An indispensable accessory for any comfortable home is a cistern and a toilet flush mechanism included in the kit. The latter most often fails, which leads to the creation of uncomfortable conditions when visiting the bathroom. To less often encounter this problem, you should select, install and configure the drain mechanism correctly. This article will help you deal with this issue.

In order for the drain mechanism to perform its functions efficiently, it must be properly installed and configured.

Content [Hide]

- 1 How the toilet cistern works: internal filling of the device

- 2 How a toilet flush should work

- 3 Types of design of drain fittings for the toilet cistern

- 4 Varieties of flush valve for the toilet as a mechanism for controlling the overflow of the system

- 5 How to choose the right toilet parts

- 6 Dismantling and installation of the drain mechanism for the toilet cistern

- 7 Testing the toilet flush system after installation

- 8 Possible system malfunctions and how to fix them

- 9 Popular manufacturers of toilet cistern flush devices

- 10 Toilet cistern device: video of repair and adjustment of the mechanism

How the toilet cistern works: internal filling of the device

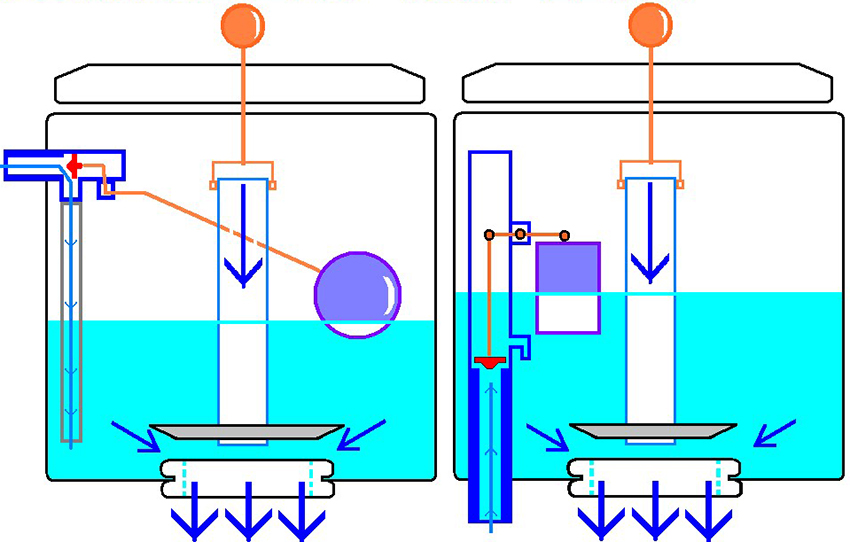

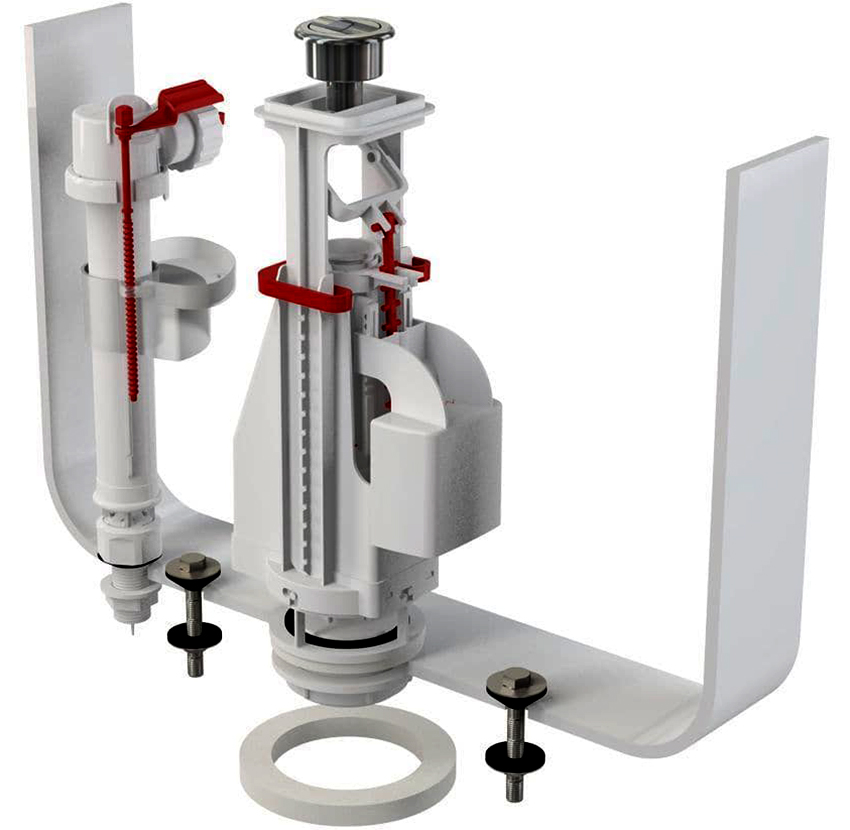

