The stationary circular saw is used for sawing workpieces made of wood, metal or plastic. Such a device is indispensable on a personal plot, in a home workshop, in a carpentry shop. The tool is presented in a wide variety of types: devices with a similar design differ in functionality. The correct choice of the saw will determine the efficiency and durability of its work.

Content [Hide]

- 1 Stationary circular saw: tool device

- 2 Strengths and weaknesses of electric circular saws

- 3 Varieties of circular saws, depending on the design

- 4 Features of hand and table saws

- 5 How to choose a circular saw: basic tool parameters

- 6 Circular saw guide specifications

- 7 How to make a homemade circular machine

- 8 Characteristics of stationary circular saws "Makita"

Stationary circular saw: tool device

The stationary circular plate belongs to the class of joinery equipment. It consists of a body fitted with one or two handles. It is located on a frame-like base with a rigid structure. The working surface is made of cast iron or steel. In some models, it is aluminum.

The presence of a cast iron bed and table top in the circular can significantly reduce the level of vibration

The work surface can be cast or prefabricated. The first option is typical for a powerful circular machine. Such a tool is more stable and has a large weight, as a result of which it will be necessary to arrange a reliable concrete base to place it. In small machines, the table for the circular saw can be assembled, which provides mobility of the installation.

Important! For the convenience of cutting the material, ruler guides are applied on the working surface.

A groove is provided on the surface, which serves for free rotation of the saw blade. In some models, it can tilt, which is possible thanks to the presence of the graduation of the leading sole. This allows cuts to be made at different (fixed) angles. In the inoperative position, the disc is covered with a special casing.

A riving knife is located behind the saw blade, thanks to which the sawn piece of wood does not rejoin, which can happen due to the elasticity of the wood fibers.

Under the tabletop there is an electric motor, from the shaft of which, by means of a pulley, the torque is transmitted to the saw blade. It also uses a belt drive. However, there are models in which the torque is transmitted by a cardan method. The pulley serves as a support for the saw blade, which begins to rotate rapidly around its axis, cutting the material.

Important! The stationary saw cuts the material exclusively in a straight line, without the possibility of curly cutting.

The working surface can be equipped with expanding elements, thanks to which the area of the machine can be increased. The stationary saw is controlled using buttons that are recessed into the control panel. This prevents accidental starting of the unit. Some models are equipped with an emergency switch.

Strengths and weaknesses of electric circular saws

The electric circular saw has distinct advantages over other tool options. The device operates at high speeds, which contributes to a high speed of rotation of the blade and a high-quality cut.

The unit is designed in such a way that its operation is safe. The sawing disc for a circular saw for wood is covered with a special protective cover, as a result of which there is no risk of injury from the sharp teeth of the knife in the inoperative position of the unit.

The stationary frame made of durable material ensures the stability of the equipment. In addition, the vibration of the tool during operation is reduced, which contributes to a significant increase in the quality and accuracy of material processing. Despite the overall dimensions and massiveness of the installation, the circular saw operates with a low noise level, which contributes to the comfortable operation of the device. It also makes it possible to fine tune the instrument.

The circular saw with a table can handle workpieces longer than 1 m. This tool also features a wide range of materials to be processed. The saw can handle wood, chipboard, fiberboard, plywood, plastic and even soft alloy products. For the latter type of material, you will need to use the appropriate disc.

Important! Most stationary models are equipped with a dust collector.

The main disadvantage of a stationary circular saw is the high cost of the tool, which is explained by the high-quality design and the creation of conditions for its safe use.

