It is difficult to imagine comfortable living conditions without hot water. But there are many complaints about the work of the water supply. Hot water is often supplied to apartments in multi-storey buildings in large cities intermittently. In this case, an indirect heating boiler will help out: the principle of operation of this unit is quite simple, and it is possible to create it even with your own hands. But right away it must be said: what, such equipment provides for connection to the heating system.

An indirect heating boiler allows you to save on electricity using the heat carrier of the heating system

Content [Hide]

- 1 What is an indirect heating boiler and what is it for

- 2 Connecting a storage boiler to a gas boiler

- 3 DIY indirect heating boiler

- 4 Heat accumulator for heating boilers: device features and connections

- 5 How to buy an indirect heating boiler correctly: recommendations and popular models

- 5.1 Characteristics of the indirect heating boiler Proterm 200 liters Protherm B200S

- 5.2 Characteristics of Dražice indirect heating boiler

- 5.3 Technical characteristics of the ACV indirect heating boiler

- 5.4 Water heater Gorenje GBK80ORRNB6

- 5.5 Features of the water heater Bosch SK 400-3 ZB

- 5.6 Features of the BOSCH WSTB 160 model

- 5.7 Features of the indirect heating boiler Baxi

- 5.8 Features of the Hajdu STA 400 C indirect heating boiler

What is an indirect heating boiler and what is it for

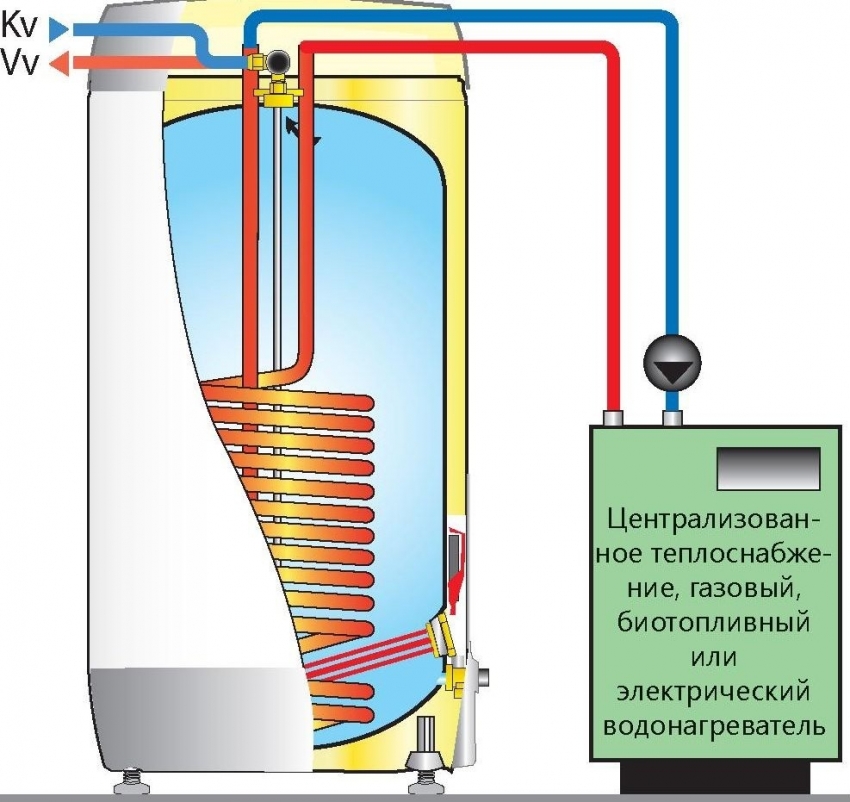

A boiler is usually called a heater or a tank that supplies an apartment or house with hot water. In general, there are 2 types of such units: direct and indirect heating. The main difference of the latest version of the water heater is that this boiler generates heat produced by the heating system. The appearance of the indirect heating tank is associated with a barrel. But on the modern market, you can find models that have the shape of a cube or parallelepiped. The former, being made with an indirect heating boiler in the same style, are usually installed directly under it. This solution saves space in the utility room.

