When choosing building materials, you should always be informed about their quality, scope, reliability and durability for the required area of use. One of the most popular wood products is fiberboard, the scope of which is quite extensive. Fiberboard: what it is and how to choose the right material to get a reliable product with a long service life is described in detail in this article.

Content [Hide]

Fiberboard: what is it

Fiberboard Is a building material made from wood fibers with the addition of a binder, adhesive additives and hydrophobic chemical components ("wet method"), or without their use ("dry method") by pressing or drying wood pulp, which is formed in the form of a rectangular carpet.

Manufacturers use waste from sawmilling, woodworking, and plant combustion as a starting material. Coarse raw materials are processed into necessary fibers by steaming and grinding in defibrators. As a binding component, synthetic resins are used in an amount of 4-7% of the ratio of hardwood and softwood fibers.

To increase the moisture resistance of the material, paraffin, rosin or ceresin is introduced into the wood fiber mass.

Fiberboard production is one of the most promising methods of using wood waste. This material is widely used in modern housing construction, to achieve sound and thermal insulation of walls and floors of premises, in the manufacture of interfloor ceilings, decoration of interior elements of premises, in the manufacture of furniture and packaging.

The history of fiberboard boards

In 1858, the scientist Lymon first patented his discovery. Later, the scientist Munchon improved the fiberboard manufacturing technology. He suggested using hot pressing equipment. No binding ingredients were used in the production of the material at this stage.

And already in 1924, the American scientist Mason proposed a modern method of making fiberboard using the "wet method", as a result of which the final material had a high density.

Fiberboard production technology

Fiberboard is manufactured on the basis of a technological map, the structure of which has been unchanged for more than fifty years.This process consists of several stages:

- Washing wood pulp. Sand and other debris is mechanically removed from it in adsorption plants.

- Removal of metals from the mixture by means of electromagnets on special separator installations.

- Chopping wood chips. The degree of grinding is set here, from coarse to finer.

- In a defibrillator unit, polymers, resins and paraffin are mixed into the bulk.

Further, the production of fiberboard is made by "dry" or "wet" method. The "wet method" is more environmentally friendly, as it involves a small dose of the binding mixture, which is toxic. The density and technical indicators of fiberboard directly depend on the manufacturing method.

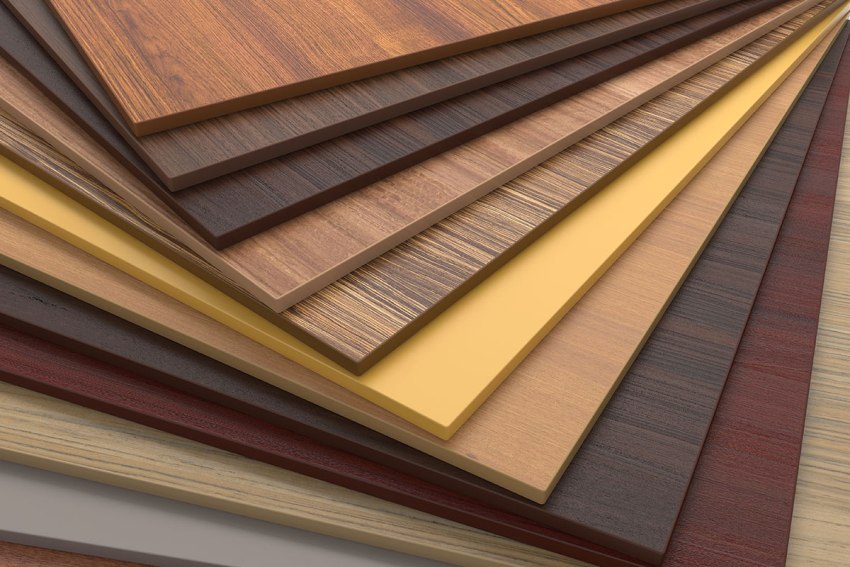

Varieties of fiberboard: photo examples

Depending on the properties of the material, the manufacturing method and the method of further application, modern industry produces the following types of fiberboards: soft, medium density, semi-hard, hard, superhard. You can buy fiberboard at any hardware store. The price per sheet is determined from the standard size and type of product.

