Along with the novelties that have appeared in stores in recent years, there is a certain list of building materials that are more familiar to the domestic buyer. Such materials include plywood, its pros and cons are well known to the consumer, but this does not make it less popular. The main parameters when choosing are the thickness and dimensions of the plywood sheet: prices for it also depend on these characteristics.

Content [Hide]

What is a plywood sheet: production features

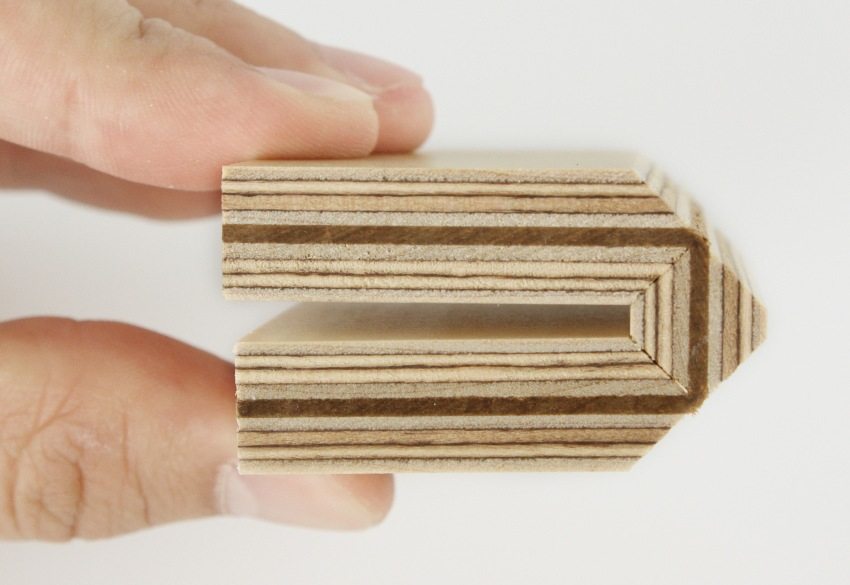

A plywood sheet is a panel glued from 3-5 layers of wood veneer. It is produced from different types of wood - deciduous (birch, alder, oak) and coniferous (pine). Birch plywood is considered to be of the highest quality and, accordingly, expensive, and coniferous plywood is the cheapest. To reduce the cost of the final product, different types of wood are often combined. For example, hardwood veneer is used for the inner layers of plywood, and conifers for the outer layers. This is done not only to save money. The outer layer of cedar veneer is used to give the plywood a beautiful pattern.

When making plywood from a tree trunk, special machines remove thin sheets (veneer) by spiral sawing. These sheets are stacked on top of each other (most often across the fibers to give the material greater strength), and then pressed into monolithic blocks under high pressure. Many types of wood do not need special glue impregnation. However, often special natural or synthetic formulations are used to improve performance.

During the production process, each layer of plywood is treated with special compounds and impregnations

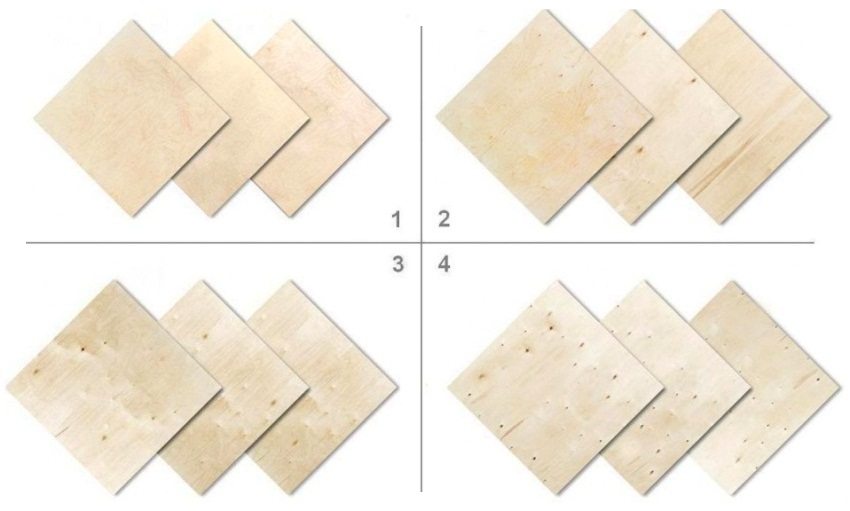

In accordance with GOST, 4 types of plywood are distinguished. The presence of minimal defects is allowed on the first grade plywood sheets. Second-grade plywood may have patches, cracks, glue seepage. The third grade assumes the presence of knots on the surface, wormholes, but the total number of defects should not exceed 9. Plywood of the fourth grade is of very low quality and has a large number of defects (intergrown knots, a large number of wormholes, uneven edges). It is mainly used for the manufacture of containers.