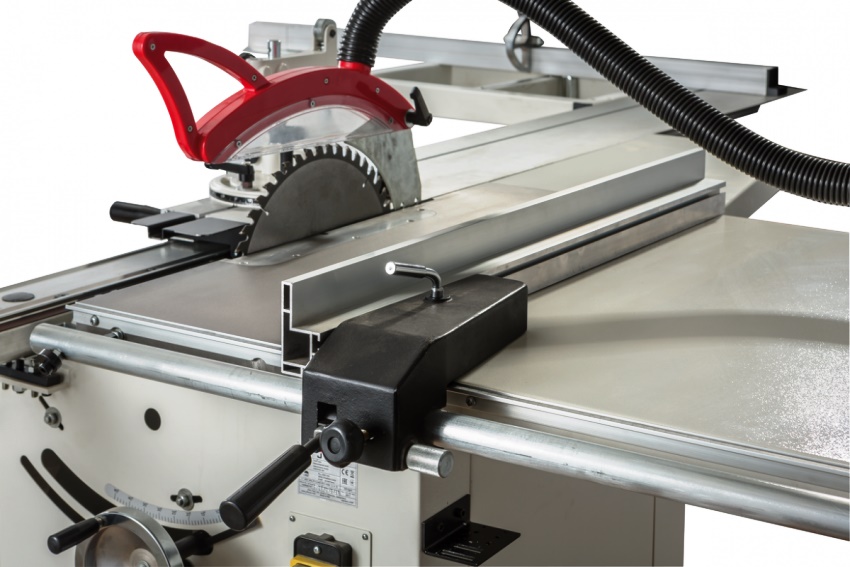

Varieties of circular saws, depending on the design

Circular saws for wood differ in design, which is reflected in the mobility of the tool and the size of the processed products.

To perform a large volume of repetitive circular work, a stationary structure is used. The tool is located on a separate frame, which has impressive dimensions. Such a device requires a separate place for installation with the arrangement of a reliable base. Stationary saws are characterized by high engine power, which allows processing large workpieces.

Stationary circular saws can be heavy or lightweight, depending on the degree of mobility. In the first case, the tool is equipped with a cast base, as a result of which the structure is heavy. These saws allow you to cut to a depth of 14 cm. Lightweight devices are equipped with open beds or removable supports, thanks to which you can transport or move the device.

Some models can be placed on a table.For this, they have a low stand, which contributes to the stability of the structure. These saws can cut up to 5 cm deep.

There is a third type of device, which is represented by a hybrid circular saw. It has a smaller cast frame (compared to heavy saws). Such a tool works with less noise and allows you to process a product up to 75 cm wide. This is the most justified option for a mini-workshop.

Features of hand and table saws

The second type of tool is the table circular mini-saw. It has smaller dimensions than the previous version. This type of device is distinguished by its mobility, the ability to process workpieces up to 60 cm wide. The cutting depth of such a tool is 4-7 cm. The disadvantage of such a tool is the increased level of vibration during operation of the device, which negatively affects the quality of sawing.

A mini circular machine is a hand tool that is characterized by mobility and the ability to process workpieces in different planes. This saw is low power and needs periodic rest. Hand tools have a limited range of jobs.

In addition, the device is characterized by a low level of safety, which is manifested in the proximity of hands to the working surface, incomplete protection of the saw blade, the need to observe not only the cutting process, but also the position of the electric motor in order to reduce the likelihood of skewing of the cut and the recoil of the tool.

The more expensive equipment of this type is a hand-held circular saw with the possibility of stationary installation. The unit body is massive, but safe. The tool has a special platform with which the saw is installed on the machine.

Tool types depending on cutting depth and workpiece material

Depending on the intensity of use, circular saws are classified into subspecies. The tool can be household and professional. The first version of the devices performs an extended range of works, but it can operate continuously for no more than 15 minutes, after which it is necessary to provide a break in the operation of the tool for the same period.

Home appliances are divided into small, medium and large machines. The circular saw of the first type cuts with a depth of 4-4.6 cm, the second - 5-5.5 cm, the third - 6.5-7 cm.

Professional circular saws can work continuously throughout the working day. They are capable of handling materials of different hardness and any size. The cutting depth made with such a tool is 6.5-14 cm.

Depending on the nature of the work and the material of the treated surface, there are stationary circular saws for wood, tools for metal and a submersible type of device. Wood saws cut wood elements at different angles.

The circular saw for metal is a versatile tool that is characterized by increased power and is adapted to work with various cutting blades. These can be standard abrasive options and high strength products. This versatile tool can handle pipes, profiles, metal sheets, wood, plywood and plastic.

