An advantageous option for supplying heating to a room and providing hot water is a waste oil boiler. The device is characterized by a simple design, which allows you to make it yourself. This will help you save additional money. If such a possibility is excluded, you can purchase a boiler at the factory assembly. Currently, the range of products is presented in a wide variety.

Different variants of waste oil can be used for the boiler, which is characterized by an abundance of various impurities

Content [Hide]

- 1 What is a waste oil boiler

- 2 How does a boiler work

- 3 Varieties of waste oil boilers

- 4 The subtleties of the process of creating a boiler for working out with your own hands

- 5 DIY waste oil boiler with a water circuit

- 6 Oil options for waste oil boilers

- 7 Review of Russian-made waste oil boilers

- 8 Finnish waste oil boilers for a private house

- 9 European manufacturers of heating boilers for testing

- 10 Other manufacturers of oil boilers

What is a waste oil boiler

Today, heating equipment that operates during testing is very popular. This is due to a number of distinctive advantages of the device. First of all, this is the low cost of installation and the availability of fuel, which can be bought for a nominal fee. Heating at mining does not require the use of resources in the form of electricity and gas, which makes it economically viable.

Important! Recycling of waste products in full has a beneficial effect on the environment, excluding the disposal of oil and getting it on the ground and into water bodies.

If the boiler is set up correctly, the waste oil is burned completely, so that no toxic combustion products are formed. The device consists of a minimum number of parts, which can be seen on the boiler diagrams. This increases the reliability and durability of the structure. It does not take much time to warm up the boiler. Forced convection causes the room temperature to rise rapidly.

Despite its many advantages, the mining boiler also has disadvantages. During operation of the device, moisture from the air evaporates and oxygen is burned, which negatively affects human health. Therefore, the boiler must be located in a non-residential area with good ventilation. The mining devices quickly get dirty. This is especially true for the plasma bowl and chimney.

For such a boiler, different versions of waste oil can be used, which is characterized by an abundance of various impurities. Therefore, to ensure a long period of operation of the device in the place where the oil is supplied to the boiler, a filter should be installed, which must be replaced as it becomes dirty.

How does a boiler work

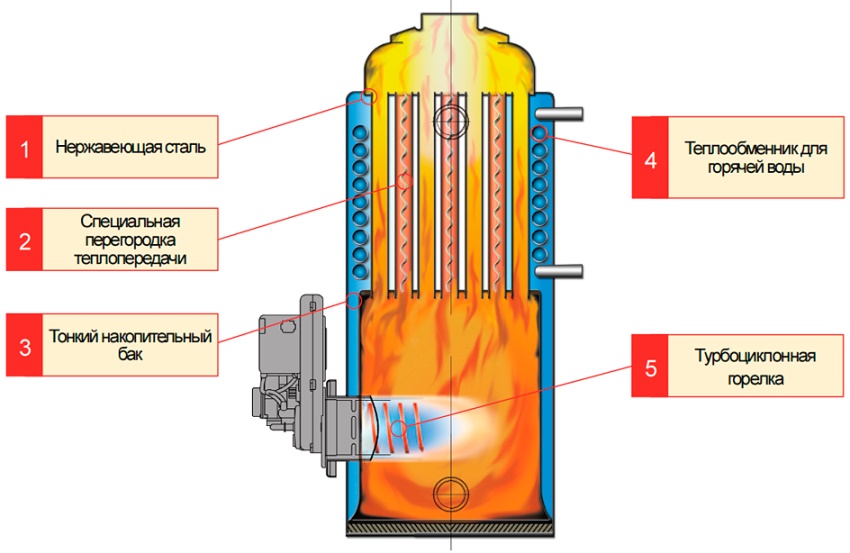

Waste oil boilers for a private house, as well as for a garage, workshop or industrial premises have a simple design. They consist of two chambers-compartments: an evaporation chamber and a combustion chamber. In the first compartment, the waste oil is prepared for combustion. In the second, it is burned. The principle of operation of the device is as follows.

