Due to the combination of mechanical and translucent properties of profile and polycarbonate, greenhouses made of these materials are very popular. The construction of a greenhouse, however small, begins with the development of a project. You can use ready-made drawings and diagrams presented on the Internet, or, armed with patience, develop the necessary sketches yourself. Do-it-yourself drawings of a polycarbonate greenhouse from a profile pipe will help you accurately calculate the required number of elements for construction, avoid possible mistakes and protect you from senseless waste of material.

Profile pipes - popular material for making greenhouse frame

Content [Hide]

- 1 We build a greenhouse with our own hands. Types of greenhouses and greenhouse designs

- 2 Do-it-yourself profile types for a greenhouse made of polycarbonate. Photo examples of frames

- 3 Designing polycarbonate greenhouses: sizes, prices for polycarbonate sheets

- 4 Do-it-yourself construction of a foundation for a greenhouse from a profile pipe

- 5 DIY polycarbonate greenhouse drawings from a profile pipe

We build a greenhouse with our own hands. Types of greenhouses and greenhouse designs

Before proceeding with the development of drawings for the frame of a greenhouse from a profile pipe, it is necessary to decide on the model of the greenhouse. Which polycarbonate greenhouse shape to choose? Greenhouse and greenhouse structures can be ground-based or recessed, with or without a foundation. Taking into account the ability to create a wide variety of structures from a profile, there are several basic forms of frames for greenhouses:

- arched (semicircular, arcuate) shape - the roof of such a structure has a semicircular shape, which allows snow to not linger on the surface of the greenhouse in winter. Differs in ease of installation and the ability to use all its space for fairly high crops;

- gable structure - the traditional form with a gable roof. This design is more difficult to assemble and requires a powerful frame arrangement. It can be used to cultivate plants of various heights;

- lean-to construction - such greenhouses are most often attached to an existing structure (house or summer kitchen), they can save space in a summer cottage or a personal plot. This design saves material and has good thermal insulation. A significant plus is the proximity of communications. Single-pitched greenhouses can also be installed as a separate building;

The gable structure is rather difficult to assemble and requires the arrangement of a powerful frame

- tent or domed structures are unique structures with excellent ability to withstand external factors: snow and wind load. They have maximum illumination and can become a memorable decoration of any personal plot;

- greenhouse-bread bin - a model of a polycarbonate greenhouse with an opening top. This design resembles the shape of a bread box. It can open in one or two directions. It has easy access to plants for care, the lid can be fully opened to provide ventilation in extreme heat. Usually small in size, used as a greenhouse, can be easily transferred to a new convenient place on the site;

Do-it-yourself drawings of a polycarbonate greenhouse from a profile pipe must take into account all the features of the selected form of construction. As an example, you can use the photos of greenhouses and greenhouses available on the network with your own hands.

Do-it-yourself profile types for a greenhouse made of polycarbonate. Photo examples of frames

Various types of materials are used to assemble the frames of greenhouses and greenhouses. It can be wood, plastic or metal profile. Often there are models made of a hat profile, a profile for drywall, an aluminum profile. Each type of profile pipe has specific properties and its use is determined by the mode of operation of the greenhouse. For lighter options for seasonal use, a plastic or galvanized profile is quite suitable.

In structures planned to be used throughout the year, material with high strength rates is usually used, since the supporting structure must withstand additional loads in the form of snow cap pressure or strong gusts of wind.

The popularity of the use of a profile pipe for the construction of a greenhouse frame is explained by the following properties:

- due to stiffening ribs, pipes have good resistance to loads and do not deform under their action;

- low cost of the profile;

- light weight;

- a properly selected pipe allows you to construct any type of frame structure;

- simple installation process;

- high strength in all climatic conditions.