The plunge-cut circular saw has a movable saw blade. The cutting edge of the tool is lowered into the center of the workpiece, starting the cut from this point, making through holes.

Important! Thanks to the ability to adjust the depth of cut with high precision, it is possible not only to cut through, but also to make straight or curly grooves, grooves and slots.

How to choose a circular saw: basic tool parameters

Before using a circular saw, you should study its technical parameters, which play an important role in the effective operation of the device. The first is the power of the instrument. It is directly related to the saw blade diameter. The larger it is, the more powerful the unit should be.

The more powerful the engine, the more force will be transmitted to the area where the disc is attached to the shaft. Powerful devices are characterized by more stable operation, they are able to withstand high rotational speeds of the disc, which allows processing of denser materials. Stationary circular saws can have a power of 800 watts.

Useful advice! The higher this indicator, the larger and more massive the tool, when working with which you will need some experience.

The cost of various models of stationary machines, depending on the configuration and equipment, reaches 800 dollars.

The next important criterion to consider when choosing a circular saw is the rotational speed of the blade. The larger it is, the easier it is to work with the instrument. The high rotational speed of the blade facilitates the processing of dense materials, contributes to a cleaner cut line, and reduces the likelihood of the blade jamming in the workpiece.

However, it should be borne in mind that high rotational speed increases the temperature at the cutting point, therefore, when cutting laminate or plastic, the workpieces may have melted edges. For working with such materials, a tool is suitable in which you can adjust the number of revolutions of the disc rotation.

Related article:

Circular do-it-yourself: how to properly assemble a functional device

Scope of application, stages of assembly of the structure. Circular from a grinder and a circular saw. Selection of elements and independent production of devices.

The blade diameter directly affects the cutting depth. A 160 mm product makes a cut with a depth of 4.5-5.5 cm, 190 mm - 6-6.5 cm, 230 mm - 8-8.5 cm. Both parameters affect the choice of the thickness of the workpiece that the tool can process. The higher the blade diameter, the more powerful the saw motor is needed. It should also be borne in mind that the saw can cut at an angle of 90 or 45 degrees. For the latter option, the cutting depth will be shallower.

If the device can adjust the cutting angle, special attention is paid to the quality of the base plate, the graduations located on it and the fasteners. Changing the position of the disc should be easy, while it is necessary to ensure high reliability of fixation, absence of backlash.

Circular saw attachments, its additional features

When choosing a circular saw, it is important to pay attention to the protective equipment with which the tool is equipped.

The spindle must be locked to replace the saw blade. This can be done manually with two keys. A more convenient option is to use a special button, which is available on some models.

For safe use, the circular saw must be equipped with protection against accidental starting. A necessary function that contributes to the convenient and efficient operation of the device is the soft start option, due to which the disc begins to rotate at low speeds, accelerating gradually. This also increases the period of operation of the electric motor, eliminates the formation of large inrush currents when starting.

As noted by numerous reviews, the circular saw, which has the ability to maintain a constant engine speed, provides an even cut in heterogeneous material. The device does not slow down if the disc hits a harder part of the workpiece.

Important! The function of maintaining the speed requires the use of an engine with a certain power reserve.

A necessary function for the normal and long-term operation of the tool is the device overload protection, thanks to which the saw automatically turns off when the device overheats or a sudden power surge.

After stopping the engine, a high inertia of rotation of the disc at idle occurs, which lasts 1-2 minutes, which is quite enough to cause injury. To eliminate this possibility, there is the option of an electrodynamic brake. However, even the presence of such a function is not able to instantly stop the engine, the inertia of which will create a kickback. It is more efficient to use a slip clutch for this.

Useful advice! For professional use, it is better to purchase a universal stationary circular saw with a jointer.

How to choose the right circular saw blade

The choice of a saw blade for a circular saw is primarily determined by the characteristics of the tool. This takes into account the fit and diameter of the element.

Useful advice! A quality saw blade is marked on the surface of the product, which indicates the diameter, fit, number of teeth, kerf width, type of material being processed, speed and direction of rotation of the element.

