Most modern public and residential buildings are covered with metal roofing materials. These include metal tiles and decking. They are made using a similar technology, so the only difference is in the shape of the pattern. If in the first one it is made in the form of a tile, then in the second it has the form of longitudinal ridges imitating slate. In order to better understand which corrugated board to choose for the roof, it is necessary to study its varieties and understand the meaning of the marking.

Content [Hide]

Classification of profiled roofing sheet

The profiled roofing sheet is produced by cold rolling of metal sheet. The product has a comb surface. This stiffens and allows the water to flow down the ridges formed by the ridges. The ridges can have various geometric shapes in cross-section, ranging from a triangle to a trapezoid. This does not affect the mechanical properties in any way, but it creates variety in the choice of material. Therefore, it does not matter which corrugated board to choose for the roof: with triangular or rectangular ridges. It's just a matter of taste for the consumer.

Types of protective coatings

The profiled sheet after the rolling mill goes to the shop, where it is protected by electroplating. There are two types of protection:

- zinc coating involves the use of zinc salts as a working substance. As a result of electrolysis, metallic zinc is deposited on the sheet, covering it with a continuous layer. This metal does not react well with oxygen, which guarantees excellent protection of steel against corrosion. The more zinc was spent, the stronger the protection;

- the aluminum-zinc coating is produced using the same technology, only aluminum salts are added to zinc salts. They are cheaper, so this coverage is more budgetary. At the same time, the degree of protection is reduced, which makes it necessary to make another decorative coating from polymeric materials and dyes.

The top colored coating is more of a decorative function, since it is not very durable. However, it is able to somewhat enhance the basic protection.

Helpful advice! You need to be careful when installing corrugated roofing, as this coating can be scratched. Scratches will be clearly visible on the surface, which will reduce the presentability of the object.

Types of decorative coatings

There are also several types of decorative coating:

- glossy polyester - the easiest and cheapest coating option. During installation and operation, it quickly loses its appearance due to scratches and chips;

- matte polyester has great reliability and resistance to mechanical stress. Its structure is similar to velvet, and its thickness is thicker, which allows it to retain color longer and not give glare;

- pural is a polyurethane, with the addition of polyamide, a coating having a thickness of 50 microns. Has high reliability, immunity to low air temperatures and ultraviolet rays. Pural is best suited for application to roofing sheets;

- Plastisol is the most reliable of all types of coatings. The thickness of the PVC layer is 200 microns. This polymer coating has a relief embossing and a line notch. It is intended for use in harsh climatic zones, has resistance to mechanical stress, and is very durable.

All these coatings are applied on a layer of paint, which can be of various colors. The color name may vary from manufacturer to manufacturer, but the most common shades of red, brown, blue and green. You can find bright orange, yellow and purple options for corrugated board. What kind of corrugated board to choose for the roof of his house, each owner decides according to his color preferences.

Types of corrugated board by appointment

Based on the scope of the material, the following types of profiled sheet can be distinguished:

- Roofing (PC) is used only for roofing. It has a profile height of over 20 mm and a wave height of over 44 mm.

- Bearing (H) is used in the construction of frames for various stalls and trade pavilions, sandwich panels and ceilings. It has a wave height of 35 mm.

- Wall and bearing (NS) has a universal purpose. Bearing structures are made of it, walls are faced. The wave has an even greater height (35-44 mm.).

- Wall (C) is used only as a facing material for walls. Its profile is from 6 to 35 mm in height.

All types of corrugated board are cut into standard sheets from 1.5 to 12 m long. At the same time, at the request of the customer, manufacturers can cut sheets of any required length.

Helpful advice! In order not to be mistaken in the amount of material required to close a complex roof, you need to buy 10-15% more. If the sheets are of standard length, the surplus can always be returned to the store.

How to read the marking of corrugated board

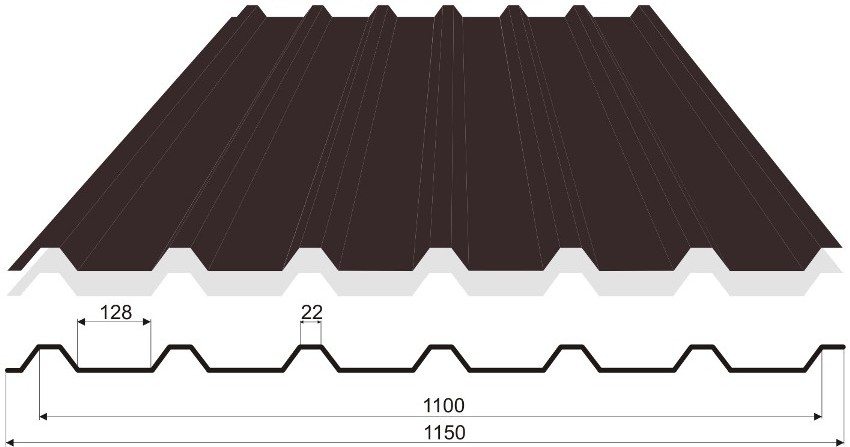

As an example, you can take the marking: НС35-0.5-750-12000. It is simple to decipher it: НС35- means that this is a wall bearing sheet 35 mm thick. The second number is the sheet thickness - 0.5 mm, the third is the width of 750 mm, and the fourth is the length of 12000 mm. The permissible loads on the profiled sheet depend on these characteristics. There is a special table of loads for different types of corrugated board. The permissible load depends on the thickness of the sheet, the distance between the ridges, their height and varies from 50 to 960 kg / m².

