A lathe is needed for the manufacture and processing of metal parts. Professional equipment is quite expensive, so in order to save money, you can make a homemade metal lathe with your own hands. This can be done in several ways, and drawings of such a product are easily found on the Internet. You can use improvised materials for manufacturing, the size of the machine can be any.

Content [Hide]

- 1 Do-it-yourself mini-lathe components

- 2 Homemade metal lathe with your own hands: assembly procedure

- 3 Choosing an electric motor for the machine

- 4 Making a lathe from a drill with your own hands

- 5 Features of the work of lathes for metal with their own hands, video instructions as a way to avoid mistakes

- 6 Safety precautions when working with a homemade lathe

- 7 Options for upgrading a homemade lathe

Do-it-yourself mini-lathe components

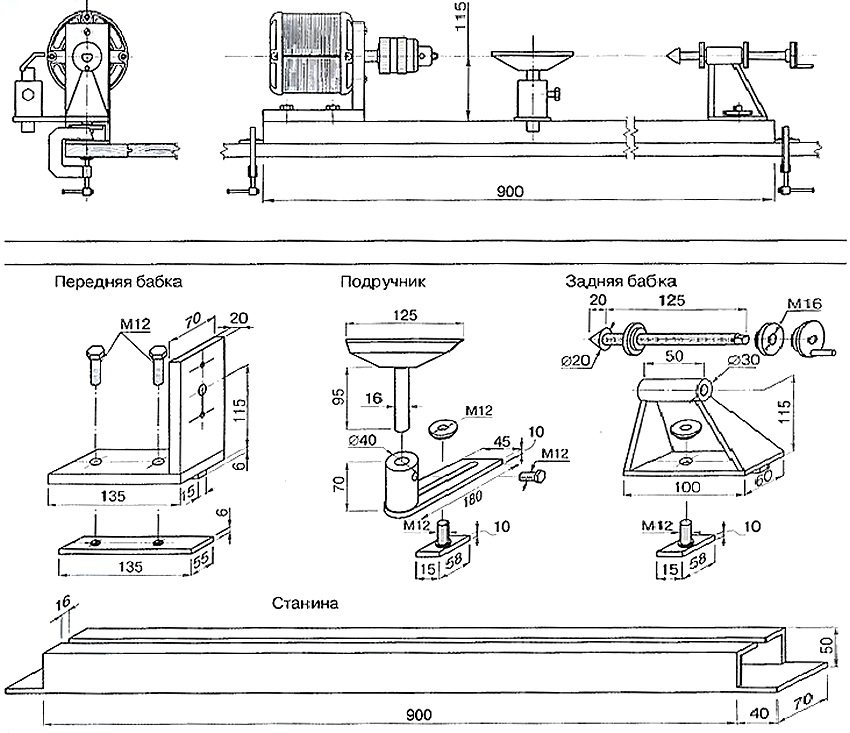

Any homemade lathe consists of the following elements:

- drive - the main part of the mechanism, which is responsible for its power. Choosing a drive with the required power is one of the most difficult tasks. In small lathes for metal with your own hands, you can use a drive from an ordinary washing machine or drill. Usually, the power of this element starts from 200 W, and the number of revolutions per minute - from 1500;

- frame - the supporting frame of the structure, which can be made of wooden blocks or steel angle. The bed must be characterized by high strength, otherwise the entire structure may fall apart from vibrations during operation;

- tailstock - made of a steel plate and a steel angle welded to it. The plate rests against the guides of the bed, and the main purpose of the tailstock of the lathe with your own hands is to fix the metal part during processing;

- headstock - a part similar to the tailstock, but mounted on a movable frame;

- master and slave centers;

- support - a thrust mechanism for the working part.

The torque from the engine to the working part of the machine can be transmitted in several ways. Someone prefers to directly install the working part on the motor shaft - this saves space and saves on spare parts. If this option is not possible, the torque can be transmitted using a friction, belt or chain drive. Each of these options has advantages and disadvantages.

The belt drive for the electric motor is the cheapest and is characterized by a fairly high level of reliability.For its manufacture, you can use a belt for an electric motor, removed from any other mechanism. The disadvantage of a belt drive is that over time, the belt can wear out and will have to be changed the more often the more intensively you work with the machine.