The normal operation of the drain system is ensured through the interaction of its individual components. The supply of water to the tank is carried out thanks to the filling or inlet valve for the toilet. It is represented by a threaded pipe that is inserted into a hole in the side wall or bottom of the tank. The presence of the thread allows the element to be pressed against the tank wall by means of nuts, which will ensure the tightness of the connection. Control over the opening and closing of the hole through which water enters is carried out by a locking mechanism connected to the rocker.

The rocker arm is a lever that drives the exhaust valve. The free end of the element is attached to a float or check valve. A float is a sealed plastic container with air inside. At the moment when the float floats up or the shut-off device is triggered, the rocker arm rises, which helps to close the gap in the filling valve, or vice versa.

Normally, the drain hole is blocked by a drain valve. It is a flat or hemispherical elastic gasket that connects the carrier to the hinge.

The operation of the drain mechanism for the tank is controlled by a push-button or lever mechanism, which is located in the upper part of the tank. When exposed to it, its bearing part rises, opening the hole for water to enter at high speed into the toilet bowl.

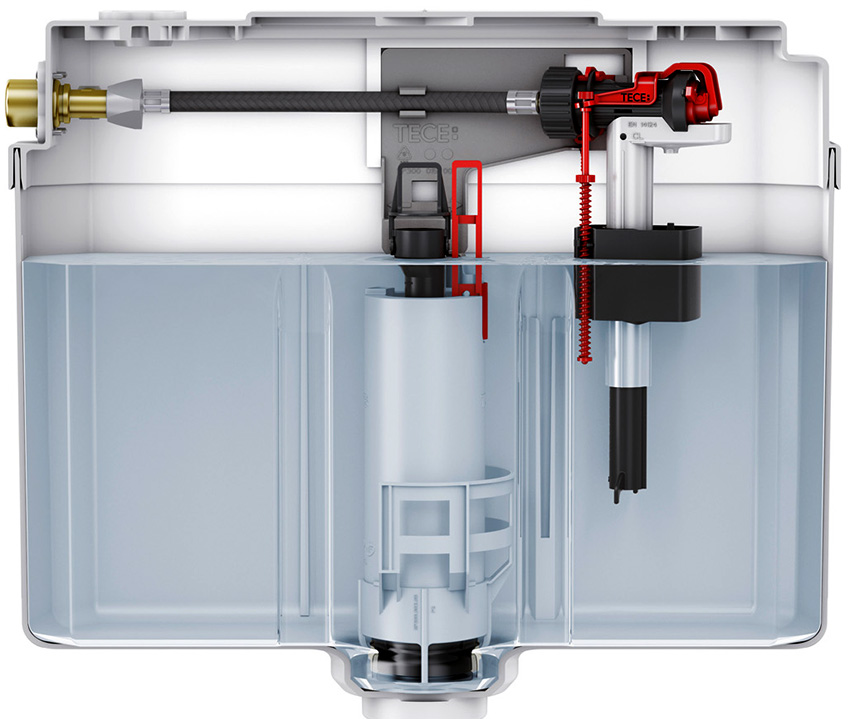

All components of the mechanism can be arranged in different ways.In older cisterns, the flush and overflow control mechanisms were mounted separately. In modern models shut-off valves presented in a single complex, which facilitates easy installation and configuration, while complicating repairs.

