The roof is an essential element of any building and structure. It is designed to protect the home from the effects of atmospheric precipitation and retain heat in the premises. Since ancient times, people have learned to cover the roof with various natural materials. With the development of science and industry, many new substances were invented, which became the basis for modern roofing. Roofing materials: types and properties, pros and cons, installation methods, you need to know before deciding to purchase any of them.

Content [Hide]

Roofing materials: types and properties

All materials for roofing today are usually classified into three main types:

- leafy roofing materials;

- flexible roof;

- piece materials.

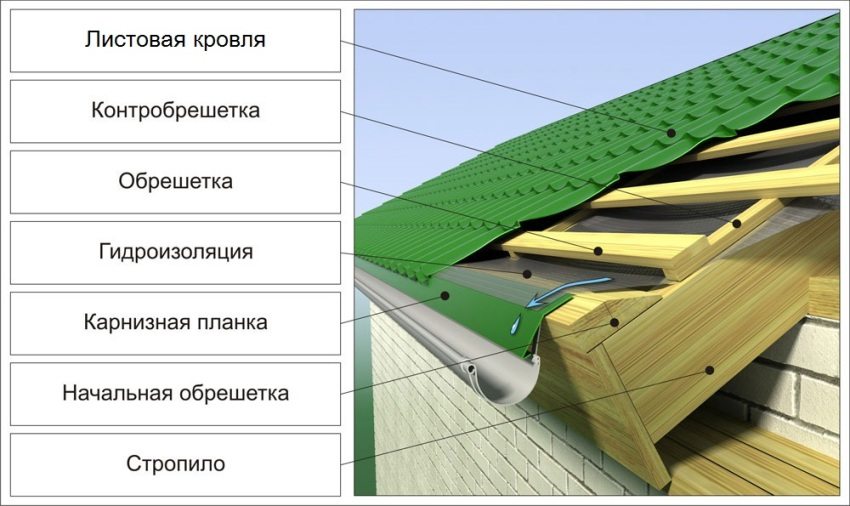

Already from the name it is clear what they are. All sheet materials are in the form of sheets of various sizes. Fastening them to the roof is carried out with screws or nails. They can be flat or more often profiled. Such products are very easy to install and do not require additional equipment other than hand tools.

Various types of roofing: 1 - ceramic tiles, 2 - sand tiles, 3 - soft tiles, 4 - metal tiles, 5 - slate, 6 - corrugated board, 7 - seam roof, 8 - copper roof

Flexible roofs are made from materials that are flexible and soft. They can be easily mounted on roofs of any complexity. Such materials can be piece or roll, self-adhesive or welded with torches. For installation on a wooden roof, a solid batten is required.

Piece roofing materials, the types and properties of which will be described below, are made in the form of separate small-sized elements. They are made from natural raw materials according to ancient technology with roasting. Therefore, they are expensive.

To better understand the technical characteristics of all roofing materials, the types and properties of each of them need to be considered in more detail.

Sheet materials

This type of materials is represented by a wide variety of types, differing in physical properties, dimensions, installation method and cost. Sheet materials include:

- metal tiles;

- professional flooring;

- ondulin;

- slate;

- folded metal coverings.

All these types have one feature in common - they look like rigid sheets that are overlapped on the roof.

Metal tile

It is made from steel coated with zinc.Galvanized sheet is rolled and stamped, after which it takes a shape that imitates natural tiles. Then the products are painted and covered with a thin polymer coating that protects against corrosion. The industry produces sheets up to 8 m long and 1180 mm wide. The thickness of the steel can vary from 0.4 to 0.6 mm. Thanks to these parameters, the weight of the finished product does not exceed 3 - 5 kg / m2... Therefore, such material does not require a powerful rafter system... Metal tiles come in a variety of profiles, both in size and shape.

Mounting this material is carried on roofs with a slope of at least 15 degrees. The sheets are laid with an overlap, connecting along the waves. Fastened metal tile using self-tapping screws with rubber washers. This material is durable, reliably protects the roof from precipitation and wind, and has a reasonable cost. He has only one drawback - noise in heavy rain, and even more so hail.

Profiled flooring

Nothing special in terms of technical characteristics does not differ from metal tiles. Manufactured using the same technology. However, there is no stamping step here. Only the rental remains. Unlike metal tiles, there is no stamped relief on it, but only longitudinal waves. They can also be of various shapes.

Helpful advice! Decking is easier to use on complex roofs. There is no need for it to "fall" into the stamped steps during installation.

