Liquid floor (according to special terminology - self-leveling self-leveling floor) is a unique innovative coating. This technology allows you to make a beautiful, reliable, functional floor with your own hands for a person with minimal construction skills. This article is intended to acquaint, including with the help of a video, the basics of self-leveling self-leveling floor technology. The very process of preparing a self-leveling floor with your own hands is not so difficult with a careful division of the issue into its components. To make a self-leveling self-leveling floor with your own hands? The video will demonstrate that this is not difficult.

Content [Hide]

- 1 Preparatory stage

- 2 Leveling stage of work

- 3 The choice of the finishing mixture for self-leveling self-leveling floor

- 4 How to choose the type of self-leveling self-leveling floor by material

- 5 We finish the self-leveling self-leveling floor with our own hands. Video. Conditions for achieving quality

Preparatory stage

On this floor, you need to acquire the necessary tools and prepare the base of the floor for filling with a leveling mixture.

Set of tools

The very first question is what tools you need to have at hand:

- a container for the preparation of mortar for the floor (preferably with rounded bottom edges);

- drill;

- a mixer attachment for a drill (sold in a number of hardware stores);

- a spatula for application in corners and other inaccessible places;

- brush or roller for applying the primer;

- needle roller on a long handle;

- studded sole for the ability to move on the flooded floor.

In addition, to prepare the floor for work, you will need a vacuum cleaner, you can use a household one. It is recommended to use a dust collector for the vacuum cleaner to avoid damage from stone dust. It is also advisable to use a respirator and gloves for work.

Foundation preparation

Basis for self-leveling floor should be:

- without cracks and cracks;

- free of debris and dust (to remove small fractions of debris, use a vacuum cleaner, preferably with a power of at least 2000 W).

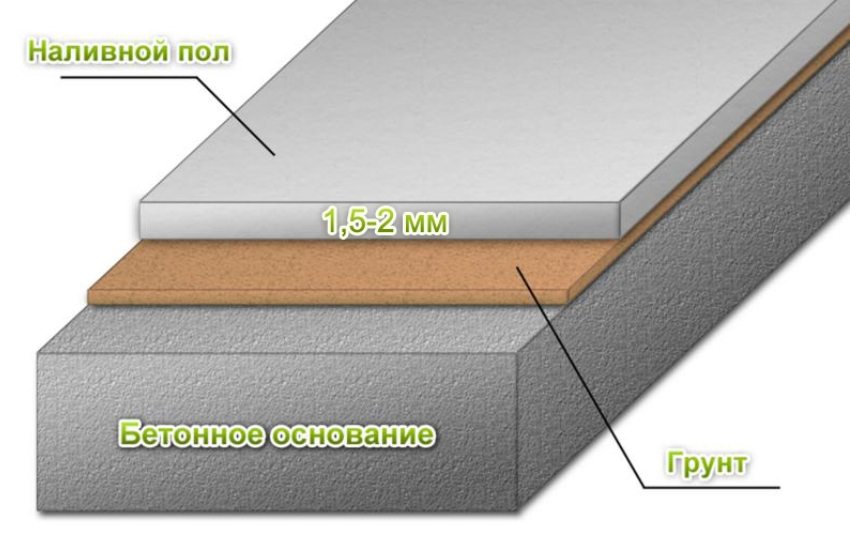

After cleaning the surface, the floors can be primed. Wait until the primer is completely dry before pouring the floor. If you do not have a primer, then you can use the same mixture, only diluted with water to a more liquid state. It should also be remembered that if there is a loose floor surface, the primer must be applied twice.

Some experts recommend using a damper tape around the perimeter of a self-leveling floor. This is only considered appropriate when the coating thickness is significant.

How to make a self-leveling floor with your own hands (video)

Leveling stage of work

To begin with, it is necessary to indicate that the floor is filled in at least 2 stages:

- "Rough" or leveling;

- Finishing.

A leveling step is necessary, since the base is almost always uneven. Especially in old houses. It is noticed that for two to three decades of operation, the center of the room "sags" by 5-15 mm relative to the perimeter. This "sinking" is found even on concrete floors. For leveling, you can use mortars - gypsum or cement. Although the gypsum mix has a lower specific gravity (about 20%), cement is recommended for more work. Gypsum mix requires either a wooden base, or very dry concrete, or pouring over an insulating material.

The technology for making a self-leveling cement self-leveling floor with your own hands is simple. It doesn't matter which cement is better to choose. Enough and the 400th mark, if only without foreign impurities, as is sometimes the case with unscrupulous suppliers. Two nuances to consider:

- The cement floor should be poured onto the reinforcement mesh.

- The filling should be carried out over the entire surface of the floor. Filling only defective areas leads to the formation of "humps", which does not give an ubiquitous zero level.

Helpful advice! It is recommended to fix the polypropylene mesh after 20-25 cm with silicone in order to avoid "floating".

The choice of the finishing mixture for self-leveling self-leveling floor

As for the finishing self-leveling self-leveling floor, at this stage the technology is a little more complicated. However, with careful separation, the task is feasible for doing it yourself. For clarity, the video filmed the work of professionals.

By the type of material, self-leveling floors are epoxy, methyl methacrylate, cement-acrylic or polyurethane

To begin with, the question is, which mixture is better to give preference to? Which supplier to choose? Which hardening period is more suitable?