Interesting fact! The production of plywood was put on an industrial basis at the end of the 19th century, and the method in which a sheet of plywood was glued from several layers of veneer was called Russian, because it was in Russia that a method for producing peeled plywood and a machine for its implementation was invented.

The main types of plywood on the domestic market

There are several main types of plywood. All of them are different in their features and areas of application. The size of the plywood sheet and its thickness also differ. All of these characteristics determine how much a plywood sheet costs:

- FC plywood (moisture resistant plywood.) The advantage of this type of plywood is environmental friendliness. In its production, adhesives based on carbamide, a natural chemical compound, are used, which makes it possible to use this material even in the decoration of residential premises, in the manufacture of furniture and packaging, in the automotive industry. This plywood is durable and easy to process. Its serious drawback is the average water resistance. FK plywood is produced in polished and not polished form;

- FSF plywood (plywood of increased water resistance). This type is characterized by a high level of moisture resistance, which is associated with the method of its production, in the process of which glue based on formaldehyde resins is used. This explains both the good wear resistance of plywood and the mechanical strength. It retains its shape well and is widely used in construction, including in roofing works, suitable for painting, cladding, easy to process, whether it be cutting or drilling. However, this type of plywood has a significant drawback - it is not environmentally friendly. During operation, formaldehyde resins, which give it such strength and water resistance, begin to emit vapors and can cause irreparable harm to health. Despite this, FSF plywood is very popular among domestic consumers;

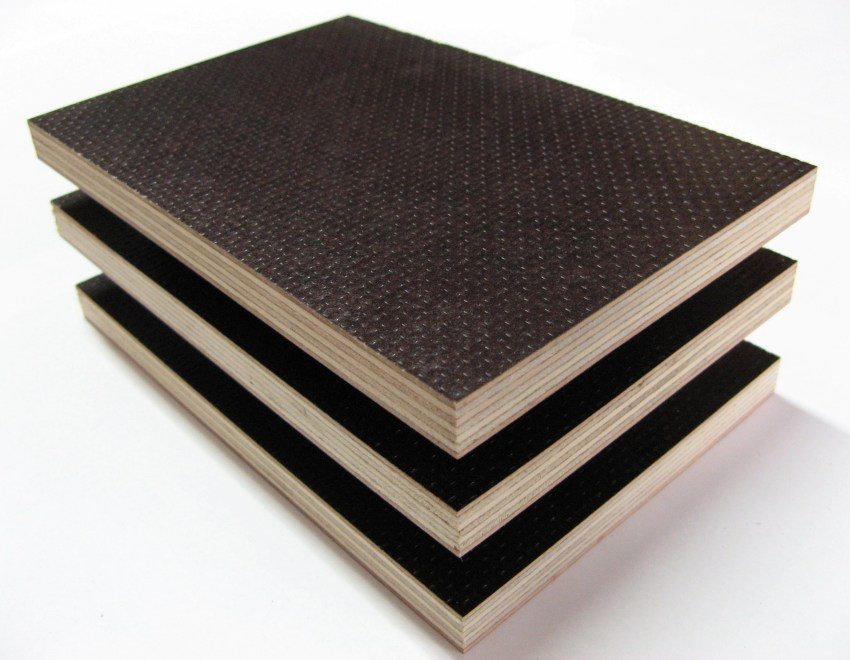

- FOF plywood (film faced plywood). A special way of processing plywood sheets can significantly increase its moisture resistance. Film faced plywood is characterized by high mechanical strength, wear resistance, holds its shape and is suitable for painting and cladding. The disadvantage of plywood, as in the case of FSF plywood, is its non-environmental friendliness due to the presence of formaldehyde resins in the composition;