The purpose of the saw blade determines the number of teeth. A product with a small number of them will provide a high cutting speed, while making a dirty cut. To create a clean cut when sawing hard workpieces, a circular saw blade for wood must have a large number of teeth.

For cutting solid wood and decorative plywood sheets, you should choose products with 50-60 incisors. For sawing wood along the grain, a disc with 15-25 teeth is sufficient. To dissolve the board, you can use a product with 10 incisors. The 40-tooth disc is a versatile option that will suit most applications. Plastics and non-ferrous metals must be processed with a product with more than 60 cutters.

The configuration of the teeth is also important. Straight elements cut quickly and cleanly. For different cutting directions, you can use a disc with alternately beveled cutters. For cutting plastic, plates and non-ferrous metal, it is better to purchase products with flat trapezoidal teeth, which prevent the top layer of the material from splitting.

For workpieces of different hardness, you can use a disc with combined cutters, where elements with different sharpening shapes are combined. They contribute to a sharp cut at high speeds. For cutting laminate, the best solution is to choose a blade with alternating concave and triangular teeth. If the workpiece contains admixtures of cement or nails, an element with flat teeth, equipped with chamfers with wide backs, should be used.

A high-quality disc has a smooth surface with divergent circles visible in the light, which is a consequence of grinding. The product may have radial slots to reduce vibration and noise.

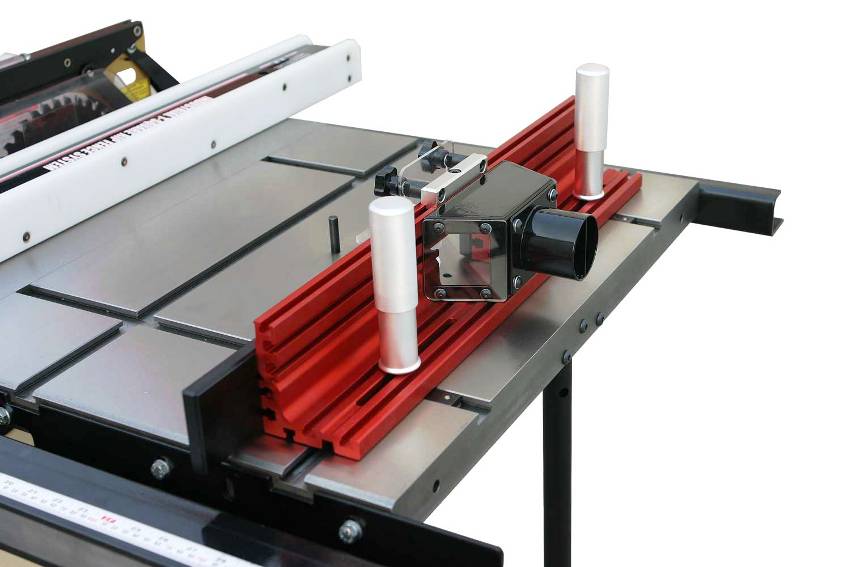

Circular saw guide specifications

To perform correct and accurate processing of the workpiece, an additional attachment for the circular saw in the form of a bar is used. This guide ensures efficient, easy and safe operation of the device. With the help of the tire, you can carry out longitudinal and cross cuts, adjust the parameters of the workpiece to be processed, and make facing of several elements.

Circular saw bars are available in single and double-sided, symmetrical and asymmetrical. There are also non-standard models with which you can process workpieces of complex non-standard configuration.Based on the way of use, guides can be divided into two types: universal and specialized. The first option is suitable for any kind of saws, and the second solves a number of tasks on specific professional equipment. These guides can only work with circular saws.

The tire is made of wood or metal. It can be made in the form of a corner, a rail, a straight bar, or has a U-shaped configuration. The guide is fastened to the base of the unit using bolts and nuts, screws or self-tapping screws.

Important! Before using the guide, you need to check its surface for deformation and test the clamps.

