Storm sewage is a very important component of any personal plot, as well as the territory from which it is necessary to drain water. Stormwater inlets for storm sewers are an indispensable component of this drainage system. Storm water inlets can be made of different materials, have different weights and dimensions, withstand different loads, and for their correct installation, certain requirements must be met.

Content [Hide]

Features of the storm sewer device

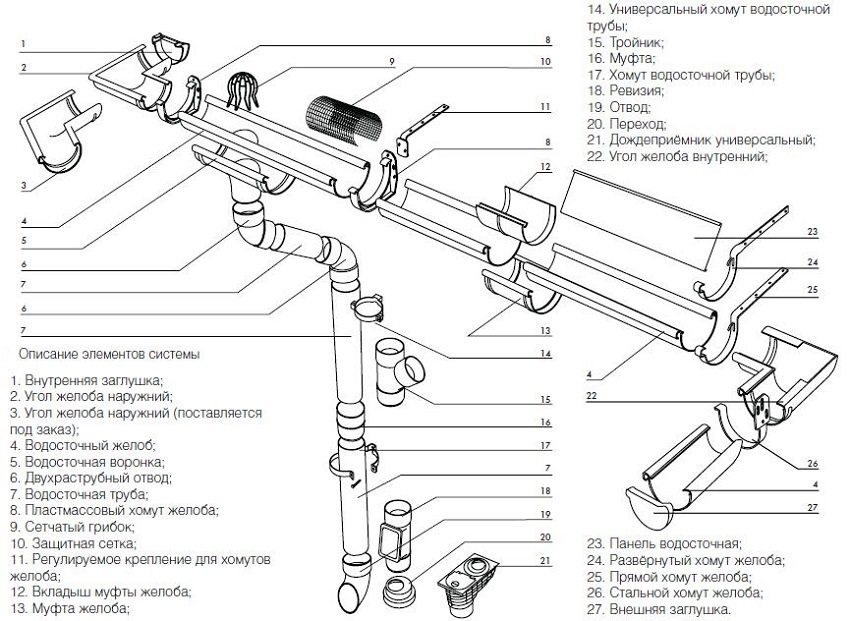

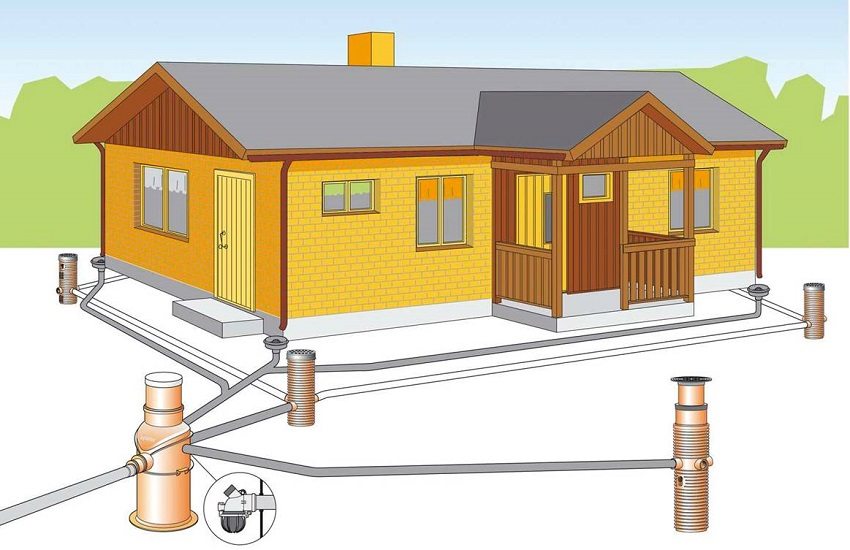

The storm sewer serves to drain not only rainwater from the site, but also melt water. This is done so that moisture accumulating in the soil does not undermine the foundation of the building, as a result of which it can begin to sag. Any such system necessarily includes the following components:

- pipes or gutters for transporting water;

- receivers for transferring water from the surface;

- gutters and drainage wells into which water flows;

- special grids and filters to prevent large and small debris from entering the system.