- plywood FBS or FBV (bakelite plywood, delta wood) is a very special product in the building materials market. This type of plywood is distinguished by increased wear resistance, fire resistance (it does not ignite when burning, but charred), resistance to moisture and sudden changes in temperature. In terms of its strength, it is close to low-alloy steel. It is made from pine or birch veneer impregnated with special alcohol- or water-soluble resins (the abbreviations FBS and FBV indicate which impregnation was used, respectively). Its service life is 10-15 years. The disadvantage of this type of plywood can be attributed to its high cost, therefore, as a rule, it is used in professional construction, for example, for formwork panels in the construction of monolithic buildings. The dimensions of the FBS and FBV plywood sheet are standard and do not differ in great variety: 5700 × 1250 mm and 2850 × 1250 mm.

It is interesting! Bakelite plywood can be used even in sea water and in tropical conditions, it can withstand temperature drops from -50 to +50 degrees Celsius.

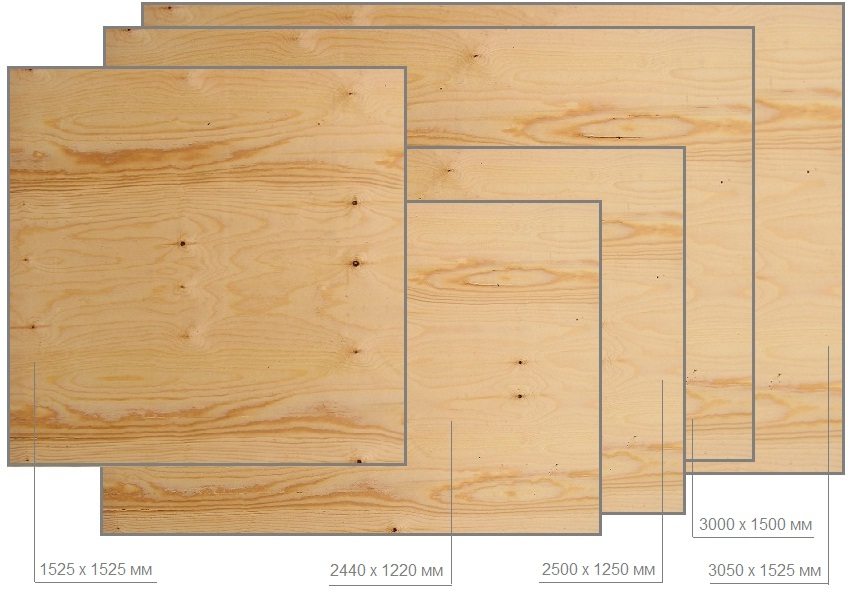

Useful advice! Depending on how the fibers are located (along or across the face layer), longitudinal and transverse plywood are distinguished. This can be determined by marking. If we are talking about the second type, then when specifying the size of the plywood sheet, the width will be put in the first place (for example, 1525 × 3050 mm).

According to GOST, the standard length of a plywood sheet is 2440 mm, and the width is 1220 mm.Nevertheless, one of the most common formats is 1525 × 1525 mm.

Related article:

Drywall sheet size. Thickness, weight of a drywall sheet. Main characteristics, types, composition and other indicators. Where drywall is used Instructions for calculating the material.

The plywood thickness is determined by the veneer thickness and the number of layers. Today, a single standard has not been adopted, and the sheet thickness varies significantly between different manufacturers. The minimum thickness of plywood available in stores is 1.6 cm, the maximum is 7.6 cm.

The price of a plywood sheet depends on many factors: the type of plywood used in the production of wood, manufacturer, grade of material, size, thickness.

The wholesale price for a 10 mm moisture-resistant plywood sheet ranges from 309 to 560 rubles (the price is indicated for a 10 mm plywood sheet of 1525 × 1525 mm). With a plywood sheet size of 12 mm, its cost will be from 371 to 505 rubles. The wholesale price for a sheet of plywood 18 mm 1525 × 1525 mm averages from 536 to 1182 rubles.

For film faced plywood, the sheet size and price are somewhat different from the previous types. So, with a thickness of 18 mm, the price per sheet is approximately 1,580 rubles, in 21 mm - 1,845 rubles. The size of the plywood sheet is also often found 10 mm, 12 mm and 15 mm.

The price of different types of plywood may differ depending on the region.