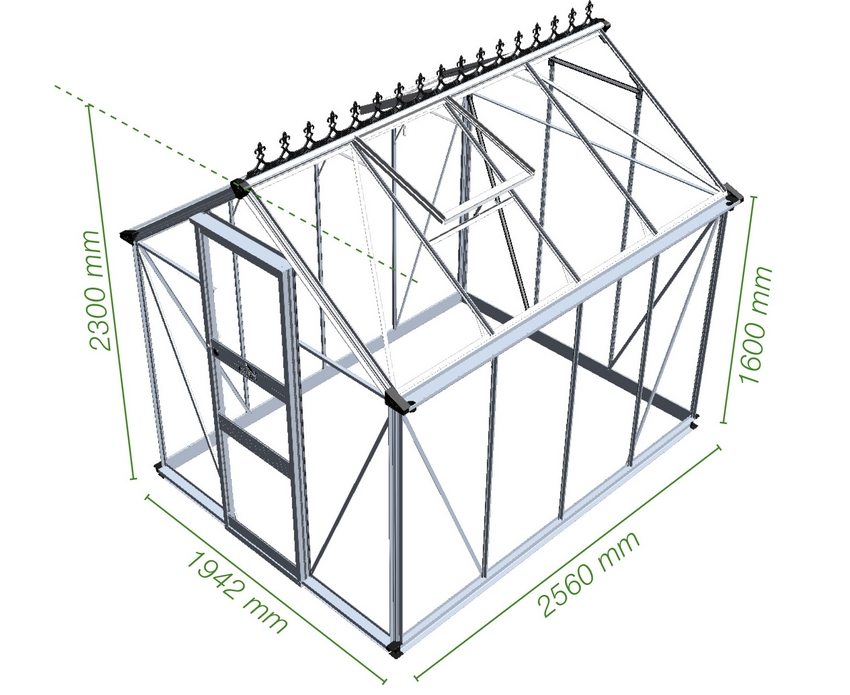

The dimensions of the section of the profile pipe used in a particular design are determined by the functions assigned to the profile: the stronger the frame should be, the larger the section is used. In the drawings of greenhouses from a profile pipe with dimensions of 2x6 m, the cross-section for the lathing frame is 20x40 mm, for the bundle of structural elements - 20x20 mm.

Helpful advice! The rectangular shape of the cross-section of the profile pipe allows you to conveniently mount the pipes on a flat surface and easily fix the greenhouse cover to them, without fear of slipping off the self-tapping screws (unlike round pipes).

If the selected frame structure from a profile pipe has a semicircular shape, it should be borne in mind that when the pipe is bent, the main load will fall on the edges of the pipe, while the middle of the profile will not be subject to deformation. In this sense, profile pipes are successfully used for arched structures. The only question is the availability of a special device for bending pipes (pipe bender). It should be noted that it is rather difficult to obtain a geometrically correct arc shape with manual bending.

If you do not have a pipe bender available, it is recommended to opt for a rectangular frame with a gable or shed roof... Such a greenhouse frame is made from a 20 * 20 profile pipe with your own hands (drawings, photos of finished structures can be found on thematic sites). Calculations, drawings and frame schemes will help you calculate the required number of profiles and avoid the acquisition of excess material.

When developing do-it-yourself frame drawings for a greenhouse from a shaped pipe, it is recommended to take into account the standard length of the profiles being sold. The dimensions of the greenhouse are selected so that as little waste as possible remains when cutting the required sections.

Designing polycarbonate greenhouses: sizes, prices for polycarbonate sheets

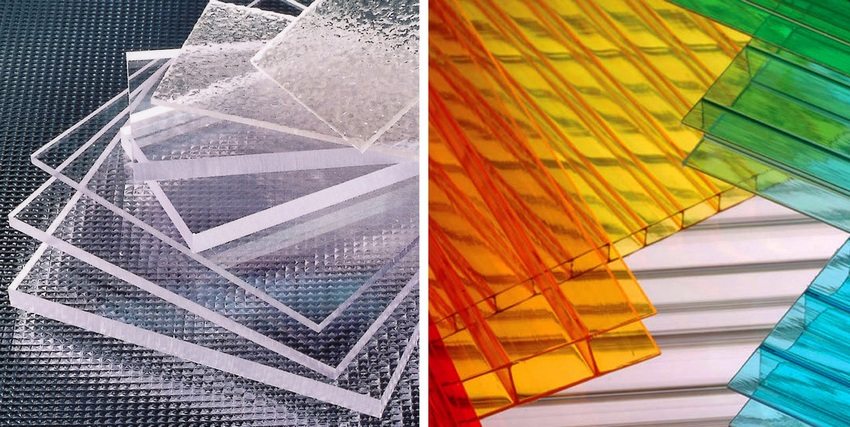

The use of polycarbonate for covering greenhouses has become possible due to a number of properties of this material. Polycarbonate sheets lend themselves well to cutting, they can be easily bent to the desired shape, they are strong and resistant to deformation. In addition, the ability to transmit sunlight and UV protection contribute to the intensive growth of crops.

The size of the greenhouse is selected so that as little waste as possible remains when cutting the required sections

The thickness of the polycarbonate sheet for covering greenhouses is selected taking into account the season of operation. If you intend to use the greenhouse only from spring to autumn, a thickness of 5-10 mm is sufficient. For heated structures operating all year round, a 15 mm thick sheet is used. The price per square meter of cellular polycarbonate sheet, depending on the thickness of the sheet and the structure of the cells, ranges from 150 to 700 rubles.

Polycarbonate sheets lend themselves well to cutting, they can be easily bent to the desired shape, they are durable and resistant to deformation

When developing with your own hands drawings of polycarbonate greenhouses, some features should be taken into account:

- sizes of standard sheets of cover and their economical cutting;

- expansion of the material under the influence of temperature;

- possible radius when bending sheets for semicircular shapes;

- ability to withstand stress from external climatic factors;

