In an effort to provide our home with warmth in the cold season, we are often faced with the choice of a suitable unit for the heating system. Among the variety of heating gas equipment, I would like to choose an efficient, economical and affordable installation. A gas wall-mounted double-circuit boiler with a closed combustion chamber may well become a priority option in your case.

Content [Hide]

- 1 Gas wall-mounted double-circuit boiler with a closed combustion chamber: advantages

- 2 Installation of wall-mounted gas appliances with a closed type of firebox

- 3 Comparative analysis of devices with different types of combustion chambers

- 4 Types and features of models of boilers with a closed combustion chamber

- 5 What models of wall-mounted gas boilers are better: what affects the choice

- 6 Features of installation of closed-type wall-mounted gas boilers

Gas wall-mounted double-circuit boiler with a closed combustion chamber: advantages

Closed-type gas boilers are used for autonomous heating of small industrial premises, offices and private houses. Wall-mounted gas boilers for heating with a closed combustion chamber have a number of advantages over other similar equipment:

- during operation, oxygen is not consumed from the room where the wall-mounted gas boiler is installed;

- combustion air inflow is provided without the involvement of additional devices;

- to heat all rooms in the room, the boiler consumes the optimal amount of gas;

- to use the boiler in private houses, there is no need to equip a chimney;

- individual selection of a suitable operating mode;

- compact dimensions;

- available automatic control;

- a wide range of models presented (reviews of users of popular boilers can be found on the manufacturers' websites).

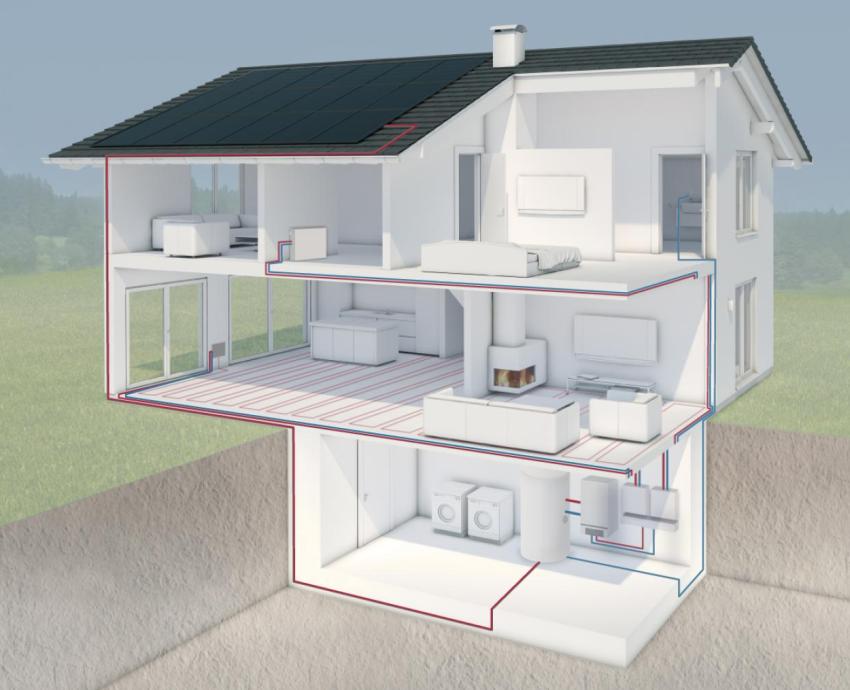

Gas boilers, based on a closed combustion chamber, are safe and can be installed directly in a heated room without the risk of a lack of oxygen in it. This is ensured by a special pipe layout (one inside the other). Air is supplied through one pipe, ensuring the combustion process, through the other, carbon monoxide is removed. This completely prevents waste gas from entering the room.

Gas boilers with a closed combustion chamber are safe and can be installed directly in a heated room