In addition, with the help of such a system, it is possible to irrigate plants on the site with melt water, extend the life of pedestrian paths and sidewalks, and also protect buildings from the harmful effects of moisture. You can buy a storm water inlet so that puddles do not form on your site or so that water does not flow into the basement.

Purpose and design of storm water inlets

The presence of a storm water drain in the system is mandatory, since it is through it that water enters the pipes or gutters. If we talk about the device of a storm water inlet for storm sewers, then it is a complex structure of a rectangular or oval shape, consisting of several parts.

A typical modern water receiver includes the following components:

- Lattice - covers the structure from above and serves not only for decorative purposes, but also to protect a person from possible injuries. In addition, plastic or cast-iron grids of the storm inlet perform the function of a primary filter, that is, do not allow large debris to enter the sewer system.

- Storm water inlet is a square or round structure that serves to direct water into the drainage system.

- The sand filter is a part of the design that is not present in all models. Serves to prevent fine soil particles, sand and other debris from entering the sewer with water. Such a filter is located below the drainage tray, so debris particles simply sink to its bottom, and the water rises to the level of the outlet from the receiver.

Note! The debris filter must be cleaned regularly, otherwise, over time, an unpleasant odor may develop from the evaporation of water from the tray.

Types and features of storm water inlets

This element of the storm sewer is available in various versions. Storm hoppers can vary in shape, depth, weight, and material of manufacture. The last parameter is one of the most important. Today the following design options are on sale:

- cast iron;

- concrete;

- plastic.

Varieties of concrete structures

Concrete storm water inlets are widespread in road construction and are also used where the surface water collection system is exposed to heavy loads. They can be made of heavy and durable reinforced concrete, as well as lighter and cheaper fiber-reinforced concrete. In addition, a concrete stormwater inlet can be light, heavy, or trunk.

The lightweight design is usually mounted under the outlet of the downpipe and equipped with a plastic outlet. The typical shape of a light receiver is cubic, and the wall thickness is no more than 2 cm. Design features of this type allow multiple receivers to be stacked on top of each other, if necessary to increase the depth of the well. Among the advantages of lightweight concrete structures are durability, a high level of resistance to temperature changes and other negative influences, as well as a relatively low cost. The average size of a lightweight concrete receiver is 40x40 cm.

The heavy concrete stormwater inlet is capable of withstanding loads of up to 3 tons. Therefore, these types of structures are installed in areas with medium traffic, which include gas stations, areas near cafes or streets with a small traffic flow. Vibrated fiber concrete is used as a material for the manufacture of modern models, and the wall thickness is at least 2 cm. The grating for such a receiver is made of ordinary or galvanized cast iron, which can withstand heavy loads.

The main type differs from others in the collapsible type of construction. It is assembled from separate elements, therefore, when installing storm water inlets made of main-line concrete, it is not necessary to use specialized construction equipment. As a rule, such models are made of reinforced concrete, which is resistant to temperature extremes and does not allow water to pass through. The wall thickness is at least 5 cm, and the grilles are made of cast iron. Trunk cast storm water inlets withstand heavy loads and are installed mainly on the roadway.

In private construction, concrete options are rarely used, since, with all their advantages, they are characterized by a rather large weight and bulky dimensions, as well as the complexity of installation compared to lighter plastic models. Also recently, the use of concrete structures in road construction has significantly decreased, since they were replaced by more durable and wear-resistant options made of cast iron.

Cast iron models of storm water inlets

Cast iron storm water inlets are also most often used in road construction to drain water from the roadway, pedestrian paths and sidewalks.They are made of grade SCh20 cast iron, which boasts a very high level of resistance to various kinds of aggressive substances, as well as resistance to constant physical exertion. Structures differ in shape, weight and maximum permissible load:

- DM - a model of small size and rectangular shape. The mass of this design option is from 80 kg, and the maximum load is 12.5 tons. Storm inlets DM2 and DM1 are installed in the courtyards of residential buildings and on highways with a low load;

- DB - large rectangular type storm water inlets with a mass of 115 kg. Storm water inlets DB2 can withstand a load of up to 25 tons, which makes them a good option for installation on highways with heavy traffic, as well as in parking lots and other similar places. The dimensions of the DB2 gully are 400x810 mm;

- DK is a round model with a mass of about 100 kg. Round storm water inlets DK are used when the existing rectangular version is under repair or under reconstruction. The maximum load is 15 tons.

