Today, various materials are used for the production of furniture and decorative coatings - chipboard, fiberboard, MDF, solid wood. However, more and more manufacturers prefer to deal with chipboard. At the same time, many buyers are still perplexed by the abbreviation of chipboard: what is it, how does this material differ from the varieties mentioned above, and what are its advantages and disadvantages. The answers to these questions will be provided in this article.

Content [Hide]

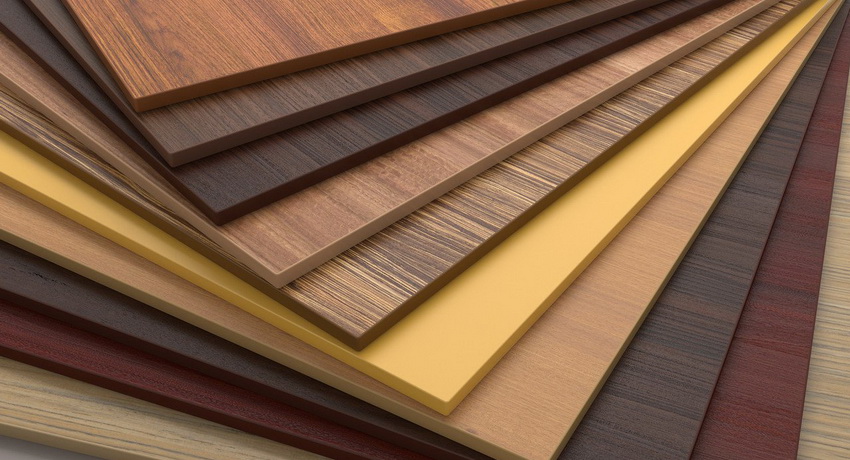

Technical characteristics of chipboard and laminated chipboard: photo

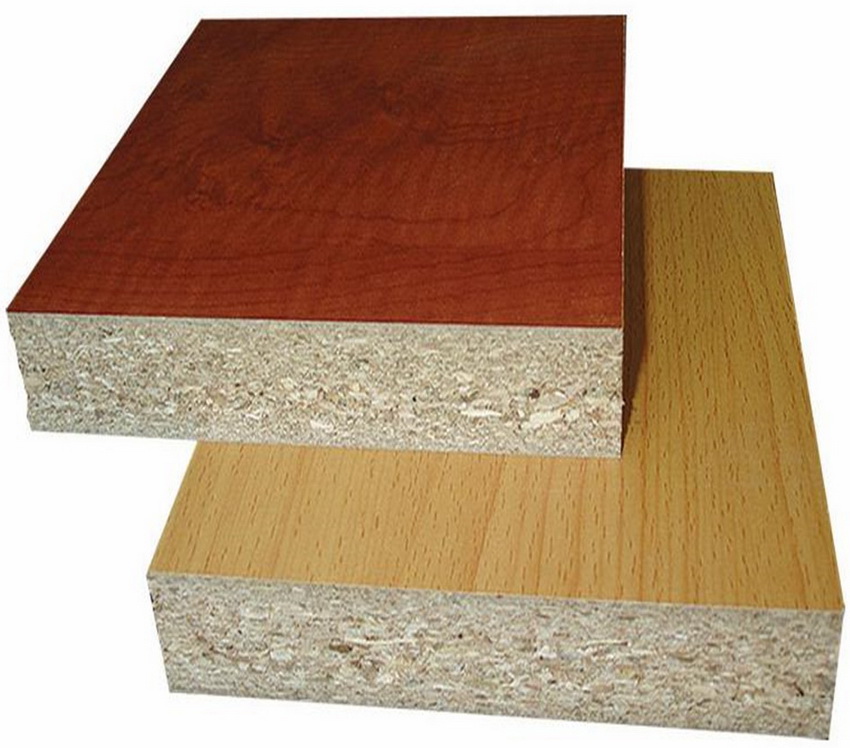

You can notice the similarity of the terms chipboard and chipboard. The latter is deciphered as chipboard or chipboard. The abbreviation itself, although it is commonly used, is not entirely correct. It would be more correct to write DSP. We are talking about a composite material, in the production of which, due to hot pressing, sawdust and shavings, together with binder formaldehyde resins, take the form of a solid sheet.

This material was first invented back in the 30s. XX century, but the mass production of chipboard began only in the 50s. Last but not least, this is due to the difficult post-war situation. For the needs of mass production, a cheap and affordable material was required, and natural wood was expensive and the waste during its processing reached 60%. In addition, the tastes of buyers have changed significantly - pretentious bulky furniture did not in any way correspond to the spirit of the era, which combined the desire for simplicity, convenience and ease with the need to save money. Chipboard, however, fully met all these requirements.