Indirect heating boiler: working principle

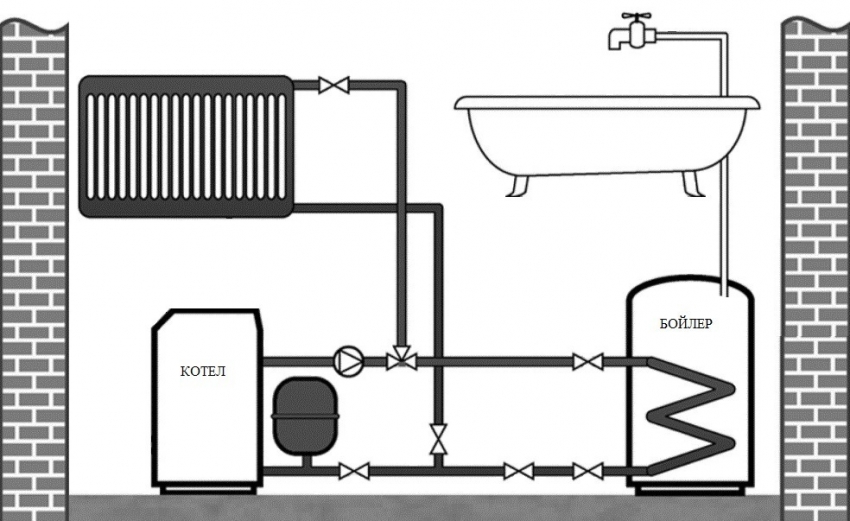

Water is supplied to the unit for 2 circuits.The first is the heating one, which is connected to the heating system of the dwelling. In the second, water is heated, coming from the water supply and subsequently distributed to the points of water intake.

Heating circuits are realized in the considered unit by two methods:

- "Tank in tank". From the name it is clear that this is such an indirect heating boiler, the design of which provides for the formation of a circuit by placing a steel container of a smaller size in the main tank;

- a coil is mounted in the main tank.

Both circuits are connected in parallel to the residential heating system. The coolant flows from it into the boiler through a pipeline. To organize effective circulation of the coolant, such a pipeline must be equipped with a pump-mixing system.

Helpful advice! When buying a boiler for a gas boiler, evaluate the capacity of the last unit. It should be enough to ensure the simultaneous operation of the heating system and the boiler turned on for heating.

Cold water is supplied to the tank for heating, and hot water is taken by consumers. It should be borne in mind that many manufacturers produce such an indirect heating boiler with several heat exchangers. This design works more efficiently, but it is extremely rare on the market.

Pros and cons of an indirect hot water boiler

The advantages of the technical solution implemented by this device include:

- during the heating season, the wiring is not overloaded, since the device does not operate from the mains;

- both the coolant and the internal system of the heater do not come into contact with tap water. It follows that such an indirect heating boiler will last a long time;

- hot water will begin to flow into the tap immediately after starting the unit, because its operation is based on the recirculation process;

- A well-designed water heating system based on this device will work efficiently at an optimal cost during the operation stage.

But there are some drawbacks here. Among those experts distinguish:

- the installation of an indirect heating boiler with recirculation requires significant preparatory work that requires considerable financial costs, which will negatively affect the family budget;

- a boiler of this type costs much more than electric or gas counterparts;

- the initial heating of water takes about 1-2 hours. During this period of time, the quality of the heating system may deteriorate markedly;

- Having bought a 100-liter indirect heating boiler at an affordable price, you will have to allocate a separate room for its installation. The fact is that even with a seemingly not such a large volume of internal capacity, the external dimensions of such a device are very impressive. Not to mention the 200-liter indirect heating boiler. But the industry even produces 300-liter samples;

One of the disadvantages of using an indirect heating boiler is the possibility of reducing the efficiency of the heating system.

- providing the home with hot water depends on whether the heating system is currently working. But for obvious reasons, there is no need for it in the summer season. There are two ways out of this situation: installation of an individual heating agent supply system serving only the boiler, or installation of a combined indirect heating boiler with electric heating element.