Note! Rectangular and round cast-iron storm water inlets are characterized by a long service life, but their installation requires the use of special construction equipment due to the large weight of the structure.

Among the advantages that the use of cast iron structures gives, the following can be distinguished:

- good throughput, they can pass a large amount of water per unit of time;

- very high strength and ability to withstand heavy physical exertion;

- long service life of the material;

- environmental friendliness, safety for the environment and human health;

- high level of resistance to corrosion, since cast iron is coated with a special anti-corrosion compound;

- relatively low cost.

The disadvantages of cast-iron storm water inlets for storm sewers include the following points:

- large weight of the material and the entire structure as a whole;

- in the absence of a special coating, cast iron begins to rust very quickly;

- during installation, it is necessary to provide for the installation of special locking mechanisms in order to insure against theft.

In private construction, cast-iron storm water inlets DB1 are most often found, since they are the most compact. The length of this model is 695 mm, the width is 470 mm, and the height is 120 mm. Cast iron gratings are made from the same material and are also characterized by increased strength, durability and wear resistance. The grilles are attached to the receivers using self-tapping screws or bolts.

Storm water inlets made of plastic

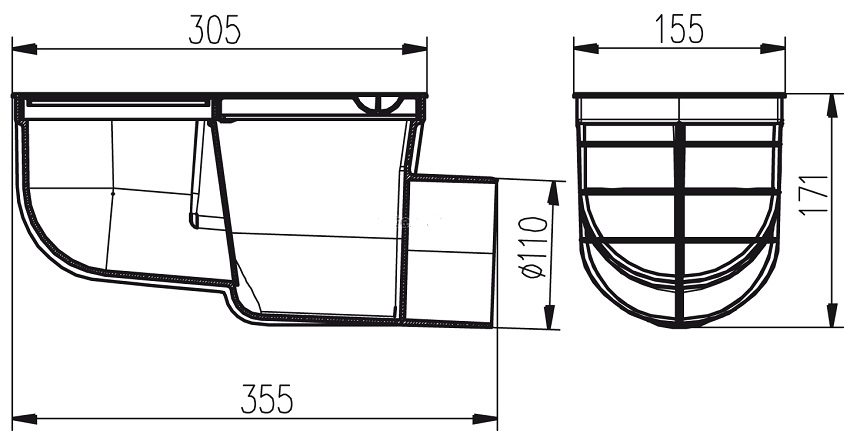

A plastic stormwater inlet for storm sewers is the most popular option for installation in a summer cottage or backyard. It is usually made from special frost-resistant polypropylene, which is characterized by resistance to temperature extremes, aggressive chemical environments and loads. The standard dimensions of plastic storm water inlets are 300x300x300 mm, as well as 400x400x400 and 500x500x500 mm.

Plastic models are classified according to the maximum permissible load on the grid. Depending on this parameter, the following classes are distinguished:

- A - the maximum load is up to 1.5 tons. Such models are used in private backyard areas and walkways;

- B - withstand up to 12.5 tons, are installed in garage cooperatives, in car parks;

- C - load up to 25 tons, can be installed on highways or petrol stations;

- D - 40 tons, withstand the weight of a truck;

- E - up to 60 t, can be mounted in truck parking lots and in other places with increased load;

- F - up to 90 t, installed on sites for the movement of specialized heavy equipment.

Helpful advice! When choosing a receiver class, it is better to play it safe a little and purchase an option with a permissible load, which slightly exceeds your calculations.

For any size of a storm water inlet made of plastic, it consists of the following components:

- Basket - serves to protect the system from getting into it of various debris. In plastic storm water inlets Gidrolica 300x300 mm and other similar models, debris settles to the bottom of the basket, so it must be removed and cleaned periodically.

- Rubber siphon - prevents the spread of unpleasant odors that can appear as a result of rotting debris and evaporation of water from the bottom of the basket.

