In order to give concrete additional properties, various substances and solutions are added to it. To ensure faster tenacity, water resistance and moisture resistance, it is customary to add sodium or potassium silicate, which is called soluble or water glass. For concrete, it is used as part of a cement mixture required for waterproofing concrete surfaces. This article will tell you about the features of the material and the rules for its use.

Liquid glass is able to give additional properties to concrete

Content [Hide]

- 1 Composition and scope of liquid glass in concrete

- 2 Liquid glass for concrete: instructions for use and preparation of the mixture

- 3 How to cover a concrete floor with liquid glass

- 4 How much liquid glass to add to concrete: recipes for the preparation of compositions

- 5 Liquid glass for concrete: customer reviews and experts

Composition and scope of liquid glass in concrete

The phrase "liquid glass" is familiar to many, but not everyone knows what this mixture consists of and for what purpose it is used. An aqueous solution of potassium or sodium silicate was discovered by alchemists in the Middle Ages, but the first plant for its production appeared only in the 19th century. Then its widespread use in the construction industry began.

Liquid glass consists of an aqueous solution of sodium or potassium silicate

The material is produced by fusing soda and sand or by combining proportions of ground silicon with hot sodium hydroxide. At the outlet, a translucent viscous substance of white or yellowish color is obtained, called liquid glass. The solution may include sodium or potassium silicates, as well as a mixture of them.

A material with different properties is widely used in construction for waterproofing concrete surfaces. For this purpose, concrete is coated with liquid glass. A silicate solution is applied directly to the cement, which is absorbed into the surface. When the substance dries, all the pores of the concrete are blocked, protecting it from moisture penetration. The maximum effect is achieved by applying several layers of this composition.

This material is used as an admixture for concrete mortar. Concrete with the addition of liquid glass has a high degree of waterproofing and hardens much faster. Therefore, it should be used for a certain period of time. In addition, liquid glass is used for the production of monolithic concrete blocks of different brands and sizes.

The use of the substance in different areas is due to the advantages of silicate material, among which are:

- high penetration and adhesion;

- the formation of a one-piece waterproof film on the surface of the material to be coated;

- small consumption of substance in solution;

- reasonable price of funds.

Why add liquid glass to concrete: the expediency of using the material

The main quality of a concrete solution with the addition of liquid glass is that the mixture sets quickly and provides a high degree of protection against moisture. However, it should be noted that the strength of the monolithic structure then decreases.

Useful advice! The use of a cement mixture with the addition of liquid glass will make it possible to successfully repair structures made of concrete, asbestos cement, ceramics, and even to restore cast-iron pipes.

It is most advisable to use a silicate-concrete solution for the following needs:

- sealing cracks with liquid glass in concrete, brick walls, for sealing joints;

- urgent repair of a concrete foundation that has collapsed from excessive exposure to moisture;

- strengthening concrete with liquid glass in ceilings, for connecting beams and other elements.

In these cases, water glass is added to the cement solution in a proportion of no more than 1: 1. Next, knead a little solution and immediately use it, since the mixture of cement and silicate dries very quickly. The correct ratio of substances will allow you to permanently eliminate defects or give additional strength to concrete structures.

The addition of liquid glass to concrete is appropriate when creating a foundation in an area where the soil contains a high level of acidic waters. This guarantees an increase in the resistance of concrete to the destructive effects of moisture. Successful pouring of such a foundation is provided by the following rules:

- the addition of sodium silicate to the concrete solution should not exceed 3%;

- produce additional and thorough waterproofing of the foundation using other materials.

With the help of liquid glass, concrete can be strengthened, cracks can be closed, seams can be insulated

Liquid glass for concrete: instructions for use and preparation of the mixture

It is possible to prepare a mixture of cement and liquid glass even at home, while observing a number of requirements. Violation of the technology for making the mortar can lead to the formation of cracks in the concrete.