Soft fiberboard

Soft fiberboard has low strength, high porosity and low thermal conductivity. The thickness of the slabs varies between 8-25 mm. The density index is between 150 and 350 kg / m³. Based on the density of the material, there are such grades of plates: M-1, M-2 and M-3.

This type of fiberboard is not used as the main building material. It can be used for heat and sound insulation of building structures, such as walls, floors, ceilings, etc. It is analogous to drywall, but lighter, more elastic and easy to install. Buy soft fiberboard can be much cheaper than a sheet of drywall of the appropriate size.

The boards can also be used as an underlay for parquet, linoleum or laminate flooring. Fiberboard is also used for leveling base defects when laying floors.

Useful advice! In the manufacture of soft fiberboard, no synthetic binder is used. This indicates the environmental safety of this material, which can be used to decorate rooms for children and allergy sufferers.

Fibreboard semi-solid

Compared to the soft type, this type of fiberboard has a higher density and strength. The average density of fiberboard boards is 850 kg / m³. The thickness of the sheet can be kept in the range of 6-12 mm.

This type of fiberboard is used as back walls of furniture, shelves, drawers of cabinets and tables. It is also often used as a substrate for floor installations. It has gained popularity as a packaging material.

Hard fiberboard

The density index of solid fiberboard is in the range of 800-1000 kg / m³. Product thickness - 2.5-6 mm. These boards are used in the manufacture of furniture as back walls, drawers and for the production of panel doors.

Useful advice! The front surface of hard fiberboard is refined with synthetic and melamine films. With a glossy, matte, pigmented and imitated wood texture, the boards can be used for interior wall cladding.

In turn, this type of slab, depending on the strength value, density value and type of the front side, is subdivided into several brands:

- T - plate with a refined face;

- Т-С - the front surface is made of a finely dispersed wood mixture;

- Т-В - a plate with a non-refined front side, and an increased indicator of water resistance;

- T-SV - a plate with a front surface made of finely dispersed mass and with an increased degree of water resistance;

- Т-П - the front side of the plate is tinted;

- T-SP - the front layer is made of a finely dispersed mass, tinted;

- NT - a plate with a low density index.

White fiberboard is very popular. Such a versatile material color can be used to create bedrooms, kitchens and children's rooms. Such a coating can be decorated with a special paint, followed by varnish application. You can buy white fiberboard at a lower price than the same sheet in any other color scheme.

Fiberboard with a refined front side

Refined fiberboards are highly resistant to moisture and mechanical abrasion. Thanks to the unique manufacturing technology, they have an attractive appearance. During the manufacture of this type of board, the technology of applying a multilayer coating to the front surface is used. The board is processed, then a primer layer is applied to its surface, which is the background for the future drawing. The drawing can be different. But each species in its own way is an imitation of a woody structure.

Such plates are used for the manufacture of door panels, for decorating walls and ceilings, and interior furniture elements. Modern industry produces doors of standard sizes made of fiberboard.

Fibreboard superhard

These slabs have a high density index of 950 kg / m³. It is a high quality material that is convenient and easy to install. High strength of the board is achieved by impregnating it with pectol. These super-hard fiberboards are used to make partitions, arches and doors. Also widely used in the production of floor coverings. A high rate of electrical insulation allows the use of plates for the manufacture of shields and panels.

Medium Density Fiberboard

Medium Density Fiberboard, or MDF, is a type of semi-solid board. This is a relatively new building material that has taken pride of place among furniture makers and builders. This is because its density is 700-800 kg / m³, its strength is equal to that of hard fiberboard, which is almost twice as high as compared to particleboard.

Due to its ease of processing, MDF is widely used in the modern construction industry. Plates, plinths, fillets, facades of cabinet furniture, window sills, roof battens, T-beams are made of slabs. They are used in the production of interior door panels. And the ceiling and wall fiberboard panels of this category will be an elegant solution for interior decoration. Laminate is also made from MDF.

