Wood lathe cutters are designed for processing wooden parts on a special machine, which are widely used to make furniture or interior elements. A wide range of different types of tools is presented on the construction market, which is selected based on the scope of use and the material of the wooden blank. Everything you need to know about wood cutters can be found in this article.

As tools for working with a lathe, special cutters are used, which have long handles so that the master can firmly hold the tool in his hands

Content [Hide]

- 1 Wood cutters for a lathe: the purpose and design of elements

- 2 Varieties of wood turning tools

- 3 How to make wood cutters for a lathe with your own hands

- 4 Sharpening wood cutters for a lathe

- 5 What to buy turning tools for wood?

- 6 Wood turning works

- 7 How to properly operate a wood lathe

- 8 Wood turning works. Video instruction

Wood cutters for lathe: purpose and design of elements

The main purpose of wood turning tools is manual processing of a part rotating in a special machine. The lathe used for these purposes is designed to give the body rotation. Wooden blanks, which are initially rounded, are mounted on lathe... One latch is connected to an electric motor, which sets the part in motion.

The choice of the type of turning tool, its sharpening and condition largely determines the possibility of certain operations, the manufacture of parts of the required configuration

Important! On the motor side, the fixation must be rigid so that rotational movements do not occur at idle.

The incisors, which are attached to the rotating mechanism, perform the processing of the rotating body. Depending on the strength, shape and sharpness of the cutter, traces are formed on the wooden blank. It also determines the shape of the workpiece.

The structure of the lathe cutter consists of a working metal part and a wooden handle. The working element conventionally consists of a blade, a body and a shank. The blade consists of a front, a back and a pointed angle. The taper angle depends on the workpiece material. Most often, craftsmen use sharp corners to work with wood. The body is the main part for which the turner holds the cutter on the armrest of the machine with his non-working hand. The shank is a tapered part into which the tool body goes. It is on it that the handle of the turning tool is attached.

The handle structure consists of a base and a neck. The base is the larger part of the handle that the turner holds by hand. The neck is represented by a small cylindrical part with a metal fastening ring.It is designed to prevent the handle from cracking while driving it onto the shank of the working part.

Varieties of wood turning tools

Today, on the shelves of hardware stores, you can find several varieties of woodworking tools for lathes: reiers, meisel, chisels, scrapers, edging cutters, oblique cutters, hooks, rings, combs.

The main purpose of the reyer is the initial, rough, roughing of the workpiece. The tool blade has a special design and is presented in the form of a semicircle. It can be made from a semicircular groove or a thick plate. With the help of a reyer, the blank can be given an approximate outline of the future product.

Meisel is used for finishing and shaping the product. Also, the tool can be used to cut the final product from the rest of the workpiece. The shape of the meiser is similar to a jamb knife and is represented by a plate with an oblique blade, sharpened on both sides at the same angle. Using a reyer and a meisel, it is possible to perform turning works of medium complexity. The workpiece is processed on the outer surface. In certain cases, you can work with the internal cavity of parts.

Other types of turning tools belong to the shaped group of products. Chisels are designed to grind smooth surfaces. The blade of the product has a special shape and sharpening. To give the workpiece a relief, you can use a special chisel with a knurled roller. Scrapers can have straight or curved incisors, which is convenient for scraping flat or cylindrical wood. This tool can also be used for roughing wood.

In cutting tools, the blades are spoon-shaped, which makes it possible to create cups or other semicircular structures. Oblique incisors are represented by grooved chisels, concave chisels and semicircular incisors. The hook and ring are designed to make cavities of any configuration in the workpiece. The comb is used to create carvings and apply decorative lines and grooves.

How to make wood cutters for a lathe with your own hands

Many craftsmen prefer not to purchase cutters in the store, but to make tools for wood carving with their own hands. It is not difficult to make a macer and a reyer. To do this, you can use waste material in the form of files and rasps. These products have the required dimensions, strength, material quality and steel grade. To give the file the required shape, use sharpening machine... Then a turned handle equipped with a fastening ring is stuffed onto the product.