How a toilet flush should work

The flush mechanism for the toilet is located inside the cistern. It does not have a complex design, but it performs important functions. The drain mechanism is responsible for draining water from the tank, filling the tank with water, and control over the water level, which eliminates the possibility of overfilling the tank when the liquid reaches a certain level.

The principle of operation of the flush tank is as follows. Water enters the tank through a filling valve, which can be located in the wall or bottom of the tank. As the container is filled, a shut-off device in the form of a float or valve is activated, which shuts off the liquid supply at the moment it reaches a certain level, blocking the filling valve.

When it becomes necessary to flush the water, they act on the button or lever, due to which the shut-off valve of the toilet cistern opens. As a result, the liquid flows into the toilet bowl. Systems with a double button work in a similar way. When the small button is pressed, part of the water is poured out of the tank, when the large button is completely drained.

Important! The flush mechanism of the toilet bowl with a button for two modes saves water.

Drainage of water entails a decrease in the level of liquid in the tank. This facilitates the activation of the control devices, as a result of which the outlet valve opens and the tank is filled with water.

Types of design of drain fittings for the toilet cistern

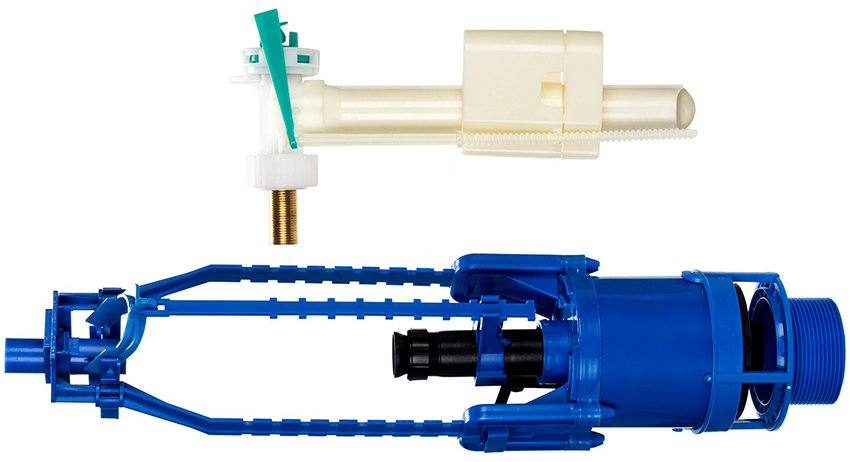

There are several versions of the drain system. The filling valve can be bottom or side mounted. In the first case, the branch pipe is located at the bottom of the drain tank. This system includes a vertical rod float, a thrust and a buoy. The last two elements are connected in a common structure, which acts as a water limiter.

When the tank is empty, the float drops. At this moment, draft begins to act on the toilet flap, opening it. When the float reaches a certain level, the valve is closed. The system is sealed with a pair of gaskets.

When placed laterally, a branch pipe with a valve is introduced into the tank through a side hole, which is located in the wall of the container under the lid. This lumen is conditionally airtight, since water does not reach it. In this design, the control mechanism of the flush tank is placed horizontally. It consists of a shut-off device, a float, a lever and a filling tube. When the tank is emptied, the float is lowered, which drives the rod, which opens the shut-off valve. When filling the tank with water, the control mechanism gradually rises.

From the point of view of effective and comfortable operation of the drain device, it is better to stop the choice on models with a bottom connection, which are more reliable, make less noise when the tank is filled with water. Systems with side connection are characterized by ease of installation, availability of commissioning and repair work.

Important! Bottom-connected tanks require close attention to the tightness of the connection.

