Laminate is a coating that requires the preparation of a perfectly flat base. But what if there is no possibility dismantle the old floor and arrange a new cement screed? Can laminate flooring be laid on wooden floors? These questions are of interest to those who decided to freshen up the interior without resorting to capital investments. You can find out about the methods of laying material on an already existing surface from the recommendations and video given in the article: how to put a laminate on a wooden floor with your own hands.

Content [Hide]

- 1 Can laminate flooring be laid on wooden floors?

- 2 How to level a wood floor under a laminate

- 3 DIY laminate flooring

- 3.1 Choosing a material: calculation and purchase of laminate

- 3.2 Preliminary preparation of the base

- 3.3 Leveling the wooden floor with chipboard

- 3.4 Necessary tools for work

- 3.5 Choosing a substrate for a laminate on a wooden floor

- 3.6 How to lay a laminate on a wooden floor: installation technology

- 3.7 Features of laying the last row of laminate

- 3.8 How to properly lay laminate flooring on hard-to-reach places

- 4 Tutorial video: how to lay laminate flooring on a wooden floor with your own hands

Can laminate flooring be laid on wooden floors?

The question of the possibility of laying laminate on an old wooden floor often arises due to the fact that the cost of dismantling and installing a new cement base in many ways exceeds the cost of purchasing the floor covering itself. In addition, the expediency of a major overhaul is not always justified, since it is associated with the duration of the process, while the interior of the room can be changed by resorting to cosmetic repairs.

Laying laminate in the apartment

Can laminate flooring be laid on wooden floor and not to be afraid that the coating will be deformed, will creak when walking or disperse at the seams? Knowing how the old wooden base behaves, and what measures must be taken to comply with the basic requirements for laying laminate floors, you can safely start work. The technology for laying laminate panels on a wooden floor is similar to the procedure for covering with a screed.

Despite the warnings of manufacturers and some laying specialists, it is possible to lay a laminate over a wooden floor, taking into account two main differences between a wooden and a cement base:

- Instability of the wooden base.Laminate floorboards laid on top of a wooden base can move. This will put additional stress on the laminate locks, which are the most vulnerable point of this flooring.

- Loss of mechanical properties of wooden flooring during operation. This fact obliges, before laying the laminate on the wooden floor, to scrupulously check the wooden structure for defects and fix the loose elements.

To laminate was perfectly flat, did not diverge in the locks and served for a long time, it is necessary to prepare the base taking into account all the requirements for the surface when laying this material. The foundation must be:

- even - the deviation from the horizon should not exceed 2 mm per 1 running meter of the surface;

- absolutely dry;

- clean - it is necessary to remove from the surface all debris and dust that arose during the preparation process;

- stable - there should be no displacement of the base elements relative to each other.

How to level a wood floor under a laminate

There are several options for leveling wooden floors under laminate:

- scraping the wooden floor;

- plywood flooring or Chipboard;

- leveling with plywood using shims and bars.

The choice of one or another option for correcting the surface depends on the degree of unevenness of the wooden base.

Repair of an old wooden base

Work on the preparation of a wooden floor for laying a laminated flooring is carried out either immediately before installation, or in advance. It depends on how complex the process will be and how long it will take to fully meet the technical requirements. First, you should check the condition of the wooden floor for all kinds of defects.

Most often, boards that have been in use for more than one year have a slightly convex surface as a result of applying several layers of paint to them. The edges of boards or parquet slats can be damaged in the form of cracks, holes and dents. In addition, it is possible that the floorboards do not fit tightly to the joists at the joints. Sometimes there is a significant slope of the floor in one or more directions. All these shortcomings require elimination.

Before laying the laminate on the wooden floor, you should close up all the potholes, wedge and fix the loose elements with glue and self-tapping screws. If there are cracks on the wood, they are pulled together with staples using a construction stapler. Moldy and rotten boards must be replaced with new ones. To eliminate the squeakiness of the wood floor, you need to go through all the floorboards.