Let us dwell on the last option in more detail. The most inexpensive and for this reason has become traditional in the boiler is a copper heating element. However, due to the intensive formation of scale at high temperatures in hard water, it quickly breaks down. In addition, these deposits reduce the degree of heat transfer from the heating element, as a result of which the power consumption increases.

Helpful advice! Purchase of a combined indirect heating boiler with "dry" heating element will save on paying electricity bills.

Connecting an indirect heating boiler is an interference with heating and water supply systems, therefore, before deciding on the purchase of a device, it is worth consulting with specialists

Such an electric heating element is made of ceramic. And they called the heating element "dry" because it is enclosed in a steel flask. That is, there is no direct contact with water, and, accordingly, no scale is formed. The presence of such a frame leads to an increase in the heat transfer area and to a decrease in the intensity of cooling. That is why less electricity is required for the operation of a combined heating boiler with a "dry" heating element.

Connecting a storage boiler to a gas boiler

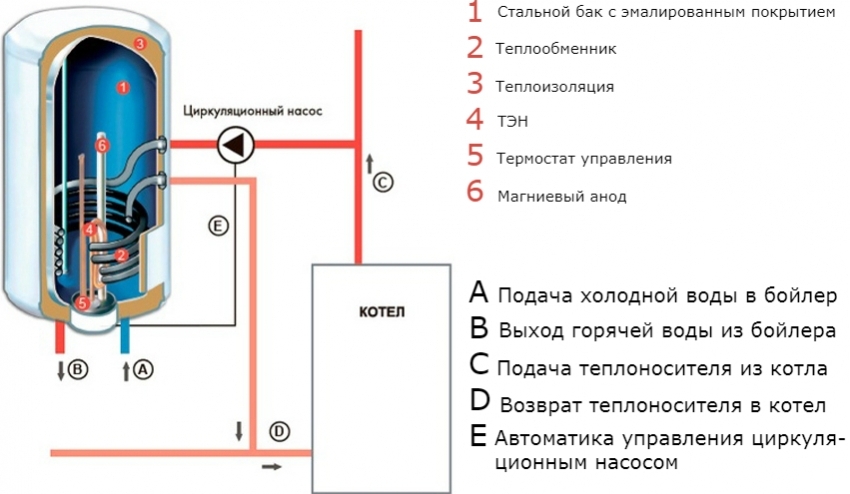

It is possible to heat water in the unit under consideration using a gas or solid fuel boiler, solar water heater or heat pump. Moreover, its operation is possible in conjunction with heating equipment of two types: single and double-circuit.

