natural moisture is preserved, which significantly reduces the duration of the preparatory stage and eliminates the need for a number of additional measures.

It is somewhat easier to buy a solid bar than any other type, since the production of this material takes significantly less time. In addition, in order to build a high-quality house from a bar, the involvement of special equipment is not required.

But this solution has its drawbacks:

- the surface of the walls will definitely require serious finishing work, which will increase costs. Most often, such houses are sheathed with siding or clapboard;

- there is still a danger of acquiring low-quality material due to inexperience;

- solid timber is susceptible to fungal attack, since there is no special drying procedure. This can be partly solved by using special impregnations, but this will also entail costs;

- because of the seams between the joints, such a house is blown through quite strongly. Therefore, you will have to think about high-quality thermal insulation in any case;

- very often cracks appear in the wood after shrinkage.

Features of the construction of houses from laminated veneer lumber

Turnkey houses made of laminated veneer lumber are not uncommon today. This wood product is very actively used in construction and is quite suitable for independent project implementation. One of the main advantages of such a solution is that the box of the house is being built quite quickly. At the same time, the walls are extremely durable and capable of withstanding serious loads.

Thanks to the special production technology, you do not have to worry that the glued timber will crack or deform under the weight of the roof, due to the fact that the fibers of the lamellas are directed in different directions. Glued laminated timber can be called an environmentally friendly material. True, there is one subtlety here - during production it is important how high-quality the adhesive used was, since it is its components that can have a negative effect on the health of people living in the house. That is why the price of a house made of laminated veneer lumber should not be too low.

Glued laminated timber is the best resistant to fire. In order for such a house to catch fire, it will take about 10 minutes of continuous exposure to open fire. Also, this type of timber is resistant to the process of decay, as well as the appearance of mold.

Interesting!Insects do not live in the walls made of glue bar, since every detail is carefully dried and fastened very tightly. For the same reason, rainwater and snow do not get inside.

Build glued laminated timber house you can do it yourself using a ready-made project

Do not forget about some of the difficulties associated with building a house from laminated veneer lumber. Reviews of the owners, for example, indicate that such material is not very cheap, and it cannot be called accessible to everyone. In addition, as already mentioned, the quality of the glue used in the production process plays an important role, which is practically impossible to verify for sure.

Sometimes you have to deal with the fact that the manufacturer irresponsibly approached the process of forming a profile and or a corner lock of a part. In this case, you may encounter a violation of the proportions of the entire box, which will negatively affect the entire building, which means that the price of a turnkey glued log house in this case will be completely unjustified. It is also worth noting the rather low level of thermal insulation of such material: glued laminated timber practically does not retain heat inside the building.

Related article:

How to build your own house with your own hands and how to do it cheaper

The main stages and important nuances of building a house. Budget projects based on various materials and the right ways of saving.

Glued laminated timber house: reviews and recommendations of the owners

Taking into account the cost of building houses from laminated veneer lumber, before starting construction, it is useful to pay attention to what the owners of such buildings say, because only they can provide the most truthful information about the quality and practicality of the operation of such houses.

Glued laminated timber is an environmentally friendly material, but you should pay attention to the availability of quality certificates from the manufacturer

“We contacted a company that is engaged in the construction of turnkey houses from glued laminated timber. The construction itself took about 1.5 months. We are living for the second year and have already gone through one winter. I can say that the house is very comfortable. The heat is well preserved and there are no problems with blowing the wind. "

Vyacheslav, Yaroslavl

“Not surprisingly, the cost of a laminated veneer lumber house is the highest. While I was studying the options, I read many times that this is the best option. Therefore, I built one for myself. In general, wooden houses made of laminated veneer lumber are like a good constructor: it is extremely easy, pleasant to work and everything is very fast. "

Yuri, Krasnodar

Wooden houses from a bar: preparation for self-construction

Having decided which type of timber is more suitable for the construction of your house, you can proceed to the preparatory work and the purchase of materials. The easiest way is to order a timber of the required size. Then all that remains to be done is to lay out a box out of it according to the instructions from the manufacturer.

The construction of a two-story house from a bar requires careful calculations in order for the construction to be safe and have a long service life

In the process of preparation, be sure to pay attention to the fact that the wood used is of proper quality. If large cracks (especially through cracks) are detected, the element must be replaced without fail. It is also necessary to inspect for the presence of traces of insects. In addition, do not forget about the importance of processing the material with antiseptic agents.

