Every homeowner at least once in his life faced the consequences of a clogged sewer, which can occur as a result of a large foreign object entering it, violations of operating conditions, and improper installation. This leads to the return of the waste masses and pouring them out of the plumbing device. It is not difficult to prevent such troubles. For this, a 110 mm sewer check valve or another size is used.

Content [Hide]

- 1 Possible causes of a clogged sewer

- 2 What is a 110 mm sewer check valve and other sizes

- 3 The structure and principle of operation of the sewer check valve 110 mm

- 4 Criteria for choosing a drain check valve

- 5 How to install a check valve on a sewer pipe

- 6 Installation of non-return valves 110 mm, made of different materials on the sewer

- 7 Why use a 110mm air check valve

- 8 Popular manufacturers of sewage check valves

Possible causes of a clogged sewer

The backflow of faeces can be caused by several reasons. The first lies in the improper operation of the sewer system, where plastic bags, intimate hygiene products and other things that block the pipe section can inadvertently fall.

In this case, you will need to think about how to break through the sewer at home. The most effective method is to use a pipe cleaning cable.

With prolonged operation, deposits appear on the inner walls of the pipes, which gradually grow, reducing the clearance of the pipeline. The settled sediment forms a rough surface on which solid particles accumulate, which leads to the formation of a plug. A good result for removing blockages is the use of chemicals that dissolve sediments inside the drain.

Another possible reason for the clogging of the sewer system is the improper slope of the collector, which occurs as a result of improperly performed installation work. It should be understood here that a traffic jam can form with a strong or insufficient slope. To prevent solid contaminated particles from accumulating on the inner walls of the pipeline, water must move along it at a certain speed. This problem can be eliminated only as a result of a complete overhaul of the system.

A common reason for clogging a sewer is the presence of a large number of bends located at an angle of 90 °. This configuration of the system contributes to a sharp change in the speed of movement of wastewater. Large suspended solids can immediately linger, forming a plug.

What is a 110 mm sewer check valve and other sizes

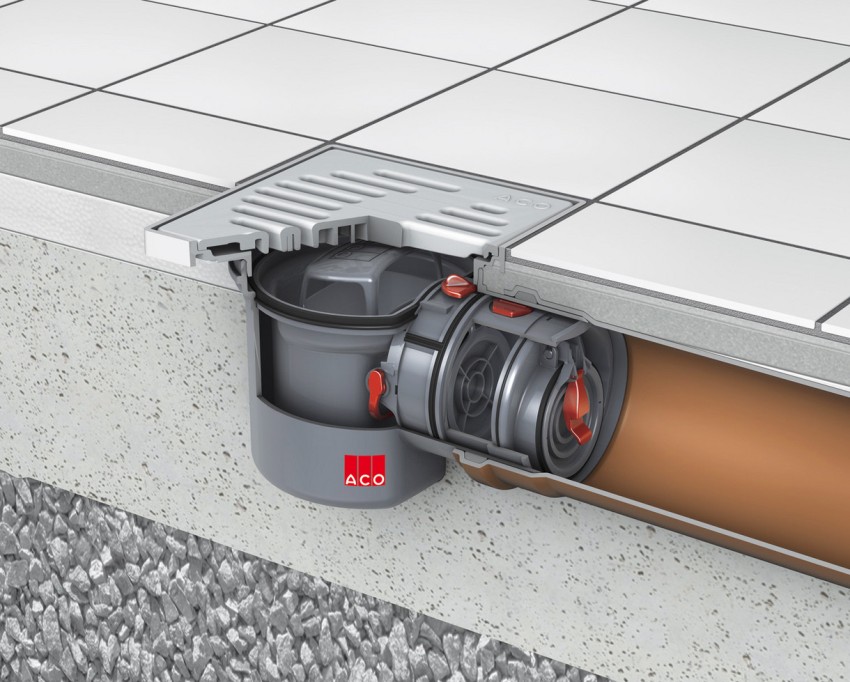

A check valve is a type of shut-off valve. It is installed in the lumen in the pipeline to block the backflow of liquid in the event of a clogged system. The device is mounted in a basement on a horizontal section of a common sewer collector at the pipe joining point. It can also be installed at a 90º turn in the pipeline.