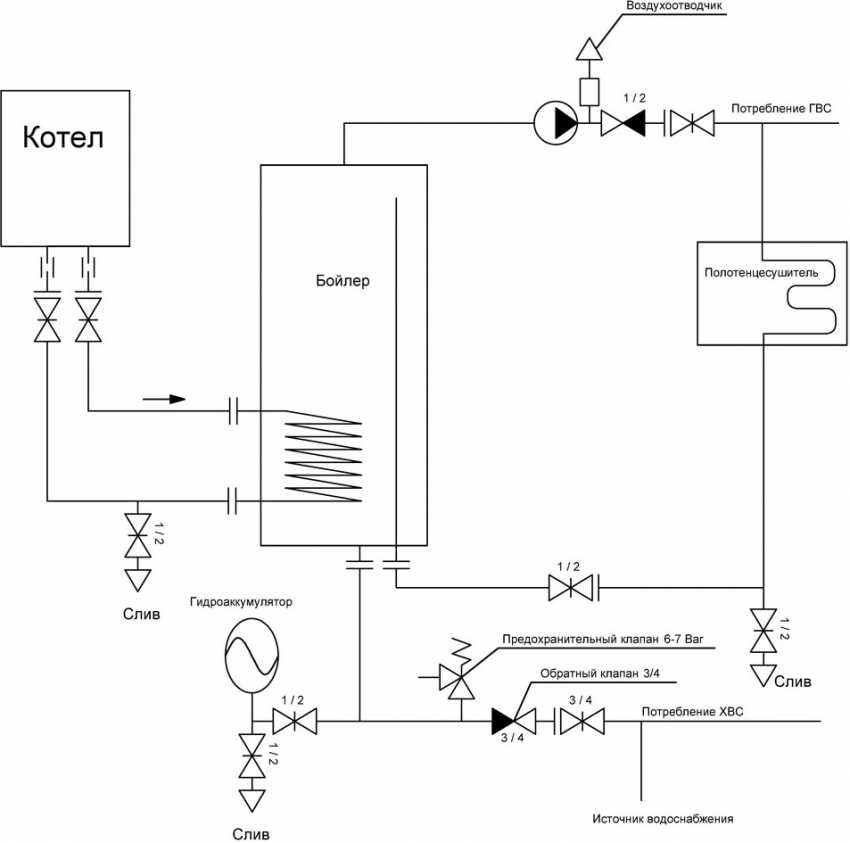

According to the standard piping scheme for an indirect heating boiler, it is connected to the heating system, as well as to the branches of hot and cold water supply. In this case, cold water enters from below, hot water is discharged from the container located on top of the tank, but the recirculation point is located in the middle of the boiler. The direction of movement of the heated coolant is reversed - from top to bottom. That is, from the gas boiler, it enters the water heater branch pipe located on top, and returns to the heating pipeline along the lower branch pipe of the unit.

Thanks to this scheme for connecting an indirect heating boiler, the efficiency of this device increases. After all, heat is first transferred to heated layers of water.

Features of connecting an indirect heating boiler to a double-circuit boiler

In order for the boiler to work successfully in tandem with a heating unit with a hot water circuit, a three-way valve is used. It distributes the heating medium flow between the additional water supply circuit and the main heating circuit.

A thermostat is installed in the indirect storage boiler. It is he who generates the control signals for the three-way valve. When the temperature of the water in the tank drops below a certain level, the valve, on command from the thermostat, will turn on and redirect the flow to the hot water supply branch from the heating pipeline. Signals from the thermostat will return the valve to its original state if the water temperature in the heater exceeds a preset level. The flow of the coolant is then directed to the heating pipeline.

When connecting an indirect heating boiler, you must make sure that all communications are possible and also purchase the necessary pressure sensors

In the warm season, the unit works differently: the flow is not redirected, but the combustion modes of the gas boiler are controlled. When the temperature of the water in the boiler drops, the thermostat sends a corresponding signal to the three-way valve. On this "command", the last device "ignites" the main burner of the heating unit. When the water temperature exceeds a certain value, the gas supply to the burner stops.

Important! When setting the maximum temperature of the water in the tank (it is also the temperature of the automatic activation of the thermostat), the user should take into account that its value should be less than the value of this parameter set for the boiler automation.

The above scheme works most effectively when using gas boilers equipped with automation and a circulation pump. In this case, the heating unit itself can control the valve according to the signal received from the water heater thermostat.Please be aware that when a water heating system is operated with a three-way valve, the priority of the heater circuit is higher than that of the heating circuit.

Diagram of connecting an indirect heating boiler to a single-circuit boiler

To ensure effective joint operation of an indirect heating boiler with a single-circuit gas boiler, a circuit with two circulation pumps is used. This type of connection can actually replace the above described three-way valve circuit. Separation of the coolant flows using pumps through different pipelines is the key feature of this type of connection. The contour priority distribution is the same as in the previous case. However, a higher priority of the water supply circuit over the heating circuit is ensured only through a special setting of the pump activation algorithm.

The alternating activation of the pumps is also controlled by signals from the thermostat installed in the tank. A check valve must be installed in front of each device. The creation of such a piping for an indirect heating boiler prevents mixing of the heat carrier flows.

This scheme works like this: turning on the hot water pump is accompanied by turning off the heating pump. That is, the heating system will begin to cool down. However, a noticeable decrease in the indoor temperature will not be observed for the reason that the heating of water in an indirect heating boiler with a gas boiler will last for a short period of time. The inhabitants of the house will feel this only at the initial start-up.

Sometimes, to create a large area in a building of a comfortable temperature, the owners use several heating units. Then an additional pump is installed in the piping of the storage water heater.