Installation of wall-mounted gas appliances with a closed type of firebox

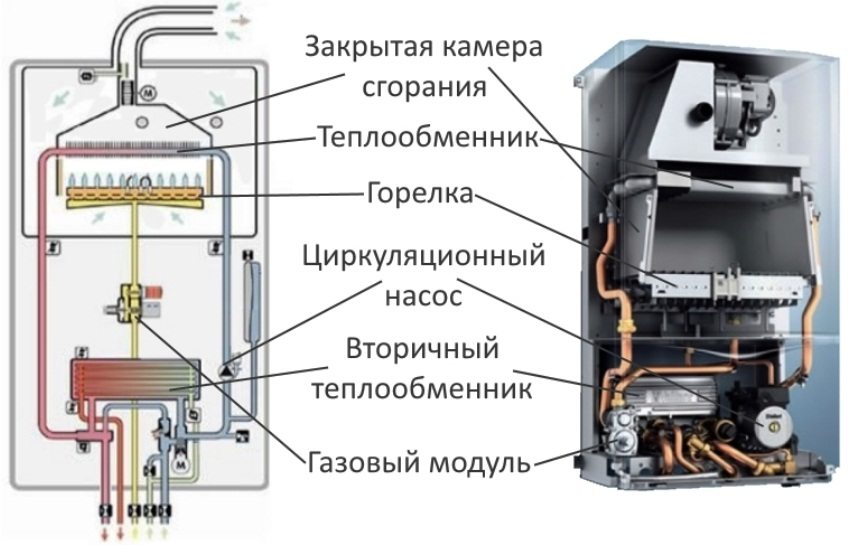

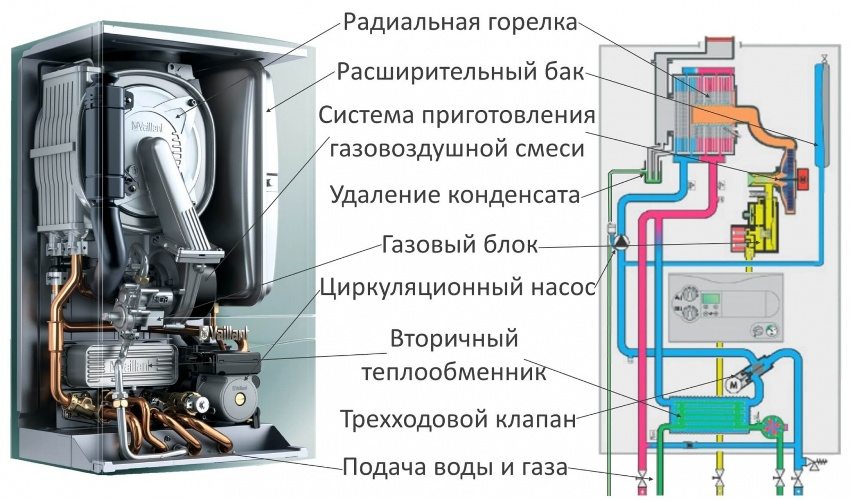

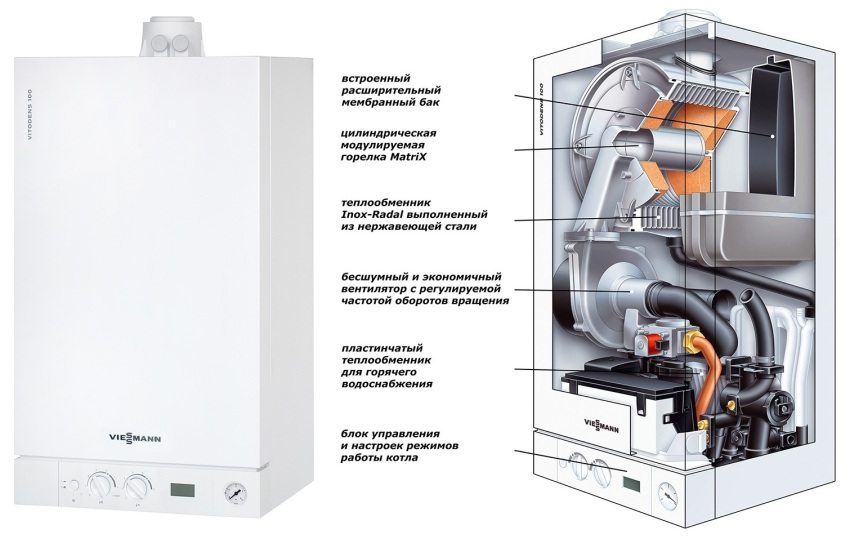

Wall-mounted gas heating boilers in modern design are rather compact equipment, consisting of the following structural elements:

- functional body;

- gas-burner;

- heat exchanger block;

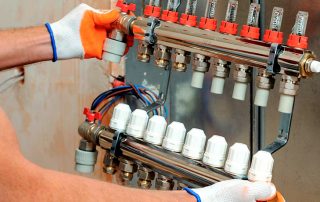

- circulation pump;

- temperature regulators and sensors;

- expansion tank;

- complete security system;

- removal of combustion products into the chimney (forced);

- Control Panel.