To achieve maximum safety, a 50 mm sewer check valve can also be installed on taps to plumbing fixtures on the first and second floors of an apartment building. Such an enhanced measure is justified by the fact that fecal water, when flowing back, can rise only above the first floor. Further, the accumulated mass is able to independently push through the plug formed in the pipe.

For the private sector, the check valve is mounted before discharge into the sewer well (for each house separately - on the inside of the foundation). Such a device is also intended for an autonomous system, where wastewater accumulates in a drain pit or in a septic tank. In this case, you should worry about how to fill the lid on the sewer with your own hands.

The check valve is characterized by simplicity of design, reliability, efficiency, durability, easy installation and convenient maintenance.

The structure and principle of operation of the sewer check valve 110 mm

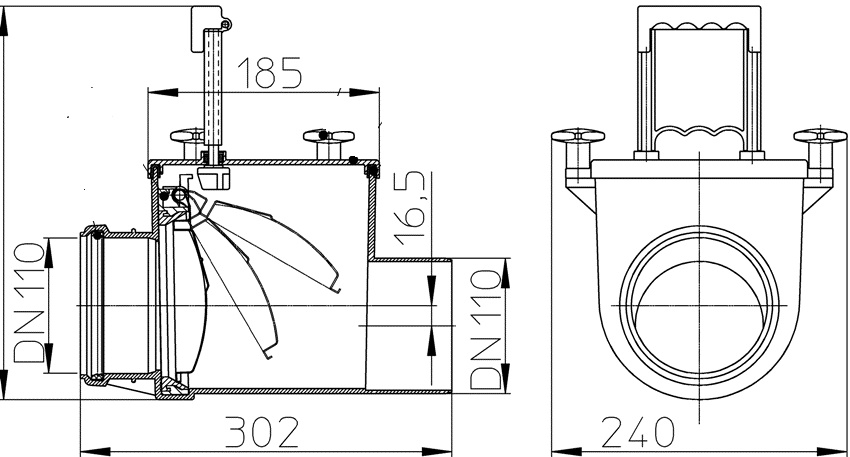

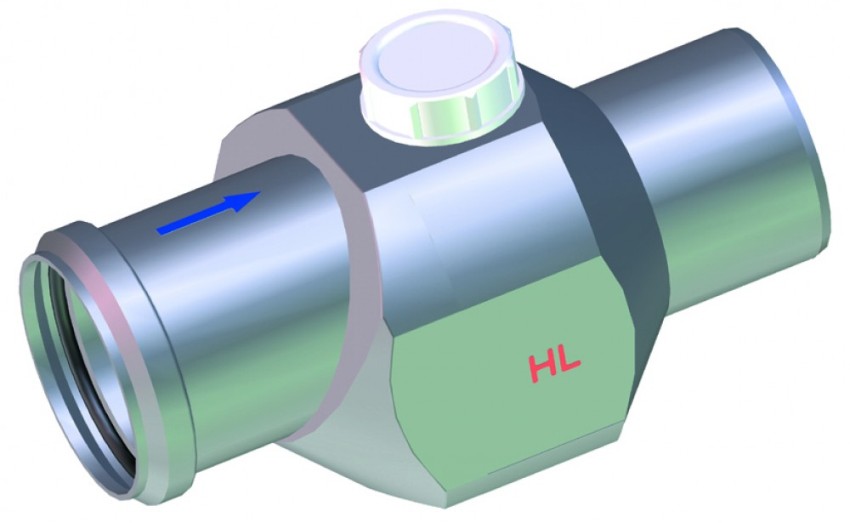

The non-return valve is compatible with all standard sewage pipes. Such safety fittings consist of a hexagonal body, which can be made of metal or plastic. The internal space is conventionally divided into a receiving part with an inlet for connection to the pipeline and a plate-shaped stopper that fixes the shut-off element and the outlet area.

Important! The restrictor is equipped with a sealing element that ensures maximum tightness when the valve is fully closed.

During normal fluid flow, the shut-off restrictor helps to create a complete clearance in the pipe. If there is a reverse flow of water, the shut-off element closes it. Through the outlet zone, the wastewater is discharged through the sewer line into the general system.