Features of piping for an indirect heating boiler with recirculation

If hot water is not drawn for a long time interval, it will start to cool down. It may take several minutes to wait until the hot stream reaches from the boiler to the final consumer. Reducing the time for draining the cooled water is ensured by using a piping scheme for an indirect heating boiler with recirculation. This is realized by organizing the forced movement of the heated flow through the pipelines closed in a ring.

Helpful advice! When choosing a piping scheme for heating and hot water circuits (with or without recirculation), it is necessary to take into account the characteristics of the heating system, as well as to carry out accurate calculations of the equipment power and the level of demand for hot water.

The recirculation solution provides almost instant hot water delivery to any connected plumbing fixture. It provides that another circuit is installed in the piping of the indirect heating boiler, equipped with its own circulation pump, and additional structural components are installed:

- safety valve (designed to protect the water heater from high pressure);

- automatic air vent (prevents the pump from airing);

- expansion tank (performs the function of pressure compensation in the DHW circuit when the taps are closed);

- check valve (prevents backflow of water in the pipeline).

Related article:

Boilers for water: an overview of the best offers on the market today

Review of the best models and manufacturers. Varieties and rules for choosing a suitable water heater. Draining water from the boiler.

DIY indirect heating boiler

All work consists in assembling the constituent parts of the structure. As an example, we will give the manufacture of a water heater with a coil. The simple principle of operation of this device instills confidence that such an indirect heating boiler can be created independently.

Manufacturing and selection of a storage tank for a storage water heater

In the boiler, a tank is used as a container. The volume of this component of the structure is a value derived from the needs for hot water of the inhabitants of the house. This indicator is calculated taking into account the fact that, according to the norms, about 50-70 liters should fall on one family member per day. Thus, if a family consists of 4 people, you can opt for a 200-liter indirect heating boiler, the price of the components of which will not greatly burden the family budget.

However, it will not be possible to do without serious costs, since the tank for the heating device must be made of expensive aluminum alloys, expensive stainless steel or other corrosion-resistant material, the cost of which is also relatively high. Alternatively, a gas cylinder is also suitable. However, its walls must first be cleaned and primed. Otherwise, the water will smell like gas.

5 holes are made in the tank: 1 at the bottom for connecting the drain cock, another 1 at the bottom for the inlet pipe, 1 at the top for water intake and 2 on the side for installing the coil. Knowing that this indirect heating boiler will have to be operated at the end of the heating season, it is necessary to create conditions for installing the heating element by drilling a hole from the bottom. Having made holes, fix ball-type valves or shut-off elements in them.

The volume of the boiler tank must be selected based on the number of people living in the house and water consumption points

Coil fabrication: materials and process description required

This element performs the function of a heating circuit in the storage boiler. That is, a heat carrier enters it - hot water from the heating system. From contact with the heated surface of the coil, the temperature of the tap water present in the second circuit rises accordingly.

A brass or copper tube is suitable for this component. Its length and diameter are determined by the volume of the tank. For 10 liters, there should be an average of 1.5 kW of heat output produced by the serpentine tube.

Helpful advice! To save money, you can use a metal-plastic tube or the same element made of another metal with good heat transfer.

Spiral the tubing onto the cylindrical mandrel. For this, a pipe or large diameter log is suitable.

When winding a coil, it is necessary to follow the turns, adhering to the following recommendations:

- do not let them touch each other. This will ensure better contact of the coil surface with the heated water;

- excessive effort is not recommended. Then it will not be easy to remove the coil from the mandrel;

- correctly calculate the number of turns based on the height and volume of the tank.

Thermal insulation of the tank and installation of the finished structure

The outer surface of the indirect heating boiler of this modification must be covered with a heat-insulating layer. Such a technical solution will increase the efficiency of the unit and reduce heat losses. To insulate the container, use foam, mineral wool or other heat-insulating material, which can be fixed to the base with strip ties, glue or wire. To make the appearance of the tank attractive, it is better to cover its body with foil insulation or thin sheet metal.

You can also create a prototype of a sandwich construction. This option provides for the installation of the created boiler in a tank with a larger diameter. The cavity formed between the surfaces can be filled with foam or other heat-insulating material, thus forming a kind of thermos.