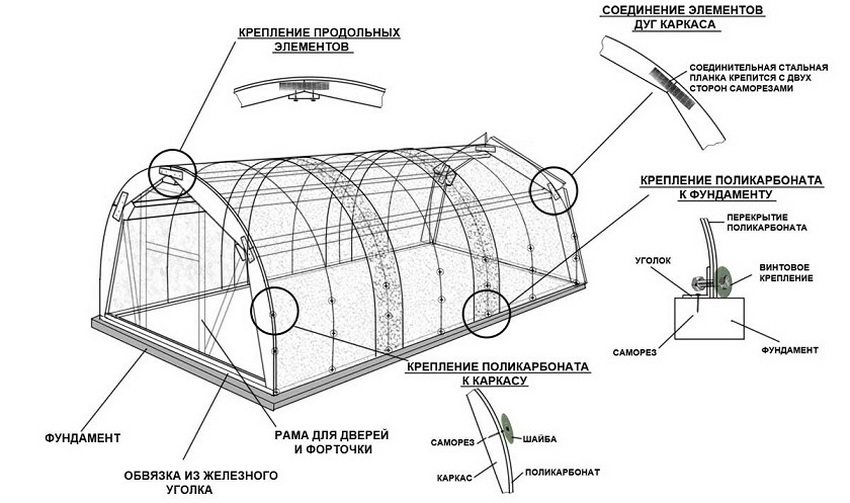

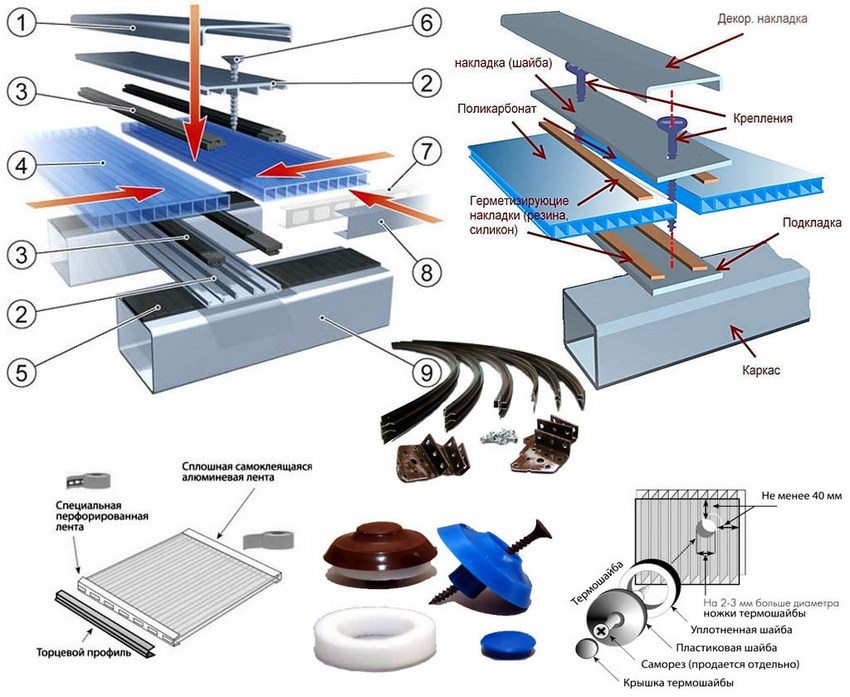

- the presence of a number of components: connecting strips, perforated tapes, end profiles, thermal washers, self-tapping screws.

The width of a standard polycarbonate sheet is 2.1 m. Stiffeners are located along the sheet. When creating drawings of polycarbonate greenhouses with your own hands (the video will guide you in coating technology), you need to take into account that the edges of the sheets should be placed on supports from the profile.

It is also necessary to take into account that the distance between the posts is taken equal to 1.05 m or 0.7 m. The carbonate sheets are placed end-to-end, connecting with each other with special connecting strips. Fastening is carried out by means of self-tapping screws with the use of thermal washers for the tightness of the joints.

Useful advice! In the drawings, provide for the correct choice of the distance between the vertical posts and the horizontal jumpers of the frame. This is the key to the strength of the polycarbonate greenhouse structure.

The diagrams also take into account the presence of gaps when joining polycarbonate plates on the plane and in corner joints. The holes for self-tapping screws must be made of a larger diameter, taking into account the thermal expansion of the material. If this is not taken into account, the coating can warp under the influence of high temperatures in the summer season, and in frost, plastic rupture can occur.

A very important point in the design is the location of the cellular polycarbonate sheet. The panels should be installed in such a way that the cells (honeycomb) are located vertically and the condensate can freely flow out through the sheet channels.

Do-it-yourself foundation for a greenhouse from a profile pipe

In order to have an idea of the specific costs of materials for the construction, the drawings of a greenhouse from a shaped pipe must reflect the presence or absence of a foundation for it. Regardless of whether the foundation will be erected, marking and preparation of the site for construction is carried out. At this stage, the choice of the place allocated for the greenhouse plays an essential role. It should be well lit, away from garden trees, and positioned to accommodate the prevailing wind direction.

Useful advice! When building a polycarbonate greenhouse with your own hands from elongated shaped pipes, it is recommended to install it in the direction from east to west. The ventilation window in the gable version of the greenhouse is located on the south side.