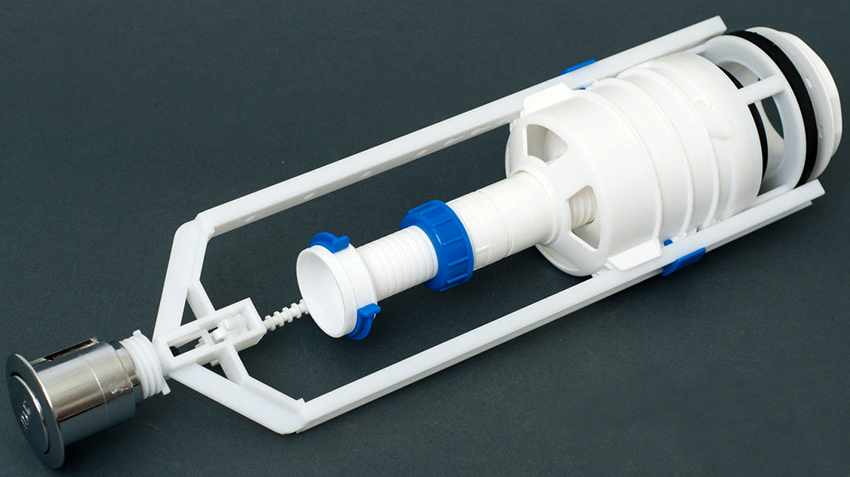

The flush mechanism is activated by a trigger, which can be a lever, a rod or a toilet button. Older models were equipped with a lever to which a cord with a handle or a chain was attached. The drain system with a stem was activated by lifting the handle up.This option has also lost its popularity and is rarely found in modern tanks.

Currently, models are most often controlled by acting on a button located in the tank lid. The push system, in turn, can be one-button or two-button. In the first case, the tank is completely emptied by pressing the button. The second option involves two modes of operation of the flush mechanism of the tank with a button. The first one ensures that half of the volume of the container is drained, and the second is the complete emptying of the tank.

Varieties of flush valve for the toilet as a mechanism for controlling the overflow of the system

The flush valve of the toilet bowl can be represented by a float or membrane shut-off device. Models of the first option may differ in structure and principle of operation. Older tanks were equipped with croydon valves, which consisted of a body, piston, shaft, seat and float arm. When exposed to the float arm, the mechanism began to function. In this case, the piston moved vertically.

Most modern drainage mechanisms are equipped with a piston valve that moves horizontally when the lever is actuated. The water supply is regulated by the contact of the piston and the seat. At the time of filling the container, the inlet is closed off with a gasket, which is located at the end of the piston.

The diaphragm valve is not equipped with a piston gasket, but a rubber or silicone diaphragm. The plastic piston, when the lever acts on it, begins to displace the membrane, which closes the water supply.

Important! The diaphragm valve facilitates quick and quiet filling of the tank.

The disadvantage of this element is the high sensitivity of the product to dirt and the presence of impurities in the water. The diaphragm valve will quickly lose its operational properties due to poor quality water in the system. A mechanical filter will help to avoid problems.

There are floatless options for the drain system. The water supply to them is stopped due to the presence of a special chamber in the form of an inverted glass.

Toilet flush valve material

Expensive models of toilet flush systems are made of bronze or brass. These materials are distinguished by their strength, reliability, corrosion resistance, and the ability to withstand mechanical and chemical stress. The design can be both simple and complex. Metallic filling is found in expensive collectible models, which are produced with a certain stylization.

In other cases, bronze and brass can be used in the manufacture of only the filler valve, which makes the shut-off and drain system universal, easy to install, configure, repair, and allows you to replace each unit separately.

Many valve models are made from polymers. The quality of the plastics and the precision of the production affect the cost of the product. The more expensive the fittings are, the more reliable and durable the drainage system will be. However, there are quality models that have an affordable price.

How to choose the right toilet parts

In case of failure of the elements of the drainage system, it is important to choose the correct option that will match the factory configuration. Knots may differ in material of manufacture. The highest quality and most durable products are bronze and brass. However, they are expensive.