Helpful advice! In order to avoid the appearance of a squeak, when rebuilding the floor, you should not use nails, but self-tapping screws, since most often the sound appears precisely at the junction of the nail with the tree.

You can also get rid of a squeak in a wooden floor by driving wedges between poorly fixed boards and joists, as well as between adjacent floorboards. This method will help neutralize the friction of the boards against each other. If the boarding is badly worn, this method may not give an effective result. Yet the main threat to integrity laminate the unevenness of the base remains.

How to lay laminate flooring on uneven wood floors: sanding the surface

If all the floorboards of the wooden base are well anchored and the surface does not have a significant slope, you can use scraping or electric planer for leveling. This method is appropriate for surfaces whose unevenness does not exceed a slope of 5-6 mm per square meter.Local irregularities are eliminated by processing defective areas with emery paper or using a hand-held scraper. This treatment is also used in hard-to-reach places.

To facilitate the process, it is recommended to start leveling with dividing the entire surface into several sections. After processing, the plane of each section and the quality of grinding are controlled. Before starting work, it is necessary to bury the heads of all self-tapping screws 2 mm into the wood in order to avoid contact with the metal blades of the grinding power tool, which can lead to their damage.

Upon completion of the leveling, check the entire surface of the wooden floor using a level, after which they carefully sweep or remove sawdust and dust with a vacuum cleaner. If the fine debris left after leveling is not removed, it is likely that it will get into the locks of the laminated coating, and this, in turn, will lead to an unwanted squeak when moving along laid laminate.

Before laying the laminate on a wooden floor after leveling, it is necessary to treat the entire surface with an antiseptic compound or to polyp and dry well. To reduce the possible deflection of the laminated coating, it is recommended to lay the panels of the material perpendicular to the direction of the boards.

Helpful advice! Before starting work on leveling with the help of scraping, you should take care of the safety of interior items in the apartment: furniture and accessories should be covered with polyethylene to prevent fine dust from getting on them.

Leveling the floor with plywood for laminate

One of the simplest and at the same time low-cost types of surface adjustment to the required level is considered to be the method of laying plywood on a wooden floor under a laminate. To perform such work, you should purchase plywood sheets with a thickness exceeding the thickness of the final laminated coating. It is recommended to choose the thickness of plywood on the floor under the laminate in the range from 12 to 15 mm.

Before starting installation, it is useful to check the humidity level in the room. This can be done by placing a sheet of polyethylene approximately 1x1 m in size on the floor. The polyethylene should be pressed firmly to the floor and left for three days. If, after this time, no condensation forms on the inside of the sheet, plywood sheets can be used in such a room.

The process begins with cutting plywood sheets. They are cut into squares 60x60 cm in size. Separate outer sheets are adjusted to fit the outlines of the room, fill niches and bypass protruding areas. When laying between the sheets, gaps of 7-10 mm are left, which act as expansion joints. The distance between the outer sheets and the wall should be between 15 and 20 mm. In order not to confuse the cut plywood sheets during assembly, it is recommended to number them.

You can fix plywood boards to the floor with glue, but you can do without it. Using the stacking scheme and numbering, the sheets are laid out on the wooden floor in their place and fixed with self-tapping screws in the corners of the square and along diagonal lines with a pitch of 15 cm. For fastening it is important to use self-tapping screws, the length of which is three times the thickness of the plywood. After final assembly, the plywood sheets are carefully sanded with coarse sandpaper.

Laying plywood under a laminate on a wooden floor with fixing on logs

Before laying the laminate on a wooden floor, you can use the leveling of the surface by laying plywood with fastening it to the logs. This method is rather laborious and expensive. The principle of this method is to install the lags so that their upper faces are in the same horizontal plane. To achieve this position, wedges or wooden blocks are placed under the logs. When laying adjustable joists, their position is fixed by means of adjusting screws.