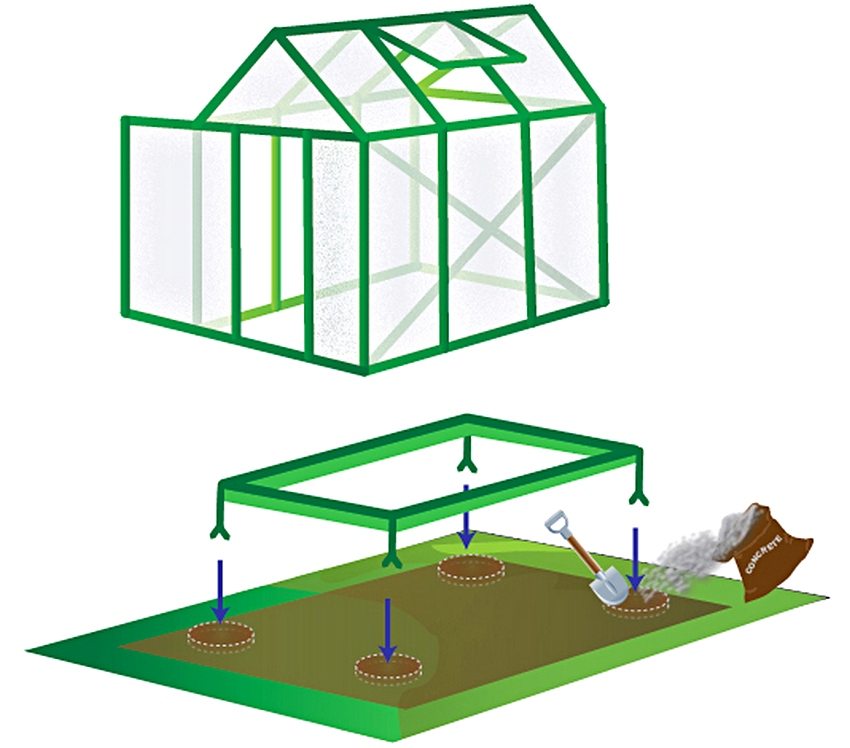

The most common types of foundations for greenhouses are wooden frames made of beams, wooden boxes, shallow strip foundations, columnar and point foundations. When choosing one or another foundation, it is necessary to take into account the weight and size of the future greenhouse structure, its functionality and the coating material.

When choosing one or another foundation, it is necessary to take into account the weight and size of the future greenhouse structure, its functionality and coating material

If the greenhouse has a light structure and is covered with plastic wrap, there is no need to arrange a solid foundation under it. When erecting a columnar base, the fact that this option is quite economical is taken into account, but the greenhouse will not be protected from cold air getting inside.

The area set aside for the greenhouse must be well lit and have an arrangement that takes into account the prevailing direction of wind flows

If wooden blocks are used under the base of the greenhouse, it is necessary to take into account their treatment with antiseptic compounds and waterproofing. This will help extend the life of the wooden base to 5-6 years. In case of using metal channels, they are subjected to anti-corrosion treatment.

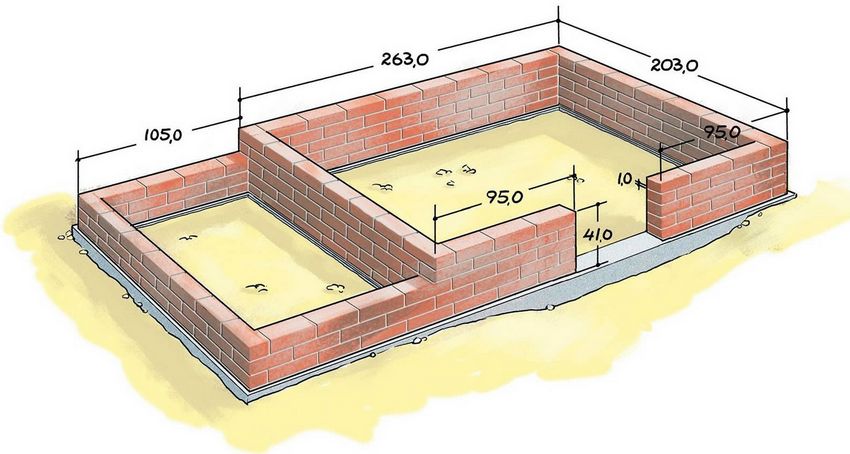

In diagrams and drawings of a polycarbonate greenhouse with your own hands from a profile pipe, the dimensions of the perimeter trench for the strip foundation, its depth and width are reflected. As a rule, the depth of the ditch for the strip base is 30-40 cm, and the height of the base is 20-25 cm.

The project provides for the required volume of mortar (in the case of pouring the foundation) or the number of bricks (blocks), if a brick base is assumed. In addition, the calculation includes the necessary elements for fixing the greenhouse frame to the foundation: corners, staples, hardware.

The calculations recorded in the project will help you navigate the exact amount of purchased materials and determine the costs of building a greenhouse

Under the construction of greenhouses, assembled from light types of profile, the foundation is not arranged. The design of such structures provides for an increase in the length of the frame profile by 80 cm on both sides. These parts of the profile are driven into the ground and thus serve as a support for the structure.