- Partition - protrudes as a water seal and is needed when connecting a water drainage system to the receiver.

- Cover - serves to completely close the storm water inlet, it is used in the cold season or when this receiver is not used for any reason.

- Lattice - through it water enters the storm water inlet. Round or square models are selected according to the shape of the receiver.

- Luke - used in closed wells.

- Extension - allows you to increase the depth of the structure.

In addition, the receivers differ in the type of water drainage. It can be carried out down or to the side, and the choice of this parameter depends on the design features of your storm sewer system and the place of the storm water inlet in it.

The main reason many people prefer to buy a plastic storm drain is their low weight compared to concrete or cast iron models. Simplicity of installation follows from this advantage. To install a plastic structure, you do not need to use specialized construction equipment and you can easily do it yourself. In addition, plastic is quite resistant to all kinds of negative influences, for example, to temperature extremes or harsh chemicals.

Another advantage of plastic storm water inlets, which distinguishes them favorably from cast-iron models, is ease of maintenance. In order to clean such a structure, it is enough to simply remove the basket and discard its contents, and then rinse. With the small size of plastic storm water inlets and the lightness of the structure, this is very easy to do. The pipe outlet to the plastic receiver is connected without the use of special fasteners, and the connection itself is possible in two planes.

Grilles for plastic structures can be made from the same polymer, as well as from tin or cast iron. The latter option is the most durable, therefore it is mounted in places with increased load.

The prices of plastic storm water inlets depend on the manufacturer and design features. The average cost is 700-800 rubles per item.

Design selection criteria and drainage system design

The choice of the size of the storm water inlet and its other characteristics must begin, starting from the proposed storm sewer system. The latter is designed based on the following data:

- the maximum amount of precipitation on the territory - this parameter is recognized from the SNiP directory, there you must also see the maximum parameter of the snow cover in winter;

- moisture absorption coefficient - depends on the type of coverage of the territory, for example, for crushed stone it is 0.4, and for roofing - 1;

- area of the territory from which water will be diverted.

Based on these data, the type of storm sewer is determined.The choice of a storm water inlet is also carried out depending on the intensity of precipitation in the area, general climatic conditions, type of soil and maximum load.

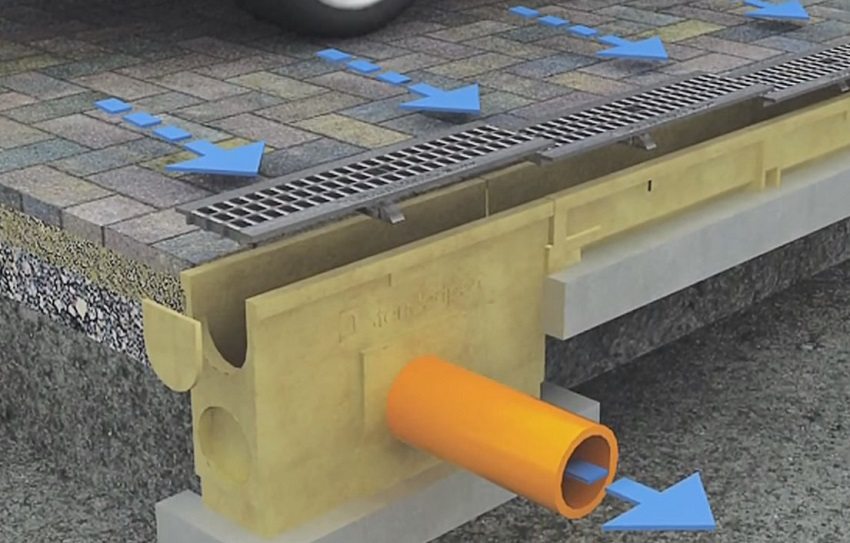

The rainwater inlet can be located anywhere, but you need to take into account the proximity of the drain

Helpful advice! If the price of a storm water inlet for a storm sewer does not suit you, but you need to drain water from the territory, then you can try a homemade option. It is made from ordinary brick, from which a small well is laid out. The walls of the well are plastered from the inside, and a pipeline is connected to it from the side.