Toilet repair kit is selected based on the tank model. Important parameters are the location of the inlet, its size, the diameter of the drainage opening and the overall dimensions of the device, which must freely enter the tank.The flush mechanism for a toilet bowl can be represented by a single structure or consist of separate (flush and filler) devices. The second option greatly facilitates and simplifies the process of replacing products.

In the event of a breakdown of the elements of the drain mechanism, the repair kit is selected based on the model of the tank

When choosing a valve, you should pay attention to the workmanship of the product. The mechanism must work under its own weight. It is necessary that all its nodes be mobile, move smoothly and unhindered. There must be no seizure of any kind.

When choosing a drain mechanism, you should carefully inspect the elements. They should have a solid, chip-free and crack-free housing and a correct geometric shape for efficient and trouble-free operation. Toilet parts made of quality material are expensive.

Seals and gaskets should be purchased from silicone. Such products, unlike rubber ones, are characterized by strength, reliability and durability. The elements are checked for squeezing and bending. They should not deform or crack.

Helpful advice! The best operational and strength properties are possessed by sealing elements, in the manufacture of which rubber is added to enhance elasticity.

Dismantling and installation of the drain mechanism for the toilet cistern

If the drain mechanism fails, you can change it to a new repair kit yourself. Replacing the drain mechanism in the toilet cistern is performed according to the following algorithm.

Related article:

How to choose a toilet: the main criteria and features of various models

Overview of the 5 most popular manufacturers and models. Common breakdowns and how to fix them.

The first step is to shut off the water supply. Next, the drain button is pressed to empty the tank. It is carefully removed, which makes it possible to remove the tank lid. Then the water supply hose is disconnected. The nut is unscrewed, which fixes the filler pipe. It is required to remove the part itself from the hole.

Helpful advice! Before changing the drain mechanism in the toilet cistern with a bottom water supply, it is recommended to install a small container under the plumbing device, into which water will drain, which did not come out into the drain.

Internal fittings are removed from the tank, which are unscrewed from the fasteners. Next, the bolts that fix the tank to the toilet bowl are unscrewed. The capacity is removed. After that, the lower part of the drain system is dismantled and the gaskets are removed for sealing. After the end of disassembly, it is necessary to clean the inner surface of the tank and all its openings, remove plaque, debris and lime deposits.

After removing the internal fittings, it is necessary to unscrew the bolts that fix the tank and toilet

Installation of the drain mechanism assumes the reverse sequence of work. The lower part of the drain system is inserted into the hole, sealing gaskets are attached. Next, you install the cistern on the toilet and fix it with the fastening bolts.

Important! If corrosion has formed on the old bolts, the elements should be replaced with new ones.

The inside of the drainage mechanism is installed in the toilet siphon. The filling valve should be inserted into the gap in the bottom or in the side wall of the tank, fixing it with a nut and sealing gaskets. The water supply hose must be connected to the outlet. The water turns on and the system is checked for functionality.

If all the elements are installed correctly, and the joints are reliably sealed, then there will be no leaks.

Testing the toilet flush system after installation

After installing or repairing the flush mechanism of the toilet cistern with a button, a system test is performed.The first step is to check for visible leaks. To do this, it is necessary to drive the water several times in the plumbing device. Water should not flow into the toilet bowl unnecessarily, and you should also make sure that there are no leaks under it. If found, it is necessary to fix the fasteners as tightly as possible.

Next, it is checked whether the water level in the tank has reached the desired mark. If this does not happen, the toilet cistern is adjusted. In this case, the filling valve should work normally, not jam. You can make sure of the quality of its work by making sharp impacts on the mechanism down or up.

Next, you need to evaluate the system by ear. If there is a hiss, whistle, or other sharp sound, the flap valve is closing. The problem is rectified by lowering or raising the element using a screw, which is activated by a screwdriver.

To ensure the normal operation of the system, the water level in the tank is adjusted. The float, which is held in place by thick wire, should be positioned so that it is 1-2 cm below the edge of the armature. For a larger collection of water, the metal lever must be bent downward. To reduce the liquid level, the product is folded in the opposite direction.