Plywood boards are cut with a circular saw and placed on the logs, while the horizontal level of the plane of each sheet is checked. Laying is done in a checkerboard pattern to avoid overlapping seams at one point. The sheets are fastened to the wooden base with self-tapping screws along the perimeter and diagonally with a step of 20 cm. For quick and easy installation, it is recommended to pre-mark the fastening points.

Helpful advice! Do not use plywood sheets with phenol formaldehyde glue for installation in a residential area. Such material has excellent moisture resistance, but it can be harmful to human health, being toxic.

After complete laying, the sheets are sanded and treated with an antiseptic solution, and then the laminate is laid on the plywood. On wooden floors leveled in this way, the flooring will hold firmly and for a long time. The only drawback of laying plywood on logs is that this option is not very suitable for rooms with low ceilings, since their height may decrease to 8-10 cm. In addition, trimming of the door leaf may be required.

Is it possible to lay laminate on fiberboard

When making repairs in an apartment, many are wondering whether it is possible to put laminate flooring on a wooden floor covered with fiberboards? Some recommendations indicate that if the plates Fiberboard laid flat and firmly in place and can be used as a base for laminate flooring. However, some experts disagree with this statement.

The thing is that fiberboard panels do not have the ability to redistribute the load over a large area, unlike plywood or chipboard sheets... Also, when made fiberboard sheets, there is no way to thoroughly examine the condition of the old wooden floor. How do you lay laminate flooring on a substrate that may be rotten or worn out? This can lead to the fact that over time all existing defects will appear on the finished flooring.

Fiberboard use, which is based on pressed paper as a base for a laminated coating, raises serious doubts about the durability of the repair. On old floors, under load, a play of up to 0.5 mm may appear, which will cause the laminate locks to loosen. This can lead to squeaking and breakage of the locks. And if you consider that the logs of the wooden floor can be cracked, the gap can be much larger.

Considering that not everyone has the opportunity to dismantle the old wooden floor or sort it out (which is also expensive in itself), you can lay the laminate on the fiberboard. However, the condition must be met that the fibreboard is sufficiently firmly fixed to the wooden floor. And if the base for the laminate is strong, then there is not much difference, which is the basis - Chipboard, plywood or fiberboard.

DIY laminate flooring

To understand how to properly lay the laminate on a wooden floor, you need to have an idea of the material itself, its classes, the types of substrate used, calculations and installation technologies. This information will help during the work to avoid mistakes that lead to damage, waste material, and will also contribute to high-quality and durable installation.

Choosing a material: calculation and purchase of laminate

The amount of laminate required is calculated based on the area of the room, the coefficient of material consumption and the method of installation. First of all, you should determine the area of the covered surface. The number of square meters of the room is divided by the area of one laminate board. The result is the required number of strips of coverage.Knowing that each pack contains 8 boards, you can easily determine the number of packages.

When buying material, you should also take into account the consumption coefficient, which varies from 5 to 14%. This or that value of the coefficient depends on how the laminate panels are laid. If you decide to lay the laminated flooring diagonally, the maximum coefficient is taken. Consequently, there will be more waste of material.

Helpful advice! When purchasing laminate, make sure that all packages are of the same batch. The same material from different batches may vary in color.

In addition, it should be borne in mind that during the installation work, the plate lock may be accidentally damaged or an incorrect trimming may be performed. In this case, it will be useful to purchase several boards in stock.

For working with laminate in residential premises, a coating with certain technical parameters is chosen. Manufacturers present four classes of material, the main indicator of which is wear resistance. The most common slabs are 6, 8 and 10 mm thick. The thicker the board, the stronger the coating. For domestic use, 31 and 32 classes of material are quite suitable.

In addition to strength indicators, laminate slabs differ in locks. There are two types of locks - CLICK and LOCK. The CLICK lock is more common, it perfectly holds the seam and allows irregularities up to 3 mm per linear meter of the surface. Panels with the second type of lock are difficult to install, require a perfectly flat base and are used less often.