You can start assembling the structure after preparing all the required parts and following the algorithm of actions:

- mount the coil inside the tank along its walls or in the center. Solder the pipes to both the inlet and outlet pipes of the tank;

- decide how the heater will be installed. There are two options here. Usually, supports are welded to the bottom of floor-standing indirect heating boilers. If you opted for a wall-mounted indirect heating boiler, then solder, or better weld, to the back surface of the hinge (or "ears");

Modern indirect heating boilers are equipped with modern temperature control devices, as well as high-quality thermal insulation, which is difficult to repeat in do-it-yourself boilers

- install the heating element;

- close the boiler tightly with a lid;

- connect the coil to the heating circuit. In doing so, be guided by the standard rules for performing this procedure;

- connect the water inlet and outlet pipes;

- lay the pipes to the bathroom or to the kitchen at the water intake point.

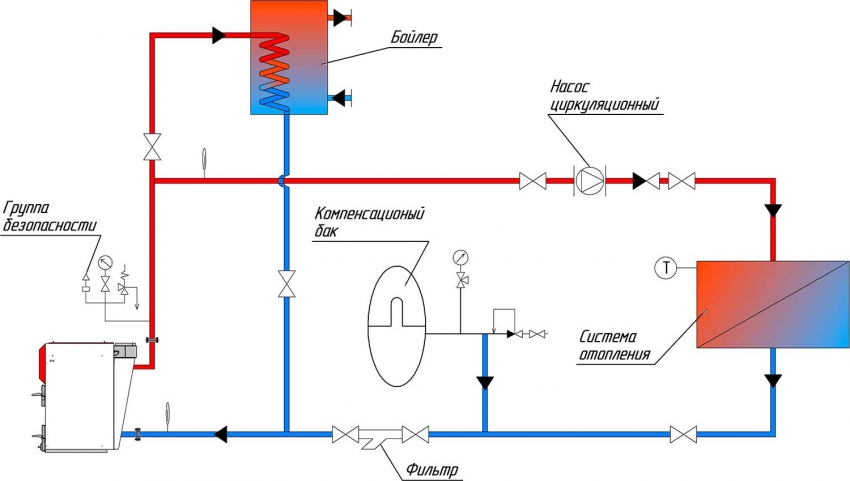

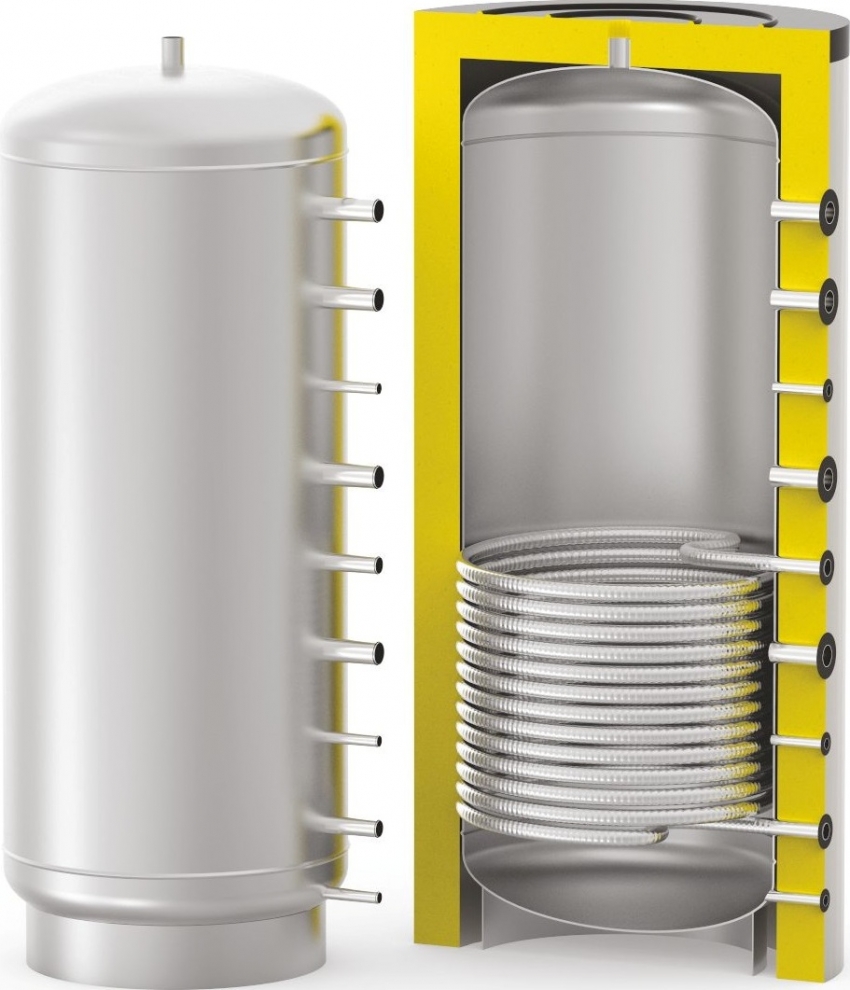

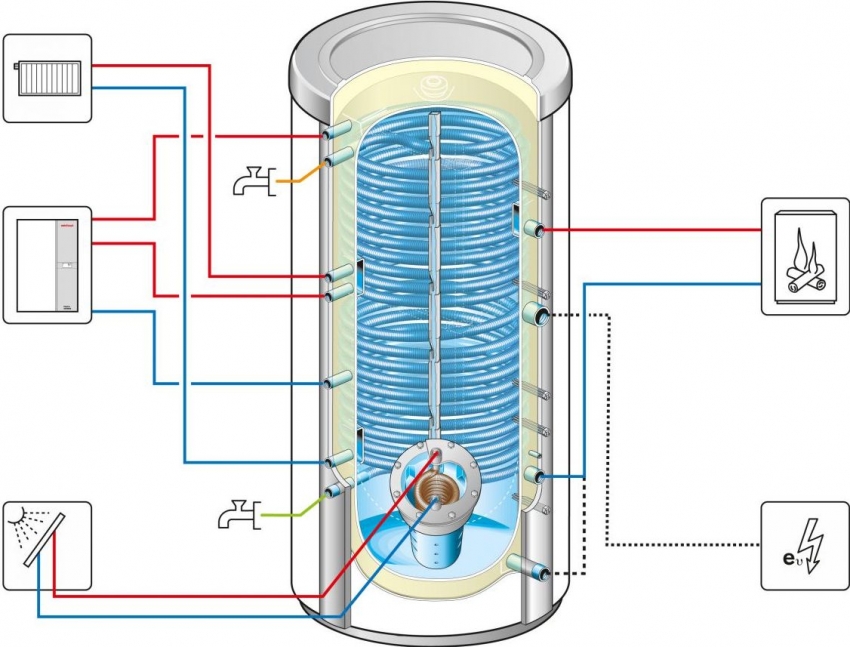

Heat accumulator for heating boilers: device features and connections

The purpose of using this unit is to collect and store the coolant heated to a certain temperature for its further transfer to the system, when the need arises. Being connected to the water circuit of the room, a battery of this type ensures that the temperature is maintained even if the heat source is turned off.

Helpful advice!If the water heating of the house is produced from electricity, the registration of the night tariff with reduced prices for the cost of 1 kW / h. will save on paying bills. The heating system will be sufficiently heated at night, and in the daytime the heat accumulator will work.

This device has other functions as well. The main ones include:

- reduces fuel consumption by almost a third. In this case, the efficiency of the fuel plant increases;

- protects heating devices from overheating, collecting excess heat;

- heats water for the DHW system. That is, in fact, this is one of the types of indirect heating boiler. The price of this unit varies over a very wide range: from 13 to more than 300 thousand rubles;

- heat storage tank can connect several heat sources operating on different types of energy or fuel;

- the design of the device allows the selection of coolant at different temperatures.