From the container with the used oil, the pump delivers the substance to the evaporation chamber, which is located in the lower part of the apparatus. The required temperature is maintained in it, sufficient for heating and subsequent evaporation of the mining. Oil vapors rise to the upper area of the housing, where the combustion chamber is located. It is additionally equipped with an air duct in the form of a pipe with holes. With the help of a fan, air is supplied through the air duct to the chamber, where it is mixed with oil vapor. The resulting mixture burns out without residue.

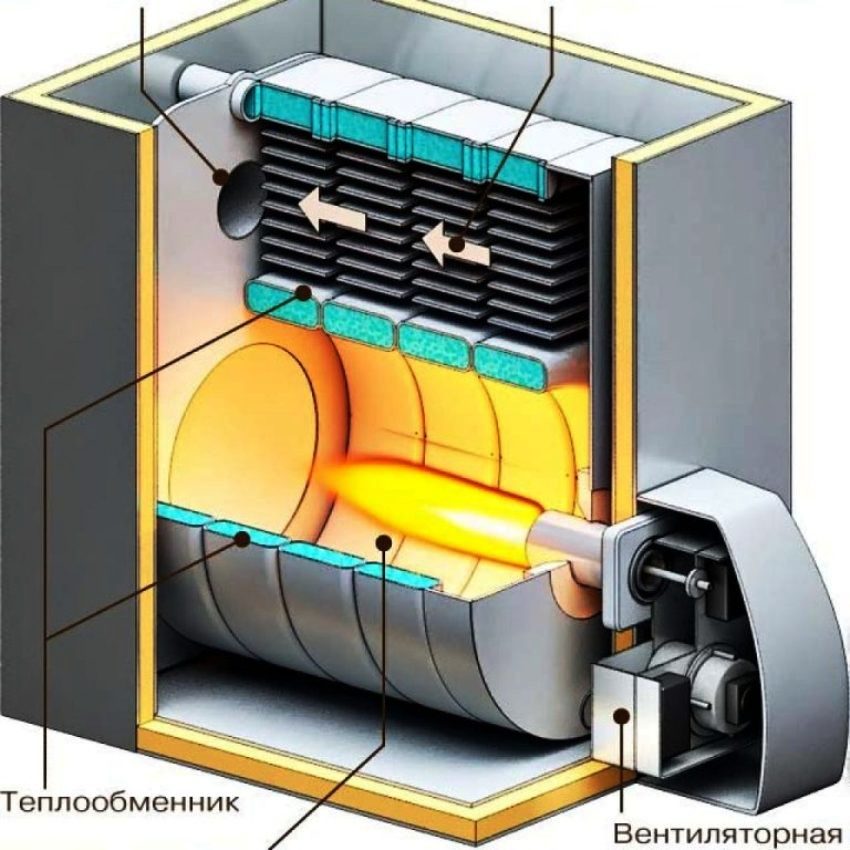

The heat exchanger distributes the heat received. The generated combustion products are fed to the chimney. A mandatory process is the preheating of the mining. Oil contains many impurities, under the influence of a certain temperature, the process of decomposition of the substance into simple carbons takes place, which are subsequently burned. As a result, water vapor, nitrogen and gas are formed, which are harmless to the body.

Complete oxidation of carbohydrates is possible only at a temperature of 600 ° C. If this value is not observed, the combustion process produces many toxic substances that are extremely hazardous to human health.

Varieties of waste oil boilers

There are three options for waste oil boilers: water heating, heating and household. The first option is an alternative to a modern boiler. Having a platform design, the device heats up a flat surface where the water tank is located. A small pump is installed at the outlet of the tank, which regulates the pressure in the system.

Important! It is very difficult to change the temperature of the water, therefore, if necessary, it is recommended to dilute it with cold water.

For hot water boilers using waste oil, a water tank with a volume of not more than 140 liters is used. It heats up for 2 hours, which is several times faster than the speed of a modern electric boiler. The oil water heater can operate in two modes: fast and wick. The first option is used to heat completely cold water. The wick mode allows the water in the container to be warmed up. However, this will require a large amount of fuel resources.

