Many residents of suburban and suburban settlements dream of decorating their garden with an elegant gazebo. They revise the pages of virtual magazines in search of an interesting solution. And it is, this is a do-it-yourself gazebo made of wood: following the construction technology step by step and adhering to the recommendations of experienced professionals, you can build a unique pavilion that will become a favorite vacation spot for the whole family and your guests. Self-construction will not only save your budget, but also allow you to get a lot of pleasure from the process.

Content [Hide]

- 1 Diy drawings and dimensions of the gazebo

- 2 Do-it-yourself gazebo made of wood: we build a structure step by step

- 2.1 Basic tools and materials for construction

- 2.2 Foundation device

- 2.3 Arbor floor construction

- 2.4 Roof installation

- 2.5 Laying bituminous shingles

- 2.6 Features of the hexagonal gazebo design

- 2.7 Arrangement of fences for gazebos made of wood with your own hands. Photos of finished structures

- 2.8 Decorative design of the gazebo

Diy drawings and dimensions of the gazebo

Arbor designs are very diverse and interesting. Some structures differ in non-standard shapes, they can be open or closed, be equipped with barbecues and barbecue. But if you decide to build for the first time, it is better to choose an open structure of a simple shape, for example, square or hexagonal. Drawings and sketches in the project of such a gazebo will not be complicated and will lend themselves well to independent development.