Chipboard production technology

For the production of chipboard, woodworking industry waste and specially crushed illiquid trunks are used:

- shavings and sawdust (previously they were simply burned as garbage) are dried in a special drying chamber and driven through a cyclic installation that rejects too large particles for re-crushing;

- raw materials that meet the requirements are mixed with formaldehyde resin and transferred to a conveyor belt, where it is cold pressed into the required shape;

- using a hot press, the layers of the workpiece are firmly glued together, then the sheets are cooled, dried and sawn into plates of standard sizes;

Pros and cons of chipboard

The resulting durable and very affordable material instantly found application in the manufacture of upholstered and cabinet furniture, wagons, in construction (as formwork, partitions, beams, floors, sheathing, frames). Among its advantages, one can note good indicators of heat and sound insulation.

However, chipboard has a number of serious disadvantages. It can absorb moisture (up to a third of its original volume) and deform. The plate can also lose shape when exposed to heat. This limits the use of chipboard sheets in the kitchen or bathroom. The only exceptions are canvases that have undergone special processing as a result of which the material becomes moisture and fire resistant.

Thanks to its dense structure, chipboard holds nails and screws well. However, due to the same structural features, the fastening hardware cannot be re-fastened as the board will begin to crumble. For the same reason, the material is not suitable for milling and creating curved paths.

And, finally, the most disadvantage of chipboard boards is the use of urea-formaldehyde and phenol-formaldehyde resins in the process of their manufacture. They prevent wood decay processes, however, they do not have the most favorable effect on human health.

Note! Formaldehyde is an extremely dangerous chemical. It can accumulate in the human body, cause poisoning or provoke the development of serious diseases. The main signs of poisoning are coughing, irritation of the mucous membranes of the throat and eyes, dizziness, fatigue.

The main types of chipboard

There are several classifications of chipboard.

The formaldehyde emission class E1 and E2 indicates the amount of the harmful substance in the chipboard. The E1 class is considered to be more environmentally safe (it corresponds to the Russian GOST 10632–89). Class E2 is not suitable for use in children's rooms. Many European manufacturers have already stopped production of this class of chipboard.

Chipboard is made from pressed wood chips with the addition of a binder - thermosetting synthetic resin

Depending on the quality and appearance of the finished product, chipboard is:

- first grade (for its production, only high-quality raw materials are taken without foreign inclusions, most often sawdust of the same type of wood. The plate is smooth, without chips or with minimal defects and must be decorated on both sides with film or veneer);

- second grade (scratches and chips are allowed, lining is optional);

- third grade (has serious defects in the form of cracks, chips, irregularities. The slab is not revetted, it is used only in auxiliary construction).

By the type of cladding, chipboard is distinguished:

- rough (do not have cladding);

- laminated (coated with melamine film or special resistant varnish);

- veneered (have a cladding in the form of a thin sheet of natural wood).

To figure out which is better - chipboard or chipboard, you need to familiarize yourself with the characteristics of laminated panels.

Chipboard: what is it, variety of colors

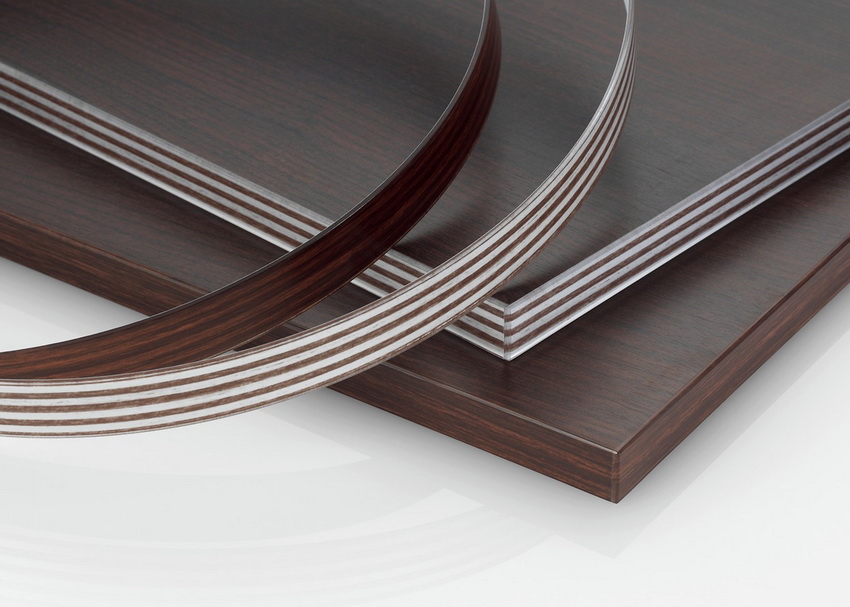

So what is the LDPC? In fact, it has already been mentioned above and the decoding of chipboard is simple - it is a laminated chipboard. For the manufacture of laminated chipboard (more precisely - laminated chipboard), only high-quality polished chipboard is used.

