Hardboard: what is it? This product is classified as a sheet building material made from various types of waste from the paper, wood and woodworking industries by hot pressing them with various additives. In a broader concept, these are fibreboards (fiberboard), however, with certain physical and mechanical properties and qualities. The article discusses the characteristics of this material in more detail.

Content [Hide]

Hardboard: what is it? General concepts and methods of making material

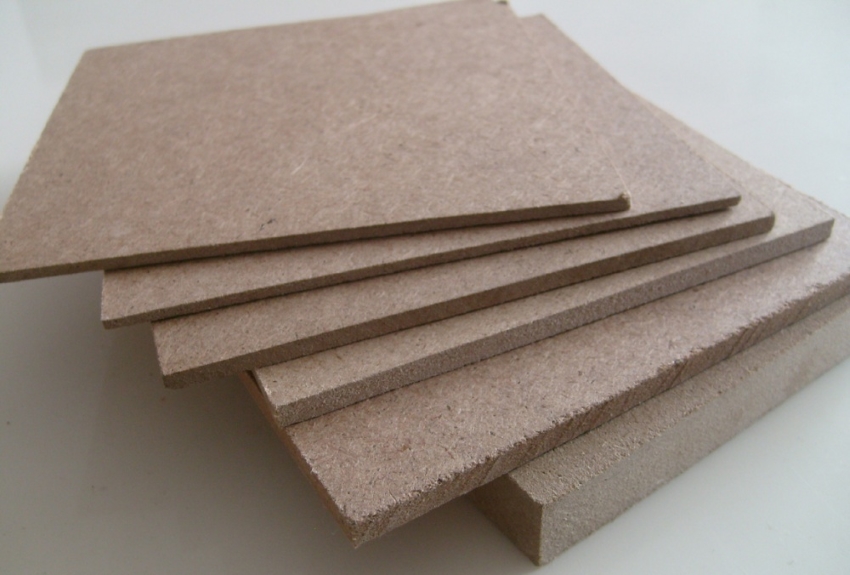

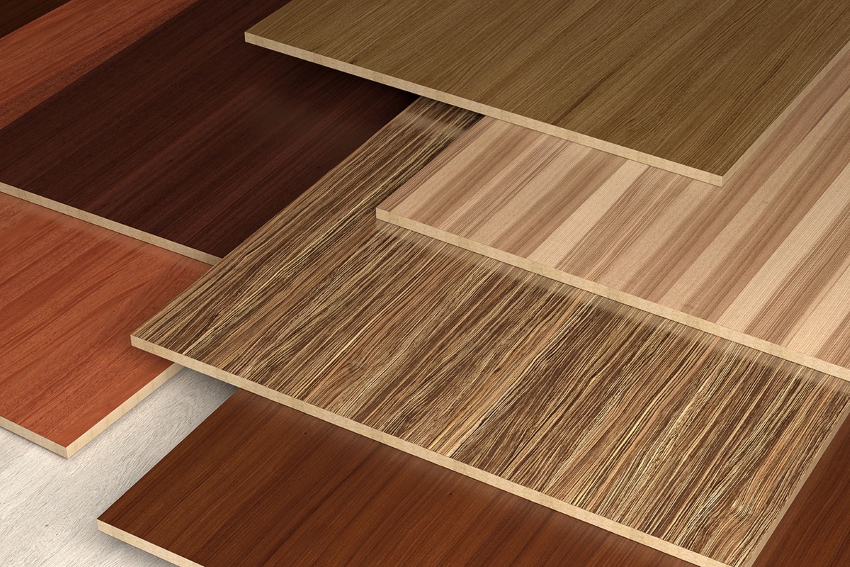

The fiberboard manufacturing method is regulated by GOST 4598-86. This technical term denotes a material that includes various materials, including relatively soft ones. Hardboard is a common name and is not mentioned in the specified regulatory document. The front surface of the slabs, as a rule, is smooth, it can be varnished, painted, faced with plastic or decorative foil. The main difference between this material and fiberboard is the structure, namely, hardness. It is customary to call hardboard only thick sheets, one side of which is decorative and front. Photos of hardboard clearly demonstrate its structure.