The principle of operation of the sewer valve 110 mm and other sizes is as follows. At the moment of stopping the free movement of fecal masses, the pressure is equalized in the inlet and outlet zones of the valve. Under the influence of gravity, the stopper begins to block the gap in the pipe. This happens due to the release of the spring that is attached to it. In this position, it firmly holds the closure element. The spring will be compressed during normal system operation.

Check valves are mechanical or automatic. The principle of operation of the devices is almost the same, except that the automatic device gives an alarm when an emergency occurs.

The check valve can be either horizontal or vertical. The first option has become more widespread. A 110 mm vertical check valve is mounted on the sewer system to automatically shut off the drainage system and to protect it in the event of a storm drain.Such an element is used as a sewer audit.

Design of drainage check valves

Based on the design features of the valves, there are ball, rotary (petal), lift and flange check valves of the sewage system. Despite the different design of working areas, all types of devices have the same operating principle.

The ball check valve is equipped with a ball-shaped stop. During normal operation of the system, the element is located in a special recess inside the body, creating an open gap. As soon as the wastewater begins to move in the opposite direction, it closes the pipe section. This shape of the closure element does not provide the closure tightness as a result of a loose ball against the side walls. This can cause drainage.

The wafer type check valve is small in size. Its body is similar to a hollow cylinder, inside there is a butterfly valve in the form of a small disc. It can, on one side, be fixed to the housing wall by means of a spring, or it can have two flaps attached to a rod that passes through the center of the device.

Such a valve can be located on both horizontal and vertical pipe sections. When installing it, additional gaskets are not used, since the device is equipped with seals.

There are two types of 110mm Wafer Type Wafer Check Valve (and a different size): disc and butterfly valve. In the first version, the locking element is made in the form of a solid disk, fixed at the top of the body. Sinking under its own weight, it completely overlaps the pipe section. This is the most reliable type of safety valve. However, it is used exclusively in a non-pressurized system.

The butterfly valve has a center stem with two petals. With the reverse movement of water, these flaps are pressed against each other by means of springs, blocking the pipe section.

Features of the Swing Lobe and Lift Check Valve

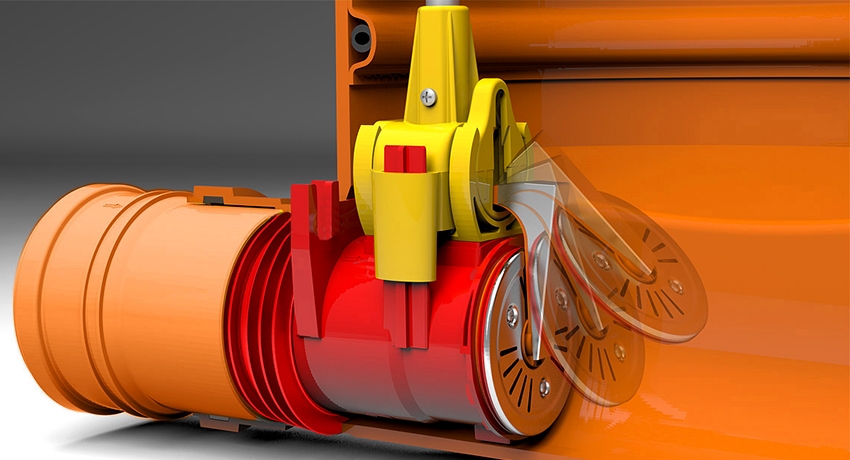

Rotary petal valves have a spring-loaded diaphragm that resembles a round petal. With the free flow of fecal masses through the sewer pipe, the plate is located in the upper part of the body in an inverted position, which does not impede the movement of liquid. If a reverse flow occurs, the membrane is pressed in the body cavity against the rim, reliably and hermetically closing the lumen in the pipe. A removable cover is located in the upper part of the case for auditing the device.

Important! There are check valves for a 110 mm petal-type pipe with a manual shutter, which is a second disc, the operation of which is controlled using a button located on the device body.