At the final stage of production, they are covered with a special polymer film at high pressure and high temperatures. This film is made from paper impregnated with melamine resin. Sometimes, in the manufacture of expensive LSDP, a special varnish is used that is not afraid of water and scratches.

Ready panels Chipboard cooled, dried and sawn in accordance with standard sizes.

Chipboard are devoid of many of the disadvantages inherent in chipboard. They are not afraid of moisture and high temperatures, so furniture makers often prefer to assemble kitchens from chipboard (photos of these headsets clearly demonstrate the popularity of such a solution).

An additional advantage of this material is its low cost and ease of processing. It is enough only to cut the chipboard sheet and trim the edges with an edge, which, by the way, significantly reduces the level of formaldehyde fumes.

Useful advice! Chipboard can be edged only on a special machine. There are many firms and stores of building materials that provide a similar service. It will not be difficult to assemble furniture from the obtained blanks do-it-yourself laminated chipboard - bed, bookcase or wardrobe.

Chipboard is very durable and holds fasteners well. They are practically not afraid of mechanical damage, and with proper and completely uncomplicated care they can last at least 10 years.

Furniture made of chipboard is able to withstand the effects of steam, water and significant temperature drops

Among the undoubted advantages of laminated panels, one can note the widest color palette presented in the laminated chipboard color catalogs. Thanks to the coating, they can imitate any material, fit into any interior.

Related article:

Chipboard tongue-and-groove moisture resistant: a new development in the building materials market

Characteristics and main advantages of the material. Areas of use. Features and installation rules. Average cost of production.

Catalogs with samples and photos of laminated chipboard, the colors of which are represented in hundreds of shades, can demonstrate several palettes:

- plain smooth (vanilla, blue, green water);

- plain textured (aluminum, titanium, concrete);

- wood-like colors (maple, cherry, wenge);

- glossy decors;

- fancy decors (various patterns and designs).

Furniture made of laminated chipboard goes well with various materials - glass, metal, ceramic tiles

All this makes laminated chipboard sheets a versatile and extremely popular material. They are used in bathrooms and children's bathrooms, to create decorative partitions, upholstered and cabinet furniture. On the forums, you can easily find a lot of positive reviews: laminated chipboard kitchens are able to withstand the effects of steam, water and significant temperature changes.

Laminated boards are perfectly combined with other materials - glass, mirrors, metal, plastic panels, as well as fiberboard and MDF.

Which is better: chipboard or MDF

The variety of materials in stores cannot but puzzle customers. What is better for furniture - MDF or chipboard?

There are fundamental differences between chipboard and MDF. Chipboard is made from wood shavings and sawdust, formaldehyde acts as a binder.

In the production of MDF, wood dust is used (woodworking industry waste crushed to a very fine fraction) and exclusively natural binders - paraffin and lignin. Thanks to this composition, MDF is much more environmentally friendly than chipboard. They can be safely used even for decorating children's rooms.

Note! Paraffin is not only environmentally friendly, but also has water-repellent properties, so there is no need to additionally treat MDF boards with special impregnations.

Unlike chipboard, MDF is a very plastic and soft material. It is easy to mill, which is why it is so popular in the manufacture of luxury furniture. Most of the curved elements, carved headboards and fanciful fronts are made from MDF. Photos of beds made of laminated chipboard or kitchen facades cannot please with such decorativeness, because the furniture is made of material with a crumbling edge, unsuitable for milling.

Nevertheless, many, choosing between chipboard or MDF, prefer laminated panels. The reason is simple: the cost of MDF is much higher than democratic chipboards. According to consumer reviews, laminated chipboard furniture is a successful leader in the domestic market, and not least of all this is due to moderate prices.

Another weighty argument in favor of laminated chipboard is the richness of color solutions. In the laminated chipboard catalog or on the websites of online stores, you can choose a suitable shade or texture that will harmoniously fit into any interior style - from classic to modern.

Leading manufacturers Laminated chipboard: Egger, Kronospan, Lamarti, Nevsky Laminate

When buying laminated chipboard, it is very important to make sure that the product has all the necessary certificates that guarantee the safety of the material for human health and be of high quality, ensuring a long service life. However, only large manufacturers can make sure that at each stage of production the norms and technical regulations are strictly observed. The leaders in the domestic market are foreign companies Egger and Kronospan, as well as domestic manufacturers Lamarti and Nevsky Laminat.

To refine the product, a special edge is glued to the visible ends of the laminated chipboard panels

Chipboard Egger: colors and material advantages

The head office of the company is located in Austria. Founded in 1961 by Fritz Egger Sr., this modest family business has gradually grown to become one of the leading chipboard manufacturers in the world.

