During the installation and assembly of various parts made of polymers and metal-plastic, glue is very often used. This is the best option when the presence of additional holes in the part makes the connection more vulnerable and susceptible to various influences. One of the best formulations is cyanoacrylate glue. This publication contains detailed information on this substance.

Content [Hide]

- 1 Cyacrine glue: features and composition of the substance

- 2 Cyanoacrylate glue: types of substances

- 3 Cyanoacrylate adhesive: technical characteristics and properties of the adhesive

- 4 Cyanoacrylate adhesive: advantages and disadvantages

- 5 What cyanoacrylate glue glues: scope

- 6 The choice of cyanoacrylate glue: price and popular manufacturers

- 7 How to dissolve cyanoacrylate instant glue and how to remove excess from the surface

- 8 Tips and tricks for using Moment cyanoacrylate glue

Cyacrine glue: features and composition of the substance

Cyanoacrylate adhesive is characterized by a high level of adhesion to a wide variety of surfaces. All this is possible thanks to the copolymers that are part of any cyanoacrylate two-component adhesive. Each manufacturer has its own unique glue recipe, as well as the secrets of its manufacture. This information is kept secret from competitors. The main feature of such adhesives is the ability to perfectly hold surfaces together, even materials that differ in quality and structure. These reagents are also characterized by a long service life.

The glue is based on cyanoacrylate and acids derived from it. They can reach up to 99% of the total volume. The composition of the glue also includes plasticizers and thickeners, which give it additional properties such as water resistance, heat resistance, adhesion. In order for the adhesive to better tolerate vibration, abietic acid is used in combination with glycerin.

Cyanoacrylate is designed for bonding hard, porous and even elastic surfaces that can be in any position. The main active component of the glue can be various monomers:

- ethyl ether shows itself perfectly on a variety of materials and practically does not wear out;

- methyl ether promotes adhesion of metals and duroplasts;

- butyl ether is an ideal substance for use in the medical field and special equipment;

- propyl ether is sometimes necessary for bonding metals and various elements exposed to high temperatures;

- compositions based on alkoxy ether do not have an unpleasant odor, but this is achieved by reducing the reliability of the compounds by 20-30%.

The principle of operation of the cyanoacrylate-based adhesive is that it begins to set when exposed to normal water or weak alkali. When gluing with a very thin layer of the substance, the setting process can occur without the participation of the cyanoacrylate glue activator.

Helpful advice! The adhesive activator should be used in an environment that is too dry or too cold. It is especially effective when bridging large gaps or handling chemically inactive materials. The recommended spray distance must be carefully adhered to to keep the surface smooth and even. It should be remembered that some types of activators can adversely affect thermoplastics and varnishes. It should be borne in mind that a primer should be used along with the activator.

Cyanoacrylate glue: types of substances

One-component transparent cyanoacrylate adhesive is characterized by very fast curing under pressure. After drying, this composition forms a thin but strong film between the elements to be joined. These characteristics make the adhesive an optimal solution for metal and synthetic materials, including parts for medical technology.

The most commonly used two-component second-hand adhesive at home. Liquid formulations, due to their low viscosity, are able to close gaps of up to 0.05 cm, and more viscous substances can seal a gap of up to 0.03 cm.Two-component adhesives are excellent for adhesion of rubber and leather parts, as well as products from wood chips.

Important! The most reliable and durable connection is formed in conditions of humidity from 40 to 70%. If it decreases to 30% or less, the seam will harden for a very long time, and if the air humidity is above 80%, then the glue polymerization process occurs extremely quickly, which reduces the reliability of the joint. Reducing or increasing the temperature by 10 degrees will slow down or speed up the adhesion process of the glue in half. Optimal conditions for working with cyanoacrylates are from 20 to 24 ° C.

Cyanoacrylate adhesive: technical characteristics and properties of the adhesive

At this time, many well-known companies are engaged in the production of cyanoacrylate glue, which glues everything tightly. The main characteristic of the substance is a high level of adhesion to a huge variety of surfaces, including wood, glass, metal, plastic and rubber. It should be noted that cyacrine glue is absolutely unaffected by substances such as water, oil, gasoline, as well as various alcohols.

