In private houses, where all communications are carried out by hand, pipes often freeze over. During severe frosts, ice plugs up to several meters long form in them, completely blocking the pipeline lumen. The cause of freezing is insufficient depth of trenches and poor thermal insulation of the track. A self-regulating heating cable for heating pipes will help to solve the problem. They stretch it both during the laying of communications and through the existing pipeline.

Content [Hide]

The principle of the self-regulating cable

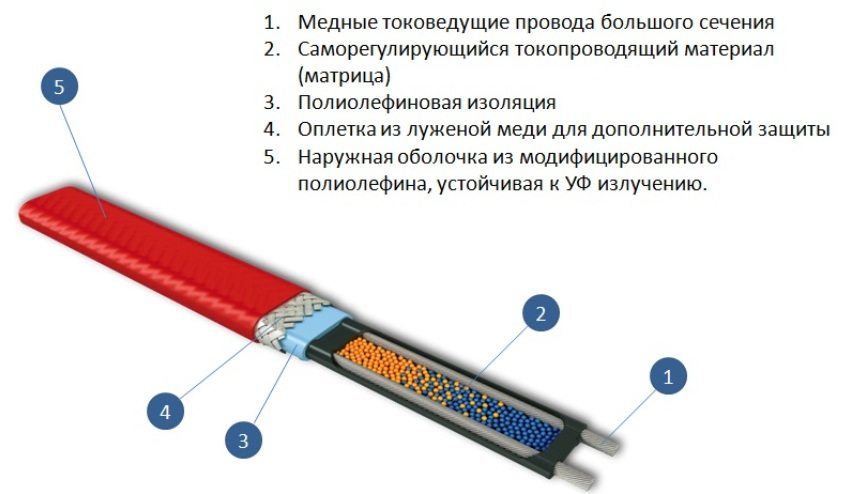

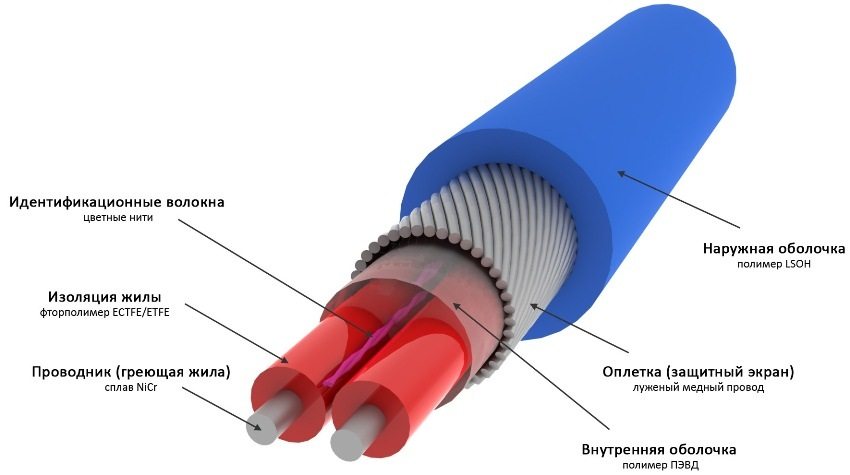

The heating wire consists of the following elements:

- two copper conductors of increased cross-section;

- conductive matrix (main heating and regulating element);

- internal polymer insulation;

- copper braid;

- external insulation.

The operation of a self-regulating heating cable for heating pipes is based on the conversion of electrical energy into heat. A characteristic feature of the wire is that it only receives electricity, but does not transmit it. The cord can be cut into sections of the desired length, from 20 cm to tens of meters. It is important to avoid sharp bending and physical abrasion of the copper core.

Cable types

There are three types of heating wires in total - self-regulating, resistive and resistive mineral insulated.