Preliminary preparation of the base

Before placing laminate flooring on a wooden floor, the condition of the existing subfloor should be analyzed. It is necessary to identify all existing defects: potholes, cracks, holes. Loose boards should be wedged and fixed with glue and self-tapping screws. Potholes should be sealed with wedges using glue and, if possible, clean the ventilation holes.

A very old floor should be dismantled to support logs. If during the examination it was found that some elements are rotten, they should be replaced. Flooring boards that have leaked on one side can be turned over with the unworn side up, and completely rotten ones can be replaced with new ones. Checking the slope of the floor is carried out using a building level and a rail.

If you find a difference in the floor surface of more than 3 mm, you should use the scraping method. If you do not have a scraper, it is always possible to rent one. It will be more reliable to level the floor by laying chipboard or plywood boards. In addition to the leveling function, such a coating will provide additional insulation and sound insulation of the floor.

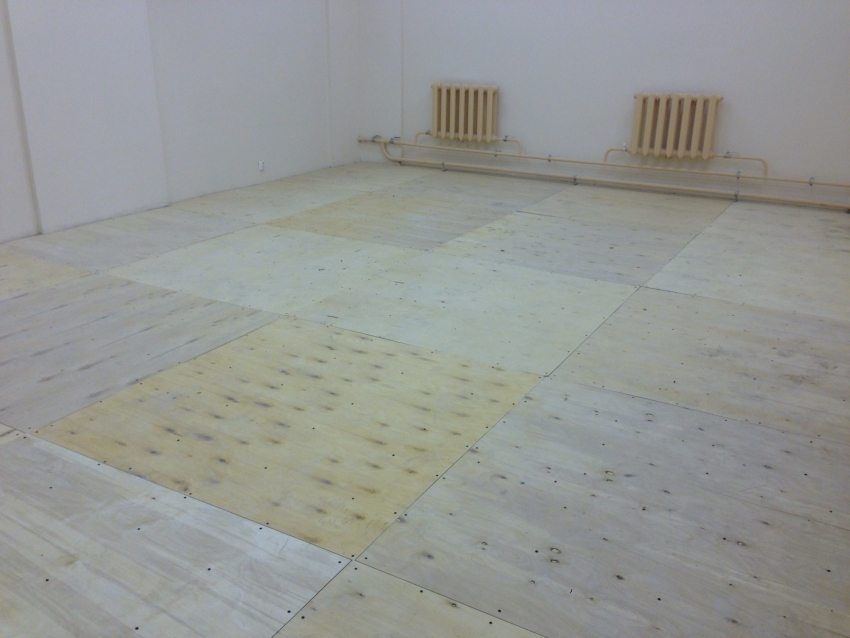

Leveling the wooden floor with chipboard

Chipboard boards are laid after strengthening all elements of the wooden floor and impregnating the base with an antifungal composition. Dismantled plinth, and remove unnecessary items that can interfere with the process. Plates are laid from the corner of the room. A gap of about 10 mm is left from the wall. Arrange the chipboard sheets so that the joints of the material fall on the line of the beams.

Chipboard plates are fixed with self-tapping screws, while you need to try so that the heads of the fasteners do not go beyond the surface. The pitch of the self-tapping screws should be about 30 cm. After all the chipboard boards have been laid, the joining lines must be putty with thin-layer compounds specially designed for working with wood. When the solution dries, the chipboard surface is sanded.

The base made of freshly laid chipboard should be thoroughly dried. Ideally, the plates should be kept for about a week so that acclimatization takes place and excess moisture evaporates. If during this time it is found that some joints have swollen or displaced, they should be looped, patched and cleaned with a sanding paper.

Helpful advice! The technology of leveling the chipboard floor allows you to prepare a wooden floor of any quality for laying a laminated flooring.

Necessary tools for work

For people who are not professionally engaged in repairs, but are going to lay the laminate on their own, a logical question arises about a set of tools for work. To lay laminate on a wooden floor, you will need a tool that should be in the arsenal of each owner:

- construction tape;

- ruler, pencil;

- construction knife;

- hacksaw or jigsaw;

- rubber mallet;

- pliers.

