Not so long ago, various glue solutions and mixtures were replaced by a new modern tool called a glue gun: which one is better to choose for certain purposes, this article will tell you. The publication will acquaint you with its design, principle of operation, advantages and varieties. The device allows not only to reliably glue various surfaces, but also quite convenient in the process of use. This is what will be discussed below.

The scope of application of the glue gun is quite wide: it is used by both builders for repair work and lovers of various crafts

Content [Hide]

What is a glue gun for: features and scope

There is such a thing as a folk instrument. It is to this category that screwdrivers and omnipotent punchers, which have long won the love of consumers, belong. Recently, a hot glue gun can be safely attributed to this list. It does not require special advertising and campaigning, since the users themselves appreciated it and included the subject in their instrumental arsenal. It is popular among both professional builders and housewives, needlewomen.

The price of a hot glue gun is relatively low. Moreover, it has a simple structure and is very convenient to use. At the same time, it is not a basic necessity in household use. At the same time, it can be used to solve a wide variety of tasks, and in some cases the tool is simply irreplaceable.

A gun with glue will make gluing much easier, while its use is not only several times more effective, but also much more economical. Gluing with it occurs literally in a matter of seconds, and with almost any surface. The professional scope of application of the glue gun is very wide: it is used by sellers in retail outlets, warehouse movers, builders for repair work, needlewomen and even children,inventing small masterpieces with their own hands.

A tool such as a hot glue gun is a really necessary thing in many industries and an indispensable assistant in almost any home. At the same time, there are a number of indisputable factors that affect the correct choice of such a universal tool, because each of its subspecies has its own characteristics and properties. Therefore, you need to understand in more detail for what purpose the glue gun is to be used.

What glue gun glues: where professionals and amateurs use it

As mentioned above, the scope of application of the glue gun is very wide, it is able to glue a variety of parts and materials. In particular, with its help, builders connect engineering communications, cover seams, seal joints and glue components. Here, as a rule, a professional glue gun with special nozzles and a thermostat is used.

The glue gun has become an indispensable tool for designers, florists, radio amateurs, home craftsmen and constructors

The tool has become almost indispensable for designers, florists and fans of such a trend as "hand-made". With its help, making various souvenirs, decorative elements and crafts has become much easier.

Useful advice! A postcard made using the polyurethane painting technique with a glue gun will be an excellent and original gift. Balls and beads made of colored or metallized drops look especially beautiful.

Radio amateurs, home craftsmen and designers also did not disregard such an engineering novelty, since the device allows even polyurethane to be melted. In this regard, the tool is of some kind of decorative value, since with its help artists can create elegant frame structures in a grid or depict various subjects with a hot melt pistol. This technique is often used to create postcards, invitation cards, and other festive attributes.

The main advantages of the hot glue gun

The connection created with hot melt glue turns out to be very reliable and is not inferior in strength characteristics to mechanical fastening. The glued parts can only be separated by heating. At the same time, on many surfaces, after removing the adhesive, practically no traces remain, which is impossible in the case of drilling holes or hammering nails.

For example, the use of a pistol is indispensable in the process of paintless elimination of dents on a car body. The technology involves gluing a fungus (piston) into a recess on the front surface of a stamped part, then a special device called a minilifter clings to the piston and pulls out the dent formed on the metal. The fungus is then removed by heating the surface.

Using a hot gun, you can ideally fill voids, seal cracks and joints, and saturate the surface. At the same time, the melt, in comparison with other sealants, even in large quantities, perfectly and completely solidifies to its entire depth within a minimum period - maximum 15 minutes. Although a small amount of glue hardens in 3 minutes.

The glue from the thermo gun does not produce toxic substances, and regardless of the state - cold or hot. The only danger is the possibility of burns and damage to materials that have an increased heat-sensitive surface. The seam on the glued surface perfectly resists moisture. Hot melt glue sticks for a gun can be stored for a long time without losing their properties.

Thus, the tool is safe, easy to use and quite ergonomic, so it can be used in children's applied arts.