Having asked the important question of how much fiberboard costs, it is important to determine the area of its further application. Here it is worth considering all the characteristics of each type and choosing the most optimal one based on price and quality.

Laminated fiberboard: a ready-made solution for finishing

The use of laminated fiberboard is very popular today. A special mixture is applied to the material, which consists of certain synthetic resins. Thanks to this technology, these boards have increased moisture resistance and strength.

In hardware stores, you can buy laminated fiberboard of the following varieties:

- Tiled type. Such a brand of fiberboard has a wide range of typical sizes ranging from 30x30 cm and ending with 100x100 cm. Such plates are fastened using a thorn-groove connection using special cleats or staples. The use of slabs allows you to form interesting patterns and ornaments. Every year the industry produces fiberboard with a new color scheme and textured patterns.

- Fiberboard under the lining. This is a new and more modern format for the material. By its method of connection, it is similar to a wooden clapboard. This sheet material has standard sizes. The joining of the sheets is the same as the fiberboard of the tile type.Such fiberboard is used for wall sheathing and flooring. The material has a high degree of moisture resistance.

- Leaf type. It is a versatile type of laminated fiberboard. It has a lot of options for textures, colors, sizes and methods of attaching the material to the ceiling, floor, walls.

Fields of application of laminated fiberboard

Laminated fiberboard has certain properties that are taken into account when choosing its further use. Due to the high rate of sound insulation, such plates are used for those rooms in which it is necessary to achieve maximum insulation. This applies to radio broadcast cameras, recording studios.

Useful advice! Laminated fiberboard has proven itself well as an aesthetic, soundproof material. Therefore, it will become a real find for interior decoration of office premises and classrooms of educational institutions.

This versatile building material is widely used in the construction of light arches, interior partitions, and complex suspended ceilings. Only this type of fiberboard can be used for facing the facades of furniture walls. More and more often, laminated fiberboard panels are used for walls, which do not require further finishing.

You can buy a fiberboard sheet at a fairly low price, which makes this building material one of the most affordable in construction among other analogues.

When calculating the total cost of construction and installation work using fiberboard, it is worth knowing how much a fiberboard sheet costs. The price of each panel is formed taking into account the size, variety and place of purchase. Online construction stores offer more reasonable prices in comparison with market rates.

The main advantages of fiberboard

Due to the high degree of moisture resistance, these boards can be used for cladding exterior and balcony doors. Fiberboard has a high rate of sound and heat insulation. The material is easy to process, has a long service life and is lightweight, which simplifies its further installation. The low price of fiberboard, depending on the type, dimensions and thickness of the product, significantly reduces the total cost of all construction and installation work, without compromising their quality.

Related article:

Wall MDF panels: prices, catalog of photo ideas and main technical characteristics

Prices for different options. Benefits of using this material. Varieties and colors of MDF panels. Various applications.

The surface of the fiberboard is lightweight and easy to clean. For cleaning it is enough to wipe the material with a damp cloth without using powder. For wall cladding using slabs, no preliminary leveling is required.

Useful advice! Without compromising the quality and structure of the material, it is easy to decorate with decorative plaster or paint.

Material disadvantages

Each type of fiberboard, except for MDF, has a narrow scope. Some types of panels contain toxic compounds. Therefore, work on processing this material should be carried out in personal protective equipment and in well-ventilated areas.

Fiberboard sheet does not withstand significant lateral load due to the small thickness of the product. Therefore, the installation of the material must be done carefully, without leaving air cushions between the wall and the panel, which can cause the slab to break.

Fiberboard is one of the most common building materials. For finishing the interior elements of a house, fiberboard has a number of advantages over other similar building materials.This practical, inexpensive, easy-to-process material allows you to achieve several goals at once: thermal insulation, good ability to absorb all external noise, resistance to temperature fluctuations and changes in humidity.