Installation of corrugated board on the roof carried out by a similar technology, the sheets have similar geometric dimensions. There are different types of metal thickness and rib height. It is one of the most common roofing materials. The types and properties of corrugated board determine parameters such as steel thickness and profile height. Sheets of this material can reach 0.9 mm in thickness, and the profile can rise to a height of 8 to 60 mm and have the shape of a triangle, rectangle, square or trapezoid. In some species, the edge is not cut evenly, but in waves.

This roofing material has the same pros and cons as metal tiles, but inferior to them in design. For this reason, it is more often used to cover outbuildings, garages and industrial facilities.

Ondulin

It is a material made from environmentally friendly raw materials - cellulose. For the production of sheets, the raw material is pressed, given the desired wavy shape and heated to 120 degrees. After complete drying, a sheet is obtained that looks like slate, but with completely different properties. It is impregnated with polymers, bitumen and painted in the desired color. Ondulin safe, environmentally friendly and completely waterproof. It is a very light material: a standard two-meter sheet 0.95 m wide weighs 6.5 kg. This allows you to do without massive elements of the rafter system.

Due to its flexibility, ondulin can be used on roofs of any complexity. For its installation, a solid crate is used, and it is nailed to the very top of the wave. Two people can easily cope with the work. Of the shortcomings, some fragility should be noted. Incorrect stacking may damage the sheets by large hail.

Helpful advice! Ondulin can not be used in child care. It is highly flammable and gives off a bitumen odor at high temperatures.

Slate

It was once the most popular and cheapest of all types of roofing materials. Its properties and characteristics are such that today it is being replaced by new coatings everywhere. Slate sheets are made of an asbestos-cement mixture (85% - cement, 15% - asbestos). There are several varieties, differing in thickness, number and height of waves, as well as sheet size. As a standard, corrugated slate sheets weigh 10 - 15 kg. Their length is 1750 mm, width is 980 - 1130 mm. He has waves - 6, 7 and 8.

Of the positive qualities of this material, it can be noted: low cost and waterproofness, as well as a long, up to 40 years, service life. It has more negative properties: asbestos is harmful to health, the sheets are very fragile and break with little impact, the material has a large specific gravity. In addition, moss may appear on sheets in shaded areas during operation.

Slate covers roofs with a slope of 12 to 60 degrees. The lathing can be made of bars with a cross section of 50 mm in increments of 50 to 55 cm. The sheets are nailed down with special slate nails or gaskets are made under ordinary nails. Today this material is used to cover the roof of outbuildings and warehouses.

Folded materials

These are metal strips with a flat surface. They have special locks, called folds, which are upright and recumbent. Sheets are made of galvanized steel and can be coated with a polymer coating. Since the material is flat, it can freely bend in an arc, which allows it to sheathe hangar-type roofs.

Installation of folded sheets is carried out using a special machine that squeezes the locks. Laying is done in parts. To do this, lay out several sheets on the ground and fasten them along the length with standing folds, and across the width with lying folds. The resulting "picture" is laid on the roof section and attached to the crate with narrow steel strips, which are called cleats. The roof slope must be at least 14 degrees. With a smaller slope, the base becomes solid.

Helpful advice! If there are no financial restrictions when building a house, then you can use copper or aluminum folded sheets. They look very beautiful and rich, but have a high cost.

All main sheet types of roofing materials are described. Their properties and characteristics are different. Which one to choose in a given situation depends on the preferences of the consumer and his financial capabilities.

Flexible roof

The main properties of flexible roofing are clear from its name. Materials of this type are very soft and can bend at any angle. Flexible roofs can be made of roll type materials and shingles.

Roll materials

Roll materials, such as: roofing felt, roofing felt, bitumen and polymer films of various types can be welded or self-adhesive. They can only be laid on a solid crate or concrete surface. The deposited materials for their installation require the use of a torch or a building hair dryer. For this, the surface is first treated with a mixture of bitumen and gasoline, and then the material itself is fused, unwinding the roll. The roof should have a slight slope (from 11 degrees). Roll materials are often used as waterproofing.