Cyanoacrylate second glue works well with gaps of less than 0.1 mm. It can be used to join tight fitting parts. There are high viscosity reagents that are optimal for gaps around 0.25 mm. The consumption of such glue per square meter is about 300 g. If it is required to close the gap of large dimensions, then Cyanoacrylate glue Cosmofen or composition CA-4 is usually used.

As for the technical characteristics of cyanoacrylate glue, they are determined by the scope of application of the substance. Let's consider them in more detail:

- The physical state. The cyanoacrylate based adhesive has a thick consistency and a high viscosity. Usually the substance is transparent, but there may be other options - it all depends on the manufacturer.

- Packaging. The glue is produced in a completely sealed container. The packaging is supplemented with instructions for use with a description of precautions when working with this substance.

- Solidification mode.In conditions of low humidity at room temperature, the gluing process is carried out in a few seconds. In the case of high humidity, this process is carried out almost instantly.

- Operating temperature range. All one-component and two-component cyanoacrylate adhesives are capable of withstanding temperatures from -60 to +80 ° C. There are special modified heat-resistant compounds that can retain their characteristics for a short time even at elevated temperatures (up to +250 ° C).

The bond formed by the glue is reliable and durable, resistant to environmental conditions and mechanical stress. After opening the sealed bottle, experts do not recommend preserving the substance for a long time. This is due to the fact that under these conditions the physical and technical properties of the glue are violated, it can become brittle and unreliable after polymerization.

It should also be noted the small consumption of cyanoacrylate glue per square meter - it is only 30-50 g. Therefore, using a dispenser, you can process with glue:

- with a 400 ml container - about 13 m²;

- by means of a 100 gram package - 2-3 m²;

- tube 20 g - approximately 0.7 m².

It is interesting! The more liquid the cyanoacrylate glue has, the better it adheres to hard surfaces. The completely transparent adhesive is ideal for glass structures. It is impossible to glue precious metals with cyanoacrylate glue.

Cyanoacrylate adhesive: advantages and disadvantages

Cyanoacrylate adhesives have many positive characteristics as well as negative aspects. First of all, they are positioned as universal compounds that are able to connect together even materials and substances of different structure. The pluses also include the following qualities:

- very fast adhesion (within a few seconds);

- strong connection of elements;

- reliable fixation of parts from different materials to each other;

- ease of use;

- invisible seams;

- the ability to use on porous surfaces and planes with an angle of inclination;

- long period of operation of the seams;

- there is no need for lengthy preparation of the glued surfaces;

- stable quality of the material itself.

Negative properties of cyanoacrylate superglue:

- difficult to use at high temperatures;

- it is forbidden to use for gluing Teflon, polypropylene or silicone surfaces;

- glue is unsuitable for joining elements, the joints of which during use receive a large fracture load;

- It is strictly not recommended to fill large gaps with such an adhesive.

Cyanoacrylate glue is not suitable for gluing elements, the joints of which receive a large fracture load

It should be noted that the joint, sealed with cyanoacrylate glue, collapses at temperatures above 100 ° C.

In addition, acetone is detrimental to the adhesive. However, most other solvents are not intimidating to cyanoacrylates. These formulations adhere perfectly to a wide variety of surfaces and are used very economically. The substance has no allergic properties and is a dielectric.

It is interesting! The cost of cyanoacrylate glue is quite high, in addition, it should be worked with only gloves. Contact with cotton cloth may result in fire.

What cyanoacrylate glue glues: scope

Most of the superglue is cyanoacrylate and its derivatives, and it is also supplemented with various additives - plasticizers. It is thanks to them that several main areas of use of such glue can be distinguished. Let's take a look at what super glue based on cyanoacrylate glues.