In order to carry out all the necessary work on the construction of the structure on your own, you will need a set of tools, among which there must be:

- electric or gasoline saw;

- building level;

- electric drill;

- yardstick;

- puncher;

- ax;

- a hammer;

- electric screwdriver;

- nails, screws and other fasteners.

A project for building a house can be developed independently or purchased from a construction company

Equally important is the presence of a drawing of a house from a bar. In the process of drawing up a detailed plan, all the necessary calculations must be carried out. And although all this can be done independently, many people prefer to turn to specialists in order to eliminate the risk of an error, which can lead to serious consequences.

On what foundation should you build a house from a bar: selection rules

Having prepared all the necessary drawings and materials, you can start laying the foundation of the future home. And in order to choose the most suitable type of foundation in a particular case, it is worth taking into account the following factors:

- characteristics of the soil available on the site;

- calculations that allow you to determine the expected load on the foundation;

- other design features of the house.

The foundation for a house from a bar must be selected based on the parameters of the building and the geological data of the area

Both wooden and concrete foundations can be used as a base. Moreover, they often resort to just the second option, laying out a brick base on top, and already laying out the walls from a bar on top. Although a wooden base is also perfectly acceptable.

The construction of a log house can be carried out on a columnar foundation, as well as on a strip basis. They also resort to both buried and shallow foundations. But given the small total weight of the structure, the base is usually made not too large. Most often, 50-70 cm is enough for the house to stand securely.

How one-story houses are built from a bar: step-by-step instructions for building walls

Building a house from a bar with your own hands without building experience is actually not as bad an idea as it might seem at first glance. It is quite possible to lay it yourself, especially if you decide in advance on the assembly technology. The walls themselves are laid out in rows, simply laying the next layer on the previous one, until the wall reaches the desired size.

The adhesion of the logs to each other is ensured by special grooves. But these places must be additionally insulated to prevent heat loss. And in order to increase the strength of the walls, it is recommended to additionally fasten the beams together with the help of special spikes.

The minimum amount of hassle will be in the case of using untreated pine timber, since due to its low weight, the layout can be done manually without using special equipment.

When erecting walls from a bar on your own, it is worth remembering two basic rules:

- all seams must be caulked in order to reduce the wind blowing of the walls;

- after the walls are laid out, they must be opened with a special compound, which will give them additional strength and fire resistance.

In other respects, one-story houses from timber: glued, solid or profiled, anyone can build. Simple but effective technology will make the structure strong and reliable.

How to build a house from a bar: features of installing the roof and floor

In trying to save money on building a house from a bar, many make a common mistake, not paying due attention to the quality of the roof. Often cheap materials are used for it, like ondulin. Doing so is strongly discouraged, since the roof is, first of all, safety.

Depending on the possibilities, as well as the individual preferences of the developer, the roof can have a very different look. It depends on the type of roofing and rafter system. But in any case, each section should be equipped with boards of various sizes, for example, if elements of 150x40 mm were chosen for the rafters, then 100x40 mm should be taken for the racks and braces.

As for the features of the floor arrangement, the main factor here is the choice of the home owners. The main thing is to take care of the proper level of heat and waterproofing, so that the coating does not soon become unusable. The same applies to the installation of the ceiling.

Important! If the house has a basement or basement room, you should pay attention to the issue of its waterproofing. In this case, it is necessary to lay a layer of waterproofing material before leveling or pouring the screed.

In order to ensure the proper level of waterproofing in a wooden house, you can use the following materials:

- waterproofing in rolls;

- coating materials;

- filling systems;

- penetrating moisture protection.

Of course, houses from a bar for permanent residence require investments, but it is better to immediately take care of the availability of a high-quality base and roof, so that in the future you do not have to correct the consequences of mistakes made. The same applies to all materials for thermal and waterproofing.

Features of finishing a house from a bar: photo examples

Having dealt with the features of the technology for building houses from a bar, you should pay attention to some of the nuances of finishing. First of all, work is carried out on the installation of interior partitions, windows and doors. After that, the subfloor, insulation and topcoat are laid. Be sure to trim the ceiling.

Important! All work on the laying of communications (water supply, sewerage, power supply and heating) must be completed before the start of finishing works.

As for the exterior decoration, there are many options: you can leave everything as it is, so that the log house looks as natural as possible. But in this case it is worth making sure that the timber you are using looks attractive enough for this. Another option is to sheathe the walls using siding and then paint it. Lining and other similar materials are used in the same way.

