The times have already passed when laminate or linoleum was chosen for flooring, because the building materials market is constantly replenished with new products, especially since recently everyone has been trying to surround themselves with natural finishes. Engineered floorboard has the aesthetic appeal of natural wood; like all modular coatings, it is characterized by durability even in high humidity conditions.

Content [Hide]

Engineering board: what is it and what are its characteristics

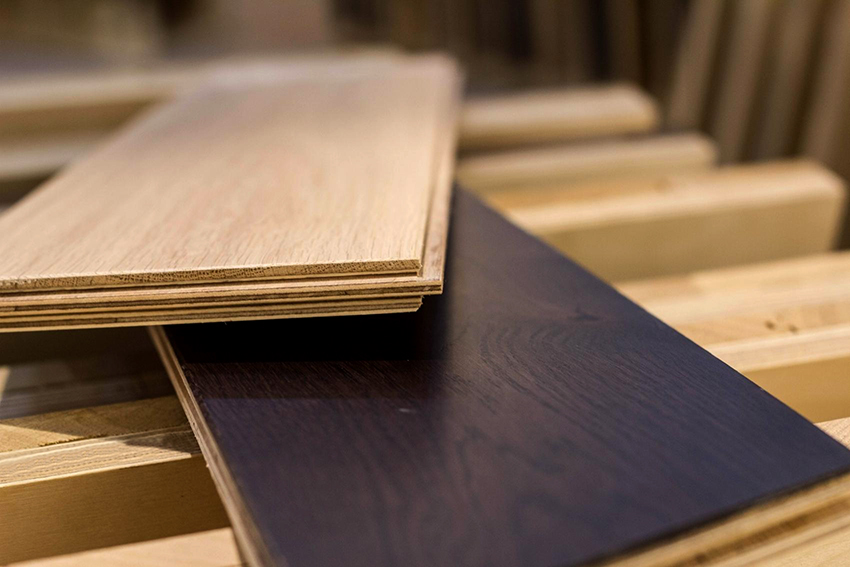

Not every user knows what an engineered board is, because the material has appeared on the market relatively recently. In general, the floor covering is a board, the base of which is plywood or chipboard, which can significantly reduce the total cost of the product. At the same time, the front layer is presented in the form of veneer, so it is difficult to distinguish the floor from the natural wooden version. In manufacturing, materials are used in the following proportion:

Externally, the coating is from an engineered board, it is impossible to distinguish from a wooden floor

- 75% - plywood;

- 25% - valuable wood species.

The thickness of the engineered board is a determining criterion for the durability of the coating. This indicator should not be less than 3 mm. The optimal thickness is considered to be about 1 cm. During production, all the layers that make up the board are reliably glued and pressed, which excludes the possibility of disturbing the geometry or structure of the floor, even with intensive use.

Information! It is considered interesting that the engineering board is a material that is used only in Russia. It is unlikely that such a floor covering will be found in European hardware stores. In Western countries, an alternative to such a material is a two-layer parquet board, which in many respects differs from ordinary parquet.

As for the parameters of the board, the following indicators are considered standard here:

- length - 50-300 cm, the most common value is 280 cm;

- width - 11-45 cm, sheets up to 60 cm in size are rare;

- the thickness of the engineering board varies from 1.5 to 2.5 cm.

How the engineered board is made: floors decorated with different types of material

According to the manufacturing technology, there are two- and three-layer boards. The base layer is usually laid perpendicular to the veneer, and if the product has a third layer, it lies parallel to the veneer grain. In short, the manufacturing technology is as follows:

- In production, using special machines, lamellas of the required parameters are made.

- Simultaneously with the lamellas, plywood blanks are made.

- With the help of a special glue for an engineered board, the inner layers are bonded together into a one-piece structure.

- The workpiece is exposed to the press, which ensures high adhesion of the layers and compliance with standard workpiece parameters.

- On the sides of the board, a lock connection is made, which is most often represented by a "thorn-groove" system.

- At the final stage, the board is varnished, although some firms use special oils or wax compositions as a finishing layer. To increase the stability and quality of the surface, at least 5 layers are applied.

Depending on the manufacturing technique, finished boards can be divided into 3 grades:

- Rustic. The cheapest material in terms of price, because veneer is used to create the face layer, formed by sawing at different angles. Often boards differ in color and texture, and small defects are found on their surface.

- Natures. Billets are made tangentially and radially by sawing, that is, the board is sawn lengthwise. This option no longer has visible defects, but sometimes the boards differ slightly in texture or shade. The price of an engineered board of this grade belongs to the middle category.