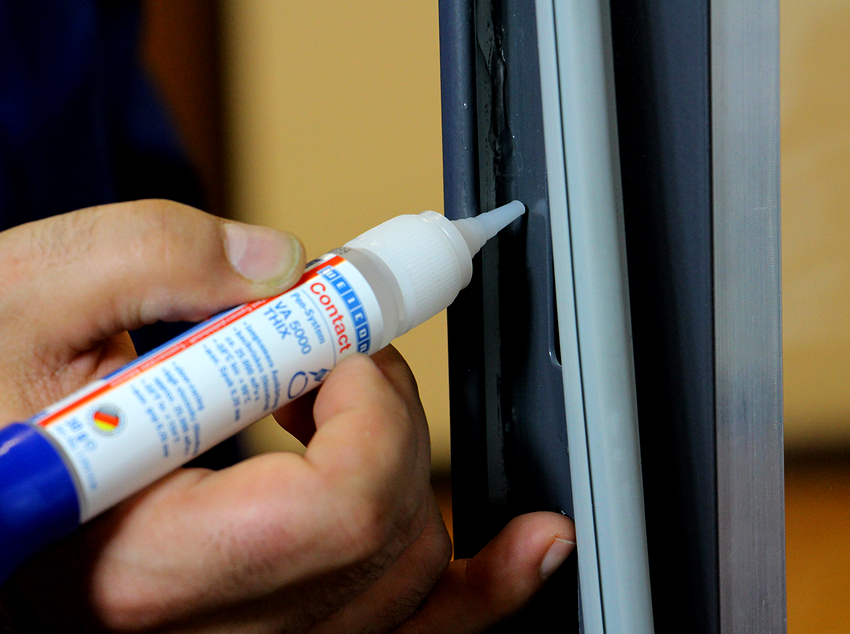

First of all, one cannot do without cyanoacrylate compounds in everyday life. Almost every owner has such a glue in the repair kit. Various formulations are used depending on the situation and the material to be glued, although universal adhesives are often purchased for the home.

Not only men use cyanoacrylate glue. It is used in cosmetology, namely during the extension of eyelashes and nails. Usually, formulations with an increased amount of acrylic are used, since they practically do not harm the nails, and can also be easily and simply removed using organic solvents.

Indispensable cyanoacrylate superglue in dentistry. Special compositions are used for gluing small chips. Adhesive is used to insulate the wires or ensure a flawless connection. The low likelihood of allergies and biological neutrality make the substance a safe product for use in cosmetology and dentistry.

Cyanoacrylate is used with pleasure by radio installers and repairmen of electronic equipment, optical devices. With this glue, you can perform the following procedures:

- glue chips and boards;

- produce thermal resistors and transistors;

- create prefabricated structures from plastic and thermoplastic;

- combine natural fabrics, organic and artificial leather;

- glue foam particles;

- connect surfaces for which consistent color is extremely important.

The choice of cyanoacrylate glue: price and popular manufacturers

Having familiarized yourself with the market for modern building materials, it is easy to see that there are a huge number of manufacturers who produce cyanoacrylate adhesives. When choosing the required composition, you should pay attention to the most popular models.

Related article:

What is the best adhesive for tiles? Varieties of adhesives

The main types of adhesive mixtures. Adhesive selection criteria, material consumption calculation, tile fixing rules and surface preparation.

Pronto CA-4 is a ready-to-use product with excellent viscosity and versatility. The substance does not require any additional additives and compounds to improve the adhesive properties. It is ideal for home use.

For joining materials that are difficult to bond, Loctite cyanoacrylate adhesive is the best option.

Loctite cyanoacrylate adhesive is a polymerizing one-component composition with low viscosity. Ideal for joining materials that are difficult to bond.

Interbond is a two-component cyanoacrylate adhesive for use on MDF, chipboard, rubber or leather. It gives the compound high moisture and heat resistance, and acts almost instantly. The composition is sold in packs of 400 ml, as well as 20 g or 100 ml. The adhesive is characterized by a high flash point and cures in 5-7 seconds. During storage, it is necessary to protect the package with glue from sudden temperature changes and direct sunlight.

Permabond С791 is a cyanoacrylate adhesive designed for reliable bonding of various elastic and rigid surfaces. The substance sets in a few seconds and is proudly called "second" glue. Since the composition has a transparent color, it is recommended to use it for gluing glass surfaces. It is very convenient to use Permabond cyanoacrylate glue, as the substance is liquid. This function is very important for the quick solidification of the composition. In addition, the adhesive is sufficiently water resistant.

The manufacturer Cosmofen provides customers with a huge selection of universal and specialized products.Cyanoacrylate glue Cosmo CA-500.200 belongs to the most popular and most widespread adhesives in this category. The substance is characterized by low consumption. Even in the instructions of CA-500.200 cyanoacrylate second glue it is said that just a few drops of the reagent allow you to firmly glue many elements.

In addition, if you adhere to all the recommendations specified in the instructions for cyanoacrylate glue, then it can be stored open for a month. Before use, you need to carefully study the instructions for CA-500.200 cyanoacrylate second glue.