What can be glued with a glue gun: interacting materials

With the help of a hot glue gun, various parts and objects are glued almost instantly. This is possible due to the fact that after heating, the molten polymer solidifies literally after 3 minutes. After hardening, the seam becomes as strong as possible, the need for prolonged hardening, as is the case with "liquid nails" or glue "Moment", disappears.

Important! Speaking about the advantages of a glue gun, it should be noted that it is economical, since the price of hot glue, which is sold in the form of silicone rods, is relatively low. It costs about two to three times less than reliable liquid glue of the same volume. At the same time, the glue mass can be dosed as accurately as possible, and a minimum amount of waste is obtained.

Glue gun glue works well with a wide range of materials, which include:

- wood;

- plastic;

- PVC materials;

- glass parts;

- leather;

- metal;

- ceramic parts;

- paper;

- rubber;

- textile.

The glue used in the glue gun perfectly glues wood, plastic, glass, leather, metal, ceramics, paper, rubber, textiles

Hot melt adhesives have poor adhesion to certain minerals such as concrete and plaster. And also, such glue is not always suitable for plastic parts. To get the maximum effect when joining, the surface must be thoroughly cleaned of dirt, dust, oil stains and dried thoroughly.

The temperature factor should be taken into account - this is a kind of limitation, since it is not recommended to use the gun in the production of parts that are deformed under the influence of high temperatures. Metal elements, on the contrary, must be initially heated, using even an ordinary hair dryer, since due to the high thermal conductivity of the base, the composition will quickly cool down and immediately harden.

The structure and material for the manufacture of a hot glue gun

Externally, the thermo gun looks like a hand tool resembling the well-known weapon of the same name, into which not cartridges are inserted, but a polyurethane rod. In the process of heating, the glue turns into a fluid state. The most common diameter of cylindrical rods for a glue gun is 7 mm, but there are also thicker ones - up to 11 mm inclusive. The tool is charged from the back.

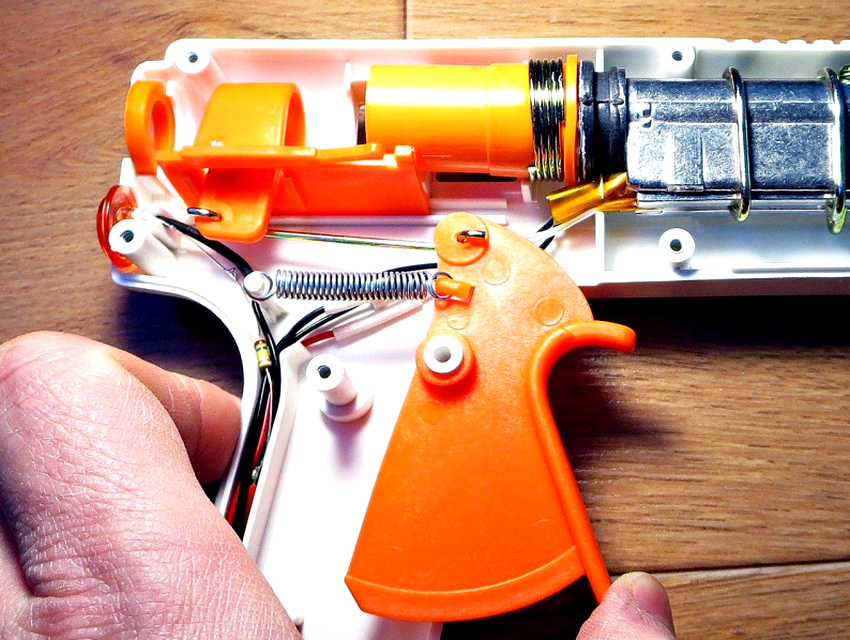

The charge is inserted into the pusher sleeve, then a tubular rubber receiver passes, after which the rod is driven into the chamber, where it heats up and melts, transforming into an adhesive with penetrating ability. For starting heating, 3 to 5 minutes is enough. When the trigger of the spare wheel, which acts as a piston, is pressed, pressure is created on the heating tank, as a result of which melt flows out through the nozzle onto the bonded surface.