Rotary valves can be either hard or soft. In the first case, the disk overlaps the pipe section under its own weight. This option is advisable to use for gravity systems with a small volume of waste. If installed on a pump or a high-capacity network, the device can cause a water hammer, which is a dangerous phenomenon for pipes. The soft system is characterized by a smooth movement of the petal locking mechanism. In this case, water hammer is excluded.

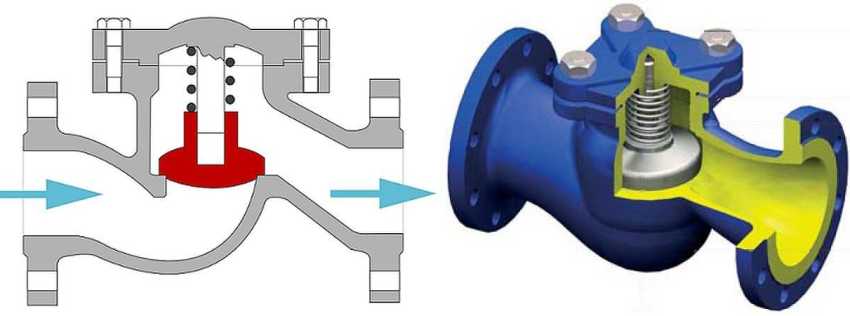

The lift check valve has a shut-off element that is lifted up during normal operation of the system, which is due to the compression of the spring by gravity. When the fluid flows back, the spring expands - and the lock closes the pipe lumen.This type of valve is more susceptible to clogging than others due to the complex configuration of the body. It needs regular maintenance to function properly. This is the most common type of valve and is most often installed on the ground floor.

When fecal matter flows through the pipe, the plate is located in the upper part of the valve body in an inverted position

Criteria for choosing a drain check valve

Before purchasing a check valve, you should decide where exactly the fittings will be installed. The size of the product is selected in accordance with the diameter of the sewer pipeline.

For the manufacture of stop valves, the same material is used as for the manufacture of the collector. Here you should also pay attention to the quality of the device. Preference is given to a durable product made of material resistant to negative consequences.

The device can be made of plastic, cast iron, steel or bronze. Plastic products are currently very popular due to the installation of a drainage system made of plastic or polypropylene pipes. Metal products are most often used for outdoor pipelines.

Helpful advice! For indoor installations a gray plastic check valve is used, and for outdoor installations an orange one.

Check valves are available in different diameters. For intra-apartment systems, devices with a cross section of 50 mm are used. Check valve 110 mm is installed on the outlet from the toilet bowl. For external systems, devices with a diameter of 150 mm or more are used.

Helpful advice! If the valve and piping have different diameters, special adapters are required when installing the device.

The valve should be simple in design to ensure easy, quick installation and convenient maintenance. For this purpose, it is recommended to choose models with a removable cover, which can be removed to clean the locking mechanism.

Related article:

Sewerage check valve: protection of the home from sewage flooding

The principle of operation and the purpose of the device. Varieties of locking devices. Rules for the selection and installation of a check valve.

A 110 mm sewer check valve can have one or two dampers. The second option is more reliable, since it is possible to close the device manually. This is a guarantee of reliable and durable operation of the mechanism.

How to install a check valve on a sewer pipe

There are two ways to install a check valve on the sewer. The first involves the installation of a shut-off element on a common sewer collector in an apartment building. In the second case, the device is installed for each drain source. This option is used for private households.

Helpful advice! According to experts, the installation of one 110 mm check valve for one riser is insufficient protection against possible flooding by sewage; therefore, it is recommended to additionally install locking devices on the ground floors.

When installing the locking mechanism, it should be remembered that the valve is not mounted on the sewer pipe in the drain gap under the revision cover. The dampers can work effectively in a horizontal system. Otherwise, there will be problems with wastewater disposal, since the membrane in this position will not create their unhindered movement.

When choosing a place for installing a check valve, it is required to take into account that convenient access to the device must be provided so that in the event of an accident you do not have to dismantle the finish or move the furniture.Sewerage check valve 110 mm is installed in the basement after the swivel elbow - before the pipeline enters the wall. In the apartment, the device is placed on a cross or tee near the central drain into the riser. If it is not technically possible, then you can fix one locking element with a diameter of 50 mm to the outlet towards the bath or kitchen, and install the second valve with a size of 110 mm on the toilet.