In addition, the CA-500.200 cyanoacrylate glue is widely used in industrial production of various scales, namely:

- when creating sewer and sealing structures;

- in the production of various types of transport;

- in the radio-electronic field;

- in the manufacture of household appliances, children's toys and jewelry.

The highest connection reliability is guaranteed by the use of Kernil glue. It is this composition that fishermen and tourists prefer to patch up damage to inflatable boats. There are also a number of popular Chinese companies that make cyanoacrylate-based adhesives:

- Lanxi Kingway;

- Taizhou Henco-Glue;

- Hunan Baxiongdi New Material;

- Audited Supplier and many others.

How to dissolve cyanoacrylate instant glue and how to remove excess from the surface

When working with adhesives based on cyanoacrylate, there is a possibility of spillage of the adhesive on surfaces that do not need to be glued. This usually happens due to a poorly prepared workplace. Therefore, the question of how to remove cyanoacrylate glue is extremely relevant. Unfortunately, at this time, a means has not yet been invented that makes it possible to dilute or dissolve the adhesive for its further removal, without damaging the surface. Since it is not known how to clean the cyanoacrylate glue from the surface, it must be handled carefully.

It is possible to remove unnecessary glue from the surface, but only mechanically. You can try to simply wipe off the stain. This can be done if the material is strong and does not break. You need to carry out the removal with a sharp knife, but you should work carefully and carefully so as not to violate the integrity of the surface. You can try to wipe off the remaining glue with white spirit. This allows small particles to dissolve on the fabric and thus remove the powdery glue layer.

How to wash cyanoacrylate glue from hands or skin? In this case, it is useless to look for how to dissolve cyanoacrylate glue. It will not be possible to wash off, cleanse or scrub off the substance, as it will be removed along with human skin. It is pointless to try ordinary thinner for paints and varnishes, gasoline and kerosene, vegetable oil and alcohol. The best option is to wait a few days until the adhesive begins to peel off on its own, only then the glue can be removed without harm to the body.

You can try acetone as a cleaner, but you should be very careful when removing adhesive from leather, plastic and other organic surfaces. Before dissolving the second glue, it is necessary to remember that cyanoacrylate is inert, which means that it does not interact in any way with substances such as gasoline, oil, ethanol, and many other common solvents.

Important! The instructions for use of CA-500.200 cyanoacrylate glue and many other similar products mention "Dimexide" as a glue remover. This substance is extremely toxic, has an unpleasant odor, so it is better to think about it before scrubbing off cyanoacrylate glue with this compound.

Tips and tricks for using Moment cyanoacrylate glue

When working with cyanoacrylate adhesive, it is important to strictly adhere to instructions and personal safety rules. All gluing operations must be performed only in a well-ventilated area, since glue vapors are very toxic, poisonous, and violation of operating conditions can cause great harm to health. Cyanoacrylate glue should not come into contact with the skin and mucous membranes.

Before using the reagent, you must read the instructions that are in the package, because different types of glue are designed for gluing certain surfaces. It is important to pay attention to the indicated storage terms and conditions, as well as the peculiarities of use.

When working with Moment cyanoacrylate glue, you must adhere to the instructions and rules of personal safety

The process of using glue looks like this:

- It is imperative to clean and dry the surfaces to be glued.

- It is necessary to apply the adhesive in a uniform and uniform layer on one of the joined sides.

- For better adhesion, the parts are fixed for a while; for better effect, you can place them under the press.

Important! When working with cyanoacrylate glue, it is necessary to use protective equipment for the skin and mucous membranes: gloves, glasses, a mask. Chemical components are harmful to the human body: if ingested, they corrode the body. It is undesirable to inhale glue vapors, as they are toxic. That is why it is extremely important to take precautions when using a substance.

Cyanoacrylate adhesive has excellent technical properties. Thanks to him, the adhesion point turns out to be strong, even when joining materials that are different in structure. It is used at various stages of work, it can be used even after the completion of the assembly of the structure. Cyanoacrylate is designed as a versatile product to meet a variety of needs. On sale there are colorless and colored reagents, instant and long-term solidification compositions. It must be remembered that finding how to dissolve cyanoacrylate instant glue is an extremely difficult task, so you need to work with it very carefully.