Important! Oil-fired water heaters for mining are installed in basements, as they are not transportable.

Domestic boilers are considered the ideal solution for country houses. They have a built-in gas cleaning mechanism, which makes the device work without smoke. Such devices are mobile designs, which will allow them to be carried to any place without disrupting the operation of the product. This multifunctional device allows not only heating the room, but also heating food. The unit can be used outdoors or while traveling.

Waste oil boiler automation can perform various functions.Here you can set up control over heating of the coolant, room temperature. Such devices are installed on the floor. Their cost depends on the functional features of the device.

Due to the compact dimensions of the hot water boiler, it is convenient to install it in the boiler room

Characteristics of a waste oil heating boiler

The waste oil boiler must be located in a non-residential area. As a rule, to heat the house, it is installed in a special annex. Despite the fact that modern devices are equipped with an improved filtration unit, they emit an unpleasant smell of engine oil during operation.

The inner part of the unit is equipped with a heating unit with a water tube and a hydraulic pump. The last element can work from the electrical network or from the energy generated by the device itself. With the help of a hydraulic pump, a coolant circulates in the circuit in the form of ordinary water.

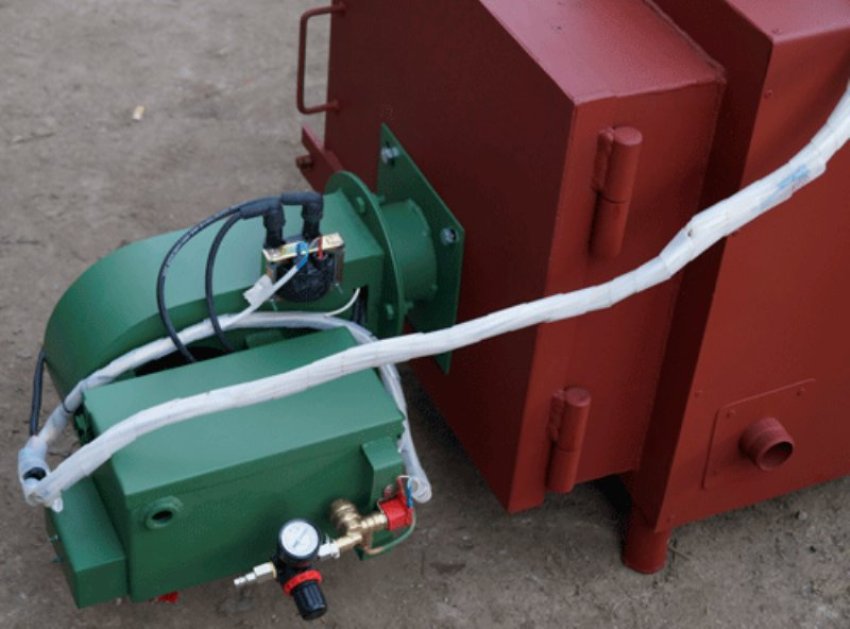

The principle of operation of the device is as follows. In the combustion chamber, the oxidation of oil vapors and air masses, which come under the influence of a ventilated compressor. The fire level is regulated using a hose with a valve. The ventilation device is the only movable element, as a result of which it can fail.

Such boilers are characterized by high performance and the ability to maintain the air temperature in the room for a long time. The fuel tank is located on the floor, and the air heater can be mounted on a wall or ceiling.

The inside of the boiler block is equipped with a heating unit with a water pipe and a hydraulic pump

The subtleties of the process of creating a boiler for working out with your own hands

The most important component of the fuel combustion process is the preheating of the mining. This will allow the heavy substance to oxidize into light components. This result can be achieved by creating a thick-walled red-hot metal bowl, where the mining will be fed in drops.

When oil hits a hot metal, the substance turns into vapors, which are discharged into the combustion chamber. There they must mix with air for better combustion, for which an air duct is used. It is equipped with an impeller, due to which the flow is swirled, which contributes to a long stay of the oil-air mixture in the combustion chamber. Only in this case the fuel will burn out completely.