Original arrangement of a terrace with a wooden gazebo and grill

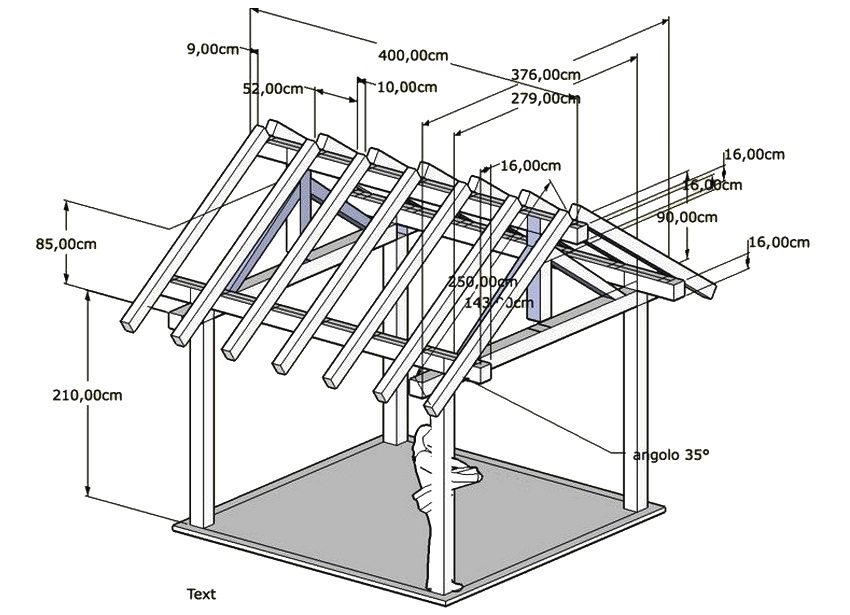

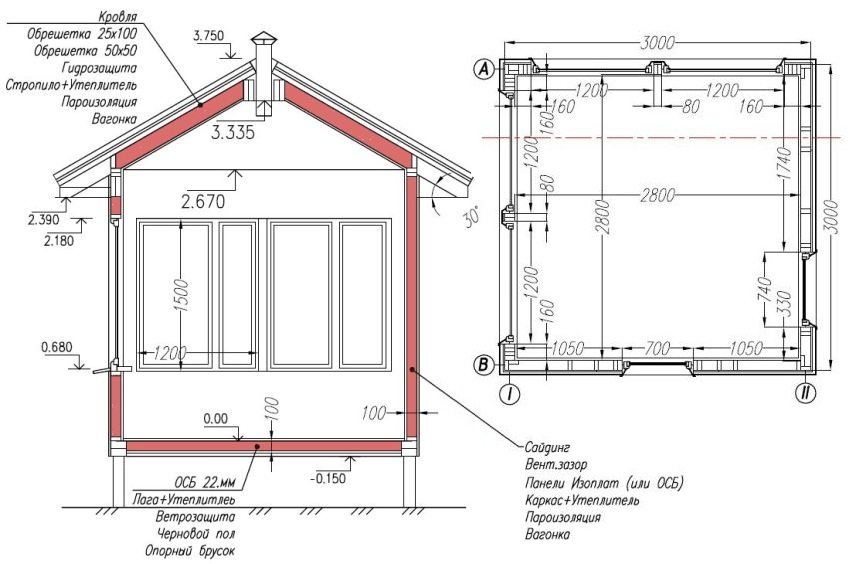

First of all, you must decide on the design of the structure and choose a place for the future building. The development of the project includes two stages: the creation of a sketch and construction drawings in profile and frontal projections. IN gazebo drawings dimensions, rack heights, roof shape, entrance location, fence height are displayed. If a stationary installation of the table is intended and shops, it is necessary to display their location in the plan.

Separately, a working diagram of the foundation and a drawing of the roof are carried out, indicating its shape, height, angle of inclination. The project prescribes diagrams of technical units (roof, rafters, steps), construction technology, specifications for the materials of the foundation, walls, partitions, floor, roof. It also takes into account the consumption of a special composition for effective processing of wood from external factors.

If it is planned to equip the structure with lighting, the installation locations of the lamps and the wiring diagram are recorded on the drawing. This also applies to the possible supply of water to the pavilion.

A well-designed project is the key to successful construction.Accurate calculations of the number of required bars, boards, fasteners, roofing, hardware and other necessary elements will make it possible to purchase a full set of materials for construction and avoid unreasonable costs.

Helpful advice! Materials should be purchased with a small margin, given that some parts may be mistakenly damaged during the installation process or defective elements may be found in the purchased materials.

If you doubt your engineering abilities, and the development of a project will seem difficult for you, you can use ready-made drawings of wooden arbors with your own hands. Photos and sketches of such buildings abound on the Internet.

Do-it-yourself gazebo made of wood: we build a structure step by step

The construction of a gazebo is a painstaking process that requires attention, adherence to installation rules and strict adherence to the project. If all the work is carried out in a certain sequence, the process will go easily and in just two or three days the structure will be ready. It is recommended that you check the availability of all the tools in advance and purchase all the required materials according to the calculations so that the business does not stall due to the lack of any part.

Basic tools and materials for construction

Wood processing requires special equipment and tools. Check their availability and serviceability. To work you will need:

- shovel or drill - for making a foundation pit or pits;

- building level, tape measure, square;

- rule;

- chisel, hammer, wrenches, roofing knife;

- hacksaw, jigsaw or circular saw;

- drill or screwdriver;

- Bulgarian;

- construction hair dryer;

- electric plane;

- construction cord - for marking;

- sandpaper, paint brushes, spatula;

The amount of materials required for construction is taken based on the specification:

- sand, crushed stone, cement - depending on the type of foundation: columnar or tape;

- formwork board - if a tape base is assumed;

- a beam with a different section - 50x150 mm is used for the lower strapping, center beam of the frame and the floor log; 100x100 mm - for uprights, top strapping; 50x100 mm - used for corner, auxiliary and short rafters, as well as for fencing; 50x50 mm - for fencing balusters;

- floor board;

- roof sheathing - plywood panels 12 mm thick;

- roofing felt - for insulation work;

- flexible (bituminous) tiles, bituminous glue;

- fasteners - screws, corner brackets, metal corners, self-tapping screws, roofing nails;

- primer, wood putty;

- paint, varnish.

Foundation device

As an example, we will use a small square wooden gazebo with a hipped roof.