Turnkey log houses: examples, projects, prices and descriptions

Despite the simplicity of the technology, not every site owner wants to tinker with building a house on his own. Therefore, there are special companies that are ready to build a turnkey log house by implementing one of the standard ones or your personal project. Let's consider what the best construction companies are ready to offer their clients.

You can choose a turnkey log house by looking at the catalogs of finished projects from a construction company

Turnkey profiled timber house from DomaTo

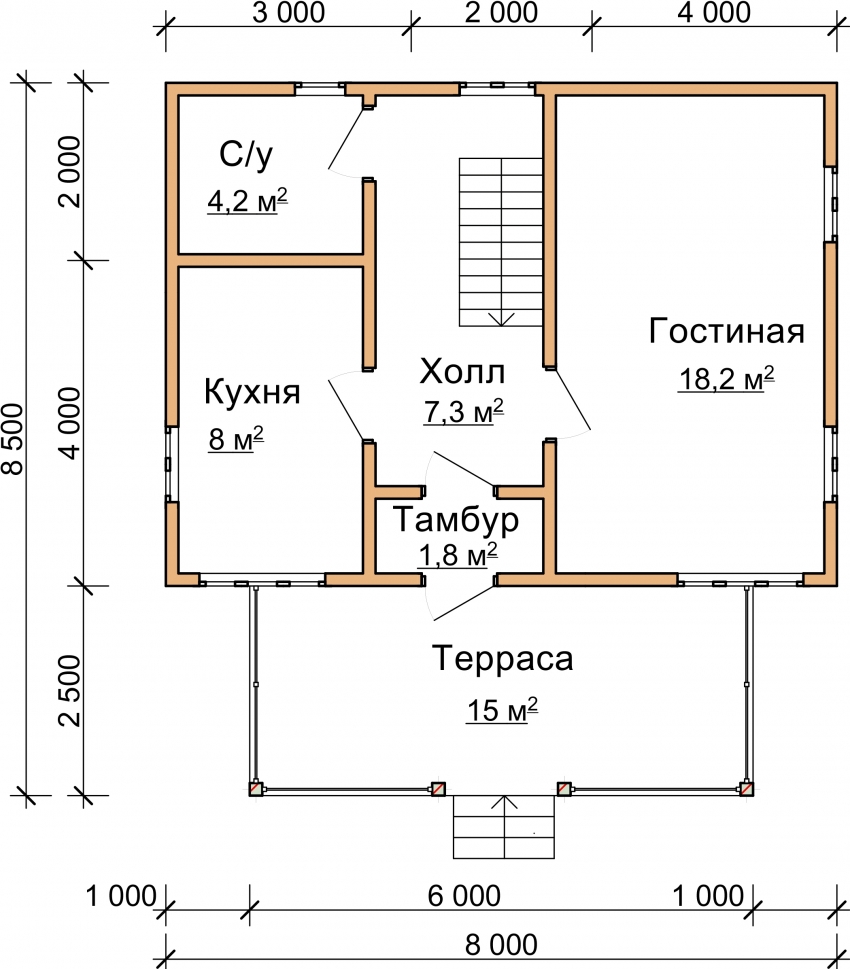

The first typical project of a turnkey log house, the price and quality of which will pleasantly please the customer, is called D1. It covers an area of 7x9 m, and its total area is just over 125 m². Such dimensions allow the whole family to comfortably accommodate.

This house is made of timber with an attic, that is, in fact, it has 1.5 floors. In addition, the plan provides for a spacious terrace, as well as a spacious balcony on the top floor of the house. In the summer season, this area is simply irreplaceable for recreation.

Consider in more detail the technical characteristics and features of this structure:

- initially, the project provides for a columnar foundation, but if desired, the company's specialists are ready to individually calculate a tape or pile-screw base for your home;

- the strapping is made of 100x150 mm timber. Elements of the same size are placed as genital lags, with a step of 90-100 cm;

- for the walls of the first floor, a profiled beam of 95 (145 or 190) mm by 145 mm is used on a jute canvas. Interior partitions are made of 95x145 mm timber;

- walls of the second floor - profiled timber 95x145 mm;

- the windows are provided with double glazing. All accessories are also included. The entrance door is metal, without fittings;

- for rafters, boards of 40x100 or 150 mm are used, maintaining a step of no more than 90 cm;

- the roof of the house - ondulin (it is possible to choose a color: brown, red or green);

- the height of both the first and second floors is 2.5 m. For filing ceilings, lining is used;

- the staircase to the second floor is wooden and can be either one-flight or two-flight.