When choosing a guide for a stationary circular saw for wood, it is necessary to take into account the features of the working equipment, as well as the material to be processed. The most popular tires are produced by the German company Bosch and the Japanese company Makita. The domestic manufacturer Interskol has also proven itself well. The guides of these companies are able to ensure the absolute precision of the cut line.

How to make a homemade circular machine

For a homemade machine, a hand-held circular saw with the possibility of stationary installation and a frame with fasteners for its installation are used.

Before performing work, a drawing of the future installation should be created, taking into account the characteristics necessary for the convenient and safe operation of the device. To make a table for a circular saw with your own hands, you can use boards, metal sheet or plywood. It can also be made from a steel angle or wooden blocks. The choice of material is determined by the needs and capabilities of the master.

To ensure the safety of the device during its operation and to prevent possible contact of the worker with rotating parts, it is necessary to make a protective cover. For this, plywood can be used, in which holes are made for air circulation, which helps to cool the electric motor.

A hole is made on the working surface of the table for the saw blade. The hand circular is secured using screws. At the bottom of the table there should be a socket with a wire that is connected to a stationary switch. The cord of the hand tool is inserted into the socket. Such a homemade circular can be installed anywhere.

Characteristics of stationary circular saws "Makita"

The Makita company is very popular among manufacturers of construction tools, whose products are of high quality, practicality and reliability. Circular saws are characterized by a high reserve of power and torque, increased efficiency of power drives, diamond coating of the disk surface, and a complete set of different carbide nozzles.

Makita circular saws feature minimal vibration and noise. The tool is completed with a splitting knife, which protects the dusty disc from jamming in the workpiece.

The Makita SP6000 model opens the rating of circular saws. The power of the device is 1300 W. The model is equipped with a saw blade with a diameter of 165 mm, capable of cutting a depth of 5.5 cm. The device has the option of speed adjustment and smooth start. You can buy the tool for 12 thousand rubles.

The powerful, reliable and convenient circular saw Makita 5704 RK, equipped with a saw blade with a diameter of 190 mm, creating a cut with a depth of 60-65 mm, is popular. The power of the device is 1200 W. The disk rotation speed reaches 5200 rpm. You can buy the tool for 9 thousand rubles.

Among the powerful models that can handle tighter materials, the Makita 5008MG saw stands out. The working disc has a diameter of 210 mm, which allows cutting depths of 70-85 mm. The power of the device is 1800 W, the rotational speed of the disk is 5200 bpm. The saw is capable of cutting at 90 and 45 degrees. Moreover, its depth reaches 57 mm. The model is equipped with additional functions in the form of illumination and air cleaning of sawdust. The cost of the circular machine "Makita" is 15 thousand rubles.

Characteristic features of Interskol circular saws

The best domestic manufacturer of power tools is the Russian company Interskol. It offers a wide range of products at affordable prices. Each model of the manufacturer is characterized by an optimal ratio of price and quality.

One of the best circular saws of this manufacturer is the Interskol DP-190-1600M model. The power of the tool is 1600 W. The device is equipped with a disc with a diameter of 190 mm, which provides a cutting depth of up to 65 mm. This multi-purpose saw can be used to cut natural wood, parquet boards and laminate.

The blade rotates at 4800 rpm for a clean cut line. The model is equipped with a soft start function, protection against engine overheating, and is equipped with a spindle stopper. You can buy a saw for 9.3 thousand rubles.

For domestic use the circular saw "Interskol DP-140/800" with a power of 800 W has proven itself well. The tool is equipped with a saw blade with a diameter of 140 mm, which provides a cutting depth of up to 45 mm. The rotational speed of the cutting element is 4500 rpm. The model is equipped with a spindle stopper. The price of a circular saw is 8 thousand rubles.

The model "Interskol DP-165/1200" is popular. The tool develops a power of 1200 W, engine speed - 4700 rpm. The 165 mm diameter saw blade enables sawing up to 50 mm deep. This tool can cut not only at an angle of 90, but also at 45 degrees. The cost of the instrument is 6.5 thousand rubles.