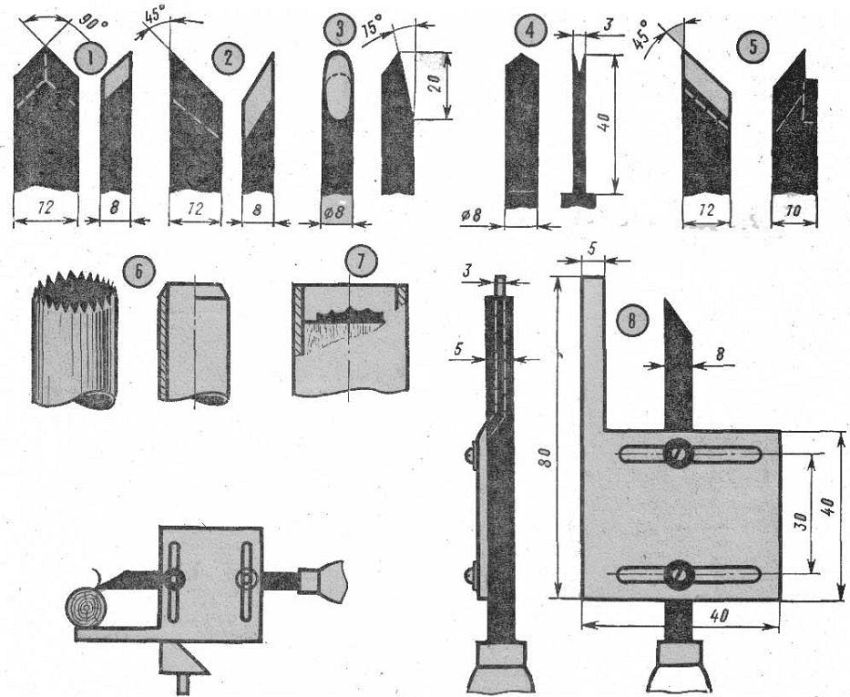

Self-made turning tools for woodworking: 1 - for deep processing, 2 - for clean processing, 3 - shaped turning, 6 - cut-off, 5 - boring, 6 - for turning balls, 7 - for face shaped turning, 8 - a cutter with a stop

With your own hands, wood cutters can be made from car springs or reinforcement bars. These materials have the required hardness. However, with this tool, you must be extremely careful during its further use. The test should be carried out first on soft woods such as poplar or linden. Next, a visual inspection of the tool is carried out for cracks and chips. If they are absent, then hand-made woodcutters for a lathe can be used for hardwoods.

When making a tool for working with wood, it is important to follow certain recommendations. The choice of body length should be based on the possibility of full grasping it with the hand, resting on the armrest.The distance between the armrest and the workpiece and the sharpening and wear margin should also be considered here. The optimal length is considered to be from 20 to 30 cm. The length of the shank should be calculated in such a way as to exclude the possibility of it being pulled out of the handle.

Useful advice! If files or rasps are used to make cutters, the length of the shank should be increased by 1.5-2 times.

Everyone will be able to make homemade cutters that will become an indispensable tool for surface treatment

The thickness of the working part of the tool should be calculated taking into account in order to prevent damage during the turning of the workpiece. Therefore, this value should be maximum, which is especially important for large-diameter workpieces. The handle of the cutter must be at least 25 cm. If this value is less, then during the turning process the tool will be difficult to hold in the hands, which will negatively affect the quality of work. You can study in more detail the process of how to make a woodcutter with your own hands on specialized sites on the Internet.

Sharpening cutters for wood for a lathe

The quality of the workpiece to be machined largely depends on the correct sharpening, namely the geometry of the turning tool. The sharpening angle is selected by each craftsman individually, depending on their own skills, the hardness of the wood, the quality of the working tool, the final desired type of the processed surface.

For a novice craftsman, the angle of sharpening of the chisel and maker should be 40 degrees relative to the working surface and in relation to each side of the blade. For a reyer, this value is 50-60 degrees. As the skill level increases, the sharpening angle can decrease to 20-35. The sharpening process is carried out on a special machine for sharpening turning tools, which is equipped with a set of wheels of various grain sizes and a velvet bar for manual dressing of the blade.

Useful advice! The set of tools for a turner must contain cutters of the same type of the same size, having different sharpening angles. This will significantly speed up the work of a specialist and extend the life of the products, since there will be no need for constant re-sharpening of the blade, based on the type of workpiece being processed.

A tool with a shallower sharpening angle is used for rough cutting and hardwood workpieces. Cutting tools with sharper corners allow for a better surface finish of the workpiece. It is used to speed up the turning process. However, in this case, the likelihood of damage to the blade and chipping of the workpiece increases. In addition, edging and sharpening wood cutters with sharp corners will be performed more often than elements with obtuse corners.

The approximate angle of sharpening of the blade is formed at the stage of manufacturing turning tools before the start of the hardening process. After the end of the heat treatment, the sharpening is carried out using an abrasive wheel and is completed on a velvet bar by hand lapping.

To prevent the appearance of scuffs and chips on the turned parts, it is important to use correctly sharpened cutters

What to buy turning tools for wood?

For working on a woodworking machine, it is better to have all the necessary tools. For this purpose, it is better to purchase not one unit, but a whole set of elements. One of the most popular and demanded options is the set of turning tools for wood Enkor 10430. There are eight elements of various profiles, which are made of high-speed steel.