The model with which control (electronic or mechanical) you choose - find out by reading the customer reviews.

Taking into account the number of circuits and the connection diagram, the wall-mounted gas boiler can be equipped with an additional heat exchanger, fan, shut-off valves.

Closed boilers can be convection and condensing. In convection models, the generated steam is removed to the outside, and in condensing models, this steam is used to heat up an additional heat exchanger. The models have their pros and cons. Convection boilers are simple, cheap and easy to operate. Condensing units are distinguished by high performance, but at the same time they are much more expensive.

Comparative analysis of devices with different types of combustion chambers

A boiler with an open combustion chamber uses room air for combustion, which can lead to a lack of oxygen. Such a boiler can only be installed in a separate room (boiler room), its chimney must be vertical. From the reviews, you can find out that the price of such a boiler is relatively moderate.

Related article:

|

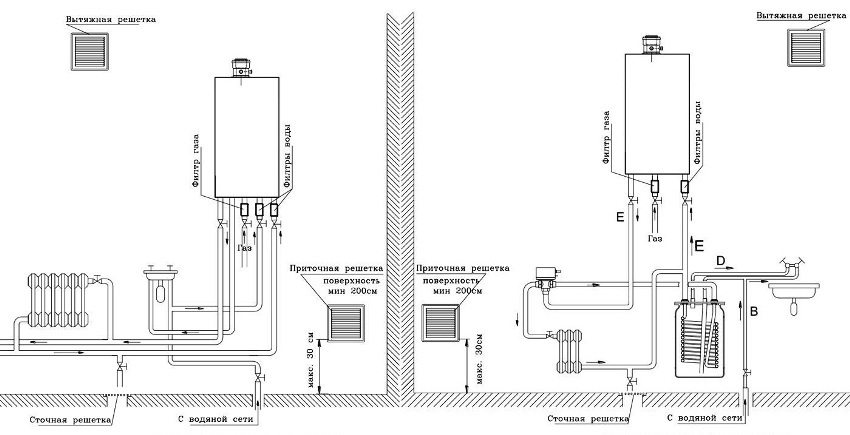

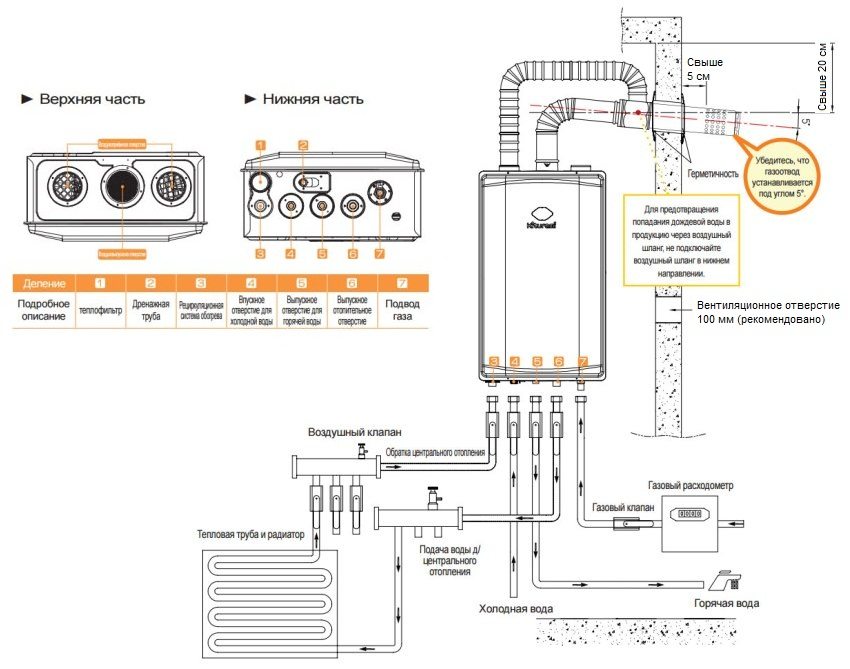

Unlike heating devices with an open combustion chamber, a turbocharged wall-mounted boiler provides air supply and removal of combustion products through a coaxial chimney, the principle of which is the simultaneous removal of exhaust gas and intake of outside air. Important advantages of boilers with a closed combustion chamber are the safety of the installation in a residential area, high performance (heat exchange between the supply and exhaust) and the level of increased comfort in the house.

Helpful advice! For efficient operation of a wall-mounted gas boiler, it is necessary to choose a place for installation next to an external wall or ventilation shaft of the room.