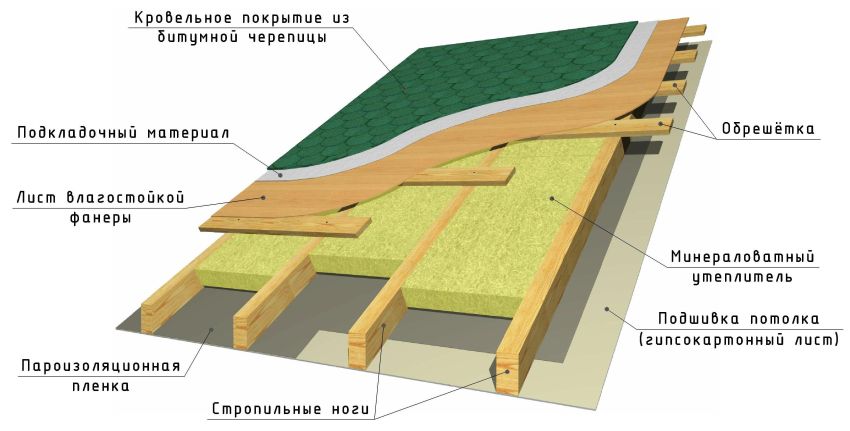

Flexible roof tiles

Flexible shingles are a modern material made of glass fiber impregnated with bitumen and sprinkled with basalt chips. It can be in the form of various small geometric shapes. It comes in different colors. Lay soft tiles on a solid crate, gluing with special glue and fastening with nails.

Soft shingles are small-sized roofing materials. It is 1 m long and 33 cm wide. The underside of the product is impregnated with bitumen mastic, which allows it to be glued to any flat surface. This is the only type of roofing materials, the properties and dimensions of which make it easy to work alone. Install soft tiles necessarily on a solid crate, which is arranged with plywood or OSB sheets... The permissible roof slope during installation is 11 degrees.

Soft tiles can be used for 70 years without noticeable changes. Of the advantages, it can be noted:

- noiselessness in rain;

- presentable view;

- non-susceptibility to corrosion and condensation;

- good flexibility;

- acceptable price.

Insignificant disadvantages include: the appearance of fragility at low temperatures, the appearance of odor in hot weather and increased flammability.

Piece materials

Piece roofing materials are presented: ceramic tiles and slate roofing.

Ceramic tiles

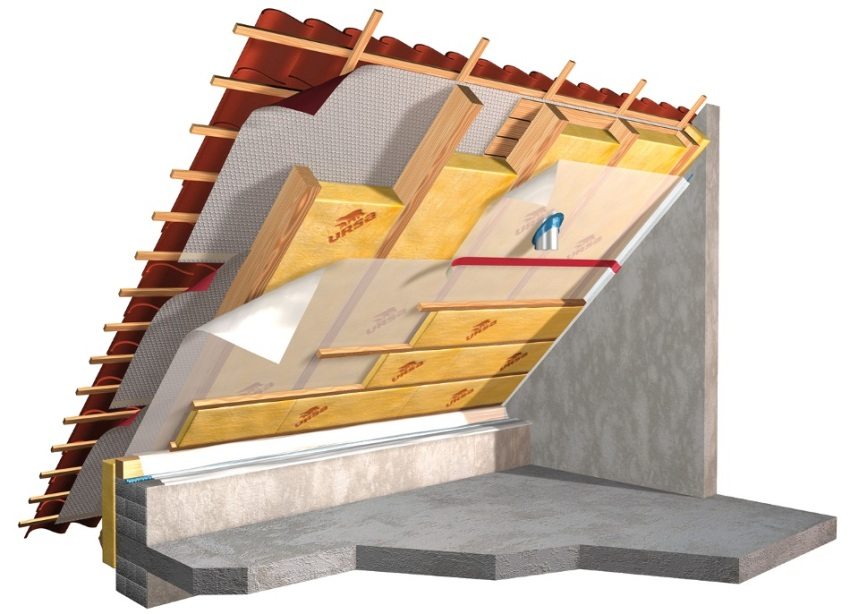

The tiles have a beautiful brick-red hue, which is achieved by high-temperature clay firing. The length of each tile is 30 cm. This beautiful material has different types of products. Each shingle weighs about 4 kg, so a solid rafter system is needed for its construction. This type of roofing materials, the properties and characteristics of which have long been known. This roofing material is not cheap.

Installation of tiles is carried out on slopes with a slope of 25-60 degrees. Each product has holes through which the tiles are nailed onto the lathing with nails. They begin to lay it from the bottom row with an overlap. In this case, the upper tile is placed on the lower one. The finished roof looks like scales. Tiles look best on brick and stone houses, some of which are over 150 years old.

There is a tile made from a sand-cement mixture. It is slightly inferior to ceramic in appearance, but much cheaper.

Slate roof

Slate roofing is the most expensive of the listed types of roofing materials. Its properties and appearance are due to its natural origin. The material looks like flat plates of natural slate. Each plate is processed manually, ensuring the required dimensions: the thickness is 4 mm, and the weight is 25 kgm2, the width is 15 and 30 cm, and the length is 20 and 60 cm.

Installation of such a roof is carried out on nails (2 - 3 pcs per tile). The roof slope is allowed over 25 degrees. With the correct construction of such a roof, it will last about 200 years. The high price is the only significant disadvantage.

When deciding on the use of this or that type of roof, it is necessary to foresee the construction of a rafter system suitable for it.