The body of the thermo-gun is made of hard plastic, which makes it possible to reduce heat transfer from the heating chamber and ensure the lightness of the product. The average weight of the tool is approximately 300 g. Quite often the handle is equipped with special anti-slip inserts. It is hollow in the middle, the wires are placed here, the carousel trigger is located. The main components of the tool are located in the barrel.

On the Internet, you can find a large number of videos on how to use a glue gun, which, in addition to describing the work process, contains detailed instructions on the structure of the unit and the location of its key parts.

Working Principle of Heating Unit, Feeder and Electric Glue Gun Clutch

The heating chamber (heating unit) is located in the barrel, which is a metal reservoir. Next to it, usually from below, there is a heating element, the so-called heating element. In certain models, there may be several heating chambers, which makes it possible to create a more uniform and stepwise heating. Thus, the thermal assembly is considered the main element, since the service life of the tool depends on it.

Important! The performance of the tool depends on the dimensions of the heating unit and the power of the heating element, which is manifested in the melting rate and the amount of mass ready for work.

The feed mechanism is an annular pusher. It can be additionally equipped with an engaging tooth, triggered by a lever that is combined with a carousel or slide type trigger. The design is quite capricious, therefore breakdowns are not excluded, especially if you try to get a large amount of glue during work. In most cases, the feed mechanism is precisely matched to a specific rod size. Therefore, even minor deviations in diameter can lead to malfunctions.

Considering the design of a silicone gun, mention should be made of the thrust guide sleeve, which is a tubular receiver located directly in front of the heat chamber. Its function is to seal the "reverse direction", which prevents melt from entering the inside of the gun. This part is the weakest link, since rubber ages and cracks over time, and during overheating it can let the material pass through, stopping the moving parts. This leads to damage to the insulation of the wires, which can eventually cause a short circuit.

Features of the structure and functioning of the nozzle of the glue gun

The clutch can be damaged when trying to spin or remove a charged rod. In such cases, it is best to simply cut off a portion of the rod and run the remainder through the nozzle. This part, which is often called a nozzle or nozzle, is designed to shape the mass of glue, dose the flow and close the outlet channel. The nozzle also houses a check valve (aka a spring-loaded ball or nipple) to prevent excessive melt flow.

The nipple does not completely close the nozzle in order to relieve excess pressure in case of overheating of the mass. Therefore, always place a piece of cardboard under the spout. Direct-flow nozzles are also installed, but in this case, more raw materials are lost.

In order to relieve excess pressure, the nipple does not completely cover the nozzle, therefore, always place a cardboard under the spout.

The nozzles are made of metal with a rubber or silicone cover on top to prevent burns.

Many products are equipped with attachments of different shapes and lengths. They are equipped with a thread for connection with a heating unit and open-end wrench slots. It should be noted that it is possible to replace them only in a heating state, since everything is firmly fixed with a frozen glue solution.

An important part of the body is the sight glass, which allows you to check the size of the remaining stem or the presence of leakage from the coupling side. Almost all products are equipped with a folding stand in the front of the case. The price of a glue gun often depends on the presence of a window. For this purpose, the end of the handle is equipped with a special penny. It is not recommended to lay the device on its side during breaks between work, as the case in this position may overheat, which means that the surface on which the tool is installed will be damaged.

Useful advice! Upon completion of work, the nozzle must be thoroughly cleaned of glue.To do this, you should hold them several times on a piece of cardboard.

Many glue guns are equipped with nozzles of different shapes and lengths, but they can only be replaced when heated

Glue gun: which one is better to choose according to technical characteristics

The power of the hot melt gun is determined by the power consumption of the heating unit. The higher it is, the faster the glue melts, although this is not the main thing in terms of performance. In addition, the capacity of the tank must be taken into account. If the heating element provides the temperature required for operation, and the required amount of glue is in the chamber, then the power is selected correctly. A professional glue gun consumes 300 W or more, and for an amateur tool, a power of 30 to 150 W is enough.