- Select. The most expensive board, in the production of which high-quality veneer is used, made by longitudinal sawing of the fibers. All products in this segment have the same color and texture, and the presence of defects is completely excluded.

The main pros and cons of an engineered floorboard

Not everyone knows what an engineered floorboard is. In terms of internal structure, it has similar features to laminate flooring, because it also consists of several layers. As already noted, a cheap bottom layer is made up of several sheets of plywood glued together. At the same time, the high strength of the coating is ensured by the fact that the direction of the fibers during production is alternated.

Walnut, ash or oak are the most commonly used expensive topcoats. An engineered board for underfloor heating is considered an ideal option, since it allows heat to pass well and has a lower thickness than other flooring options.

Checked! The use of plywood as a base allows not only to significantly reduce the cost of the material, but also at the same time maintain increased indicators of decorativeness, strength and durability. It is these advantages that are characteristic of coatings made of natural material.

According to reviews, the engineering board has the following key benefits:

- Durability and practicality. The floor covering tolerates various mechanical damages well, even under the influence of increased pass loads. Don't worry about scratches or scuffs starting to appear after a short time.

- Resistance to all kinds of influences. The board does not deteriorate under the influence of high humidity and does not change color even with constant exposure to sunlight. Users also note the absence of deformation and loss of appearance during temperature extremes.

- Aesthetic appearance.During installation, there is no need to additionally purchase and install thresholds, because the plates are attached using a special adhesive mixture that does not allow the fragments to loosen at the joints.

- Good insulating qualities. In addition to the fact that after the installation of the engineering board, the thermal insulation of the room increases, an additional layer also provides sound insulation qualities.

- Long service life. With careful use in an ordinary residential building, the material can last more than 30 years.

Before buying, it should be borne in mind that it is the thickness of the outer layer that determines the possibility of carrying out restoration work, since when grinding, at least 1 mm of the outer coating is removed at a time.

What other qualities are characterized by an engineering floorboard?

The significant advantages of the material also include the possibility of carrying out repair and restoration work. The thick top veneer layer allows for sanding surfaces by removing 1 to 3 mm of the damaged layer. At the same time, it is possible to renew the texture of the surface and restore the primary beauty of the floor. After carrying out the work, it is important not to forget to cover the board with varnish or other protective compound, which is based on wax.

As testimonials testify, some disadvantages are inherent in engineering floorboards, for example, the ability to collapse and deform. Despite the fact that most manufacturers emphasize the high resistance of the board to high humidity, some buyers note that with sharp changes in indicators, the inner layer begins to disintegrate. In most cases, this happens with engineered floorboards, the price of which is suspiciously low. When making cheap materials, the manufacturer saves too much and uses low-quality adhesives.

Other negative points:

- Large material thickness. Due to the fact that the coating has a thickness of 1.5 cm or more, sometimes difficulties arise in terms of combining the board with other floor coverings. At the junctions of two different coatings, you will most likely have to put thresholds.

- Complexity of installation. Laying the board requires a competent approach, and the process itself takes a rather long period.

- High cost compared to other modular materials. The price per m2 of engineering board starts from 2 thousand rubles. and increases with increasing material thickness. In addition, you need to additionally take into account the cost of glue, while the board will last longer than the most expensive laminate.

- Inability to shift the cover. For the reason that, unlike parquet, the engineered board is glued directly to the floor, there is no way to lift and move it if necessary.

- The likelihood of acquiring a fake. Due to the fact that the material appeared relatively recently, fakes are often found in retail outlets. In order not to get on low-quality material, you need to ask the seller for certificates confirming the originality and quality of the coating.

It is interesting! An engineering board laid in a herringbone looks beautiful on the floor. In addition, the floor can be made with squares or decorative inserts.

What is a parquet flooring

Many people know that parquet board is one of the varieties of flooring, consisting of three layers, each of which is represented by wood planks. At the same time, most manufacturers use a material for the middle layer where the fibers are directed perpendicular to the board. It is this fact that makes it possible to obtain a high-strength parquet that can withstand the effects of external factors.The planks are fastened together using a lock connection.

The main feature of the floor covering is its structure. Like engineering, parquet board consists of three layers:

- The front outer layer is represented by valuable wood, the thickness of which reaches 4 mm. The surface can be tinted, oil impregnated or varnished. It is precisely because of the presence of the upper impregnation that the inner part of the panel is reliably protected from the effects of moisture, and also the indicators of wear resistance increase.

- The middle layer of the coating is made up of perpendicularly laid small slats up to 1 cm thick. Inexpensive wood is mainly used, most often pine. It is in the middle part that the lock connection is used for laying, thanks to which the sheets are connected to each other.

- The bottom layer is most often made of conifers, which have the lowest price. The thickness is 1-2 mm.