The structure of the product consists of a cutting part, a base, a wooden handle and a fastening ring.The cutting part with a metal base is rigidly and securely fixed in a wooden handle and securely fixed with a ring that prevents the blade from falling out when working with the product. Each cutter is equipped with a comfortable, long, varnished handle that is comfortable to grip with both hands.

The cutters are sold complete with a wooden box, which is equipped with sockets for each element. The blades of the products are made of high-strength steel, which exhibits increased wear resistance and can remain without sharpening for a long time. The tool allows you to process a workpiece from any type of wood, regardless of the hardness of the wood. High quality sharpening the blade allows you to process products of any shape. When using these cutters, labor productivity increases, which is associated with the possibility of increasing the spindle rotation speed without lining for the formation of chips and notches. You can buy cutters for a wood lathe for 4600 rubles.

Another good option is the JET 19500118 lathe cutter set. The blades are made from high quality HSS tool steel. The set includes 6 incisors: grooved, semicircular, grooved elongated, flat, detachable and oblique. The cost of the set is 7000 rubles.

The cutting tools for the HSS NAREX wood lathe have proven themselves well. The blade is made of high quality high speed steel HSS, which is hardened to a hardness of HRC 64. The set can include cut-off, semicircular and oblique products. The cost of a set of five elements is 7,500 rubles.

The German company KIRSCHEN is one of the leading manufacturers of tools for woodworking. The catalogs contain a wide range of different types of chisels and wood turning tools, which are distinguished by a convenient and reliable design. The blades are made of special high carbon steel. The tool can be used for soft and hard woods. A set of cutters or chisels for wood for a lathe can be purchased for an average of 10,000 rubles.

Every beginner and experienced woodworker should have in his arsenal the necessary set of cutting elements. Before purchasing wood cutters, you should familiarize yourself with the characteristics of the products and choose the most appropriate option that can be effectively used for a specific task.

Related article:

Homemade metal lathe with your own hands: manufacturing and operation

Components and assembly. Choice of engine power. Creation of a machine tool based on a drill. Safety engineering, modifications.

Wood turning works

Wood turning is the artistic processing of wooden blanks. The milling process is very complex and time-consuming, and consists of certain components: the choice of a wooden blank and a tool, determining the required rotation speed, milling and finishing.

The size of the workpiece directly depends on the dimensions of the future product. If there is a cam chuck for a wood turning machine in the design of a woodworking device, then 8 cm must be added to the selected workpiece length, if a machine spindle with a faceplate is used, 4 cm must be added.The product thickness must be at least 20 mm in reserve.

It is better to use hard woods as material, such as ash, beech, apple, pear, hornbeam, walnut, oak and cherry.Products made of beautiful woods, such as walnut, ash and apple, whose texture has a pronounced pattern, will have a good aesthetic appearance.

Useful advice! An adult white acacia tree has an incredibly beautiful texture, which resembles malachite in section.

With the help of a machine and wood cutters, you can create attractive and unusual decorative elements

The first step is to create a deck or blank. Next, the workpiece is installed in a lathe and roughing is performed. This allows you to level the surface and eliminate all kinds of defects. Then the artistic processing of wood begins on a lathe. With the help of cutters, the product is given the required volume and surface relief. The appearance of the future element depends on this stage. Then the finishing is performed, which consists of grinding the product and impregnating it with antiseptic agents. You can learn more about all the features of the process thanks to the video "Turning work".

How to properly operate a wood lathe

The wooden lathe is widely used in the manufacture of furniture and decor items. The device differs in the dimensional grid, due to which the dimensions of the machine are determined, depending on the purpose. You can choose a machine for a small project or choose a massive baluster grinder, which is used in the manufacture of stair railings or furniture elements.

When choosing a machine, you should pay attention to the length of the bed, which allows you to determine the maximum length of the bar, which can be used when turning the workpiece. The turning diameter over the bed indicates the permissible value for the diameter of the wooden block. The horsepower value determines the motor power, due to which the maximum allowable weight of the product is selected without loading the machine and the cutter. Engine speed should be taken into account when defining tasks for the machine. At low speed, processing of a continuous shape product can be performed. Machines with a high number of full revolutions in a matter of minutes will polish the product at the finishing stage of processing.

Lathes range in size from hobbyist models suitable for workbench use to industrial ones weighing hundreds of kilograms

The weight of the machine determines the mobility of the device. Steel frame and cast iron models have a strong enough structure and a sturdy work platform, but require a stationary position. For high-quality and efficient operation of the machine, it is important to choose the right cutters for wood, which should be easy to use and effective for a specific task.