The spiral staircase is rightfully considered the queen of staircase systems. Always luxurious, with unsurpassed design - this structure serves as the central decorative element around which the entire interior is formed. The spiral staircase systems are extremely functional, but they do not take up much useful space. The review "Spiral staircases to the second floor in a private house: photos, prices for structures" will help to study existing staircase options and give preference to a functional, safe and compact design.

Content [Hide]

- 1 Spiral staircase: types of structures

- 2 Calculation of spiral staircases

- 3 DIY spiral staircase. Drawings and diagrams of structures

- 4 Installing a spiral staircase with your own hands made of metal: construction drawings

- 5 Construction of spiral staircases to the second floor in a private house: photo in the interior

- 6 Spiral staircases to the second floor in a private house: photos, prices, manufacturers

Spiral staircase: types of structures

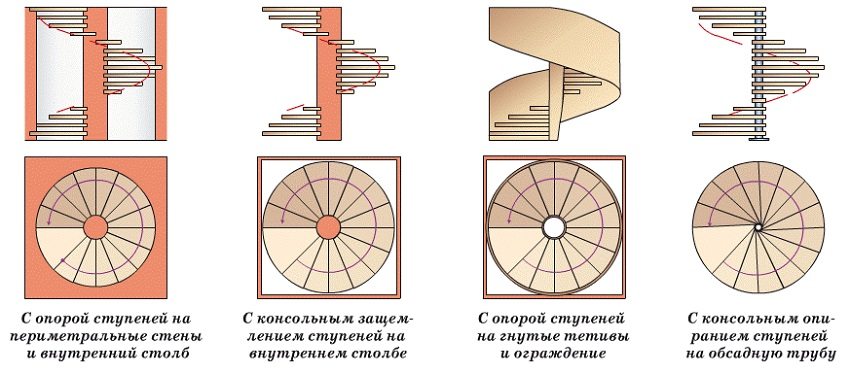

Spiral staircases are the most attractive and unusual designs. They can differ in the materials used to make them and in the style of construction. Spiral staircases are classified depending on the method of supporting the treads (steps):

- support of steps on walls and pillar - in such a design, the steps of a wedge-shaped spiral staircase rest their wide part on the perimeter walls, while the narrow part of the steps is supported in the form of a middle pillar. The support pillar is made of stone or can be recruited from thickened steps;

- cantilever fastening of steps around the support post - the steps of such a screw system are cantilevered to the central post in the form of a pillar. The fastening of the steps is quite rigid, so such a ladder can be installed optionally next to the wall;

- support of steps on a curved bowstring and a fence - such a staircase design does not provide for a central support. The steps are mounted in spirally curved bowstrings, which at the same time serve as barriers. The manufacture of such a screw structure is fraught with certain difficulties, however, it has a very attractive and original appearance;

- the steps are threaded with a narrow part on the casing support pipe - the most common way of fastening steps: metal treads are cantilevered on an internal support in the form of a pipe. In this design, it is important that the pipe is at least 50 mm in diameter, since it acts as a supporting element in the staircase system.

Various materials are used for the manufacture of spiral staircases, including:

- metal - stainless steel, alloy steel, brass, brushed aluminum, cast iron;

- wood - oak, maple, beech, larch, pine and others;

- stone, brick, ceramics, glass, marble.

Various combinations of materials are used to create screw systems, resulting in original and unusual designs. Their main advantage is their high strength and resistance to heavy loads.

Calculation of spiral staircases

Calculation of the dimensions of a spiral staircase largely depends on the purpose of the structure: whether it will be primary or secondary. If the staircase plays the role of the main one, it is recommended that the size of its steps be taken not less than 90 cm in length, and the diameter of the opening in which it will be installed is 200 cm.It turns out that the diameter of the opening should be approximately 20 cm more than two steps length. This size of the opening is explained by the need to equip the spiral staircase with a fence and railings. Then between railings and a gap of 10 cm remains on the surface of the opening, which will contribute to a comfortable support on the handrail. In the case of an auxiliary spiral staircase, an opening with a diameter of 140 cm and a step length of 60 cm is sufficient. Typically, such stairs are used to ascend to the attic or descend into the basement.