By choosing the right place for gazebos, start preparing the site. It is necessary to remove all debris, remove shrubs and tree roots there. If there are bumps or depressions, they are leveled.

Helpful advice! If possible, do not install a gazebo near the roadway or neighbor fence, try to place the gazebo in such a place that a beautiful view of the garden, alpine slide or pond opens from it.

Next, markings are made for the future structure. To do this, the first wedge is driven in and the entire perimeter of the structure is marked from it, fixing the corners with wedges. A construction cord is pulled between them. At this stage, it is very important to maintain the correct angle, as this will subsequently affect the strength of the entire structure.To verify this, you need to check the diagonals of the resulting square. If they are the same, then the marking is done correctly and the angle of 90 degrees is observed.

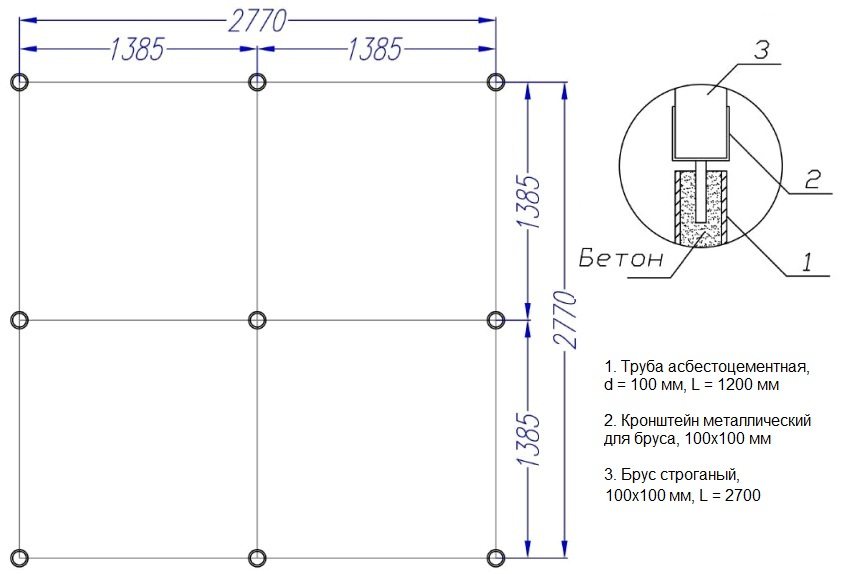

Basically, for small wooden structures, a strip or columnar foundation is used. Since the construction of a wooden square gazebo is quite light, a columnar foundation is chosen as its base. To do this, pits up to 80 cm deep are made, a layer of sand (5-6 cm) is laid on their bottom and poured with a layer of concrete approximately 8-10 cm.

When the concrete mixture hardens a little, the racks are lowered into it. They must be installed vertically. After the vertical alignment of the supports is made by the level, their position is fixed with temporary jibs.

It is possible to fix the support rails using adjustable anchors. For this, pieces of metal pipes of suitable size are placed in the pits, the solution is poured into the cavity of the pipe, and after a slight setting of the solution, fasteners (anchors) are installed. When the concrete has finally set (at least 48 hours), the uprights can be secured. After installing all the supports, it is necessary to make sure that their position is correct: the distance between adjacent supports must be strictly the same over the entire height of the supports (bottom, middle and top).

Related article:

Summer kitchen in the country: projects, photos of interesting ideas. Types of summer kitchen designs in the country. The advantages of closed buildings. Independent construction of a summer kitchen in the country.

