Do-it-yourself vegetables can be much more beneficial than store-bought vegetables. That is why many owners of suburban areas are striving to acquire a greenhouse, which will become an ideal environment for the life of most crops growing in our region. Consider how to choose a polycarbonate greenhouse: sizes and prices of structures, as well as the varieties and features of each type.

Content [Hide]

Materials for creating a polycarbonate greenhouse frame

Ready-made greenhouses that can be found on sale today are agricultural structures, the purpose of which is to protect the plants that are in it from adverse environmental conditions. Despite the seeming simplicity of such structures, their production is regulated by the requirements and norms that are formulated in GOST R 34257 - 2010, SNiP 2.10.0485 and SP 107.13330201. Therefore, before buying, everyone can familiarize themselves with the detailed conditions and requirements that apply to greenhouses.

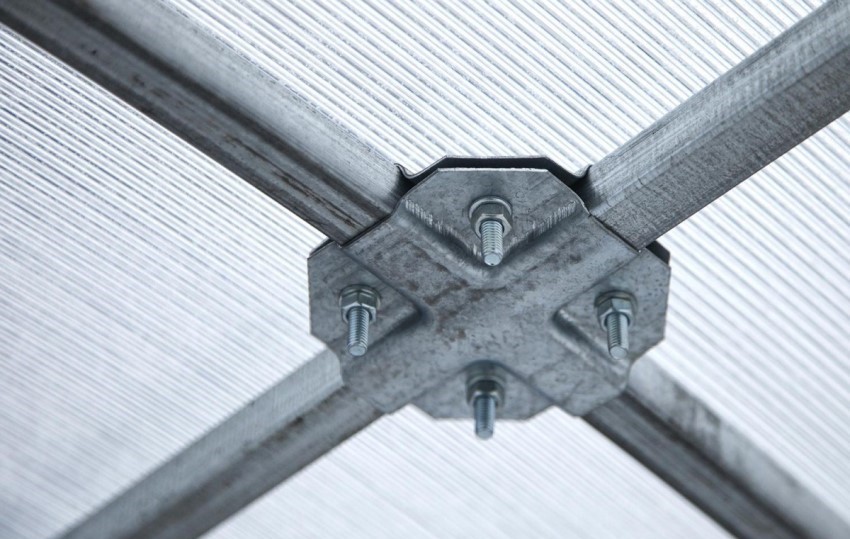

Greenhouses consist of two components: a supporting frame and polycarbonate, which covers this frame. In this case, various materials can be used as a base, for example, steel pipes (both rectangular and square) or a thin-walled galvanized profile. Each of these options has its own advantages and disadvantages that must be considered when choosing.

The advantages of using a bent profile polycarbonate as a base for a greenhouse include its low cost and low weight. But at the same time, the strength of this material is not too high, which often leads to the fact that more elements are required to create a fairly strong base.

In addition, during the production process, they must resort to additional reinforcement of the joints, since there are quite a lot of joints and not too thick metal (0.5-0.8 mm) can deform under the influence of strong winds or other loads.

The steel profile is capable of withstanding significantly more severe loads and is highly durable.Almost no natural mechanical stress is able to affect it, which makes this option more durable. But there is also a significant drawback - the tendency of the material to corrosion and the need for constant protection against rust.

The price of a polycarbonate greenhouse, the frame of which is made of a steel profile, is much higher due to the complex manufacturing technology. First of all, because the arcs in this case are either solid or consist of only a few separate elements. Of course, both options are worthy of attention, however, your financial capabilities will play a decisive role in this matter.

Helpful advice! As a rule, all serious manufacturers have frame samples. So before buying, you should carefully read several options, comparing the material in terms of quality, strength and other characteristics.

The main criteria for choosing a frame for a greenhouse made of polycarbonate

In order not to be mistaken in the choice, you must clearly understand what the frame of the greenhouse should be and what you should pay attention to. Here are some simple guidelines that will help you make the right choice:

- The fewer elements make up the arc, the more durable the frame will eventually be. Solid arches are ideal.

- Rectangular metal profile has a higher resistance to loads. It is best if a 20 × 40 mm profile was used for the frame, since a section of 20 × 20 mm is far from always enough, especially when it comes to the base of the greenhouse.

- In order to be sure that the greenhouse will last for a long time, you need to make sure that the thickness of the metal used to make the frame is at least 1.2 mm.

In addition to the basic ability to provide plants with comfortable conditions, for some models, lighting, irrigation and ventilation systems can be additionally installed. If you want to save yourself the hassle, we recommend that you consider options that initially provide for such opportunities.

What to look for before buying a polycarbonate greenhouse

Of no less interest is polycarbonate itself, which is used for the manufacture of a greenhouse. In the selection process, you need to pay attention to several fundamental aspects, namely: the type of material, its thickness and the presence of a stabilizing layer. It will also be useful to read reviews of which greenhouse is better to buy. Take a closer look at each of these three points.