Important! In any case, veneer acts as the face layer of the parquet board. Sometimes a valuable tree is also used for the manufacture of the lower layer, but the middle one is always represented by conifers.

The floors covered with parquet board always look attractive and reliable, and the lock connection ensures strong fastening of the panels to each other and prevents the sheets from twisting. It is for these reasons that surface deformation is almost completely excluded. Like all materials, parquet has advantages and disadvantages. So, among the advantages, the following points are distinguished:

Related article:

Concrete floor paint: choosing a quality coating for surface protection

Classification of compositions suitable for painting surfaces. How to choose the best protective coatings for indoor and outdoor use.

- No need for gluing to the floor surface. Due to the fact that the internal strips are perpendicular, it is possible to reduce internal stress and avoid surface deformation.

- Simple installation. The cost of laying an engineering board (due to the need to glue each panel) is at least 6 times higher than the cost of installing parquet, the boards of which are simply fastened together. Almost everyone with minimal construction skills can lay a parquet board.

- The ability to dismantle if necessary. The parquet floor can be easily disassembled and assembled, which is especially important in the event of a move or the need for complex repairs in the room.

How a parquet board differs from an engineering board: material cons

Despite the large number of advantages, the parquet board has certain disadvantages:

- The need to purchase a substrate. It is categorically impossible to lay material on a bare floor, because shifts and irregularities may appear, and sound insulation will also be completely absent.

- Using only certain styling techniques. The board is recommended to be laid only by deck method. If you install the material using a different method, the grinding process will be much more difficult.

- The inability to organize a warm floor system, because the flooring does not transmit heat well.

The main common feature of parquet and engineered boards is considered to be their similarity to flooring made of natural solid wood. Both options are considered safe for others and do not change color when exposed to UV radiation. In general, from the above information, it is clear that the materials have many similarities, but there is also a difference between them.

An important difference between parquet and engineering boards is their installation.If the first option can be installed both in a floating way and on glue, then the installation of an engineered board without using an adhesive is impossible. Some people note that after gluing, the engineered board is quite difficult to remove without damage. This fact can be considered a significant disadvantage.

A table indicating the main differences between engineering and parquet boards:

| Index | Engineering board | Parquet board |

| Length | 3m | 2.2 m |

| Width | 0.45 m | 0.25 m |

| Thickness | 0.25 cm | 0.14 cm |

| Styling options | Deck, squares, herringbone, etc. | It is most practical to use only the classic deck mounting method. |

| Installation method | Only with glue applied to concrete or plywood base | Floating, adhesive, no glue |

| Number of resurfacing | No more than 7 | Maximum 4 times |

| Re-styling possible | Practically impossible due to the presence of glue between the material and the base | It is easy to remove the dies and shift the boards without losing their appearance and deformation |

| Life time | 30-50 years old | 20-30 years old |

| Texture | Presented in a small number of tones and options | A large selection of textures and shades is available for purchase |

Main manufacturers and texture of engineering boards: oak, fir-tree, walnut and others

If an engineering board was chosen as the flooring, you should decide with the manufacturer. A wide range of materials is available on construction sites. To make it easier to make a choice, it is better to first familiarize yourself with the manufacturer's reputation and the operating features of the engineered floorboard (user reviews will help you make the right decision).

Wood Bee engineered board is popular among consumers of the Russian market, because it has an optimal price-quality ratio. The material of the Dutch manufacturer is made in cooperation with Chinese companies, which makes it possible to obtain a product available to almost every buyer at the exit. In terms of quality, the board meets European standards, and the coating itself is distinguished by various stylistic solutions and a large selection of textures. Among the disadvantages, users note some softness of the coating, on which traces remain from falling metal objects, as well as the appearance of dents from the legs of furniture.

Finex engineering board of the Russian manufacturer is presented in a wide range of shades and textures. It is also possible to create various effects, for example, aged wood, which is achieved through the use of manual processing technology:

- gouging;

- planing;

- brushing.

In order not to lose color during use, methods of smoking and staining are applied, allowing the color to penetrate deep into the wood. An additional protective layer is provided by treatment with hard wax oil and a special varnish. The manufacturer gives a guarantee for the goods for 25 years, because in the manufacture they use ultra-strong and elastic adhesive mixtures that can withstand a 10-hour stay in boiling water.

Other popular engineered board manufacturers

Coswick engineering board is based on plywood, which does not deform when exposed to high temperatures. It is this fact that allows the material to be laid on top of the underfloor heating system. Even when heated, the board does not emit any harmful substances that can affect the health of residents.