To carry out the heating process of the evaporation bowl, a wick soaked in fuel should be placed in it. Then a little diesel fuel or gasoline is added and ignition is performed. When the metal is heated to the desired temperature, oil is supplied. This process is simple but very dangerous. Therefore, it is important to properly organize the flow of the substance into the nozzle for the waste oil boiler.

When oil hits a hot metal, the substance turns into vapors, which are discharged into the combustion chamber

If the oil flows in a jet, the fuel will not have time to burn. As a result, toxic components are formed that are dangerous to human health. For efficient combustion without smoke, a drip fuel supply should be organized. For this, a hose is used, at one end of which a filter is installed. Better to use a full filtration automotive oil element. Then a fragment of a medical dropper with a control wheel is put on the hose. The element is fixed to the union. The oil from the dropper is directed into a funnel, which is connected to the pipe. It supplies fuel to the combustion bowl.

DIY waste oil boiler with a water circuit

Based on the study of the boiler drawing with your own hands using waste oil, the following necessary materials and tools are prepared:

- a sheet of metal 4 mm thick for a tank or pipe with a diameter of 500 mm;

- pipes with a section of 200 mm;

- sheet metal with a thickness of 6 mm to create a cover;

- metal plates 3 mm thick;

- a piece of pipe for installing a chimney;

- oil supply pump;

- fan;

- steel adapters;

- heat-resistant sealant;

- metal corner for supports;

- grinders with a cut wheel;

- drills;

- hammer;

- a set of keys;

- welding machine with electrodes.

Helpful advice! To facilitate the creation of a homemade mining boiler, you can use ready-made barrels for oxygen or propane.

The boiler body is conventionally divided into two parts. At the bottom there will be a heating radiator, and at the top - a water jacket.

The process of making a boiler with your own hands using waste oil begins with the manufacture of an internal tank in the form of a container with a water jacket, an oxygen supply channel and a pipe for oil.

The dimensions of the tank elements are applied on a sheet of metal according to the drawing of the waste oil boiler. All parts are connected by welding. In the bottom of the body there is a door for removing the bowl and igniting the oil. To speed up the process, the body can be made from a piece of pipe with a diameter of 500 mm and a length of 1 m.

Two circular elements are cut out of metal plates, which will act as the bottom and cover of the case. A round hole is made in the upper part of the size corresponding to the diameter of the perforated pipe, into which it is inserted and welded. The body is covered with two plates by welding. Legs made of reinforcing bars are attached to its bottom.

The top tank is made in a similar way. A hole for the chimney is made in the lid. To connect two containers, a burner tube with a diameter of 100 mm and a height of 35 cm is used. 50 holes with a diameter of 9 mm are made in it. over the entire area of the product.

Related article:

Waste oil oven: DIY options for making a device

Principle of operation. Device types. Factory assembled models. Making a furnace for testing with your own hands, design options.

All elements are connected by welding according to the drawing of the waste oil boiler. After installing the device on a flat concrete base, the chimney is installed. Its length is 3.5-4 m. In order to ensure good traction, the pipe must be inclined. The outer part must be vertical, and it is equipped with a special cover to protect it from snow and rain.

Oil options for waste oil boilers

Any type of used oil can be used for these boilers. It is considered suitable not only machine, but also depreciation, transformer, transmission, motor, hydraulic, rapeseed, vegetable and other types. The main requirement for fuel is the absence of water, flushing liquids, antifreeze and other undesirable components in its composition. Machine oil is the cheapest and most affordable option. It can be purchased in sufficient quantities at any service station.

The diesel boiler is characterized by maximum efficiency. Oily substances can be added to it, which will act as a catalyst, which contributes to a good combustion process. It can be fuel oil, kerosene, means for igniting barbecues.

It is strictly forbidden to use alcohol, gasoline and other flammable substances as fuel for working boilers.

Important! Fuel must not be added to containers during combustion. Its filling occurs only after complete burnout of the filling and cooling of the tank.