Popular models of circular saws from other famous brands

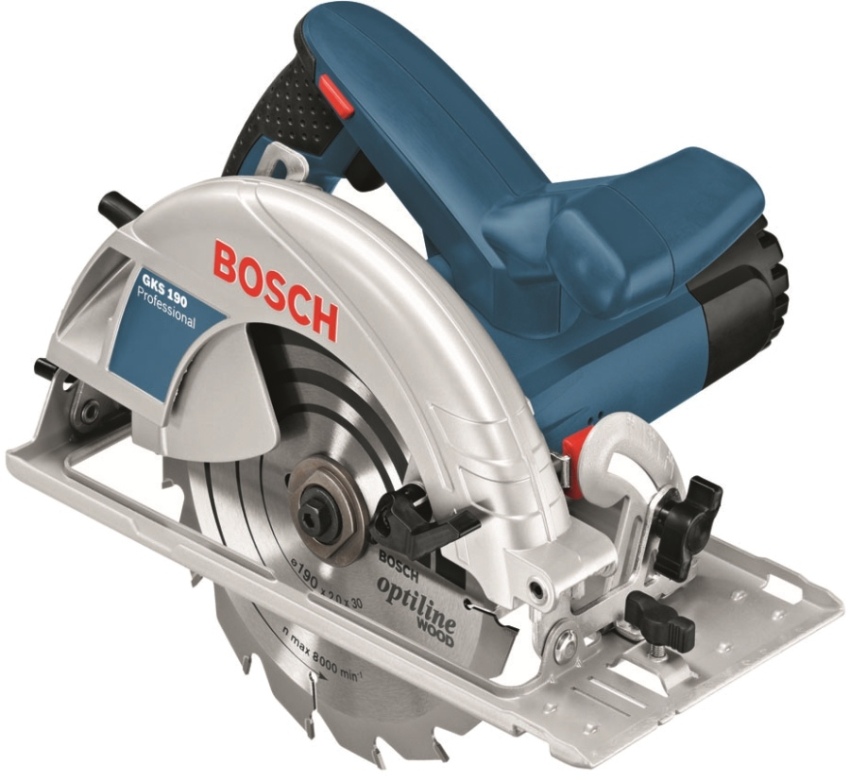

A wide range of quality power tools is offered by Bosch. The products are distinguished by the high quality of the models, their multifunctionality and versatility.

The Bоsch GKS190 circular saw with a power of 1400 W is well-deserved. The saw blade rotates at 5500 rpm for a smooth and clean cut. The cutting element diameter is 190 mm, which creates a cut 70 mm deep. The Bosch circular saw has a motor auto-brake function and is equipped with a dust extraction fitting. You can buy the tool for 15 thousand rubles.

Powerful, efficient and high quality equipment is offered by the Japanese company Hitachi. One of the best practical models is the Hitachi C7SS circular saw, which is suitable for all types of wood. It has a power of 1000 watts. The 165 mm diameter cutting element provides a cutting depth of up to 55 mm. You can buy a Hitachi circular saw for 11 thousand rubles.

The Zubr company is considered to be a direct competitor of the domestic manufacturer Interskol. Circular saws of this brand are characterized by an optimal ratio of price and quality.

A good model is the Zubr ZPD-1600 saw, which is distinguished by its high-quality cutting line and high working speed. The power of the tool is 1600 W. The rotational speed of the working element reaches 4500 rpm. The disc diameter is 185 mm, which provides a cutting depth of up to 65 mm.The model is additionally equipped with a switch-on blocking function, protection against accidental switching on, has a spindle stopper and a connection for a vacuum cleaner. You can buy the tool for 6 thousand rubles.

A powerful and efficient model is the PIT PKS200-C circular saw with a power of 2000 W. The cutting element diameter is 200 mm, which provides a cutting depth of 75-80 mm. The tool can work at an angle of 45 and 90 °. The disc rotation speed of 5500 rpm ensures a clean cut. The cost of the saw starts at 8 thousand rubles.

The circular saw is characterized by its versatility. It is suitable for a wide range of tasks that involve sawing wood, metal and plastic products. When choosing a carpentry tool, the further purpose of the device should be taken into account, for the effective operation of which its technical characteristics must be taken into account.