Liquid glass should be added to the dry mixture. To do this, first, in the right proportions, combine all the dry components and mix them thoroughly, without using water. Then, water glass, previously diluted with water, is gradually poured into the composition.

It is necessary to strictly observe the ratio of all ingredients when preparing the solution in accordance with the recipe used for a particular type of work. For example, if we are talking about the amount of glass in concrete, then it should not exceed 25% of the total weight of the mixture. For the preparation of a primer using a cement composition and silicate glue, the ratio can be 1: 1.

It should be taken into account that the acceleration of the speed and density of the solidification of the solution is influenced by the liquid glass for concrete. The instructions for use recommend preparing the mixture in small quantities and using it quickly.

The setting time depends on the amount of liquid glass added to the concrete. If the mixture contains 2% of this substance, then it begins to set in an hour, if 5% - then after 40 minutes. The hardening process also depends on the proportion. If more than 4% of silicate glue is added to the solution, then the strength of the concrete after complete hardening will decrease by about 25%. However, if the concrete contains only 3% liquid glass, then the strength of the structure will increase.

Useful advice! Sodium silicate, in addition to the waterproofing function, has antibacterial and antifungal properties. The chemical composition of the material is not a suitable environment for the development of any life.

Technological features of the mixture and types of concrete impregnation with liquid glass

Liquid glass in a solution mixed in cement M400 at a temperature of 20 ° C begins to set in 2-3 hours, and completely hardens in a day. Over time, the monolithic base will only get stronger. The maximum hardness effect is achieved after a maximum of 4 weeks. Liquid glass is also used as an impregnation for various surfaces, ensuring their smoothness, evenness and waterproofing. Concrete processing with liquid glass is carried out for the following structures:

- concrete floor;

- flat roof;

- wells;

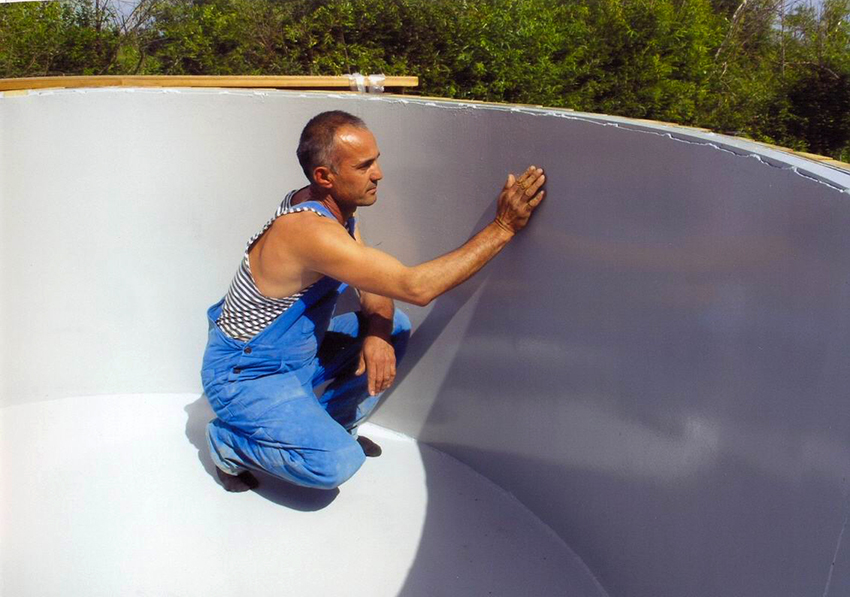

- swimming pools;

- basements;

- plinths;

- concrete walls and ceilings.

The impregnation process includes several stages. First of all, preparation of the base is required. To do this, the surface is thoroughly cleaned of old coating, paint, debris, dust and dirt. Next, they are cleaned with a metal brush, the base is covered with a bitumen emulsion with a layer of 2 mm. The base is given time to dry.