All the calculations recorded in the project will help you to maximize the exact amount of purchased materials and determine the cost of building a greenhouse.

Fastening of polycarbonate is carried out by means of self-tapping screws with the use of thermal washers for tightness of the joints

Do-it-yourself arched polycarbonate greenhouse: drawings, photo materials, sketches

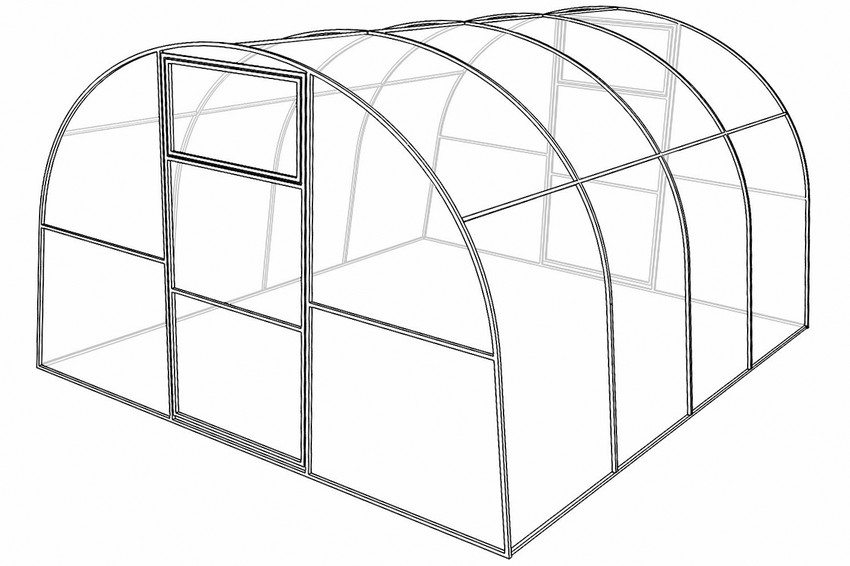

Arched structures are great for both small suburban greenhouses and massive greenhouses intended for commercial purposes.

Related article:

Do-it-yourself greenhouse made of plastic pipes. Lightweight construction assembly. The advantages of plastic frames. Forms of structures and materials of coatings. Phased greenhouse construction.

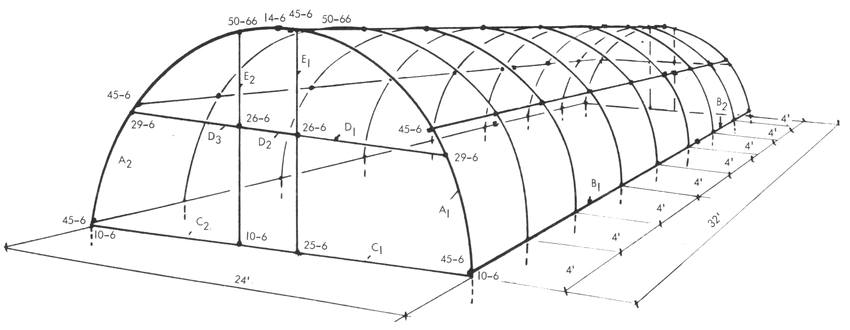

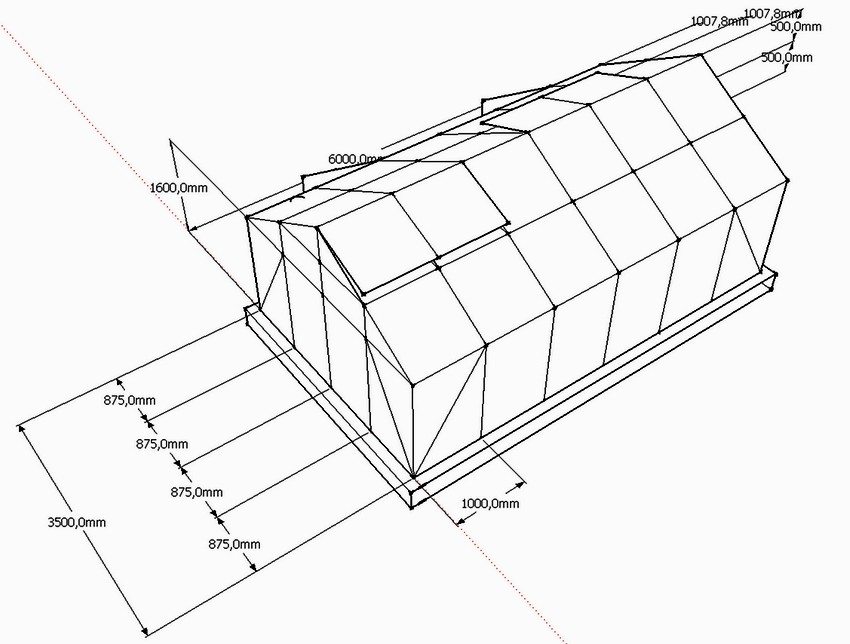

Answering the question of how to make a greenhouse from shaped pipes with your own hands, we can safely say that the development of drawings and the preparation of correct calculations is paramount. Arch-shaped pipe greenhouses have their own design features. The main determinants are the height of the structure and the dimensions of the standard cover sheets. Polycarbonate sheets are traditionally sold with parameters 6 x 2.1 m. The length of a sheet of 6 m will limit the height of the arched structure.