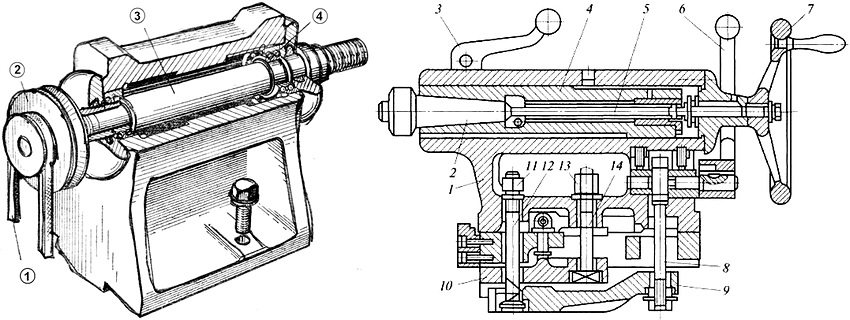

The device of the headstock and tailstock of the lathe. Headstock (left): 1 - V-belt; 2 - two-stage pulley; 3 - spindle; 4 - ball bearing. Tailstock (right): 1 - body; 2 - center; 3, 6 - handles; 4 - quill; 5, 12, 14 - screws; 7 - flywheel; 8 - thrust; 9, 10 - levers; 13 - nut

A chain drive is more expensive and takes up more space, but it will also last much longer than a belt drive. Friction transmission has intermediate characteristics between belt and chain.

Helpful advice! When assembling the lathe, select the gear type that best suits your application. For example, for a mini-lathe with your own hands, it is better to install the working part directly on the shaft.

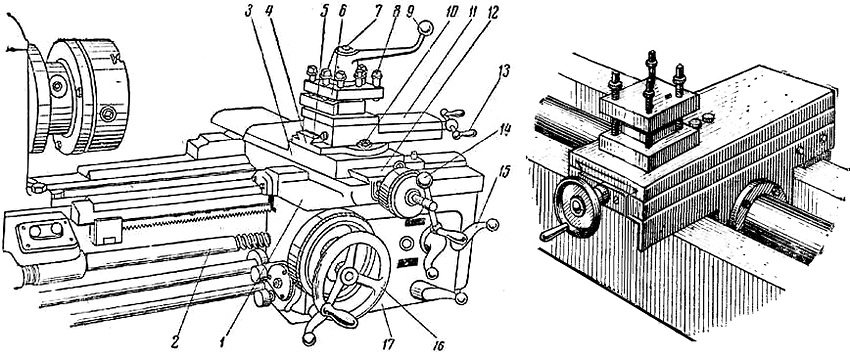

Diy lathe support: drawings, how to make from scrap materials

The caliper is one of the most important parts of a homemade lathe - the quality of the future part depends on it, as well as the amount of time and effort that you will spend on its manufacture. This part is located on a special slide that moves along the guides located on the bed. The caliper can move in three directions:

- longitudinal - the working part of the machine moves along the workpiece. Longitudinal motion is used to grind a thread in a part or to remove a layer of material from the surface of a metal workpiece;

- transverse - movement perpendicular to the workpiece axis. Used to grind grooves and holes;

- inclined - movement at different angles to grind grooves on the surface of the workpiece.

When making a do-it-yourself lathe caliper, it is worth considering the moment that this part is subject to wear as a result of vibrations arising during operation. Because of them, the fasteners loosen, a backlash occurs, all this affects the quality of the part being manufactured. In order to avoid such problems, the caliper must be regularly adjusted and adjusted.

Do-it-yourself adjustment of a self-made caliper for a lathe is carried out according to clearances, backlash and oil seals. Clearance adjustment is needed when the screw is worn out, which is responsible for moving the part in the longitudinal and transverse planes. As a result of friction, the caliper begins to loosen under loads, which significantly reduces the accuracy of the part. You can eliminate gaps by inserting wedges between the rails and the carriage. The backlash of the part is eliminated with the fixing screw.

If the oil seals in your machine are worn out, they should be thoroughly rinsed and soaked in fresh engine oil. In case of critical wear, it is better to completely replace the oil seals with new ones.

Support device: 1 - support carriage; 2 - lead screw; 3 - cross slide of the support; 4 - the rotary part of the support; 5 - guides of the turning part; 6 - tool holder; 7 - screw for fixing the tool holder; 8 - screws for fixing the cutters; 9 - handle for turning the tool holder; 10 - nuts; 11 - the upper part of the support; 12 - transverse guides of the carriage; 13 - handle for moving the upper part of the support; 14 - handle for moving the cross slide; 15 - handle for turning on the caliper feed from the lead screw; 16 - handwheel for longitudinal movement of the support; 17 - apron

Homemade metal lathe with your own hands: assembly procedure

The assembly of the mechanism is performed in the following order:

- The frame of the machine is assembled from metal beams and channels. If you are going to work with large parts, then the materials for assembling the frame must be used with the expectation of a large load.For example, if you plan to work with metal workpieces over 50 mm long, the thickness of the materials for the frame should start from 3 mm for the corners and from 30 mm for the rods.