Features of installing a storm water inlet

The installation of a storm water inlet for storm sewers is carried out under the outlet of the drain pipe or in those places where puddles form after rain or as a result of melting snow. When installing, pay particular attention to the installation depth. It is also recommended to choose such an arrangement of the structure so that the water from the pipe falls exactly into its center. And if it is not possible to locate the drain at the lowest point of the territory, then special depressions must be drawn to it, through which water will flow into the receiver.

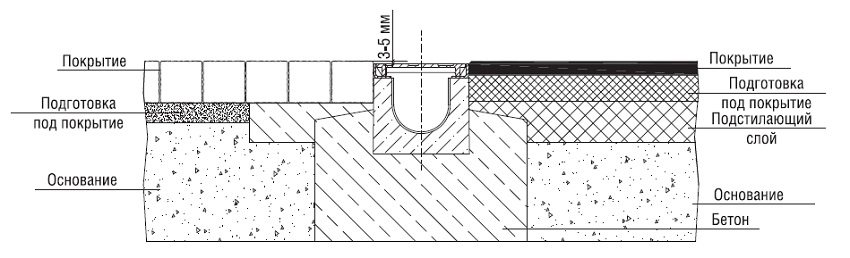

After you have decided on the type of structure and the place of its installation, you can proceed directly to the installation of the storm water inlet. It consists of the following steps:

- A pit is being dug. Its depth is determined by the size of the receiver itself, to which it is necessary to add 30-40 cm. The width of the pit should also be larger than the dimensions of the structure by about 3 cm on each side, since it will be strengthened with concrete mortar.

- A special sand cushion is mounted at the bottom of the pit. After falling asleep, the sand is filled with water and carefully compacted.

- The rainwater inlet is connected to a pipe or tray system. In this case, it is necessary to ensure that the entire structure is precisely aligned in height.

- The bottom of the pit is filled with a small layer of concrete, into which the receiver is installed. When installing a storm water inlet with your own hands, it is necessary to securely fix the structure in concrete in order to avoid its displacement later.

- Concrete mortar is poured from the sides of the structure. In order for the plastic model not to deform under the pressure of concrete, its walls can be additionally reinforced with a metal grid.

- Partitions and a rain inlet basket are installed.

Remember that the service life and efficiency of the structure depends on how correctly you installed the storm water inlet. As many videos of the installation of storm water inlets show, this must be done before installing the coverage on the territory. It is worth paving the area adjacent to the rainwater receiver only a few days after the installation of the latter is completed. During this time, the concrete will finally harden, and you can safely lay any type of coating.

Helpful advice! If you are going to asphalt the area where the receiver is located, then it is recommended to fill the place around it with a diameter of 1-1.5 m with sand, gravel or bitumen. This will prevent the asphalt from damaging the branch structure.

One of the key factors that must also be considered when installing a storm water inlet is the strength and reliability of the base. Please note that with temperature drops, the soil in which the receiver is installed can expand and contract, therefore the concrete pad and the walls surrounding the structure must be extremely reliable. Otherwise, you will have to reinstall the storm water inlet in the very first spring. Numerous thematic videos on the Internet will tell you how to avoid this.

If you do not have sufficient building skills for self-assembly of the structure, then you can entrust this matter to qualified specialists. In this case, the price of installing a storm water inlet will depend on the type of receiver, installation depth and a number of other factors.

Construction maintenance rules

The storm water inlet is one of the most demanding elements of the storm sewer system in terms of maintenance. This is due to the fact that water enters it directly from the surface, and it is here that its primary cleaning of debris takes place. If you want the receiver basket to get clogged less often, then you should pay attention to the models with a fine-mesh grill, which will not let small debris through.

In any case, the basket should be removed and cleaned at least once every 2-3 months. Otherwise, you risk getting not only a blockage, but also a source of an unpleasant odor under your house. If the blockage has formed at the junction of the structure and the pipeline, then it should be removed using special plumbing fixtures.

Regular cleaning of all elements of the drainage system will help to avoid the negative consequences of blockages

The prices of storm water inlets in the modern construction market allow you to easily purchase such a structure for arranging storm sewers on a private territory, and the ease of installation and operation has made this element of the water drainage system very popular.