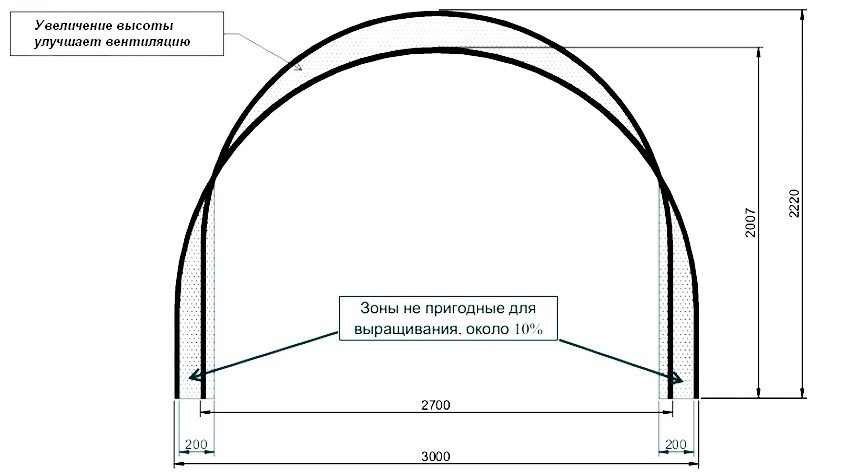

To obtain an arched shape, the sheet is placed in a transverse (relative to the frame) position. In this case, the radius of the semicircle will be 1.90 m, and the width of the structure will be 3.80 m.Taking into account the geometric formulas, the height of the greenhouse will be equal to the radius, i.e. 1.90 m.This height of the greenhouse is not suitable for everyone.

An arched greenhouse can be assembled by combining a rigid profile and PVC pipes

In order for the arched greenhouse to have a height that meets your needs, you can resort to arranging the basement. Moreover, stopping at a basement height of one meter, you can get the width of the greenhouse up to 2.4 m, and increase the total height of the entire structure to 2.2 m.Correctly setting the main dimensions of the greenhouse, you can develop drawings and sketches for the manufacture of greenhouses from a profile pipe do it yourself.

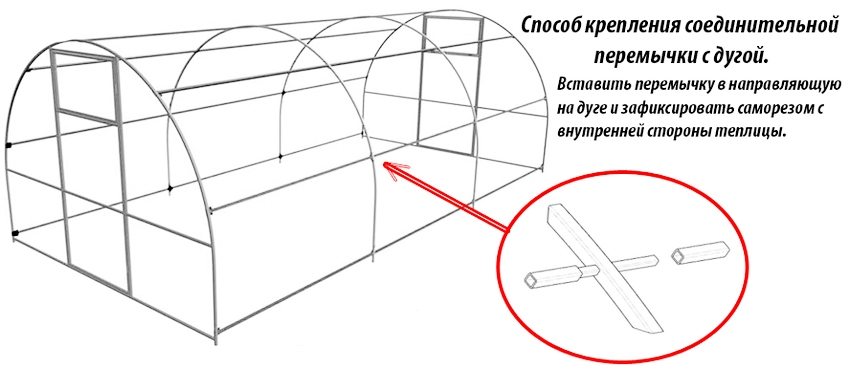

Another feature of the arched forms of the frames is that the profile needs to be bent into the desired shape. If a special pipe bending machine is not available, you can purchase ready-made arched profiles or create an arched shape from small lengths of segments connected by metal plates.

For the design of a small (4-5 m) arched greenhouse, two arched frames will be enough: the initial and the final one. In the case when the length of the greenhouse is 6 m or more, the required number of support frames is calculated, which must be a multiple of the thickness of the polycarbonate sheet. In a separate diagram, the dimensions of the window and door opening are indicated.

Useful advice! When choosing the width of the greenhouse, it is necessary to take into account the number of beds planned in it, and the arrangement of the path between them. Convenient working width - up to 0.7 m.

Further, a drawing is being developed that clarifies the features of installing a polycarbonate greenhouse cover with your own hands (the video will help you understand the process in detail) with an indication of the step of fasteners. He should take into account that polycarbonate panels in arch-type greenhouses should be located with ribs along the arc.

It is also necessary to take into account that the bending radius of polycarbonate sheets should not be less than that provided by the manufacturer for this material. Polycarbonate sheets from the ends must be covered with punched tape. For clarity, you can use a selection of photos of polycarbonate greenhouses.