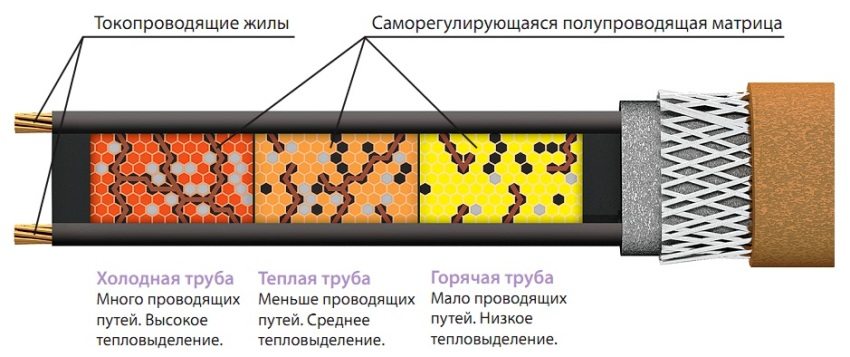

Self-regulating cable is most widely used among electrical heating systems. Its main advantages:

- the ability to regulate heat transfer without personnel control;

- significant energy savings.

The specified cable is classified by power. Products are produced with a maximum allowable temperature of 70, 105 and 135 degrees. The degree of heating depends on the thickness of the copper cores - the larger the core diameter, the higher the temperature. The energy consumption per meter of wire is about 30 W. It is recommended to connect the cable through a separate transformer. Heating can be carried out on pipelines made of metal, metal-plastic, polypropylene.

The resistive cable is heated by a constant resistance that does not change over its entire length. Such wires are produced in sections of a certain length, which cannot be changed. Each coil is equipped with a coupling. Self-regulation in a resistive system is excluded, therefore, a large excess consumption of electricity is possible. In addition, the cable requires constant cleaning from debris to avoid overheating.

Mineral insulated resistive wires are used to heat objects in aggressive environments - alkaline, acidic, saline. The products can also be used in hazardous areas, at high temperatures and loads.

Related article:

|

Application

A self-regulating heating cable for heating pipes is used to supply heat to the following objects:

- Pipelines for various purposes, water supply systems, sewerage networks.

- Technological tanks, tanks, tanks with liquid.

- Platforms in front of the cottages.

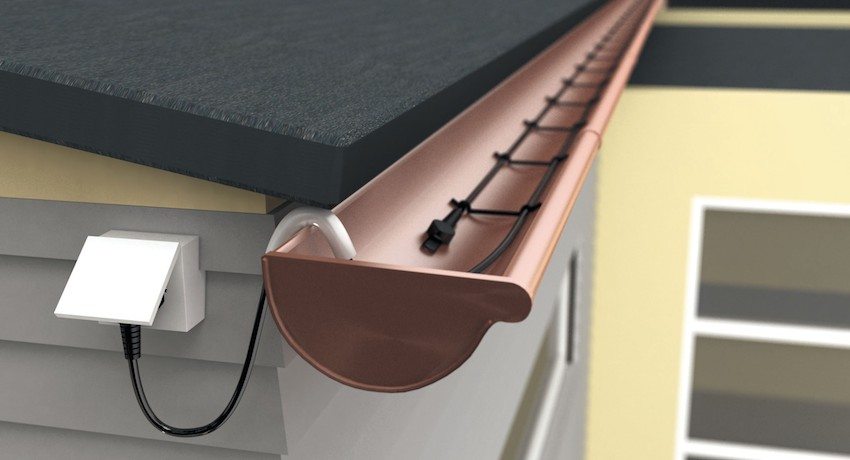

- Roofs and downpipes to prevent icing.

- Underfloor heating systems.

- Greenhouses and winter gardens.

- Terrariums, aquariums, closed biospheres.