Then the surface is impregnated with a solution with liquid glass. The proportions of water glass in concrete depend on the type of surface (in accordance with the instructions for use). If the surface is horizontal, then a layer of 2-3 mm is applied to it and the mixture is smoothed with a spatula. The floor and floors are poured in several layers, taking a break for a certain number of hours. You can use the surface after a couple of days.

During work, you need to adhere to a number of recommendations. In particular, the solution must be distributed evenly. The coating should be done as quickly as possible, preventing the composition from hardening. Reliable impregnation is ensured by applying the mixture in two or even three layers. A special spray gun is used to insulate the walls and ceiling, which contributes to the uniform distribution of the solution. Cover the surface in two to three layers.

How to cover a concrete floor with liquid glass

Liquid glass is used not only for priming, impregnating surfaces, but also as a coating. For this purpose, a special solution is prepared, including a finely ground filler, sand, active silica, water glass and water are added to it. The ingredients are mixed with a construction mixer. The resulting substance should be viscous and thick.

Solutions with liquid glass for concrete floors are used to apply a protective waterproofing layer on floors, walls and ceilings in rooms with high humidity: in bathrooms, saunas, laundries, swimming pools or baths. It is also recommended to use these mixtures in basements.

Before applying liquid glass to concrete, the surface to be treated is thoroughly cleaned and leveled. As a topcoat, liquid glass is used in the form of a strong hydrophobic solution. Surface coating is carried out by pouring onto screeds, which are formed by strips installed parallel to the wall.

Useful advice! Liquid glass has high thermal conductivity. Therefore, the material is often used to provide additional thermal insulation. Adding liquid glass to concrete in the right proportions provides a high thermal insulation of the surface that can withstand temperatures up to 1200 ° C.

The quality of work depends on the even distribution of the material. This can be done with a special needle roller, putty knife and squeegee with an extended handle. The layer size is 2-4 mm. Considering the short drying time of liquid glass on concrete, the work must be done rather quickly. To do this, it is better to divide the covered area into sections, and the whole process into several stages.After preparing the floor surface, the concrete is painted with liquid glass.

How much liquid glass to add to concrete: recipes for the preparation of compositions

Depending on the purpose of using liquid glass, proportions are drawn up. The main thing in this business is responsibility and accuracy. The universal impregnation recipe provides for a mixture of silicate and water in a 1: 2 ratio. There are several options developed by experienced builders that are time-tested.

If a silicate solution is used as a primer, then the mixture is prepared in proportions 1: 1 (with cement and the addition of the required amount of water). That is, 1 kg of liquid glass is added to 1 kg of cement, and such an amount of water is gradually poured in so that it is convenient to prime the surface with the resulting mixture. If the solution quickly solidifies, a little water can be added to it after a while.

For waterproofing wells, liquid glass is combined with carefully sifted sand in a 1: 1 ratio. The resulting mixture is covered with the walls of the well.

In underground concrete rooms, reliable water protection will be provided by adding liquid glass to concrete in the following ratio: 1 liter of silicate glue to 10 liters of cement mortar. Such a composition guarantees reliable insulation of walls and floors of basements located underground. The refractory mixture is prepared as a cement-sand mortar with the addition of a small amount of liquid glass.

An antiseptic for wood is obtained in this way: water glass is mixed with water in equal proportions. At the same time, a slippery protective film forms on the tree, which cannot be painted. For this reason, this solution is not recommended to be applied to concrete walls.

Various types of impregnation are prepared, mainly based on the following proportions: 400 ml of liquid glass per 1 liter of water. The next layer is applied after 20-30 minutes - exactly after such a period of time as the liquid glass dries on concrete.

Related article:

Water repellents for concrete and bricks: modern water-repellent technologies

Basic properties, specificity of application, their differences. Councils for the choice of water-repellent agents.