The design of spiral staircases is such that when moving along them, not the entire length of the steps is used, but only its wide part. If, for example, the projected staircase has a step width of 90 cm, then part of this step will be attached to the support post, on the other side a fence will be attached. Thus, about 80 cm will remain for walking. But given that the steps of the helical structure have a running-in location, that part of them that is attached to the post will hang over a part of the next step. Consequently, the step width suitable for movement will be reduced by another 25%. As a result, it turns out that out of the entire 90 cm wide step, about 50 cm will be used for movement.

To achieve a more comfortable movement, the diameter of the opening and the size of the spiral staircase are increased. However, the size of the opening should not be taken more than 300 cm, in this case the space under the occupied staircase will allow you to install the marching structure.

DIY spiral staircase. Drawings and diagrams of structures

Numerous photos of spiral staircases to the second floor with their own hands indicate that the independent production of such structures is quite possible. When starting to manufacture stairs, it is necessary to determine the place of installation, calculate all parameters, understand the drawings of spiral staircases.

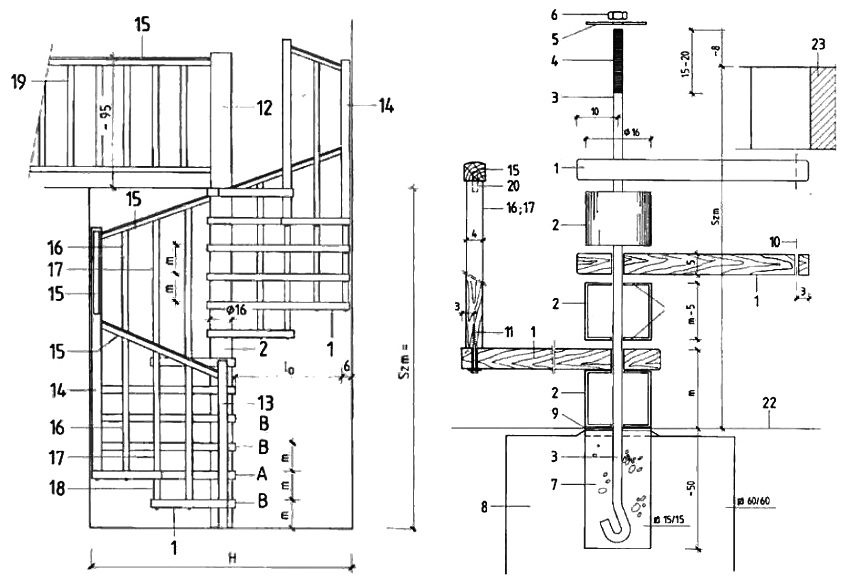

For example, consider a spiral staircase with wooden wedge-shaped steps and a bearing support in the form of a metal pillar. Such a ladder can be installed both next to the wall and in the middle of the room.

Ladder design diagram

The structure of the spiral staircase is based on a bearing support in the form of a rod, to which the steps are attached. As a rule, a massive metal pipe is used for the supporting post. The steps are supported by bushings attached to the rack. You can make them yourself by cutting the steel pipe into cylinders of certain sizes. On both sides, linings are welded to the cylinder-bushings, which have holes for fitting them onto the support post.

To give the bushings an aesthetic look, they are pasted over with a decorative film of the appropriate texture.It can be imitation of wood or marble, depending on the combination with the material for the steps. Sometimes cylindrical wooden elements are used as bushings. The main thing here is that the ends of all bushings are parallel to each other.

How the spiral staircase is made: installation procedure

The installation of the stairs begins with the installation of the bearing support. Its length should be 7 cm more than the sum of the height of the room and the thickness of the upper slab. A thread about 20 cm long is cut at the upper end of the support, and the lower edge of the support is concreted.