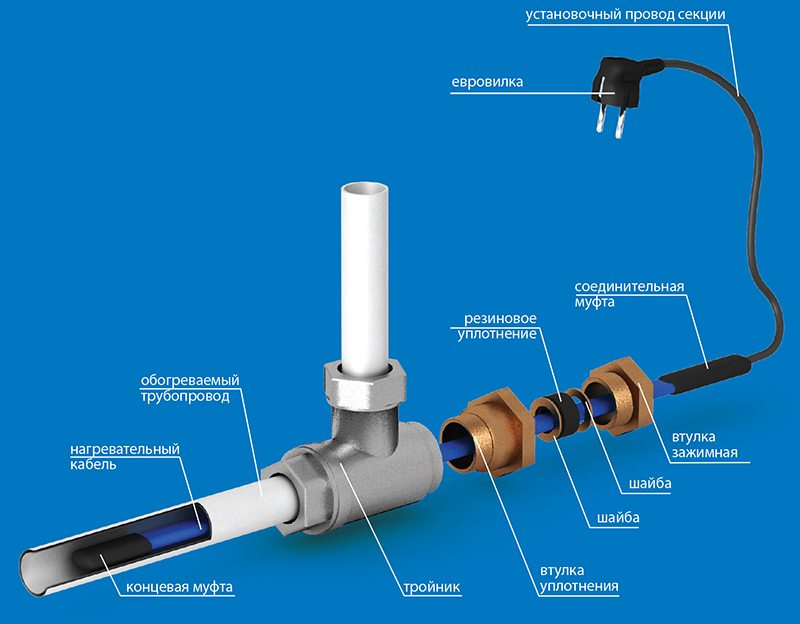

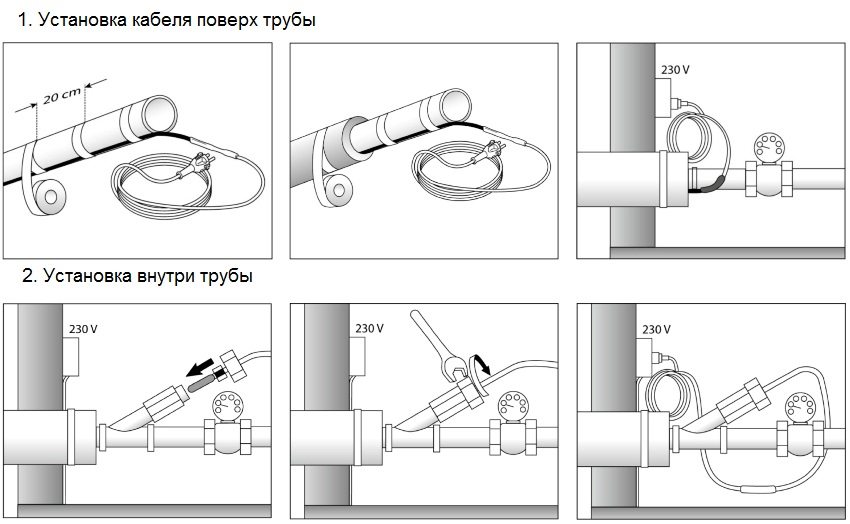

Internal installation

The cable is inserted into the pipe if the communication channel is already underground and there is no access to it. Then, at the point where the cable enters the underground network, a saddle with a 1 cm outlet is installed. A pipe insert is screwed into it and a wire is brought in. First, you need to measure the length of the section that needs heating, and adjust the cable size along it.

Helpful advice! To warm up potable water systems, food grade approved products are required. Typically, the plumbing cable is insulated with a safe fluorinated polymer.

Do not run the heating cord through shut-off valves. If the cable insulation is damaged, a person may be electrocuted while using the water supply.

External mounting

On overhead or newly laid communications, the cable is laid over the pipe. There are two main accommodation options:

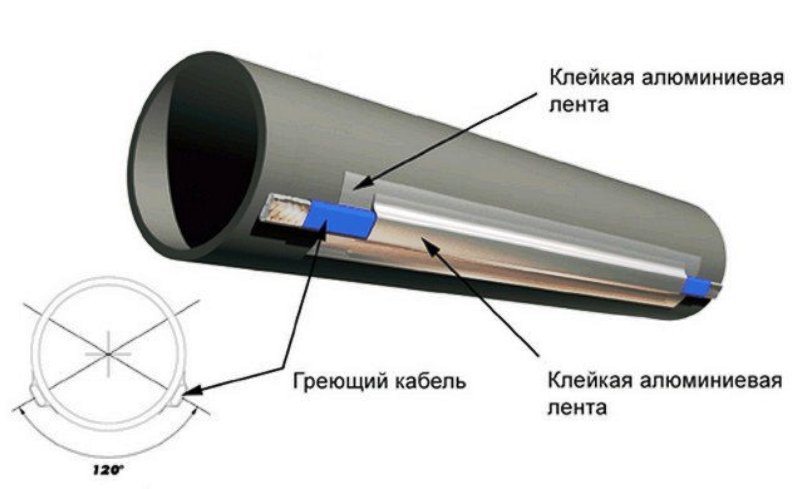

- linear. The wire is rolled out, straightened and laid directly on the pipe. The length of the heating element in this case should be equal to the length of the intended section. The method is used for small diameter channels (up to 50 mm). It is possible to pull several parallel cables along the pipe;

- in a spiral. On medium and large pipelines, the cable is laid in the form of a spiral.

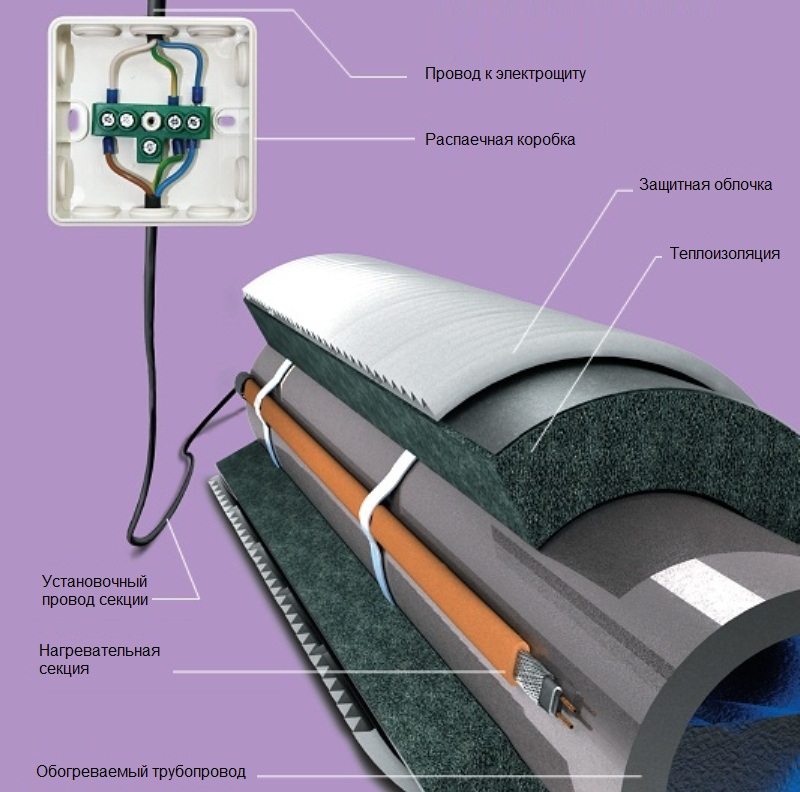

When winding or pulling a wire along the pipe, it is necessary to ensure that there are no kinks, stretching, compression, chafing, and the passage of the cord through sharp parts. Having applied a self-regulating heating cable for heating pipes, the area is completely wrapped on top with adhesive aluminum tape. Plain plastic tape will not work. Further, the pipeline is wrapped with any thermal insulator in the form of half-cylinders. Insulation joints are sealed with mineral wool and sealed with waterproof tape.

Helpful advice! Wrap foil around the pipe before installing the cable. Then the heat will be distributed more evenly.

The cable is AC powered. For a more economical consumption of electricity, you must install relay and a thermostat. Then smart automation, if necessary, will turn on and off the heating itself.