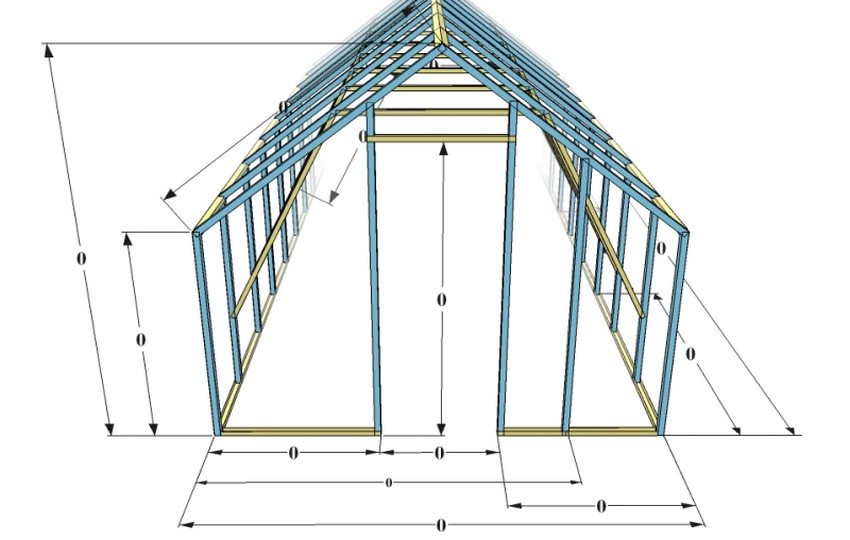

Drawings of the frame of a greenhouse with a gable roof

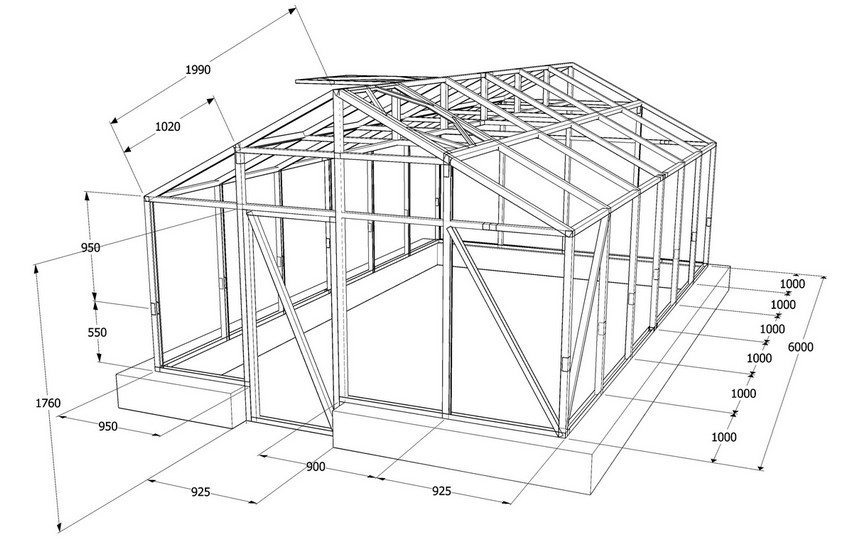

Projects of greenhouses with a gable roof provide for the implementation of the greenhouse frame with your own hands from a 40 * 20 mm profile pipe. Such a profile can withstand a significant load in the form of a snow cap or gusty wind.

The drawings show a diagram of the supporting frame, including the dimensions of the walls, the angle of inclination of the roof, in which ventilation vents are traditionally installed. If a small greenhouse is planned, an option with shed roof, one edge of which will be located above the other, providing water flow and snow removal.

The angle of inclination of the rafters in the roof of the gable structure is 25-30 degrees. Such a slope will facilitate the descent of precipitation from the surface. The roof is considered to be rather flat and does not require the arrangement of the rafter system with auxiliary slopes.

Projects of greenhouses with a gable roof provide for the manufacture of a frame from a 40x20 mm profile pipe

In structures of this type, it is assumed that a more durable profile (20x40) is used for the main posts and base, rafters and ridge girders. For horizontal lintels, you can use a 20x20 profile pipe. The drawings provide for the location of the vertical posts in one meter increments. It should also be borne in mind that in the case of covering the greenhouse with polycarbonate sheets, the connecting lines must fall on the profile. Rafters are also located at a distance of no more than one meter from each other.

The design of a greenhouse with a gable roof has several features. Here it will be necessary to carefully approach the cutting of polycarbonate sheets for gables. If all dimensions are kept according to the drawings, this will lead to an economical use of polycarbonate.

Seasonal greenhouse projects

Seasonal greenhouse structures do not have specific requirements for reliability and strength. Drawings of these structures are easy to develop and do not involve complex calculations. The frames of such greenhouses can be built from lightweight shaped pipes, and the covering material can be polyethylene film or sheets of thin polycarbonate. As a rule, light greenhouses and greenhouses are not equipped with foundations.