Review of Russian-made waste oil boilers

Domestic-made waste oil boilers are manufactured mainly in Voronezh, where the manufacturer has all the necessary documents related to the production of products. There are also other small businesses. However, most of them do not have a state certificate for the manufacture of heating equipment. You should pay attention to this when buying a boiler.

The waste oil double-circuit boiler Teploterm GMB 30-50 kW is characterized by high quality workmanship in every detail. It is equipped with an automatic control system thanks to a multifunctional microprocessor. The device has many options that simplify the operation of the device, making it safe. Fuel consumption - 3-5.5 l / h. The cost of the model is 95 thousand rubles.

A popular model is the Gecko 50 pyrolysis boiler. The device can operate not only on mining, but also on crude oil, diesel fuel, fuel oils of all brands, kerosene, fats and various types of oil. The boiler is undemanding to the quality and viscosity of the fuel. There is no need for preliminary filtration and heating.

The design has small dimensions (46x66x95 cm) and a weight of 160 kg. The device is characterized by high efficiency, reliable performance of all elements and connecting assemblies, ease of maintenance and repair. The maximum temperature in the device reaches 95 ° C. The fuel consumption is 2-5 l / h. The power consumption is 100 W. The price of a waste oil heating boiler is 108 thousand rubles.

Boiler Stavpech STV1 is characterized by high efficiency. The power of the device is 50 kW. The fuel mixture consumption is 1.5-4.5 l / h. Body dimensions - 60x100x50 cm. The device is equipped with a reliable modulating waste oil boiler burner with a high emission rate. The device is equipped with a fuel filter, pump and water tank. Various types of oil, diesel fuel and kerosene can be used as fuel. The boiler price is 100 thousand rubles.

The combined apparatus KChM 5K has a cast iron body. It can operate not only on mining, but also on gas and solid fuel. The power of the device is 96 kW. The model is distinguished by high quality workmanship of parts, operational safety and durability. You can buy a boiler for 180 thousand rubles.

Expensive domestic waste oil boilers

The domestic automatic waste oil boiler Teplamos NT-100 is characterized by an expanded configuration. A double-circuit boiler can be used not only for heating, but also for providing hot water supply in the house. The model is characterized by high quality workmanship of all components. The external parts are powder coated to protect them from corrosion. The body has an internal heat-insulating coating in the form of high density glass wool.

For ease of operation, the device is equipped with a remote control, which allows it to work in automatic mode. It consists of a switch, thermostat, thermo-hygrometer and emergency thermostat.

The boiler measures 114x75x118 cm and weighs 257 kg. The maximum power consumption reaches 99 kW. The consumption of a combustible substance ranges from 5-6 l / h. The price of a waste oil boiler is 268 thousand rubles.

A single-circuit heating device based on the Ecoboil-30/36 can be used to heat a room up to 300 sq. m. It has dimensions 58x60x110 cm. The power of the device is 28 kW. Fuel consumption can range from 0.9 to 1.6 l / h. The boiler works with any type of oil, regardless of its quality. You can also use kerosene and alcohol for it. The cost of the boiler is 460 thousand rubles.

Hot-water fire-tube boiler Belamos NT 325, with a power of 150 kW, is capable of heating a room with an area of more than 500 sq. m. Fuel consumption reaches 1.8-3.3 l / h. Due to the presence of a heat exchanger, it has a high efficiency. Equipped with a control unit with a smooth adjustment function and the ability to maintain the set temperature of the coolant. It can operate on any type of liquid fuel that does not need filtration and heating. The price of the boiler is 500 thousand rubles.

The double-circuit boiler Teplamos NT 100 can be used not only for heating, but also for providing hot water supply in the house

Finnish waste oil boilers for a private house

Based on numerous reviews, the Ecoheat 60S waste oil boiler equipped with a burner is very popular. The device can be connected to a boiler for hot water production. The boiler has dimensions 102x67x79 cm. Fuel consumption does not exceed 5.4 l / h. The power of the unit is 60 kW.