What type of polycarbonate to choose for a greenhouse

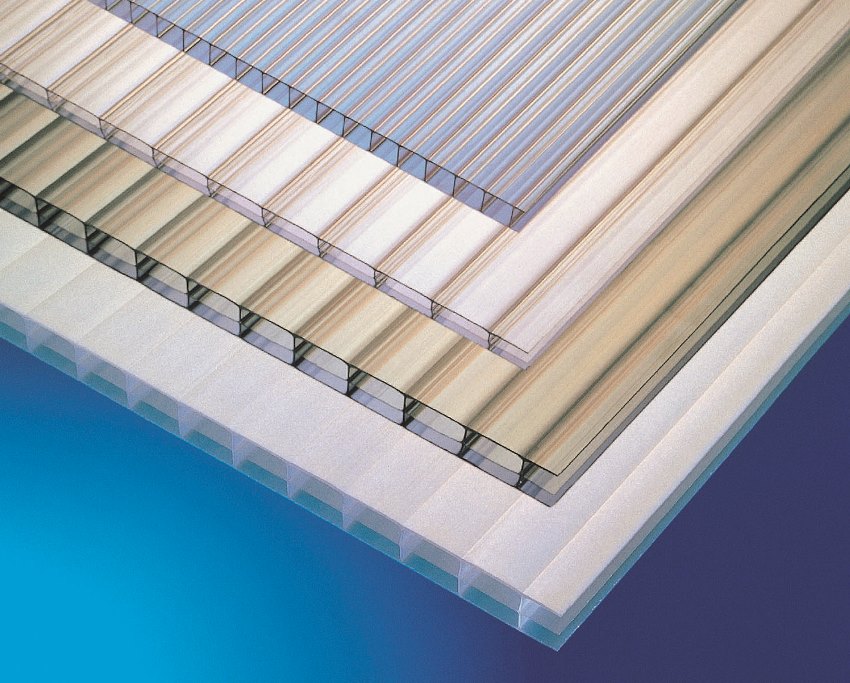

There are two types of polycarbonate: solid and honeycomb. The second option is more suitable for sheathing greenhouses, as well as various roofing works, since it surpasses monolithic in many characteristics.

Cellular polycarbonate is a sheet material that belongs to the group of thermoplastics, consisting of several layers. Internal bridges are located between these layers, which provide additional strength and have a positive effect on the duration of the operational period and the technical characteristics of the structure as a whole. So, thanks to this technology, cellular polycarbonate has the following advantages:

- light weight;

- high resistance to changes in ambient temperature;

- excellent light transmission;

- flexibility;

- strength and resistance to various loads.

Polycarbonate thickness for greenhouse

The thickness of the polycarbonate chosen for the greenhouse cladding largely determines not only its strength, but also its ability to transmit sunlight, as well as thermal conductivity level... As a rule, sheets from 4 to 10 mm are considered the most suitable for this purpose, since they meet all the basic requirements and standards.

A greenhouse made of cellular polycarbonate allows you to completely eliminate drafts, overheating of plants and perfectly tolerates any bad weather

Of course, there is a direct relationship between the thickness of the polycarbonate sheet and some features of the frame to which they are attached. The denser the materials used, the better the greenhouse will withstand wind and snow loads. In some cases, it is even permissible to use sheets of different thicknesses in one design.

Since flat and arched roofs are subject to the greatest stress, thicker polycarbonate is used for their construction, while thinner material is suitable for vertical side walls. Panel thickness of 4-6 mm was set as a standard parameter.

Helpful advice! Before you buy a mini-greenhouse or a full-fledged polycarbonate greenhouse, you need to make sure that the thickness of the material declared by the manufacturer corresponds to reality. For this purpose, you can use a caliper.

The use of polycarbonate of varying degrees of transparency in the construction of the greenhouse allows creating the necessary conditions for growing certain types of plants

If you find that the actual thickness of the polycarbonate differs from the one indicated by the manufacturer, it is best to skip the purchase. It is strongly not recommended to purchase a greenhouse for which material with a thickness of 3.5-3.7 mm was used. Unscrupulous sellers may argue that its density is higher, and therefore it may well replace the recommended 4 mm polycarbonate. In fact, this is not the case and, most likely, this will greatly affect the service life of the structure, and its resistance to various factors.

Another way to spot cheap and low-quality material is to bend it with your fingers. An easily bendable material, which often does not have a designation on which side the stabilizing layer is located, is a fake that will definitely not last more than 2 years.

Helpful advice! The information presented on thematic forums and sites can help you find the best option. Often, users share their own experiences and advise where to buy polycarbonate greenhouses at an affordable price.

In warm weather, it is recommended to leave the greenhouse open to provide the plants with the most favorable conditions.

The approximate cost of one sheet of domestically produced greenhouse polycarbonate 4 mm thick, 2.1 m wide and 6 m long is 2 thousand rubles.