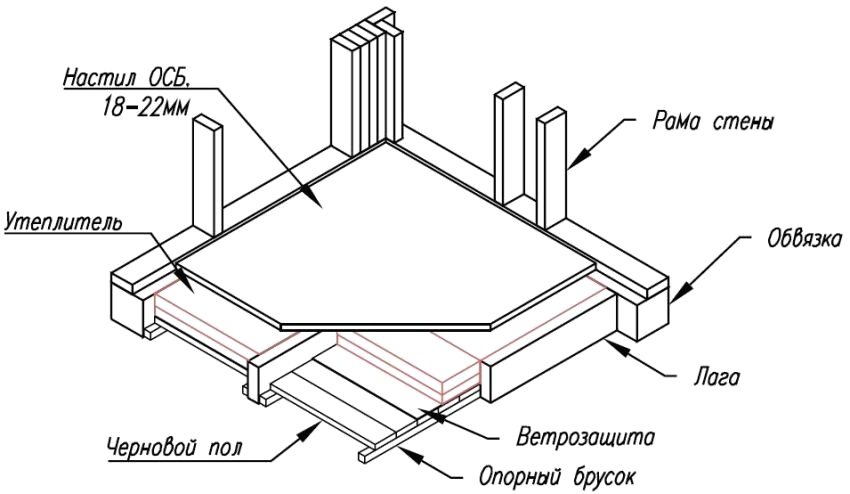

Arbor floor construction

The next step after the installation of the supports is the lower strapping of the vertical posts. For this, a bar with a section of 50x150 mm is used. The floor frame is carried out by installing lags, which are located at a distance of no more than 45 cm from each other. This will allow the frame structure to support the weight of the wooden platform. The lags are attached to the horizontal strapping beams using angle brackets, having previously drilled the mounting holes for self-tapping screws.

Next, proceed to the installation of intermediate racks. They will subsequently bear the weight of the wooden roof structure and will be used to fix the upper horizontal rail. Racks are attached to the logs with nails. The same rule applies here as for corner supports - all posts must be installed strictly vertically.

As soon as the floor frame is assembled and the intermediate supports are installed, they proceed to the installation of the flooring from the board. For the floor, a board suitable for outdoor use is used, which withstands well the effects of natural factors. Then you will not have to find out after a short period of time that the boards have rotted in some places.

To fasten the board to the crate, nails or screws are used. Fix the board using two nails or self-tapping screws from each end.

Helpful advice! If nails are used to fasten the boards, it is necessary to make holes for them in advance. This will help avoid cracking the wood.

After laying the plank floor, proceed to the upper horizontal connection of the supports gazebosusing a beam of 100x100 mm. Do-it-yourself strapping of the pillars of a wooden gazebo (photo examples provide visual information) is carried out by sawing out locks from the ends of the timber, which are connected to each other and fixed with two nails.

Roof installation

For a square gazebo, the most attractive will be a roof consisting of four slopes. Roof construction begins with the construction of the frame. Inclined rafter legs are cut from the timber, they are fixed in pairs with nails at an angle.Auxiliary struts are symmetrically attached to each of the main inclined legs. They are fixed with one edge to the strapping beam, the other to the main rafters.

Helpful advice! To work on the roof, invite an assistant, since it is impossible to cope with the installation alone.

Next, proceed to covering the roof. For this, you can use both a board and a plywood sheet. Fastening of plywood panels is carried out on the surface of the rafters with a pitch of 20-25 cm using self-tapping screws. The surface of plywood sheets is covered with roofing insulating material - roofing felt, and then soft (bituminous) tiles.

Laying bituminous shingles

Flexible shingles are lightweight and easy to install. Fix the flexible roof to the flooring with wide-headed nails. Eaves tiles are mounted to the eaves on all sides. For ease of installation and good pliability of the material, a building hair dryer is used. Next, the laying of ordinary flexible shingles begins. When fixing the first row, it is necessary to choose such a length of nails so that they can pass through the eaves and ordinary tiles and reach the wooden base of the gazebo roof.

Before using the tile, remove the protective film from it. The sheets are overlapped. When laying each row of material, the sheets are positioned so that the cutouts of the previous row are covered with the protrusions of the next one. When fixing the shingles, it is necessary to ensure that the nails reach the roof sheathing in the places of the double layer of material. Otherwise, the nails will subsequently be forced out and provoke the tiles to peel off.