If the float arm is made of plastic, it is adjusted with a special screw that rotates until the float is in the desired position. The optimal level is the liquid level in the tank, at which the water will be 3 cm lower than the overflow hole.

The correct position of the displacer indicates that water does not overflow through the system and does not go into the toilet bowl unnecessarily. After adjustment, the lid is installed on the tank and fixed with a button.

Possible system malfunctions and how to fix them

Studying how the toilet works will help to identify possible malfunctions and eliminate them. If the overflow control does not work, it is required to find the reasons that caused the damage to the system. The most common can be found in the skewed lever or rocker arm holding the float. It needs to be leveled to ensure proper float movement and system recovery.

For toilet flush systems with a diaphragm valve, when the element moves to the upper position, the hole can remain open. In this case, the diaphragm position is adjusted or replaced. The reason for the failure of the overflow control system may lie in the perforation of the float with water ingress. Such a problem requires a complete replacement of the element. If the above operations did not lead to the elimination of the malfunction, it is necessary to replace the inlet valve.

Leakage at the filler valve occurs primarily as a result of wear of the sealing gasket. In the early stages, the problem can be remedied by tightening the retaining nut. In an advanced case, you will need to replace the gasket.

If the drain button does not work, the cause may be a skewed lever that connects it to the drain valve. Such a malfunction may appear due to the breakdown of the plastic elements of the internal fittings. In this case, replacement of the drain mechanism is required.

During initial use of the reservoir, malfunctions can occur as a result of improper adjustment of the system. To ensure its operability, it is necessary to select the height of the drain cup corresponding to the height of the tank, fixing it in the correct position.

If a weak pressure is observed during filling the tank at normal pressure in the general system, the hose supplying water is dismantled, cleaned, and limescale deposits that have blocked the lumen are removed. If cleaning is not possible, the hose is replaced with a new one.

If the problem is not resolved, it is necessary to inspect the intake valve and check it is working. To do this, open it, clean the inner chamber and adjust the overflow system. If the problem persists, the valve must be replaced.

Popular toilet cistern flush manufacturers

One of the most famous manufacturers of sanitary ware and spare parts for them is the Czech company Alka Plast. It produces high quality, functional and durable products at an affordable cost. A popular universal model is the AlkaPlast A2000 drain mechanism with a stop-button function. The device is suitable for replacing the existing mechanism in ceramic tanks. Thanks to the special design, the height of the product can be adjusted within the range of 310-405 mm (depending on the height of the tank).

The device is equipped with a stop-function button, which helps to start draining water when it is first pressed and stops it when it is repeated. The mechanism is made of ABS plastic, which is resistant to abrasion and various kinds of stress. You can buy a drain device for 850 rubles.

The Alka Plast A08A double flush drainage mechanism has two modes of water discharge with a volume of 3 and 6 liters. The design of the device allows you to adjust the height of the drainage mechanism within the range of 315-450 mm. The product is made of ABS plastic. The cost of the device is 1.1 thousand rubles.

Another equally popular manufacturer of toilet flush mechanisms is the Swiss company Geberit. The products of the world manufacturer are of high quality. The company is constantly improving the method of manufacturing plumbing elements, introducing technological innovations.

Popular waste systems include the Geberit Impuls Basic 230 double flush mechanism with a chrome button. The device is made of durable high pressure plastic, which improves its technical and operational properties. You can buy a Geberit toilet flush mechanism for 2.3 thousand rubles.

A quality model is the Geberit Impuls Type 290 drainage mechanism, designed for two operating modes - a drain for 3 and 6 liters. The device is designed for tanks with a height of 300-450 mm. The water supply can be carried out both from the side and from below. The cost of the Geberit drain mechanism is 2.8 thousand rubles.

The drainage mechanism is a simple design. Having understood the principle of its operation and following the above tips, you can independently perform the installation, adjustment and repair of the device without completely replacing the toilet tank.