The presence of a light-stabilizing layer in polycarbonate for a greenhouse

High-quality polycarbonate is characterized by amazing light-stabilizing properties and the ability to completely absorb ultraviolet radiation, the wavelength of which does not exceed 400 nm. It is thanks to this ability that the greenhouse effect is achieved, which has a beneficial effect on plant growth.

In order to protect the material from the destructive effects of ultraviolet radiation, a special stabilizing layer is applied to one of its sides using the extrusion method. You can verify the presence of this layer on the surface by following the manufacturer's instructions, who glues a plate with the corresponding information over the protective film.

Helpful advice! Having seen polycarbonate on sale, on which there are no marks about the presence of a light-stabilizing layer, you need to understand that such material can only be used indoors and is not suitable for greenhouses.

A polycarbonate greenhouse has excellent light transmission and light-scattering properties, which creates the most favorable microclimate inside

If polycarbonate without a protective layer is used for cladding the greenhouse frame, this will lead to the fact that the coating will fail extremely quickly. And while manufacturers and sellers may argue that the protection is already inside the material in an attempt to sell low-quality products, this is actually not enough. So when it comes to a greenhouse, the presence of a light stabilizing layer can be considered a prerequisite.

Various forms of polycarbonate greenhouses: photos, prices and features

Looking through the prices of polycarbonate greenhouses and greenhouses, you can see that their cost depends not only on the technical characteristics of the materials that were used for their manufacture, but also on the features of the design itself. In addition, the size of the greenhouse plays a significant role. Let's consider several main types that are most often found on the market.

An arched greenhouse is the most common design option, which is a structure with a semicircular ceiling. The advantages of this option include the fact that by adding or removing individual sections, it is quite easy to change the size of the greenhouse, although this option is not provided in all models.

Related article:

DIY polycarbonate greenhouse drawings from a profile pipe

Types and schemes of greenhouse frames. Coating materials. Features of the foundation.

The Butterfly design is ideal if you want to buy a mini greenhouse for your summer cottage. With its small size, this design allows for the most comfortable care of the plants, since its sides rise. For some of these models, a thermal drive is provided, which allows you to control the ventilation level automatically, without human intervention.

Trickle arch greenhouses are the most suitable designs when faced with severe snow conditions. Due to the presence of an additional stiffener, the greenhouse is very stable, and the very shape of the walls prevents the accumulation of snow on the surface.

Single-slope (wall) greenhouses are one of the simplest structures in which the wall of the building acts as one of the supports. In this case, the angle of inclination of the roof is made quite large to prevent the accumulation of snow on its surface. In this case, it is very important to position the greenhouse on the sunny side of the building so that the plants receive sufficient sunlight.

Gable greenhouses are a classic version that existed long before the use of polycarbonate. Outwardly, it resembles a house of the simplest form. For the base of such a structure, not only a metal profile can be used, but also wood.

When choosing the most suitable option, the owner must take into account his financial capabilities, as well as real needs. For growing seedlings, you can consider purchasing a mini greenhouse and a greenhouse. You can buy them at a very reasonable price. If you plan to grow cucumbers or tomatoes, you need to buy a greenhouse for this purpose of such a size that adult bushes feel comfortable in it.

Arc greenhouse with a drop-shaped arch has an additional stiffener

Helpful advice! If there is very little free space on the site, you can buy a portable mini-greenhouse for a summer residence. After the end of the season, it can be easily removed or rearranged where it will not interfere with free movement.

Polycarbonate greenhouse: sizes and prices different models

A huge selection of models of a wide variety of designs is available to buyers and it is simply impossible to cover all the offers. As examples, consider several polycarbonate greenhouses, the sizes and materials of which are different:

| Palram Sun Tunnel Polycarbonate Mini Greenhouse | Consists of two parts, does not require assembly. Ideal for growing seedlings | 110×50×40 | 2310 |

| Greenhouse made of polycarbonate "Lotus" | Frame made of galvanized pipe with a section of 20 × 20 mm. Construction weight - 20 kg | 210×90×80 | 6100 |

| Open-top greenhouse "Alyoshenka" | A metal profile with a square section of 20 × 20 mm was used as a base. There is a thermal actuator | 200×100×85 | 9300 |

| Arched polycarbonate greenhouse | The frame is made of a profile pipe with a section of 20 × 20 mm. Does not require a foundation | 400×300×210 | 12600 |

| Arched polycarbonate greenhouse | Frame made of a profile pipe with a section of 25 × 25 mm | 400×300×210 | 20000 |

| Greenhouse model | Description of construction | Size (l / w / h), cm | price, rub. |

In addition to these standard greenhouses, a wide variety of polygonal models can be found on sale. Moreover, you can order the production of a greenhouse according to individual measurements. Of course, this will affect its price, however, this way you can get a design that is ideally suited in size and shape.

Polycarbonate greenhouse construction protects plants from rain, strong winds and other adverse weather conditions

Buying a polycarbonate greenhouse opens up enormous opportunities for the owners of summer cottages for growing vegetables, seedlings and other crops. So all that remains is to choose the most suitable and high-quality option, then install a greenhouse on the site and start using it.