The shut-off valve is mounted in such a position that it is possible to ensure free flow in one direction. A pointer on the valve body, which indicates the direction of the drain, serves as a clue. The valve must be at least 100 mm above the highest siphon.

Important! The check valve must not be able to absorb compressive, tensile or torsional loads from the connected pipes.

Valve size and material must match the characteristics of the pipeline. Otherwise, you will have to use adapters, which will weaken the reliability of the system.

Sewer installation non-return valves 110 mm, made of different materials

Currently, as evidenced by the reviews of the owners, a 110 mm sewer check valve is most often chosen in a plastic version. This is due to the fact that the drainage system is assembled from this material. Installation of the product does not cause any difficulties.

After choosing a place for installing the valve, cut off a section of the pipeline, the length of which must match the dimensions of the shut-off device with an allowance of 5 cm. The pipe sections must be filed. A valve with a socket connection is put on the section of the pipeline. The same procedure is carried out from the side of the exhaust manifold. The connection is sealed using the sealing elements of the locking device.

Helpful advice! To ensure the most reliable connection, the edges of the pipes are recommended to be sealed with a sealant before installation in the socket.

When using a 110 mm plastic drain check valve for cast iron or steel pipe, you must additionally purchase two adapters. The sequence of work is the same as when installing the shut-off element on plastic pipes. With the help of a grinder, a place is cut out on the manifold for mounting the shut-off element. The edges are sanded.

An adapter is put on a pipe section, then a check valve, after which an adapter is again, which is attached with the other end to the pipe by means of a socket connection using tow. To make the system reliable, the seams are treated with silicone.

Important! The cast iron check valve is bolted together by pulling the mounting plates and rubber bands together.

Why use a 110mm air check valve

To eliminate the likelihood of sewage entering the room, an air valve is mounted on the waste pipe, which lets air into the system and does not allow it to come out. This closure also helps to reduce the noise level in the system when the waste stream moves.

When water is drained, a vacuum occurs in the sewer system, as a result of which air enters it. This is done due to the presence of ventilation or a plumbing device with the smallest water seal. As a result of the vacuum, the membrane opens, and after the pressure stabilizes, it closes, which excludes the flow of air back into the room.

The sewage air check valve is made of high quality plastic material.The element consists of a body, diaphragm or stem, rubber seal and cover. The membrane reacts to overpressure in the network and is activated when it occurs. The operating mode of the stem is regulated by a sealing gasket. The element is connected to the pipeline through the side hole.

A 110 mm drain valve for sewerage, like a non-return valve, is installed no higher than 2 floors. It must be located above the largest drain connected to the unit. The valve is fixed in a vertical position. It is mounted to the pipeline by means of a socket joint, which is completely sealed with silicone treated rubber cuffs.

Important! The air valve is installed in a place where the temperature does not drop below 0 ° C.

The locking element can be automatic, anti-vacuum or combined. The first type of product has a low throughput. The second valve option works well at low pressure. The combined version combines the features of both types of fixture.

Popular manufacturers of sewage check valves

The Hemkor North-West company has recommended itself from the best side. It is a reliable manufacturer of a wide range of products for private and public sewerage systems.

The check valves of the leading company are manufactured using innovative technology, the best grades of metal, which provide high quality products with the appropriate level of reliability and durability. The price of a 110 mm sewer check valve averages 700-900 rubles.

Stop valves of the German manufacturer VIEGA are in great demand. The company manufactures a wide range of check valves in various designs. Products are predominantly manufactured from high quality polypropylene with high operating pressure and temperature thresholds. Therefore, shut-off valves can be used not only for gravity, but also for a pressure sewer network. The cost of production starts from 1500 rubles.

Stop valves of the Polish brand Capricorn are no less popular in the domestic market. The company offers petal and lift type check valves. For the manufacture of products, high quality polyethylene is used, which provides the device with reliability and durability. You can buy a check valve for a 110 mm sewer pipe for 1000 rubles.

Installing a check valve on the sewer network is the key to the normal and smooth operation of the system. This will exclude the occurrence of an emergency in the event of a reverse flow of fecal masses when the collector is clogged.