The project of a house from a bar should be drawn up in such a way as to optimize the loads and prevent subsidence and deformation of the walls

What exactly will be the price of building a turnkey log house, the company's specialists calculate individually, taking into account many factors, including the individual wishes of customers. The only thing that can be identified with absolute certainty is the cost of materials offered by this company:

- timber 100x150 mm - 744 rubles;

- timber 150x150 mm - 806 rubles;

- timber 150x200 mm - 898 rubles.

We can say with confidence that the construction of houses from a turnkey bar may not be the cheapest option, but more than justifies itself, since it saves you from having to do everything yourself.

Helpful advice! Before finally deciding on a company that will build your house, it is advisable to talk with specialists from several companies. You can order free calculations of the cost of construction from them, and then choose the most profitable for yourself.

Summing up, we can say that a log house is a great idea, which, in fact, is not so difficult to implement. Almost all the necessary work, if desired, can be carried out independently. You can also contact one of the companies that specializes in this matter and will be able to quickly and efficiently build a house from turnkey glued laminated timber.

"Woodstail" - a house made of laminated veneer lumber: photo, description, reviews, cost

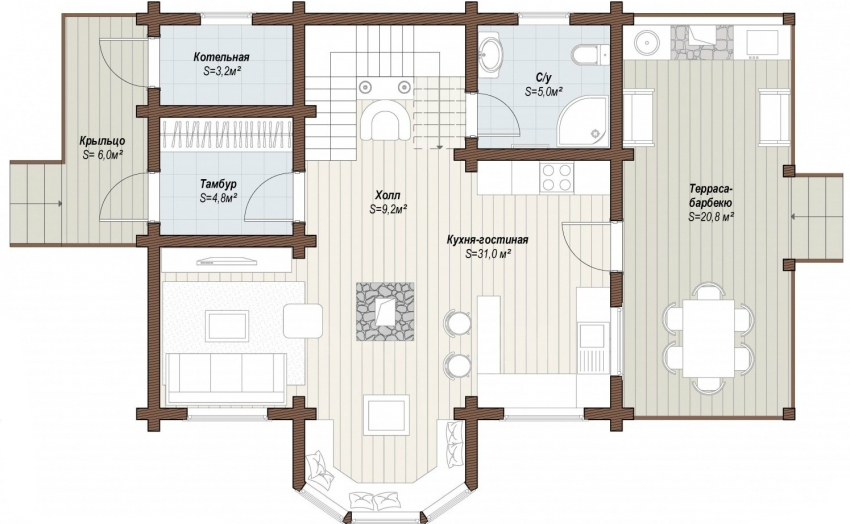

To consider in more detail the question of how much it costs to build a house from a bar, you can use the example of this model. The construction company advertises the cost of 1,303,170 rubles. The total area of the house is 118.37 m² (9.7x9.3 m).

The cost of building a turnkey house from the Woodstail company includes laying the foundation, erecting walls and a roof

So, this price of a house made of laminated veneer lumber from the manufacturer "Kedr" includes the following types of work:

- laying the foundation;

- erection of walls from glued laminated timber with a height of 2.7 m. The assembly technology provides for the use of wooden dowels, which are located at a distance of 1.5 m. In addition, a 5 mm linen-jute canvas is laid between the crowns. All surfaces must be treated with a protective compound;

- for floors, a waterproofing material is used - hydrostekloizol;

- for overlapping between floors, beams of 50x200 mm are used;

- for the attic floor, a 50x150 mm timber is used;

- rafters - timber 50x200 mm. Crate made of edged boards 25x100, the pitch of which is 25 cm. It is used as a roofing material metal tile.

Interesting! This company offers its customers an interesting service - weekly photo reports on the work done by e-mail. This allows you to observe the process, while not wasting time on trips to the construction site.

Turnkey one-storey log houses: project OD-7 8x12

As an example of a one-storey house, consider the project proposed by the company "Domabrus". The price of building a house from a bar in this case directly depends on the thickness of the material used. Customers are offered three options to choose from:

- timber 100x150 mm - 720,000 rubles;

- timber 150x150 mm - 806,000 rubles;

- timber 200x150 mm - 900,000 rubles.