A boiler with a closed chamber does not require a specially equipped separate room with the provision of all fire safety standards. The chimney can be horizontal and small in length. A device with such a combustion chamber has a high level of safety:

- gas leakage protection;

- protection against popping when ignition;

- protection against excessive heating of water;

- fan operation control.

This boiler is suitable for installation both in a private house and in apartments (mainly in kitchens) of multi-storey buildings. Taking into account the likely absence of hot water supply in high-rise buildings, the use of gas wall-mounted double-circuit boilers with a closed combustion chamber in them will be quite reasonable. Reviews indicate the frequent use of such boilers in residential apartments.

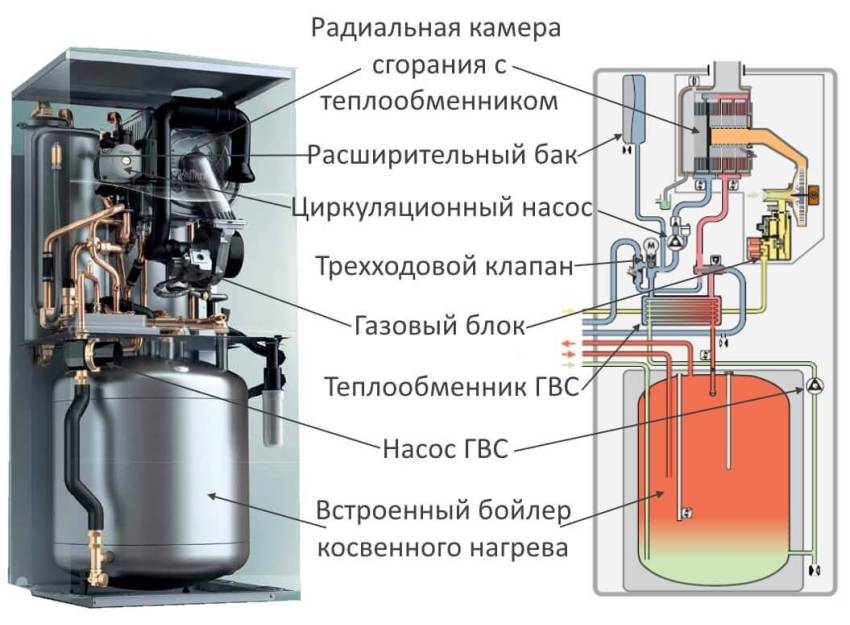

Types and features of models of boilers with a closed combustion chamber

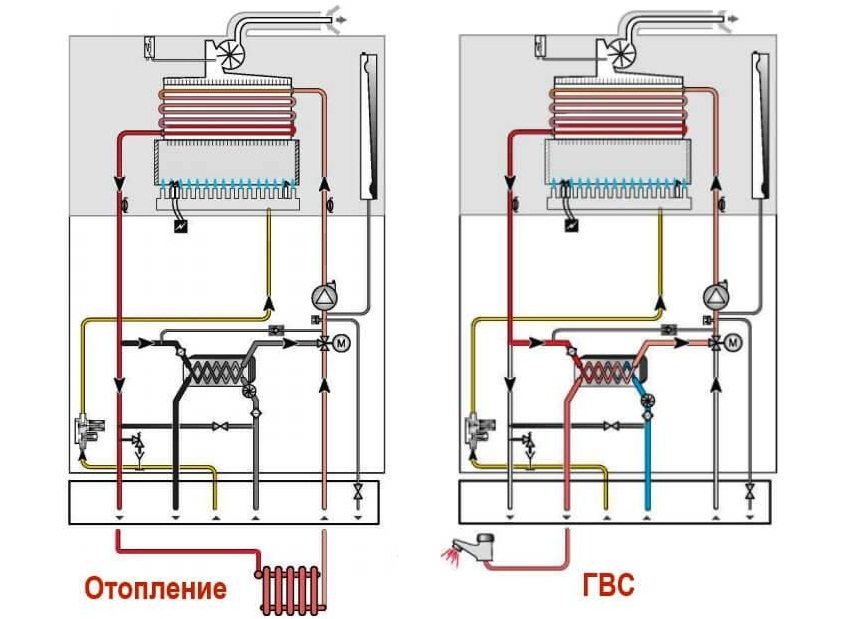

Wall-hung boilers with a closed-type combustion chamber are divided into single-circuit and double-circuit. Models of gas wall-mounted single-circuit boilers for heating a house only work to heat heating radiators. If there is a need for hot water supply, then you should choose a single-circuit boiler with the ability to connect a secondary heating water heater (boiler) to it. Such a single-circuit boiler can satisfy the hot water needs of a large family living in the same private house. Another option for a single-circuit design is a single-circuit boiler with a built-in boiler. It has large dimensions.The price of such boilers is noticeably higher, however, it pays off with an uninterrupted supply of hot water, even in flow mode. On which model of a single-circuit wall-mounted boiler is better to opt for, find out from user reviews.