The type of frame of a seasonal greenhouse does not really matter - the main criteria are ease of assembly and the budgetary cost of the structure. Several recommendations will help you avoid mistakes when building small greenhouses:

- when developing drawings and sketches, the presence of ventilation hatches at various levels should be taken into account. This will contribute to high-quality ventilation of the greenhouse;

- fastening of polycarbonate sheets should be carried out by means of fastening profiles that do not damage the plastic surface. In addition, they can be easily dismantled at the end of the season, eliminating the possibility of deformation of the light greenhouse frame;

The ability of polycarbonate to transmit sunlight and protect against ultraviolet radiation contributes to the intensive growth of cultivated crops

- the project should provide for the option of simple disassembly of the frame for transfer to another place or storage for the winter.

Design features of the greenhouse-bread bin

The main advantages of a greenhouse-bread bin are:

- unusual ergonomic design;

- the minimum number of connecting lines;

- regulation of greenhouse ventilation by opening the cover to the required angle up to 90 degrees;

- ease of assembly and full use of the greenhouse area.

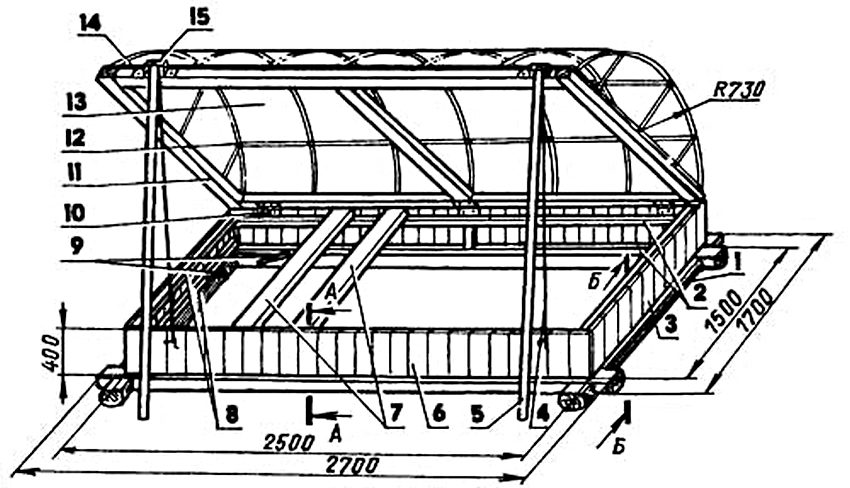

An example of a drawing of a greenhouse-bread bin in the form of a chest: 1 - a bed (edged antiseptic log 120, 4 pcs.); 2, 8 - wall strapping (timber 35x35, 8 pcs.); 3, 6 - wall sheathing (tongue-and-groove board s15); 4 - safety cord; 5 - support pole (wooden rod 40, 2 pcs.); 7 - technological scaffolding (board 200x35); 9 - staples (wire 5, quantity - as required); 10 - card loop (3 pcs.); 11 - frame strapping (timber 40x30, 4 pcs.); 12 - frame of the frame (wire 5); 13 - frame covering; 14 - clamping glazing bead (rail 20x10, 4 pcs.); 15 - handle (steel strip 30x3, 2 pcs.)

The drawing of such a greenhouse provides for the construction of the upper part of the frame of two half-arcs, which are fixed to the base on hinges. The greenhouse frame is made of a small section shaped pipe.The radii of the covers are selected taking into account the fact that they can easily open without interfering with each other. The difference in diameter is equal to the width of the polycarbonate sheet - this ensures that there are no gaps when closed.

Useful advice! Considering the fact that small greenhouses are usually used for breeding seedlings, which need a special microclimate, it is recommended to use polycarbonate with UV protection for the coating. The percentage of heat retention with such a material is much higher than that of plastic wrap.

The dimensions of the greenhouse are selected individually. The length can be from 3 to 4 meters, the height is no more than one meter. The width is taken taking into account how it will open greenhouse - from one or two sides. For one-sided opening of the greenhouse, it is advisable to choose a width of 0.7-1.2 m so that it is comfortable to care for the seedlings.

Drawings of greenhouses of various types

There is an option for a simple greenhouse made of a light metal profile. Such a greenhouse is being assembled without a foundation. A strapping from a thin profile acts as a base. Drawings can represent various shapes and parameters of such greenhouses.

Light structures are assembled according to the principle of a designer. The only drawback is that a thin frame with a low weight can easily deform. In this regard, the scheme reflects the distance between the posts not more than 0.5 m. The frame elements are connected to each other using tees and crosses, and fixation to the strapping is performed with a glass fastener.

The structure of a greenhouse from a light profile can be assembled in any shape: with a gable or a pitched roof. To give the structure rigidity and strength, it is possible in the project to envisage the use of an aluminum profile and the arrangement of one of the types of foundation: brick, stone or concrete.

The structure of a greenhouse from a light profile can be assembled in any shape: with a gable or a pitched roof

From an aluminum profile, you can assemble a gable structure greenhouse using internal struts (inclined installed racks), which will provide the structure with the required rigidity. The disadvantage of this design is that the useable space inside the greenhouse is reduced due to the inclined posts. Such a frame can also have individual dimensions and be located on the foundation or on the prepared surface of the site.

Having certain knowledge and using the existing drawings, you can independently develop a project and build a greenhouse of any shape and different sizes on your personal plot using various materials available to you.