There are manufacturers who offer products with automatic power control. For example, a power of 200 W is required for warming up, 40 W is sufficient for operation, and a maximum of 16 W in standby mode.

Related article:

Adhesive for expanded polystyrene for outdoor use: which one to choose

Features, requirements, benefits. Varieties of adhesives, their characteristics and methods of application.

The melting point of the hot melt glue is also important when choosing a gun. To work with paper, textiles and certain polymers, you should choose rods that melt at a temperature of 105 ° C - it is under these conditions that almost all rods begin to melt. At the same time, the majority of pistols are capable of heating up to 170-200 ° C. Therefore, if there is no need for regular use of a pistol, then there is no point in purchasing an expensive copy. The best option is a unit designed for a hot melt temperature of 160-170 ° C.

There is another concept, such as gun speed, although it is more correct to speak of productivity, which indicates the mass of melt that comes out of the nozzle in a certain unit of time. Such information is contained in the passport for the product and can have an indicator from 5 to 30 grams per minute. For example, a lot of glue is required for construction work, so it is better to take rods with a diameter of 11 mm, and a gun with a high performance.

The power of a hot melt gun is the main parameter when choosing a product, the higher it is, the faster the glue melts

Choosing a glue gun according to additional criteria

In deciding which one is better to choose a glue gun, one should be guided not only by its technical characteristics, but also take into account additional options that will help to significantly facilitate the work, making it much more comfortable and productive.

It is worth paying attention to the temperature regulator, which indicates the possibility of using the tool for working with special materials, in particular heat-sensitive ones. If more than three modes are installed, then this is a versatile tool.

If the gun is equipped with electronic temperature control in the "automatic" mode, you should not be afraid of overheating of the unit and significant loss of adhesive material. In this case, the tool itself changes the mode and you need to get used to working with it. At the same time, the "smart" device independently disconnects from the network, thereby preventing overheating, which significantly extends the life of the gun.

Useful advice! When using a hot glue gun, you must adhere to safety rules when working with electricity and adhesives.

You need to pay attention to the temperature controller, if more than three modes are installed on it, then this is a universal glue gun

The ready status indicator in the form of an LED indicates that the device has reached the desired temperature and is ready for use. At the same time, there is no need to fear for the integrity of the mechanism, including the take-up sleeve on the glue gun. Customer reviews indicate that this feature is very useful.

A push-button switch is an added convenience, especially when you need to turn off the power during extended operation. This option is especially useful on devices not equipped with control electronics.

Do I need additional options on the glue gun: user reviews

There are many models that, in addition to the listed set of basic and additional options, also have a number of so-called "bells and whistles" that are needed in certain areas of work with a glue gun. In particular, the correct choice of a glue gun is to some extent influenced by the presence of illumination of the working area, which is carried out using a built-in flashlight. This function is very necessary for working in hard-to-reach places.

You should also pay attention to replaceable nozzles. They decently expand the functionality of the device, since they make it possible to receive a different amount of glue mass, and elongated nozzles help to get into the blind spots.

The nipple in the nozzle, used as an additional part, can significantly reduce the amount of glue emitted from the gun in standby mode, and the viewing window helps to monitor the size of the charged rod and control the integrity of the take-up sleeve.

When choosing a pistol with a stand-leg, you should pay attention to its stability and practicality, which is manifested in the reliability of its fixation in the assembled state. Reliable and high-quality models of glue guns have a fairly wide support area, including a hoof on the handle, and sometimes a trigger.

Actually, you should also pay attention to the construction of the trigger. The most convenient is the mechanism with a rotary trigger, thanks to which it is much easier to monitor the dosage of the melt without applying unnecessary effort.

The most convenient trigger with a rotary mechanism, it allows you to monitor the dosage of the melt

The detachable cord can significantly improve the ergonomics of the instrument, as it allows up to 20 minutes of battery life. The availability of additional options affects the price of the thermo gun.

Features and Specifications of Glue Gun Sticks

Glue sticks, also called spares and stickers, vary in diameter. The most popular options are 7 and 11 mm. They are also classified by shape, length, color, and melting point. Before deciding which glue gun to choose, you need to decide on the type of glue you will have to work with.