When the material reaches the slope break, the excess edges of the tiles are cut flush with the slope line. In these places, the material is additionally anointed with bituminous glue.

Next, they start laying the ridge tiles. To do this, a sheet of tile is cut into three parts and each resulting plate is laid with the adhesive side across the ridge with an overlap of 5 cm. Fix each plate with nails in four places. In this way, all the kinks of the slopes are processed.

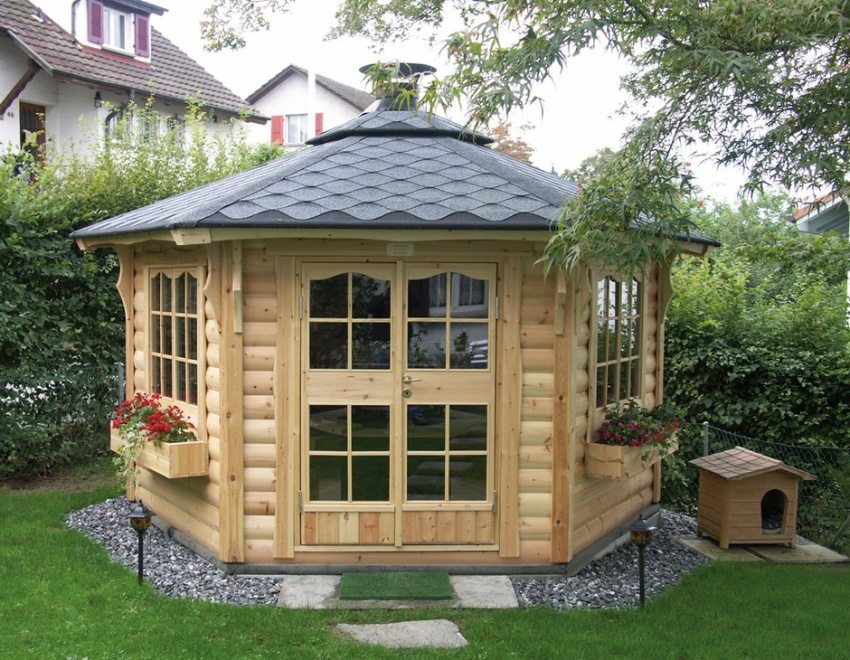

A roof made of bituminous tiles for a wooden gazebo with your own hands (the photo illustrates this) looks quite attractive due to the variety of shapes and colors. One of the advantages of such a roof covering is noiselessness in rain and hail.

Helpful advice! When purchasing shingles, make sure that all packages correspond to the same batch. Material from different batches may vary in color.

Tile roofing works are carried out very carefully, trying not to damage the material with nails.