All the necessary parts of the stairs must be prepared in advance: steps, spacer bushings, cuffs, couplings. All parts are sequentially mounted on a bearing support. Once the very last stage has been installed, the entire system is secured by means of a disc and screwing a fastening nut onto the threads.

Useful advice! So that over time the ladder does not creak when walking, it is necessary to tighten the upper fastener nut as the treads shrink.

Next, all the elements of the fence are fastened, the fixation of the steps and rods of the obstacles is checked and the upper fastening nut is finally fixed.

Explanations for the Ladder installation diagram:

| 1 - stair steps; | 12.13 - upper and lower railing posts; |

| 2 - bushing for steps spacer; | 14 - corner post of the fence; |

| 3 - bearing support; | 15 - railings; |

| 4 - thread for securing the rack; | 16 - short fence post; |

| 5 - a disk for a nut; | 17 - long fence post; |

| 6 - fastener nut; | 18 - additional fence post; |

| 7 - fastening the support by concreting; | 19 - balustrade; |

| 8 - the foundation of the house; | 20 - connecting pin; |

| 9 - ledge; | 21 - sleeve lining; |

| 10 - hole for the fence; | 22 - floor surface; |

| 11 - fastening the fence; | 23 - overlap. |

Installing a spiral staircase with your own hands made of metal: construction drawings

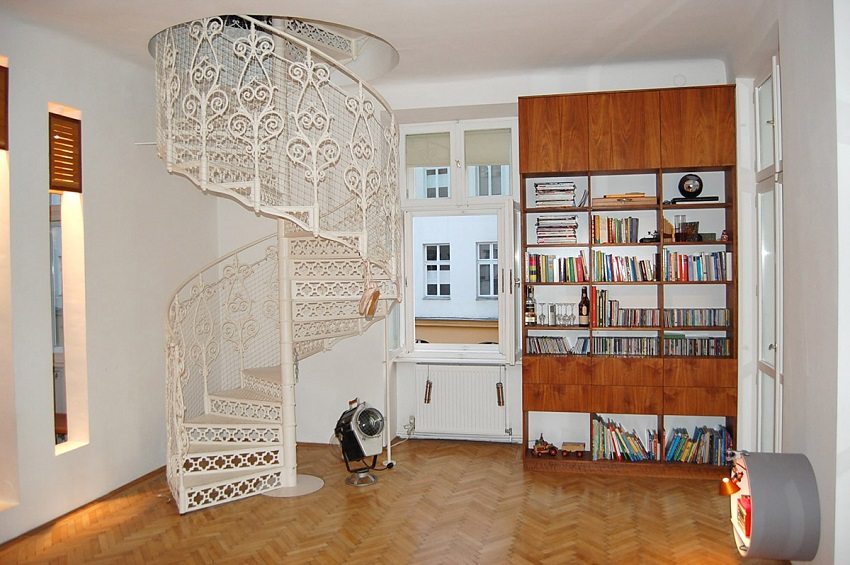

Spiral staircases made of metal can be used for outdoor and indoor use. If a metal staircase is installed outside, it should be in harmony with the window bars and the entrance door. In this case, the designs of forged spiral staircases will be quite appropriate. If the staircase is installed indoors, it is desirable that its design supports the style of the interior. Spiral staircases made of metal can be prefabricated, cast, welded.

When self-manufacturing spiral metal staircases, it is recommended to familiarize yourself with and use ready-made schemes and drawings of structures that are adapted to individual sizes.