- Longitudinal shafts with guides are installed on channels. The shafts can be welded or bolted.

- The headstock is being manufactured. To make the headstock of a lathe with your own hands, a hydraulic cylinder with a wall thickness of 6 mm is used. Two bearings must be pressed into the cylinder.

- The shaft is being laid. For this, bearings with a large bore are used.

- The hydraulic cylinder is filled with lubricant.

- A pulley and a caliper with guides are installed.

- The electric drive is being mounted.

In addition, according to the drawings of a metal lathe with your own hands, you can see that to increase the stability of the cutting mechanism, a handcuff is made, and a thin strip of metal is fixed on the lower part of the structure. The latter serves to protect the working part of the machine from deformation during operation.

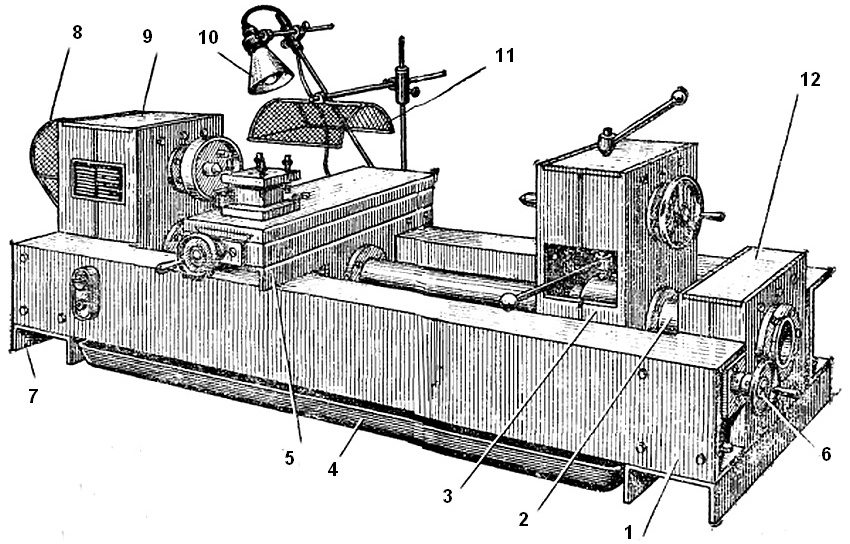

The device of a homemade lathe for metal processing: 1, 7 - channels; 2 - running pipe; 3 - tailstock; 4 - pallet for collecting shavings; 5 - support; 6 - lead screw; 8 - electric motor; 9 - fixed headstock; 10 - lamp in a protective reflector cap; 11 - mesh screen to protect the turner from chips; 12 - support

Helpful advice! A self-assembled metal lathe can be used not only for its intended purpose, but also for grinding and polishing metal parts. For this, a grinding wheel is connected to the electric shaft.

Choosing an electric motor for the machine

The most important part of a homemade metal lathe, the production video of which can be easily found on the Internet, is the electric motor. It is with its help that the movement of the working part of the machine is carried out. Accordingly, the power of the entire structure depends on the power of this mechanism. It is selected depending on the size of the metal blanks with which you plan to work.

If you plan to work on a machine with small parts, a motor with a power of up to 1 kW is quite suitable for this. It can be removed from an old sewing machine or any other similar electrical appliance. To work with large parts, you need an engine with a power of 1.5-2 kW.

When assembling according to ready-made drawings of a homemade metal lathe, keep in mind that all electrical parts of the structure must be reliably insulated. If you do not have the necessary experience with electrical equipment, it is best to seek help with connecting to a specialist. So you will be sure of safe operation and reliability of the design.

Making a lathe from a drill with your own hands

If you want to save on spare parts and greatly simplify the task of assembling a homemade lathe, you can use a regular electric drill as a drive. This constructive solution has a number of advantages:

- The ability to quickly assemble and disassemble the structure - the drill is easily detached from the bed and can be used for its intended purpose.

- Easy to carry and transport the machine is a good option if you have to work with metal workpieces in the garage and outdoors.

- Savings - the drill acts not only as an electric motor, but also eliminates the need to use a gear, and also allows the use of interchangeable nozzles as a working tool.

Of course, there are also downsides to a drill lathe. How to make machining of large parts possible with this tool? This is impracticable as the drill has relatively low torque and high RPM.Of course, you can increase these parameters if you still install a belt drive and, with its help, transfer torque from the drill to the spindle, but this will greatly complicate the design, the main advantage of which is simplicity and compactness.