The highest quality of manufactured products, an extensive catalog of Egger laminated chipboard colors and reasonable prices are achieved through the opening of local production facilities in 7 European countries, including Russia. First-class raw materials are mainly made from softwood and do not include foreign elements. Laminated boards fully comply with European safety standards.

A huge variety is provided by the Egger laminated chipboard color catalog, which allows you to realize any design solution:

- plain laminated chipboard (white, lagoon, alabaster, beige sand, canyon, pumpkin yellow, green water, Chinese red, reed, Baltic blue and dozens of other colors) - are presented in matte and glossy versions;

- textured decors (lightweight concrete, beige leather, gray-white amalvi marble, titanium, quartz bronze, indigo quartz, etc.);

- Laminated chipboard Egger colors imitation wood (calvados pink, light venchester oak, blossoming pear, natural rosewood, cremona oak champagne, zebrano havana, natural merano - more than 100 shades that perfectly imitate natural wood).

We can state a steady increase in demand for laminated chipboard Egger. Feedback from customers only confirms the positive dynamics, while noting the high wear resistance of the material, excellent quality and minimal presence of formaldehyde resins ("pine smell without chemistry").

Chipboard Kronospan: high kaquality and rich assortment

Another Austrian company, whose history began with a small family sawmill in Salzburg in 1897. Currently, its activities cover 24 countries of the world.

Among the undoubted advantages of the laminated boards of this company are:

- good moisture resistance, which allows them to be used in bathrooms and kitchens;

- increased wear resistance;

- solid color catalog of laminated chipboard Kronospan;

- environmental friendliness;

- anti-static, which guarantees additional protection against dust;

- a fairly democratic pricing policy;

- long service life (up to 20 years).

The colors presented in the catalog of laminated chipboard Kronospan can be classified as follows:

- textures (deep pores, wood pores, office, smooth, shagreen, mother of pearl);

- plain (blue modra atoll, lime green, white facade, burgundy, Inca gold, lavender, viola);

- woody (laminated chipboard milan walnut, snow birch, laminated chipboard guarneri walnut, dark corduroy, light chipboard bodega, alder plank, rustic oak, shimo warm ash);

- fancy (sakura white, nameo white, dark twist).

Even such a short overview of the colors of Kronospan laminated chipboard gives a good idea of how rich their palette is and how diverse the textures are. Actually, a surprisingly believable imitation of the rough surface of natural wood is a kind of visiting card of many lines of laminated chipboard of this Austrian company.

Lamartie: characteristics Laminated chipboard, colors, photo with names

Due to strict quality control at each stage of production, laminated chipboards from the Syktyvkar Plywood Plant successfully compete in the Russian market with products of foreign companies. Chipboards of this company are made from high-quality raw materials (coniferous and birch wood without foreign inclusions like bark), have an ecological certificate and excellent technical characteristics.

They are wear-resistant, not afraid of the effects of steam, moisture and high temperatures, are environmentally friendly, durable and retain their original color for a long time, and Lamartie's impressive laminated chipboard color catalogs will make it possible to bring any design idea to life.

Lamarti laminated chipboard color catalog includes:

- solid colors (topaz, chili, serenity, coral, monsoon, lemon, sepia);

- textured decors (slate, titanium, chinon, aluminum, pine exotic concrete);

- imitations of wood (plum, marsala oak, light chipboard wenge, latte, bamboo, noche amati, bleached oak, elm, chipboard Italian walnut);

Extensive catalogs of laminated chipboard colors will make it possible to bring any design idea to life

- imitations of wood (plum, marsala oak, light chipboard wenge, latte, bamboo, noche amati, bleached oak, elm, chipboard Italian walnut);

- fancy colors of laminated chipboard Lamartie (linen, spring, arabica flowers, modern, luino, graffiti).

LDSP Nevsky Laminat: affordable price, European quality

Laminated sheets from the Nevsky Laminat Plant compare favorably with their foreign counterparts in their low cost. Moreover, they have all the necessary quality certificates and good environmental performance. Chipboards from this manufacturer hold fasteners well, are not afraid of moisture, are resistant to mechanical damage and have a long service life.

The catalog of colors of laminated chipboard "Nevsky Laminat" offers customers a large selection of shades and textures:

- plain (orange, lime, anthracite, yellow daffodil, wine red, dark chocolate, white pearls);

- textured (linen, titanium, aluminum);

- fancy decors (litera nero, newport, hay, titanium, flora verde, mocha stitch);

- wood decors (chipboard ash shimo light, Indian ebony light chipboard, French oak, macassar, Swiss elm, jarrah, canterberry oak, caramel).

Regardless of whether the boards are produced in Europe or in Russia, laminated chipboard will be an excellent choice for many years to come due to the optimal combination of price and quality.