All products of the company have European certificates of environmental safety E1, which indicates the absence of formaldehyde in the composition. The board is distinguished by its ability to withstand all kinds of mechanical stress. Strength is ensured due to the fact that the basis is moisture-resistant plywood made of birch. The material has a low cost.

Topwood is a Croatian brand that has been on the market for over 20 years. The main direction of the company is the preservation of the natural properties of wood. Therefore, the entire assortment accurately conveys the rich wood pattern and shade of natural wood. The company, thanks to full-cycle enterprises, supplies to store shelves goods of the correct geometry, of the same grade, with good characteristics. Engineered board walnut, oak and other options are available for purchase. The only drawback is the high cost of the material, but in terms of operation, there are no negative customer reviews.

The Swiss company Bauwerk offers high quality products that are in great demand among customers. The thickness of the engineered floor board is only 11 mm. In addition, the company offers products with unique shapes and colors that cannot be found in other manufacturers.

Lab Arte engineering board is supplied by a domestic company that harvests mature hardwood oak from ecologically clean regions of the foothills of the Greater Caucasus. In production, the material undergoes a number of technological operations:

- sawing;

- drying;

- calibration;

- profiling;

- coating with varnish or oil;

- drying.

The manufacturer guarantees the high quality of the product, because at each stage the product undergoes strict control necessary to confirm compliance with the technical conditions.

NATURA engineered vinyl flooring is distinguished not only by its excellent technical characteristics, but also by its exceptional appearance. The Belgian manufacturer guarantees 100% water resistance of the coating, which is achieved thanks to a large number of additional layers, such as:

- UV;

- polyurethane;

- decorative - in the form of a film that imitates the texture of wood;

- vinyl.

It is the presence of the vinyl layer that ensures the constancy of the geometric characteristics, regardless of humidity and temperature drops.

How the engineering board is laid: recommendations and rules

It is important to know that before laying the engineered board, the material must be given time to lie in the room for at least 1-2 days. However, it is not necessary to unpack it. This is due to the fact that the material is of natural origin and small changes in geometry are possible when the surrounding conditions change. After the board is laid down in the room where it is planned to be laid, it will adapt to the conditions and acquire a shape convenient for itself.

In addition to the fact that you can use different methods of gluing (for example, the option of laying an engineering board - a French Christmas tree, when the sheets are laid at an angle to each other) is considered popular, there are several different installation options. So, you can lay the coating on a concrete base, which is pre-leveled and primed with water-repellent mixtures. It is best to primer in 2 coats to improve the adhesion of the adhesive. After applying a layer of polyurethane, the installation of an engineered floorboard begins using the “thorn-groove” technology, which is identical to the installation of laminate and parquet boards.

Another option is to lay on plywood. In this case, it is important to choose sheets with a thickness of at least 12 mm, the optimal thickness is 18-22 mm. Plywood should not bend. Between adjacent sheets, a thermal seam with a width of 5-7 mm must be maintained. To remove possible defects, it is required to sand and level the surfaces. You need to retreat from the wall 1-1.5 cm. Next, a layer of glue is applied, then each row is screwed separately with self-tapping screws. The seams between the boards are covered with glue.

Important! When calculating costs, in addition to the cost of the material, you need to take into account the price of the adhesive mixture, on which it is better not to save money and immediately purchase a high-quality and proven option. The price of the mixture is about 3000 rubles. for 10 kg. Average consumption - 600-700 g per m².

Important recommendations:

- Installation of the board must be carried out in a room where the temperature is within 18-22 ° C, the humidity should not exceed 70%. If the indicators are insufficient, it is recommended to turn on the heating devices to bring them back to normal.

- Before gluing, it is recommended to spread the boards on the floor to check the color consistency and absence of defects. If there is a board that is different in color or texture, it can be used in an inconspicuous place, for example, under furniture.

- To exclude the displacement of the first row, it is recommended to set at the wall, taking into account the expansion gap, at the building level and attach a guide bar.

- It is better to apply the glue with a notched trowel, and the board must be glued carefully, row by row.

- A gap of at least 1-1.5 cm should remain between the door leaf and the material. If the gap is less, it is worth cutting the door a little.

- To prevent crushing of the end seams on the planks, the first board should be laid with the groove against the wall.

- During installation, it is strongly not recommended to hit with a hammer directly on the surface of the coating.

- For more attractiveness, the planks should be laid with an offset to prevent the formation of a continuous row of seams.

- Work best in good daylight.

An engineered board is considered one of the best options for organizing flooring in a residential area, since outwardly it practically does not differ from wood, but at a much cheaper price. The coating has a minimum number of disadvantages, which are lost against the background of a large number of advantages. In any case, the board can be considered an excellent and more sustainable alternative to laminate.