Calculation of the metal structure

The calculation of all parameters of the ladder system is carried out taking into account the following points:

- in order to move up the stairs safely, the distance between adjacent turns of the screw structure must be at least 2 m;

- if the structure is the main one and is installed indoors, the diameter of the opening should correspond to the size of 200 cm, and the length of the step should be 80 cm;

- the bearing metal support should be selected in the form of a pipe with a diameter of at least 5 cm;

- the width of the tread (step) along the midline is at least 20 cm;

- if the spiral staircase is surrounded by perimeter walls, the distance from the handrail to the wall surface should be about 10 cm so that when moving up the stairs it is convenient to hold onto the handrail;

- do not increase the angle of the ladder above 45 degrees;

- a spiral metal staircase must have a high-quality and stable fence;

- It is recommended to use anti-slip coatings for safe movement on the steps of outdoor stairs.

For safe movement, it is better to equip the spiral staircase with reliable handrails and anti-slip coating of steps

Having decided to make a metal ladder yourself, you need to know that such a structure will require knowledge and experience in working with a welding machine. The metal structures of spiral staircases to the second floor of the economy class are subject to self-production. The device of such ladders provides for the fastening of steps to a supporting metal rack. All elements of the staircase are prepared separately in a comfortable environment, and the staircase itself is assembled indoors.

Preparation of elements and parts of the stairs

All elements of the staircase are pre-procured according to drawings and diagrams:

- the pipe of the bearing rack is cut to the size of the height of the room;

- a pipe of a larger diameter of the same size;

- metal rod for making bolt mounts;

- metal corner for making steps.

From a pipe of a larger diameter, cylinders are cut for sleeve-sleeves, which will fix the steps at a certain height. The length of the sleeve must match the height of the step. Sleeve sleeves must be tightly threaded onto the support tube. If a small gap remains between the pipe and the sleeve, the rings are additionally welded to seal. After completing the work, all welds are cleaned.

The metal corner is cut according to the template of the steps and the frame for the steps is welded from these elements. A sleeve-sleeve is welded to each step and the seams are also cleaned. The bolts are preparing.

Spiral staircases have a very narrow step width along the line of movement. When moving on such a ladder, the leg that steps closer to the central support rests on a part of the step with a smaller width. This can cause the foot to slip, especially when moving downward.

Useful advice! For the convenience of moving along a spiral staircase, the steps of the structure should not be equipped with risers. This will position the foot behind the step line in a narrow space.

Next, all parts and elements of the spiral staircase are assembled. One by one, bushings with steps are threaded onto the support pipe. When all the steps are assembled, their position is aligned according to the drawings, and all parts are welded together. All welds are ground. The metal surface of the stairs is treated with a primer and painted. The frame of the steps is filled with facing material.

When the staircase with steps is mounted, proceed to the installation of fences and railings.

For clarity of the installation process, you can use a photo of spiral staircases to the second floor in a private house.

Construction of spiral staircases to the second floor in a private house: photo in the interior

The spiral staircase to the second floor of the house, in addition to its functional load, carries the main decorative component. In this regard, not only the reliability and convenience of the design are thought out, but also its corresponding design.

If you prefer minimalism or high-tech style, it will be appropriate to choose a metal structure. These ladders look light and will always attract attention. Do not forget about the role of the color of the stairs. For example, if the staircase is black, dark furniture, black and white paintings or carpets with a combination of black and white stripes will support it well.

If in the interior you are planning, the staircase is given a place for secondary decor, you should choose options for designs painted in light shades. A matte staircase that does not reflect other objects looks much easier than a dark one and will be almost invisible. Many people choose models painted in bright colors, and sometimes with multi-colored steps.

Useful advice! To avoid injury when moving up the stairs, it is necessary to equip the structure with a high-quality fence, it can be solid. This is especially true for families with small children.

Spiral staircases made of precious wood are suitable for the classic style. Such structures should also be supported by appropriate furniture, preferably almost in tune. Special charm wooden stairs attach fences made of carved balusters. Forged fences in combination with a wooden staircase look no less elegant.

Using a wooden spiral staircase to connect levels, you can fill the house with warmth and comfort. After all, wood is a material that absorbs the energy of the sun, wind, rain and transfers it to the entire room.