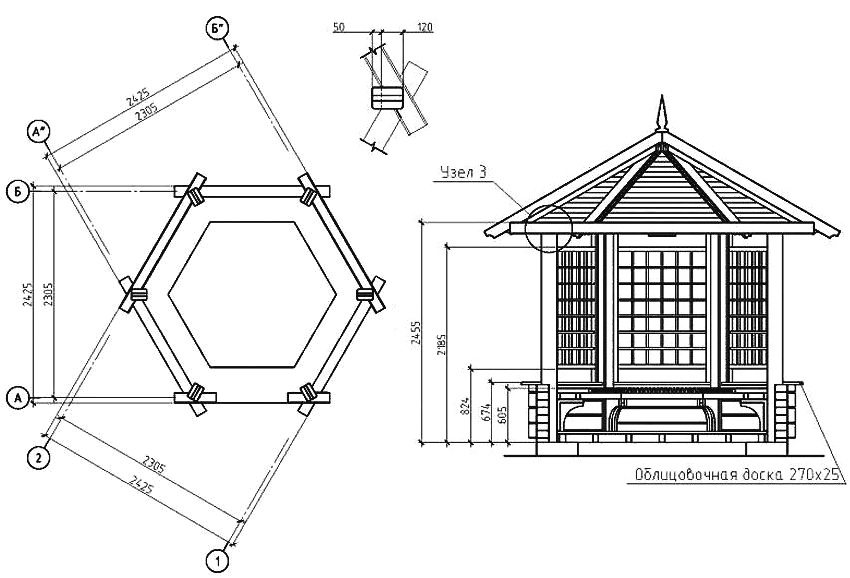

Features of the hexagonal gazebo design

All stages of self-erection of a hexagonal arbor are similar in installation to a square structure. The foundation, floor and posts of the gazebo are made according to the available drawings. As for the roof of six slopes, the device is recommended to be made on the ground and the finished structure is raised and attached to the frame of the gazebo.

Due to the absence of a central supporting element in the structure, it is very difficult to connect all the rafters together. Therefore, it is recommended to give the timber the shape of a hexagon, each side of which should correspond in size to the thickness of the rafters. The ends of the rafter boards are cut at an angle and, in turn, are fixed with nails to the cut out bar with a hexagonal section. At the other end, the rafters are inserted into the grooves, which are pre-cut in the strapping beam.

Then the roof frame is sheathed with a board or plywood, and the finished structure is lifted and mounted to the support posts of the gazebo.

Arrangement of fences for gazebos made of wood with your own hands. Photos of finished structures

The appearance of the gazebo largely depends on the type of fence. It can be solid or lattice. Depending on your preferences, the railing can consist of railings and balusters, of two or three horizontal wooden elements located along each side of the gazebo, as well as in the form of rhombuses installed between the vertical supports of the structure. Some people prefer to arrange a railroad fence or block house. It all depends on your creative imagination and the availability of free time.

The height of the fences is traditionally 75-85 cm, but this value can be changed as you wish. The horizontal parts of the fence are fixed with self-tapping screws or corners. Moreover, the screws should enter the tree at an angle. It is not recommended to use nails driven into the ends of the baluster bars through the railing for fastening horizontal bars. This can lead to cracking of the timber. For attaching balusters to the railing, it is advised to use pins.

Balusters can be installed vertically, at an angle, in the form of a diamond. To fix the inclined balusters in the horizontal bars from above and below, grooves are arranged at a certain angle. The ends of the balusters are also cut at an appropriate angle, which are then inserted into the grooves.

In addition, to give the gazebo an openwork look, arrange a horizontal decorative border on top. The height of the curb is one third of the height of the fence itself. The curb pattern usually follows the configuration of the lower railing, but you can make them different. The main thing is that they do not contradict the general style of the wooden gazebo.

Decorative design of the gazebo

As soon as all the work is completed, proceed to the processing of wooden surfaces. If some of the wood elements have small cracks, they must be filled with wood filler. After the putty has dried, they begin to sand all the elements. For this purpose, sanding paper with a medium-grained coating is used. Further, all wooden surfaces are treated with varnish in two layers, and the second layer is applied after the previous one has completely dried.

Near basin mounted gazebo on a small wooden platform

Helpful advice! Coating with varnish is carried out with uniform brush movements, first along the fibers, and then across. The varnish coat should be distributed thinly and uniformly over the surface, without sagging.

The service life of a wooden gazebo largely depends on how well the wood is processed.

The interior of the gazebo can be very diverse. It can be a wooden table and benches, made independently and permanently fixed in the structure. Many people prefer to install comfortable portable furniture in the gazebo in the form of sun loungers or rattan armchairs... You can supply electricity to the gazebo and install beautiful lights around the perimeter. Some bring water to the structure of the gazebo. Beautiful climbing plants are often planted along the fence of the gazebo.

A symbol of calm and tranquility in your garden is a do-it-yourself gazebo made of wood. Following all the recommendations step by step, it is not difficult to assemble the structure yourself. And handmade products are always distinguished by special comfort and warmth.