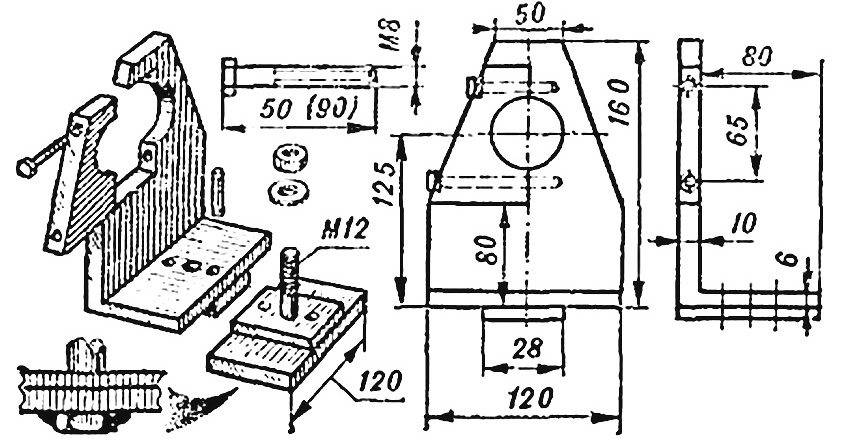

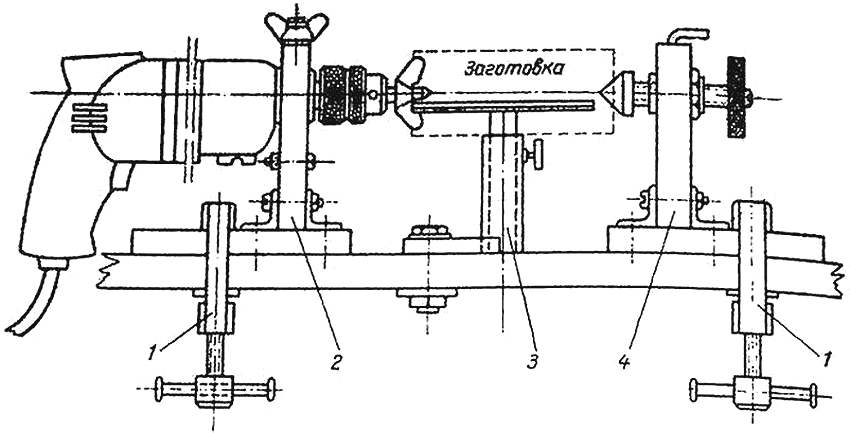

Diagram of the device of a homemade lathe based on a drill: 1 - attachments to the table or workbench; 2 - front support; 3 - support for the workpiece; 4 - back support

Making a homemade desktop metal lathe based on a drill makes sense in cases where you do not need to carry out large-scale work, and only small parts need to be turned.

To make a metal lathe based on an electric drill, you will need the same parts as for a conventional design, with the exception of the electric motor and headstock. The role of the latter is also performed by a drill. Given the compactness of the structure, a regular table or workbench can be used as a bed, on which all the components of the machine will be fixed. The drill itself is fixed in the structure with a clamp and a clamp.

Helpful advice! The functionality of an electric drill-based lathe can be significantly expanded by adding various attachments and additional accessories to its design.

With the help of a homemade lathe, you can not only grind parts, but also apply paint to a rotating workpiece, wind wire onto a transformer, make spiral incisions on the surface of a part, and perform many other actions. In addition, if you assemble a copier attachment for the machine, then with its help you can quickly and effortlessly produce small identical parts.

Features of the work of lathes for metal with their own hands, video instructions as a way to avoid mistakes