The cost of building a turnkey house from the "Domabrus" company depends on the thickness of the timber used

Initially, a support-column foundation is provided, however, it is possible to replace it with a pile-screw foundation for a fee. For strapping, a timber of natural moisture 150x150 mm for the 1st row and 150-100 mm for the 2nd row is used. The lags of the floor are made of 50x150 mm timber with a step from 60 to 70 cm.

A timber of natural moisture 90x140 mm is used as a material for the walls, together with a jute insulation, the thickness of which is 4 mm. For partitions, the same timber is used, but already without insulation. The blockhouse is assembled on wooden birch dowels.

For the ceiling, take a beam of 50x100 mm with a step of 60-70 cm, and then additionally hem the Euro-lining of category "B" and roll insulation, which provides the proper level of thermal insulation. The vapor barrier material is laid on both sides. Usually Nanoisol or its analogs are used.

Rafters - timber 50x100 mm, located at a distance of 800 mm. Ondulin is used as a roofing material in one of three colors: brown, cherry or green. The 30-centimeter overhang is hemmed with clapboard.

The windows in the house are wooden, with double glazing, and all the necessary fittings. In addition, blind interior doors are installed.

Helpful advice!If you are in no hurry to move, you can order a house made of timber for shrinkage. In this case, the structure should stand for 6-12 months without finishing materials.

Finnish houses made of laminated veneer lumber: what they are and how they differ from the rest

Interested in the question of how to build a house from a bar, every reader will certainly meet the wording "Finnish house from a bar". Let's consider what it is, and what advantages these structures have.

These houses got their name from a Finnish company that produced excellent quality laminated veneer lumber. Thanks to the latest technologies, as well as considerable experience in this area, their products have won a leading position in the market, which is the reason for the emergence of such a name.

What are the advantages of Finnish houses in comparison with Russian counterparts and why do many prefer them? The answer is extremely simple - it all depends on the quality of the raw materials used. Of course, the market situation is constantly changing, and today many domestic companies are quite capable of competing with Finnish competitors, but the reputation of the latter still keeps them at the forefront.

The price of a house from a bar, built using Finnish technology, is determined by many factors and aspects. This includes the materials used and the size and complexity of the structure. All this can be calculated in advance by drawing up a detailed project and estimate.

What is the secret of Finnish glued laminated timber? Historically, in the post-war years, Finnish growers abandoned the use of trees that grew by themselves. For this purpose, territories throughout the country were specially planted. The same growing conditions and care did their job, and almost all trees differed in the same size and shape, which significantly increased the quality of the laminated veneer lumber that was made of them.

Interesting! Today, Finnish houses have extremely little in common with Finland, and in fact, this phrase practically means simply profiled timber made using a special technology.

It is important to understand that the cost of building houses from a bar of this type is almost never low, and usually exceeds the Russian counterparts by at least 2 times. This is due to many factors, including careful quality control of products, as well as our own unique manufacturing technology.

Rules for caring for a house from a bar: how to extend the life of a wooden house

Looking through the options for houses from a bar: photos, prices and characteristics, many are wondering what needs to be done in order for the building to last as long as possible. Consider the recommendations of experts on how to properly care for a wooden house and what can be done for each of its constituent parts:

- The roof of a log house requires additional protection from moisture, since it is this that leads to the destruction of the structure. To avoid this, the outer roof covering must be solid and of high quality, and technical inspection must be carried out at least 2 times a year. You also need to regularly clean the roof of dry leaves, moss, lichens, etc. Otherwise, moisture may accumulate there. It is extremely important not to allow the appearance of scratches on the surface, as even seemingly insignificant defects can seriously degrade the performance of the roof.

- The walls of a house made of timber also require maintenance, which should be expressed in regular treatment with a protective compound that prevents the appearance of fungus and mold. The joints are considered the most problematic area, so more attention should be paid to their inspection and processing. It will also be extremely beneficial to treat the surface with fire retardants that prevent combustion and protect the house in the event of a fire.

- Oddly enough, windows and window openings of a wooden house also require careful maintenance. So, in order to prevent decay processes, it is necessary to apply special compositions to them several times during the year in the following order: antiseptic, primer, water-dispersion paint.

If you regularly pay due attention to a wooden house, you can be sure that it will regularly serve for many years, without succumbing to the destructive effects of external factors.

How to build a house from a bar on your own: video instruction for beginners

Since the price of a turnkey prefabricated log house is often quite high for buyers, many people prefer to carry out their own installation. And in order to avoid the common mistakes in this case, it is worth watching the training video. Building a house from a bar is a task that can be done for everyone. It is enough just to listen to some advice and recommendations.