Liquid glass for concrete: customer reviews and experts

On the Internet, you can find many reviews that characterize the silicate solution mainly from the positive side, although there are negative opinions. In particular, the material is not considered environmentally friendly, and its use out of proportion can lead to cracking of the concrete surface. Some users do not like that the silicate-concrete mixture sets quickly. For example, there are cases when an inexperienced builder mixed a cement mortar with the addition of water glass in a ratio of 25%. When pouring the screed, the mixture immediately froze, and after a day it simply crumbled into dust. I had to re-prepare the solution. In this case, the main mistake of the wizard is the non-observance of the proportions.

Other reviews, on the contrary, characterize liquid glass as an excellent tool for waterproofing screed. Masters note that after applying the product, the surface is much less covered with dust and practically does not wear off, and also indicate the fire safety of the silicate-concrete mortar.

Useful advice! Builders are strongly advised to work with the material very quickly. To create a screed will require some experience and skill, because such a process does not tolerate delay.

Some people believe that the use of additives such as water glass is advisable when it is necessary to improve the performance of certain materials.For example, it is appropriate to use it in pouring the foundation for a country house located on soil with high humidity. Thus, opinions were divided about liquid glass in concrete: consumers express their positions for and against the material.

Liquid glass for concrete: rules of use and protection measures

The silicate substance is non-flammable, non-explosive and non-toxic. Before using liquid glass for concrete, you need to prepare a certain set of tools: a special container for preparing a mixture, a construction mixer, brushes, brushes, rollers and gloves, and for spraying on a wall or ceiling - a spray gun.

The use of such a universal tool in combination with concrete presupposes the observance of certain safety measures. Although liquid glass is not toxic, it splashes onto the mucous membranes and can irritate them. Therefore, when spraying, care must be taken to protect the eyes and upper respiratory tract. You need to work in a well-ventilated area.

Avoid getting the solution on open skin areas, therefore it is better to work in special closed clothing, a headdress, and it is also recommended to use personal protective equipment. Penetration of the substance into the eyes can lead to burns, therefore, in this case, you should immediately rinse your eyes with plenty of water and contact a medical institution for help. If the composition gets on the skin, it is enough to rinse it with warm water and soap and lubricate it with baby cream.

The container used to dilute the solution cannot be used in everyday life. Therefore, it is better to take packing buckets from under the putty or use cut plastic five-liter jars.

You need to take care of the storage conditions for ready-made solutions. It should be a cool and dry place with an air temperature of 5 to 40 ° C. It should be noted that liquid glass is a frost-resistant material that can withstand temperatures down to -30 ° C.

Liquid glass for concrete: price and product quality

The cost of liquid glass for concrete, in comparison with other materials, is quite affordable. In particular, a fifteen-liter canister will cost the buyer within 300 rubles, that is, the average price is 50 rubles. per kg. The wholesale cost, accordingly, will be even less. For example, a 200-liter tank costs approximately 4.5 thousand rubles. When buying in bulk (for a large volume of work), it must be borne in mind that certain delivery costs will be required.

If a decision is made to attract professionals, then the costs of paying for their labor should be taken into account. The total cost depends on the type and scope of work. For example, services for the implementation of a waterproofing layer will cost approximately 1,300 rubles. per m³.

Useful advice! Liquid glass can become a lifesaver in deciding what to replace a plasticizer for concrete. Due to the use of silicate glue, concrete becomes water-repellent and can withstand aggressive environments. Sodium silicate is added as a plasticizer in a ratio of 1:50.

The use of liquid glass for the purpose of waterproofing and strengthening concrete is the most effective and optimal solution both in terms of technology and in terms of price. The main condition is compliance with the instructions for use, which regulates not only the order of work, but also strict adherence to the proportions of materials. It is better to inject the sodium silicate mixture into the solution, and not use it as a separate painting material.

The use of liquid glass for external processing is considered the most budgetary option, but in aesthetic terms, such a coating is much inferior to more expensive counterparts. If it is necessary to impregnate concrete at minimal cost, liquid glass is the best solution.