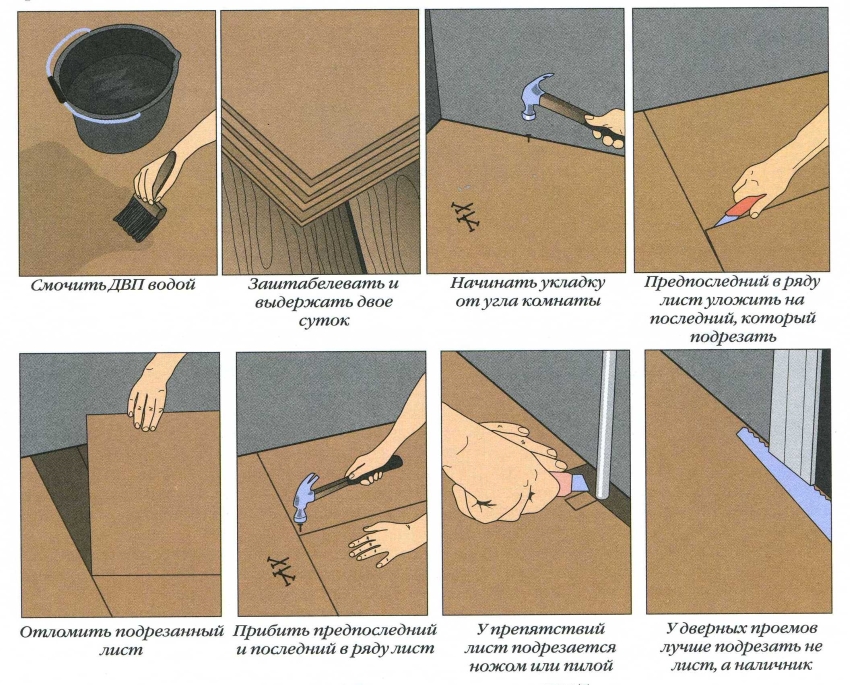

Such material greatly simplifies and speeds up finishing and construction work, and is indispensable for cladding walls and ceilings of premises, flooring, installation of internal partitions. Practically, there is no alternative to hardboard in the manufacture of furniture, the production of containers and packaging. Its main advantages are low cost, ease of cutting, processing and installation.

Hardboard: what is it? Material composition

To impart certain properties to the material, the corresponding components are included in the raw material during the production process. Adding the necessary substances can improve one or another indicator. The composition of fiberboard includes the following components:

- astringents (synthetic and phenol-formaldehyde resins) make it possible to obtain a dense and durable structure;

- polymers (pectol, etc.) improve strength and mechanical properties;

- hydrophobic substances (paraffins, rosin, etc.) are used to impart moisture-proof and moisture-repellent properties to the product;

- antiseptic components improve biostability, prevent the appearance of mold and rot;

- fire retardants give a certain resistance to fire.

Only low-toxic resins are approved by the technical documentation.The content of the binder in the material should not be more than 1.3% of the total initial mass.

Important! If the material you have chosen has a strong chemical odor (high content of formaldehyde resin), then it is better to refuse to use it in residential premises.

Marking and quality

Hardboard grades are divided into types according to physical and mechanical characteristics. These qualities must be considered when choosing it.

The difference can be seen immediately upon external examination. The surface of the slabs may or may not have a coating, be smooth on one or both sides. There are products with a decorative layer only on one of the surfaces, while the opposite has a corrugated structure. The smoothness of the material can be achieved in various ways: by painting, varnishing, applying film or plastic, lamination.

The corrugated surface of the reverse side of the sheet makes the material cheaper. It is ideal for bonding to durable surfaces or where decorative function is irrelevant.

There is no need to purchase thicker and, accordingly, more expensive fiberboard sheets if they are intended only for rough work. On the contrary, if the material will be used for external decorative finishing, it is better to use harder and more durable boards covered with a laminated film. Accordingly, such sheets of hardboard will cost more, but in this case it is justified.

Conventionally, the entire variety of hardboard can be divided into the following types:

- soft material "M";

- semi-solid material "NT" (grade PTS220);

- solid material "T" (grade Tc450, 400, 350, 300);

- superhard material "ST" (grade STs500);

- sheets with a refined surface;

- sheets with a non-refined surface.

Characteristics of hardboard by surface density

Marking "M" means soft hardboard. The sheet has a density of 100 to 500 kg / m³. Visually, the surface structure resembles a cork coating. It can be used for interior decoration (walls, ceilings, floors) and partitioning.