The boiler body is made of sheet steel and covered with heat insulation in the form of dense fiberglass. The advantage of the unit is ease of maintenance, which is ensured by the classic shape of the combustion chamber and the dual fuel filtration system. You can buy a waste oil boiler for 280 thousand rubles.

Another noteworthy model is the Danvex B-60 boiler, which is operating in mining. It is used to heat a room with an area of 150-200 sq. m. Power of the device - 63 kW. The body is made of high-quality heat-resistant steel with a heat-insulating coating. The efficiency of the device is 88%. It can be connected to a boiler. Fuel consumption is 5.6 l / h.

The boiler body Danvex B-60 is made of high-quality heat-resistant steel with a heat-insulating coating

The model is distinguished by high-quality and professional assembly and stylish performance. The unit is easy to operate and maintain. The sealed fuel line eliminates the possibility of oil evaporation and the presence of unpleasant odors in the room. The average price of a boiler is 290 thousand rubles.

European manufacturers of heating boilers for testing

Reliable and durable heating equipment is offered by the German company Kroll. The models are characterized by a power of 25-200 kW. Fuel consumption is in the range of 2.1-16.9 l / h. The boilers are equipped with a horizontal inversion combustion chamber and a universal automatic burner. The smoke tubes are equipped with stainless steel turbulators inside, which allows you to regulate the temperature of the flue gases by choosing the pressure level in the furnace. The steel body has a fiberglass thermal insulation shell.

Another German manufacturer Buderus is engaged in the manufacture of low-temperature cast iron waste oil heating boilers. The devices have a power of 25-100 kW. Most models are equipped with an electronic control system with an option for smooth regulation of the temperature of the water in the boiler. The boilers can additionally be combined with water heating tanks for hot water supply.

Most models of Buderus boilers are equipped with an electronic control system with an option for smooth regulation of the water temperature

The Spanish company Roca offers a range of heating boilers with a capacity of 58-1744 kW, which can be used to heat a room with an area of 580-17500 sq. m. The devices are equipped with a reversible combustion chamber. The body is made of sheet steel.

The Italian manufacturer Unical produces boilers with a capacity of 35-1100 kW. A cylindrical firebox with a blank bottom has an inversion memory. The device has three boiler block gas ducts. Thanks to the short torch, a high quality of heat exchange is ensured and the level of convection is increased.

Other manufacturers of oil boilers

The two-circuit liquid fuel boilers Energylogic of the American manufacturer are of high quality, reliability and durability.The models have a capacity of 41-218 kW. The heat exchanger operates on a wet effect, cooling the water. This eliminates the formation of burn-out points and helps to slow down metal wear.

A special head is located in the fan burner, which forms and holds the flame, normalizing the combustion process of fuel. The devices have the ability to heat up the fuel before it enters the nozzle. The boilers are equipped with a reversible two-pass furnace.

Chinese waste oil boiler plants Norteс have a capacity of 15-7000 kW. Due to the presence of a mesh filter, the fuel enters the nozzle in a clean form. The devices are equipped with a fuel overflow sensor and a reliable sliding secondary air control damper.

Another Chinese manufacturer, Smart Burner, manufactures boilers with a capacity of 24-595 kW. The devices have a smooth ignition system and an option for adjusting the fuel supply, which contributes to high efficiency.

Korean-made two-pass boilers operate on the basis of OLB single-stage burners. They have a capacity of 15-1600 kW. The devices are equipped with a pressure regulator, with the help of which the fuel consumption per injector is adjusted, which is determined by the fuel viscosity. They have a system protection function in the event of a malfunction of one of the boiler elements.

Kiturami boilers in Korea operate on different types of fuel. They are equipped with a self-diagnosis device, so that the operating mode is adjusted. In the secondary combustion zone, the boilers are equipped with a cyclonic flow aerodynamic burner.

Kiturami boilers are equipped with a self-diagnosis device, due to which the operating mode is adjusted

Waste oil heating is very popular nowadays. This is primarily due to the economic feasibility of this option. Working boilers are characterized by a number of distinctive advantages, however, factory-made devices are quite expensive. To save money, the device can be made independently, having studied all the subtleties of the process.