If you want to give the stairs lightness and transparency, you can use designs with glass steps. Fences in these structures can be selected in a variety of ways: wooden railings in combination with aluminum balusters, horizontal aluminum fencing or a transparent plastic fence.

Spiral staircases to the second floor in a private house: photos, prices, manufacturers

The use of spiral staircases is not limited only to private and country houses, they are used with pleasure in offices, hotels, sports centers, clubs and other public premises. Thanks to their unusual design and equipment with various decorative elements, spiral staircases fit perfectly into the interior of a room of almost any design.

By connecting different levels with each other, the helical structure significantly saves the space allocated for movement along it. This allows you to place the structure even in two-story houses of small area. This fact influenced the incredible popularity of spiral staircases to the second floor in private houses. Photos, prices for products sold to order can be seen on the websites of manufacturers. As a rule, companies offer their ready-made spiral staircases (check the prices with the manufacturer). But many of them can also embody the design projects of the customers themselves, taking into account individual sizes and personal wishes.

Related article:

Attic staircase with a hatch: simplicity, practicality and affordability. Types, advantages and disadvantages. How to make a folding ladder with a hatch with your own hands. Smart use of space.

Spiral staircases to the second floor in a private house (photos, prices are indicated on the corresponding sites), offered by manufacturers, can be made in any style: square or oval steps, forged or carved fences, wooden or glass decorative elements. It all depends on your individual preferences and the chosen style of the room.

Useful advice! Finding a professional ladder craftsman is not so easy today. Follow the recommendations of acquaintances, schedule personal conversations, find out all the points of interest and check out the specialist's portfolio.

Where to buy inexpensive spiral staircases to the second floor? On the Internet you can find product catalogs of various manufacturers. The models presented in them are made of a variety of materials: metal, wood, combined, with elements of inserts made of glass, marble, ceramics, stained glass windows and forged products.

Many companies, in an effort to make product prices affordable for any buyer, offer discount systems on the most popular stair systems. Check out the prices for some models of screw structures made of various materials from the Mister Step company:

| Spiral staircase model | Material | Price for 1 p / m, euro | ||

| Steps | Handrail | Balusters | ||

| GENIUS 010 T, diameter 110-160 cm, height 210-380 cm, step 21 -24 cm | Ash, beech | Ash, beech | Metal with stainless steel cables | from 1250 |

| SCENIK ONE T | Ash | Ash | Ash | from 2290 |

| GENIUS 030 T, diameter 110-160 cm, height 210-380 cm, step 21 -24 cm | Ash, beech | Ash, beech | Metal with stainless steel cables | from 1200 |

| GENIUS 050 T, diameter 110-160 cm, height 210-380 cm, step 21 -24 cm | Ash, beech | Ash, beech | Polished Stainless Steel with Stainless Steel Bars | from 1750 |

| SCENIK Sport | Ash tree | Ash | Machined aluminum with stainless ropes | from 2450 |

| SCENIK CHIC-LINE Q | Ash tree | Ash | Anodized aluminum with stainless steel cables | 2345 |

To order a spiral staircase design at an affordable price, you must provide the manufacturer with the following data:

- diagram-plan of the room in which the installation of a spiral staircase is planned;

- the location of the structure relative to the room;

- the dimensions of the room, indicating the height and diameter of the hole for the spiral staircase;

- model type stairs to the second floor, preferred materials for its manufacture, features of the general style of the room.

Taking into account all the data, specialists in a short time will create products that must strictly comply with operational requirements and standards, regardless of the chosen design. In addition, for the sake of operational safety, it is recommended to order staircase structures with their equipment with railings and railings.

The implementation of stairs is a relatively new type of service in the construction industry. In addition to imported designs, there are many products of domestic manufacturers on the market.

Firms selling stairs usually accept orders for custom designs. In addition, they provide services for the delivery and assembly of stair systems. But it should be borne in mind that the cost of a ladder made according to individual drawings will be 20% more expensive than the standard model. It's up to you.