Marking "T" refers to hardboard. It has a density of 500-800 kg / m³ and its structure is visually similar to cardboard. The material has a certain moisture resistance, especially in combination with moisture-resistant coatings and has a bending strength of the sheet. Hardboard can be used in construction work, used in the production of containers, furniture and joinery.

Marking "ST" means superhard hardboard. It has a density of 800-1100 kg / m³, has a very strong structure and can be used in construction, furniture production and other areas.

Since this material can be considered a type of fiberboard, they have the same labeling and classification. According to GOST 4598-86, products differ in surface type, density and strength:

- "T" - a hard sheet with an untreated front surface;

- "TS" - a hard sheet with a front layer of fine wood pulp;

- "TP" - a hard sheet with a painted front surface;

- "T-SP" - a hard sheet of finely dispersed wood raw material with a painted front surface;

- "Т-В" - a hard sheet of increased water resistance with an uncoated surface;

- "T-SV" - a hard sheet of finely dispersed wood raw materials with a colored face layer and increased resistance to moisture;

- "NT" - low density rigid sheet (or semi-solid);

- "ST" - superhard sheet of increased density and strength with a non-refined front surface;

- "STs" - a superhard sheet made of finely dispersed wood raw materials of increased strength and density with a refined face layer.

Hard fiber sheets of grades T, TP, TSP and TS, depending on their physical and mechanical characteristics, belong to groups A and B, and are divided by surface quality into I and II grade.

Paints, varnishes or films are used to refine the hardboard surface. A universal option is white hardboard. It is most often used in the manufacture of interior surfaces of furniture, cabinets, drawers, as well as in the production of containers.

General characteristics by brands of fiberboard are given in the table:

| Material characteristic | M3 | M2 | M1 | NT | ST | T, T-C,

T-P, T-SP |

T-SV,

Tv |

| Humidity,% | — | — | — | — | — | 5 | 3 |

| Density of fiberboard, kg / m³ | 100-200 | 200-350 | 200-400 | Over 600 | 950-1000 | 800-1000 | 850-1000 |

| Ultimate tensile strength, MPa | Undefined | 0,32 | 0,3 | 0,3 | |||

| Ultimate bending strength, MPa | 0,4 | 1,1 | 1,8 | 15 | 47 | 38-33 | 40 |

| Daily swelling in thickness,% | Undefined | 40 | 13 | 23-20 | 10 | ||

The resistance to moisture is not the same for different brands of fiberboard. As can be seen from the table, semi-solid fiberboard (NT grade) swells by 40% when it is in water during the day. ST grade material (superhard) - withstands the same test with a swelling of 13%. The best indicators are for brands TV and T-SV.

Given this property, they can be considered moisture resistant hardboard in their group. The TV brand is produced, as a rule, without external coating and is used for the construction of partitions in conditions of possible humidity and for the manufacture of furniture. The T-SV brand has the same field of application, however, it is more aesthetically attractive because of its decorative front surface.

Important! Not all fibreboards can be used in rooms with high humidity and temperature. During transportation, contact of the material with water must be avoided.

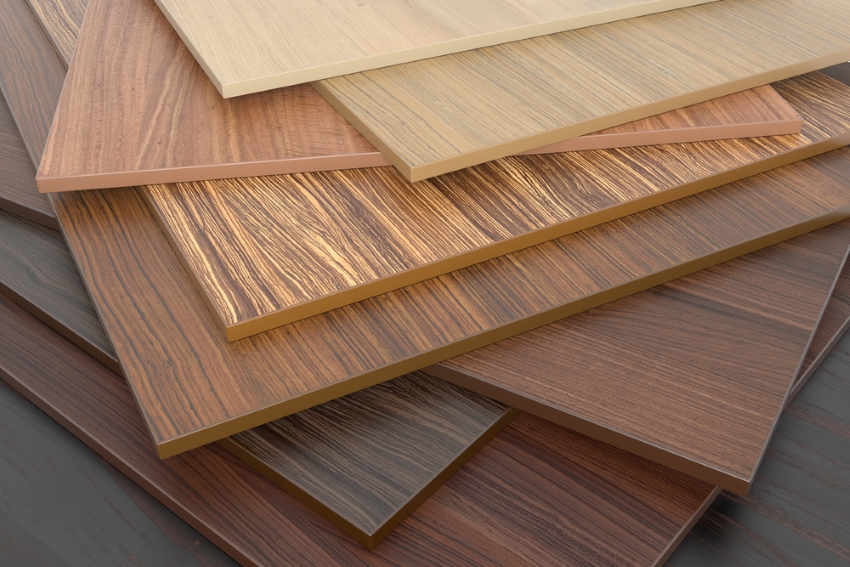

Laminated hardboard

The surface of hardboard can not only be given any color or applied to it in a variety of patterns. Also, decorating this material with a plastic film is widely used. The price of laminated hardboard per sheet is much higher, however, this material has a number of advantages:

- increased mechanical strength (the decorative layer protects against accidental scratches and damage);

- practicality (the laminated coating is less dirty, easy to clean);

- durability (major manufacturers claim a service life of up to 20 years);

- aesthetic characteristics (a wide selection of various shades and structures, lamination can imitate wood, stone, tiles).

Depending on the quality of the coating and the manufacturer, prices for laminated products may vary. The average cost is 950 rubles per sheet.

Sizes of hardboard sheets

Sizes of slabs offered by manufacturers can be very diverse and have a length of 1.2-6 m and a width of 1-1.8 m. However, products of this size are most often used for industrial needs. The standard size of a hardboard sheet suitable for domestic use is 2140x1220 or 2750x1220 mm.

Possible sizes of different types of hardboard (fiberboard):

| Parameter | Soft mark |

Semi-hard, hard and super-hard grades |

| Length, cm | 122, 160, 180, 250, 270, 300 | 214, 244, 274,5, 305, 335, 366 |

| Width, cm | 120, 170 | 122, 152.5, 183, 214 |

Important! Estimate in advance the size of the sheets you are purchasing and the method of transporting them to the place of repair. Almost all building materials stores provide a service for cutting material if it turns out to be inconvenient for transportation.

A sheet of fiberboard has dimensions and characteristics that correspond to GOST 4598-86, 19592-80 and 8904-81. These regulations are old, but they are in effect with amendments.

Related article:

Fiberboard: what is it? How to choose the right building material

History of origin. The main types of fiberboard and selection criteria for fiberboard. Areas of use. Advantages and disadvantages of the material.

The table shows the maximum permissible dimensions of a hardboard sheet in accordance with GOST 4598-86:

| View | Width, mm (max) | Length, mm (max) | Thickness, mm (max) |

| Soft stamps | 1220±5 | 5500±5 | 16±1 |

| Solid grades | 2140±3 | 6100±3 | 6±3 |

If sheets are cut to order, deviations from standard sizes are permissible.

The thickness of hardboard can vary from 2.5 to 40 mm, which means that the sheet is relatively thin. This can be regarded as both an advantage and a disadvantage. For sheets of medium and low density, the thickness is most often 8, 12, 16 and 25 mm. It is good to use them for the purpose of noise and heat insulation of the partitions being built, but they are not very suitable for interior decoration of premises. Semi-solid types have sheet thicknesses of 12, 8 and 6 mm. Superhard and hard grades of the material are produced in sizes 6, 4.5, 3.2 and 2.5 mm. These sheets are well suited for wall, ceiling and floor cladding.

Useful advice! When choosing products, it is necessary to take into account the conditions of their use. Sometimes it will be justified to use only moisture resistant brands.

Hardboard price per sheet, depending on size

When buying hardboard sheets, you should pay attention to the following points:

- A standard premium slab of material is often 3.2 or 2.5 mm thick. With other dimensions 1220x2140 mm, such fiberboard has a high price from 120 to 220 rubles. per m².

- Second-class material often has large dimensions, which can reach 2745x1700 mm.

The main producer of hardboard in Russia is Orgalit-Plus.

The table shows the dimensions of the hardboard sheet, prices per sheet and square meter:

| Name | Dimensions, mm | Price per sheet, rub. | Price per m², rub. |

| Fiberboard "T" | 2745x1700x3.2 | 230 | 49 |

| Fiberboard "ST" | 2440х1220х3.2 | 145 | 47 |

| Fibreboard packaging | 2745х1220х3.2 | 165 | 48 |

| Insulating fiberboard | 2750x1830x16 | 730 | 220 |

| DVPO | 2745x1700x3.2 | 350 | 75 |

Useful advice! Inspect the slabs carefully before purchasing. On the outside, top-notch products should not have pits or chips.

In conclusion, we can say that hardboard is a versatile material that can be used to make furniture, carry out finishing work, as the main material for inexpensive interior doors. A variety of fiberboard types can meet all your building needs.