Do not forget about plinth, for fixing which you will have to expand the range of tools somewhat If you intend to install wooden skirting boards, you will need a miter box. In the case of plastic skirting boards, this device is not needed. You will also need a screwdriver or drill to tighten the screws.

For mounting holes for fasteners skirting boards a hammer drill may also be helpful. Not everyone has this power tool, but it can be rented for the duration of the work.

Choosing a substrate for a laminate on a wooden floor

Before laying the laminate on a wooden floor, it is correct to cover the surface with a backing. This layer allows you to compensate for minor irregularities, to provide moisture and sound insulation of the laminate, as well as the space between the coating and the base. There are many types of substrates, and they differ in composition, properties, cost, appearance and other characteristics.

The material for the manufacture of substrates can be synthetic (polyethylene foam), natural (cellulose, cork, needles, etc.) and combined. The most budgetary option is polyethylene foam - lightweight, easy to install, but fragile material that quickly compresses and does not provide proper moisture exchange. A more durable substrate is made of polystyrene in the form of 1x1 m plates, it does not cake and provides high-quality sound insulation. But these types of substrates are more often used when the base is made of concrete.

Before laying the laminate on a wooden floor, it is recommended to install a natural material underlay. The cork backing has excellent properties; in combination with the laminate, it demonstrates excellent heat and sound insulation. Its cost is quite high, but this is offset by the long-term preservation of the wooden base. The thickness of the substrate is selected based on a similar parameter of the laminate board.

Helpful advice! Do not use multiple layers of underlay to level the base surface. Uneven floor surfaces are removed in other ways.

For example, a 3 mm thick substrate is selected under an 8 mm board. With regard to laying the material, it should be noted that the strips of the substrate are placed end-to-end without overlaps and stationary attachment to walls or a wooden base. Docking lines are glued with tape along the entire length or in periodic places.

How to lay a laminate on a wooden floor: installation technology

As soon as all the preparatory work is completed, you can proceed directly to the installation of laminated panels. The process of installing laminate flooring is relatively simple and does not require special knowledge and skills. However, it is still worth familiarizing yourself with some of the nuances of installation. Choose the place where the packages with laminate will be located, remove the doors from the hinges, free the room from unnecessary items.

Before laying the underlay, remove all debris and thoroughly dust the surface of the substrate. Stripes substrates stacked parallel to the future arrangement of the laminate boards. If a single piece of the substrate is not enough, it is necessary to connect several parts with tape, cutting them using the mirror cut method.All docking lines are also glued with tape.

Related article:

Do-it-yourself step-by-step instructions for laying laminate flooring: features of work. Tips for laying a new floor in an apartment for a beginner. Materials, foundation preparation, laying rules: step-by-step photos of work, video.

Next, the first row of the coating is laid. Keep in mind that the laminate panels should run across the planks of the wood base. Carefully connect the lamellas of the first row to each other. First, we assemble solid panels, and then measure the length of the last board of the row and outline the cut line. When trimming, you must turn the board 180 degrees, otherwise the locks will not match. Cut off the excess part at the mark. Use the video on how to lay laminate flooring on a wooden floor with your own hands as a visual aid.

Do not forget to leave gaps between the end of the panel and the wall, in which you can put 8-10 mm wide stoppers made from laminate scraps. After the formation of the starting strip, the next one is going. The distance between adjacent rows should be small to make it easier to connect them. The formation of the next row begins with a cut lamella.

After assembling the second strip, it must be carefully lifted, holding on to the end joints, and slightly unfold so that the lock snaps into place. It is necessary to go along the entire length of the strip, alternately lifting the end joints and snapping the locks. In order for the locks to be tightly fastened, it is necessary to bring them in by tapping with a palm or a mallet.

By this principle, all other rows of coverage are assembled. Laying laminate panels is best done in a chaotic manner, i.e. some of the rows should not start with the trimmed board of the previous strip, but with the whole board or with a shortened trim.