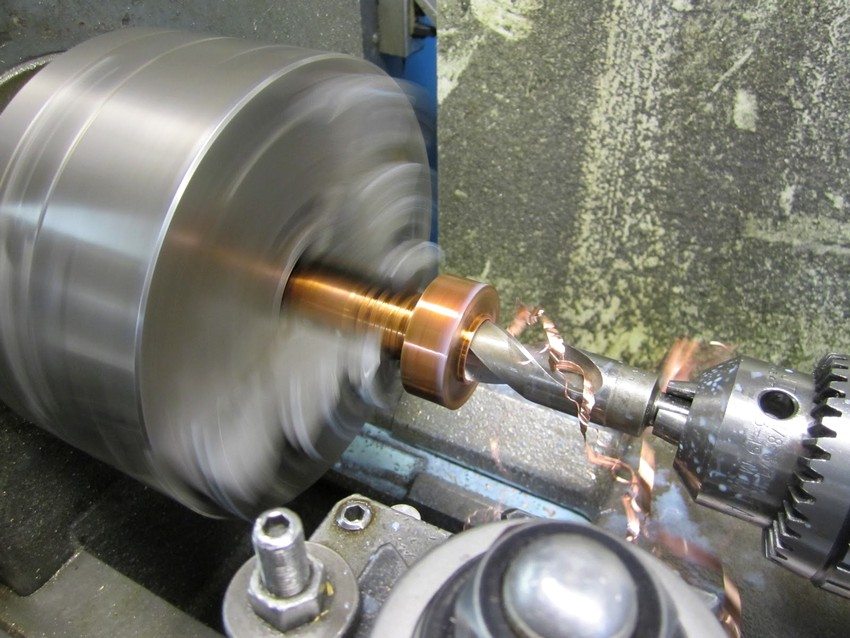

Like any other equipment, homemade lathes have their own characteristics that must be taken into account when assembling and operating. For example, when working with large parts or when using a powerful electric motor, strong vibrations occur, which can lead to serious errors in the processing of the part. To get rid of vibrations, the driving and driven centers of the machine must be installed on the same axis. And if you plan to install only the driving center, a cam mechanism must be attached to it.

In do-it-yourself desktop lathes for metal, it is not recommended to install a collector motor. It is prone to spontaneous increase in the number of revolutions, which can lead to overhang of the part. This, in turn, can lead to work-related injuries or property damage. If, however, you cannot do without installing a collector motor, it is imperative to install a gearbox with it to reduce the speed.

The ideal motor option for a homemade lathe is an asynchronous one. It does not increase the speed during operation, is resistant to heavy loads and allows you to work with metal workpieces with a width of up to 100 mm.

The rules for installing and operating any type of electric motor for a lathe can be viewed in numerous video instructions on the Internet. With their help, you will not only avoid common mistakes during assembly, but also save time and effort thanks to the clarity of the material.

Safety precautions when working with a homemade lathe

When working with the structure, certain safety measures should be observed. So, after assembling the machine, you need to check its performance. The spindle should rotate easily and without delay, and the front and rear centers should be aligned with the common axis. The center of symmetry of the rotating part must coincide with its axis of rotation.

On any video of a lathe with your own hands, you can see that after the installation of the electric motor, it is covered with a special casing. The latter serves not only to protect the machine operator, but also to protect the motor itself from dust, metal particles and dirt. For a machine made on the basis of an electric drill, such a cover is not needed.

Helpful advice! If you are planning to install a structure based on a powerful electric motor, then be sure to make sure that your electrical network has enough power to work with it. At home, it is better to get by with a motor from household appliances, which will definitely work from the voltage in your outlet.

You should also adhere to the following safety rules:

- The working tool must be located parallel to the surface of the workpiece being processed. Otherwise, it may come off and damage the machine.

- If you are machining face planes, the part should rest against the tailstock. In this case, it is very important to observe the alignment, otherwise you risk getting a defective part.

- To protect your eyes from metal shavings and particles, you can build a special shield or just use protective glasses.

- After work, the structure must be cleaned by removing metal filings and other production waste. Make sure that small parts do not fall into the motor.

Options for upgrading a homemade lathe

If you need a mechanism that can not only perform turning work, but also grind and paint a workpiece, the basic machine can be easily modified. It is best to do this for an electric drill-based design, since it is easiest to replace the working part in it.

A lathe can be a multifunctional device in a workshop, with which you can perform various work, including household work: sharpening knives, scissors, etc.

There are several popular modifications of a metal lathe. How to make a tapered hole? To do this, two files must be attached to the base so that they form a trapezoid. After that, a spring mechanism is mounted, which ensures that the files are fed forward and at an angle, which allows you to drill tapered holes in the part.

In addition, a machine with a collapsible base can be made to work with metal parts of different lengths. With the help of several boards or metal corners, you can bring the working tool closer or further to the fasteners holding the part, and also change the size of the gap between the fasteners. It is most convenient to make such a structure on the basis of an ordinary table or workbench.

If you attach a grinding wheel to the electric motor as a working tool, using the machine you can do not only polish the surface of the part, but also sharpen knives, scissors and other household tools. Thus, the lathe turns into a convenient multifunctional mechanism.

Making a lathe with your own hands will allow you to get equipment that is optimally suited to the needs of the owner

Assembling a lathe at home is a fairly simple task, which is further simplified by numerous video instructions and drawings from the Internet. At the same time, the structure can be assembled literally from scrap parts, using old household appliances and waste from assembly and construction production for this.

The main advantage of self-assembly is cost savings. In addition, it is worth noting the ability to independently adjust the dimensions and power of the device in order to adapt it to your needs. Homemade machine can be not only large, but also very miniature, designed for processing small parts.