For convenience, the main brands of finishing mixtures are summarized in the table:

| P / p No. | Name | Curing time | Layer thickness, mm | Consumption, kg / m2 |

| 1 | Eunice Horizon | 3-7 days | 2-100 | 3-4 |

| 2 | BOLARS | 3-4 hours | 2-100 | 3-4 |

| 3 | Vetonit | 3-4 hours | 1-5 | 1,5 |

| 4 | Perfecta Multi Layer | 2-3 hours | 2-200 | 7-14 |

| 5 | Axton | 3-4 hours | 6-100 | 14-16 |

| 6 | Palafloor | 4-6 hours | 2-100 | 1,4-1,6 |

| 7 | GLIMS-S-Level | ≈ 24 hours | 2-5 | 3 |

Note 1... Consumption is indicated for a minimum reasonable layer thickness of 5 mm.

In the selection process, pay attention not only to the value "consumption kg / m2», But also by the layer thickness on the label. Thickness can be indicated in different ways and often in small print at the bottom. Some manufacturers indicate consumption in kg / mm / m2.

The self-leveling floor has high moisture-repellent properties, so it can be equipped in kitchens and bathrooms

Note 2... Amount of material for self-leveling self-leveling floor (consumption per m2 in kg) in practice may differ from that declared by the manufacturer, therefore the mixture must be purchased with a margin. In order to calculate the consumption for sure, you need to take the maximum value from a series of measurements in different places in the room for the layer thickness.

Note 3... Since the consumer is interested not so much in crystalline hardening as in absolute hardening, the 3/24 rule can be used. The rule of thumb is that it takes 24 hours for every 3mm layer to cure completely. Building experience has established that after this period it is possible not only to apply finishing decor (linoleum, carpet, etc.), but even to put furniture. It is not difficult to independently calculate that a 6 mm layer hardens in 48 hours, 15 mm in 5 days, etc.

Helpful advice! Be wary of quick-hardening mixtures if you are making a self-leveling floor with your own hands for the first time. To practice your skills, watch how self-leveling self-leveling floors are poured in the video.

How to fill the self-leveling floor with your own hands (video)

How to choose the type of self-leveling self-leveling floor by material

What self-leveling self-leveling floors are better? By type of material, floors are:

- epoxy;

- methyl methacrylate;

- cement-acrylic;

- polyurethane.

Bright blue liquid floor in the children's room

All these types of floors are suitable for both residential and industrial premises. Although there is no consensus on which material is best to choose, a number of experts recommend pouring polyurethane floors. They are durable, waterproof, sound absorbing well. In addition, they combine impact resistance and elasticity, which is important when rearranging furniture. Indeed, in the place where the heavy furniture stood, stable deformations are formed. It is pleasant to the eye when the deformations even out over time. You can, of course, imagine installing furniture once and for all, but this rarely happens. Usually, furniture is moved to new places at least once every five years. Finally, do not forget the fact that polyurethane floors are still the most environmentally friendly in terms of toxic fumes and subsequent disposal.

We finish the self-leveling self-leveling floor with our own hands. Video. Conditions for achieving quality

Fill

The finishing solution should be mixed in small batches, no more than 20 liters. Ideal if there is a partner mixing the mortar while you are laying. It is necessary to mix with a drill with a mixing attachment, since manual mixing is ineffective. Also, attempts to dilute a solution that is already crystallizing with water lead to quality losses. The described experience is demonstrated in the video for your operational work.

Related article:

Pros and cons of self-leveling floors. Positive and negative feedback from the owners about their quality and characteristics. Self-leveling floor consumption per 1 sq. meter: how to cut. Types of self-leveling floors.

Since the need to fill the floor with your own hands may arise at different times of the year, you should pay attention that the operating temperature range for most mixtures is 15-30 ° C. At low temperatures, water has time to decompose important chemical constituents, which reduces strength. At high temperatures, water evaporates so quickly that there is no time for a complete leveling of the surface, that is, a "hedgehog" is formed.

It is necessary to stir with a drill at low speeds (300-500 rpm) by gradually adding the powder to the water. The mixing time is 3-4 minutes before the solution begins to thicken. Then the solution must “ripen” (residual microdisperse mixing during diffusion) for 5-10 minutes (check the time with the manufacturer).

Helpful advice! Although the technology is available for do-it-yourself execution, still for large areas (more than 40 m2) it is recommended to take the help of an experienced specialist. At least in order to more accurately calculate the material consumption.

If you save material consumption, please note that the thickness of the finished mortar in the thinnest place should not be less than 5 mm.

The application process itself is simple. This is essentially pouring a bucket onto the floor. It is, of course, almost impossible to pour the mixture out to perfectly fill the corner. Use a spatula to "stretch" the mixture into a corner.

Deaeration

Now the final part of the work remains - deaeration. Often, when doing work with your own hands, this stage is forgotten. Neglect of this stage of work leads to the emergence of air bubbles upward, and as a result - the "lunar soil" of the surface.To carry out deaeration, you need to stock up on studded soles and choose the right needle roller. A properly selected roller is considered one in which the length of the needles exceeds the layer thickness by 1-2 mm. Then the layer is mixed without significant displacement of the mixture horizontally. In addition, the roller must be equipped with a splash guard. This will increase the material consumption by exactly 0.01%, but it will eliminate microdefects. Microdefects can cause droplets of the solution to freeze on the fly.