Taking into account that sheets with PC marking are used for the construction of the roof, it is necessary to decide which corrugated board to choose for the roof.

Which corrugated board to choose for the roof

Before you start choosing a roofing material, you need to learn the following important things that you should pay attention to when buying:

- it is preferable to buy a product marked - "State Standard" (GOST) than - "Technical conditions" (TU), since state requirements are always higher than the standards of the manufacturer itself;

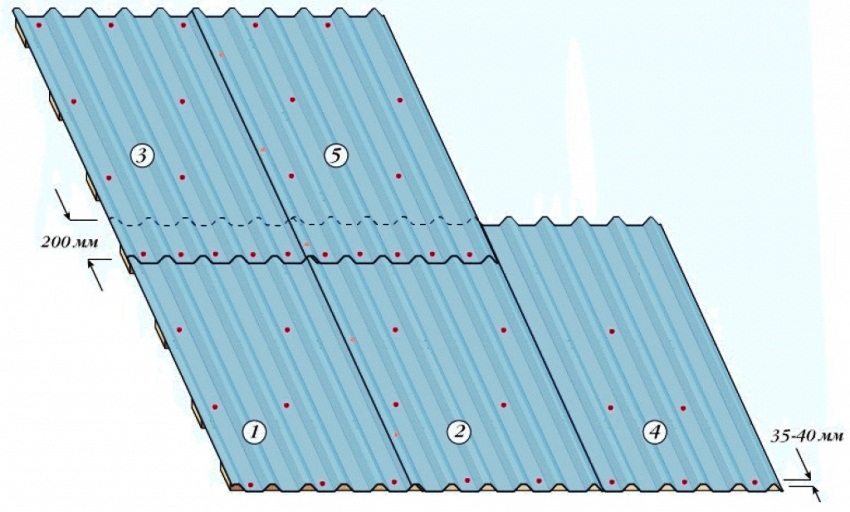

- when calculating the roof area, you need to take into account the 200 mm tolerances;

- you cannot buy too cheap non-galvanized sheets, which will quickly rust and deteriorate under the influence of adverse environmental conditions.

Helpful advice! For the roof, only a roofing sheet with a wave height of at least 20 mm is suitable, while the more precipitation falls in a particular area in winter, the higher the ridge should be.

So which decking for the roof to choose from the listed options? Experts advise making a choice taking into account the region of residence, since climatic conditions are decisive in the choice.

Related article:

Roofing materials for the roof: types and prices of modern coatings. Varieties of coatings. Comparative characteristics, disadvantages and advantages. Classification of materials for the construction of roofs.

Among the main options for corrugated board, which can be used to cover the roof, there are:

- PK20 - used in roofing works in the zone of moderate precipitation. A lathing device with a pitch of no more than 80 cm is required.The sheet has a working width of 110 cm.

- Although C21 is a wall profile, it can be used for roofing work in the temperate zone. The lathing step is also no more than 80 cm.

- NS-35, 44 are used in more severe climatic conditions, since they have a higher permissible bearing load.

In addition, N-57, 750 (900), N-60, 75 are used in roofing works, depending on the required bearing load.

When a question arises, what kind of corrugated board to choose for the roof, you should not discount such a parameter as coloring and decorative properties. After all, the roof, which is in harmony in color and texture with other buildings on the site, looks much more attractive and gives the impression of the integrity of the entire architectural environment.

Features of installation of corrugated board on different types of roofs

General rules installation of corrugated board on the roof the following:

- the crate is made solid or with a step, but no more than prescribed for a particular brand of sheet;

- film or roll vapor barrier is laid on the crate;

- the sheets are fastened with special roofing screws with rubber gaskets along the waves.

The rules are slightly different for different types of roofs. So, flat roofs begin to close from the right edge. The installation of hipped roofs is carried out simultaneously from both sides, and starts from the highest point of the slope.

Helpful advice! It is better to cover complex roofs with corrugated board than metal tiles. It does not require alignment in length, which greatly saves material.

If you decide correctly which corrugated board to choose for the roof and lay it in accordance with the requirements, you will get a beautiful and reliable roof.