The device of gas wall-mounted double-circuit boilers for home heating allows you to function both for heating and for preparing hot water. Such boilers are equipped with two circuits. When using hot water, the supply of heat carrier to the heating system is interrupted. The double-circuit boiler is equipped with a valve that automatically stops heating the heating circuit when hot water is used. This gives many reasons to think that heating radiators cool down at this time. As a rule, the percentage of temperature drop in radiators is negligible (consumer reviews confirm this).

There are models of double-circuit wall-mounted boilers, in which the heating circuit is heated by an additional heat exchange unit. In such installations, the hot water gives off part of the heat to the heating circuit (heat recovery principle). Reviews of such equipment speak of the high performance of the boilers.

Helpful advice! A gas wall-mounted double-circuit boiler, equipped with a boiler, ensures independence from the water pressure supplied by the water supply.

What models of wall-mounted gas boilers are better: what affects the choice

What criteria should be considered when choosing a gas wall-mounted double-circuit boiler? How to choose the model that suits your room? First of all, you should pay attention to the following indicators:

- equipment power;

- economical installation;

- conditions and complexity of installation;

- heater price.

How to choose the power. The power rating is usually calculated by a specialist. If this is not possible, you can resort to the generalized method of the so-called aggregated calculation. Its essence is that to heat one square of the area of the room, 0.1 kW of heat energy is required. This means that you can find out the required power (kW) by multiplying the entire area of the heated room by 0.1.

As for the efficiency indicator, the wall-mounted closed-type boiler, due to the efficient combustion of gas, is a device with high efficiency (up to 98%) at rated power.

Helpful advice! The closed-type wall-mounted gas boiler is a volatile device. If electricity is often cut off in your area, this should be taken into account when choosing a boiler.

The complexity and cost of installation depends on where it is supposed to place the installation of a gas double-circuit wall-mounted boiler. How to choose a place in the kitchen or bathroom unit? Gas equipment installers will help you with this. If accurate placement is required in tight spaces, installation will be slightly more expensive.

Every potential buyer wants to choose a model of a gas appliance with an acceptable price. It depends on what power of the unit you prefer and with what functions. The more technical elements made of high-quality materials in the design, the better the boiler and the higher its cost. Two-circuit wall-hung boilers with a heat exchanger made of steel received positive reviews. Such a boiler is capable of quickly heating water, is lightweight and easy to install.

What models of gas wall-mounted double-circuit boilers are better to buy? Feedback from people using such equipment testifies to the ease of control and the ability to adjust the temperature regime with an accuracy of 1 ° C. In the event of a technical malfunction, an error code is displayed on the display.

Features of installation of closed-type wall-mounted gas boilers

Before purchasing a gas wall-mounted double-circuit heating boiler, prices and reviews can be checked with the consultant of the trading organization.

When buying a boiler, you must make sure that the device is properly equipped. After removing the packaging, the housing of the unit must not be damaged and an operating manual must be attached to it. It is also worth checking the availability of all component parts, so that, if they are not available, immediately contact the seller.

In addition, it is necessary to compare all the characteristics of the device on the body and packaging of the boiler. They, in turn, must correspond to these indicators from the instructions.

Before installing a wall-mounted gas boiler, you must contact your local gas service to agree on the installation scheme.

To ensure the combustion process, air enters the closed-type boiler from the street. There is no need for an individual chimney, the waste gas is removed by connecting to a common chimney. Pay particular attention to ensure that the fan mounting position is not clogged during installation. Before starting the system, it is advisable to check this place for debris and dirt.

The adjustment of the electronics of the double-circuit boiler must be carried out by a qualified specialist.

The outside air intake pipe must be 2.2 m above the floor and protrude at least 18 mm from the wall. In order to remove the resulting condensate from the chimney, the chimney pipes must have some slope. The gaps between the pipe and the wall must be sealed.

The wall-mounted boiler is mounted on well-fixed hooks (fasteners at the top of the device). The unit is installed so that, in the event of a malfunction, service and repairs can be carried out without disconnecting it from the gas and water pipeline system. It is necessary to provide shut-off valves on the water supply pipes to ensure repair work.