Helpful advice! When laying laminate flooring, it is recommended to separate the covering of each room from other rooms by means of an expansion joint. It is arranged in the doorway between adjacent rooms.

Features of laying the last row of laminate

The closer the styling moves to the last row, the more inconvenient it will be to carry it out. When the room is covered by 80%, it is necessary to lay the panels, turning in the opposite direction and standing on the already laid laminate. Some difficulties are caused by laying the last row, which must be carefully measured and cut along the strip.

From quality laying laminate its service life will directly depend

When the laying process reaches the last strip, the distance from the edge of the penultimate row to the line of the opposite wall along the entire length may not be the same. In view of this, the marking of the last row is carried out in stages: first the first board is marked and cut out, then the next one is measured and cut off, and so on until the end of the row. We outline the outlines of the first panel with a pencil and cut out the necessary strip according to the marking.

As soon as the laminated flooring is laid, proceed to fixing the skirting boards. Docking places between rooms are covered with special thresholds to prevent dust from entering there. At the end of the work, sawdust and debris are removed from the coating and the surface is wiped with a slightly damp cloth.

How to properly lay laminate flooring on hard-to-reach places

Laying laminate flooring in places where pipes, heating radiators, around doorways and in other hard-to-reach places pass through, does not present any particular difficulties. The pipes are bypassed in the following way: they make marks on the board with a pencil and cut the corresponding holes in it, not forgetting to take into account the temperature gap between the coating and the pipe (8-10 mm).

Gaps around pipes and other ironwork should be sealed with a matching acrylic sealant, while expansion joints around walls should be left unfilled. Subsequently, their unaesthetic appearance will be covered skirting boards... Similarly, the material is laid near the thresholds, steps and other ledges.

As for bypassing doorways, before laying the laminate flooring on a wooden floor, it is correct to remove the canvas from the hinges and determine if the door will close after laying the covering. To do this, add up the thickness of the laminate, backing and leveling layer (if any). Subtract this value from the distance from the edge of the door to the wooden floor. If less than 3 mm remains, the door leaf will need to be trimmed.

After all calculations are laid laminate around the door frame, leaving an allowance of 8-10 mm, return the door to its place and check its movement. If necessary, file the door to the desired size.

Tutorial video: how to lay laminate flooring on a wooden floor with your own hands

According to the principle, it is better to see once than hear a hundred times, home craftsmen are invited to familiarize themselves with the training video of laying laminate on a wooden floor. From the rollers, you can learn everything about the coating device on a wooden surface.

Video: DIY laminate flooring on a wooden floor

You can find a whole series of courses on the internet on how to lay laminate flooring. Video instructions for the installation of flooring contain visual information and practical advice from both experienced craftsmen and those who first tried to level a wooden base and lay the lamination on their own.

In the training videos, you can see master classes on leveling the floor with plywood and chipboard, learn about the features of a wooden base, the choice of a substrate, as well as step-by-step instructions for laying laminate flooring. In addition, in the videos you can find recommendations on how to eliminate possible defects in the wood flooring.

Video: how to lay laminate flooring near the doorway

There are many tutorials about the installation of skirting boards, the peculiarities of the interlocking joints of the flooring and the technology of fastening the panels of the material to each other. Thematic video tutorials contain information on how to lay the coating around radiator pipes, in niches, ledges, near doors and steps, as well as in other hard-to-reach and inconvenient places.

Some video tutorials are devoted to the elimination and sealing of defects on an already laid laminate flooring. From them, you can learn how to disguise scratches formed on the laminate, dents from fallen heavy objects or heels, as well as how to repair damage formed during the installation process: chipped corners and edges, seams divergence, puffing of the coating.

Leveling a wooden floor using any of the existing methods allows it to be used as a base for laminate flooring. If all the work on the preparation of the floor surface is carried out in compliance with the technical requirements, the floor covering will last a long enough period, without requiring repairs and at the same time maintaining an aesthetic appearance.