Useful advice! For work it is best to use the “native rods” that come with the glue gun.

It should be noted that basically all rods are round in shape, but pistols that operate on oval stocks constitute a separate category. As for the length of the rods, it can fluctuate in the range of 4-20 cm. It is worth considering that this criterion does not affect the final result, it is just that long stickers will not have to be changed often during the work. The price of glue for a hot gun does not depend on this factor either.

There are colored glue sticks that serve to mask the seams. The most common colors, besides the classic transparent, are blue, yellow, red, white and black. In addition, manufacturers use color coding to determine the purpose of stickers, where transparent is universal, black is intended for sealing, and yellow is for gluing glass products.

Rods are also distinguished by their melting point, although this factor does not affect the choice of the pistol itself. A sticker with a low thermal value will simply melt faster in a gun warming up to 200 ° C.At the same time, high-temperature rods melting at temperatures of 150 ° C and higher are not suitable for pistols with low heat. Such rods are more expensive, respectively, and the price of a hot melt gun is higher.

The chemical composition of gun glue and its features

One of the main differences in hot melt glue, in addition to color, size and melting point, is its chemical composition. Half of the rods are made of thermoplastic polymers, the rest is resins and plasticizers. It should be noted that in terms of its composition, hot melt glue is practically harmless, since it does not contain harmful chemicals and organic solvents. The most common blends are based on ethylene vinyl acetate and polyamide. Varieties of glue for a gun in composition:

- Ethylene vinyl acetate (EVA) adhesives are the most popular, as they are of good quality, and the price of gun glue is quite acceptable. They are produced in the form of rods with which you can glue any household products, use them during repairs and even at a construction site.

- Polyamide (PA-adhesives) are used for gluing materials that require increased strength and can be exposed to both very low and high temperatures - from -35 to +135 ° C. Compounds based on polyamides are resistant to the effects of water, mineral and vegetable oils.

- Polyolefin adhesives have high adhesion properties, so they are economical in consumption, while having great flexibility compared to other types of hot melt adhesives.

- Resin-based polyester adhesives allow reliable bonding of fiberglass parts, metal to glass, foil to cork and asbestos to various metals.

- Adhesives based on synthetic rubber, after drying, retain a certain stickiness without losing heat resistance. They have good elasticity and moisture resistance.

- Amorphous polyalphaolefin (as solid thermoplastic polyester) has good adhesion to all surfaces except Teflon. It is especially widely used in the automotive industry.

- Reactive polyurethane in the glue after polymerization forms a high-strength film, but it hardens for a long time.

How much does a glue gun cost: model rating

The range of hot glue guns is very wide. Having studied the characteristics described above, it remains only to choose the desired model. The tool itself has a simple design, so the price of a simple type of glue gun is quite affordable - from 7 to $ 10. For that kind of money, you can purchase a functional device, but devoid of additional options. If you wish and have minimal engineering skills, you can build such a glue gun with your own hands.

A professional tool of a brand manufacturer is much more expensive - from 40 to $ 50, but it will open up wide opportunities for its owner for gluing a wide variety of materials.

Many companies specialize in the manufacture of glue guns. One of the most popular models is the Zubr 06850-60-12 glue gun. It is a compact unit with an anti-drip valve. For it are suitable eleven-millimeter rods 30 cm long. Power consumption - 60 watts. The device is equipped with a special valve that prevents drops from falling onto the workpiece, and the silicone pad protects the user's hands from burns.

Quite a big difference in cost between professional tools and glue guns for needlework. The price of an inexpensive device suitable for performing these tasks can start from 50 rubles. A striking example of this is the Fix Price glue gun.

It weighs less than 100 g and is perhaps the smallest instrument in its class. The device has only 2 advantages - a low price and a compact size that is suitable for women and children. The disadvantages of this unit are much more, the main ones are the low quality of components and a short service life.

Thus, when choosing a glue gun, you should be guided by various functional and technical characteristics of the product, and not just personal preferences. Feedback from consumers and professionals will also be helpful.