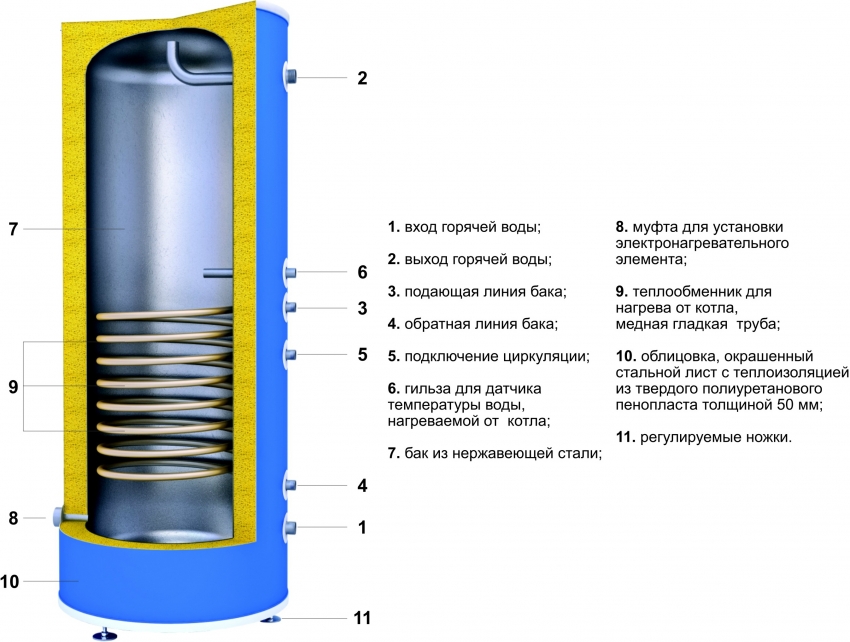

Heat storage device and rational connection of external devices

The main part of this unit is a cylindrical stainless steel tank filled with a liquid characterized by a high heat transfer coefficient. Its strapping is carried out with heat-insulating material. In combination with the installation of an upper jacket, this design solution increases the cooling time of the heat accumulator. Inside the cylindrical tank there are 1 to 3 heat exchangers. The number of coils is determined by the capabilities and needs of the homeowners.

Heated water from solid fuel or gas boilers enters the cavity of the accumulator tank from above, and the cooled liquid settles closer to the bottom and is pumped back into the boiler for heating.

The lower compartment usually has a temperature of the order of 35-40 ° C. Therefore, it is advisable to connect it to the underfloor heating system. The temperature of the middle part is 60-65 ° С. Therefore, heating devices should be connected to it. The upper part of the tank is connected to the hot water supply. The water temperature there reaches 80-85 ° С.

How to buy an indirect heating boiler correctly: recommendations and popular models

When choosing a device to provide a certain object with hot water, its appearance should not be the main criterion. It is necessary to take into account the characteristics that directly affect the operating efficiency of the unit of this type.This concerns, first of all, its volume. Moreover, the peak load on the water heater should be taken into account.

Experts recommend starting from the following values:

- for 1 person, a volume of 50-60 liters will be enough;

- for 2-3 people you will need a boiler with a volume of 80-120 liters;

- for 3-5 people, consider 120 to 200 liter models.

Modern manufacturers offer consumers a wide selection of indirect heating boilers of various sizes and shapes.

The most popular were, judging by the reviews, indirect heating boilers below the brands presented.

Characteristics of the indirect heating boiler Proterm 200 liters Protherm B200S

This unit is insulated with polyurethane foam. The inherent properties of this material keep heat loss to a minimum. The control panel provides an indication of the temperature of the water in the boiler. The titanium anode and enamelled surface provide reliable protection of this water heater against corrosion and scale formation. A twin steel heat exchanger is located at the bottom of the unit. This allows you to significantly increase the supply of hot water and speed up the heating procedure.

Helpful advice! To achieve maximum efficiency of functioning of the indirect heating boiler Proterm of this model, operate it in combination with boilers "Medved" and "Grizzly" stationary type from the same manufacturer from Slovakia.

Below are the main technical characteristics of the Protherm B200S water heater:

| Volume, l | 200 |

| The form | Cylindrical |

| Type of allocation | Outdoor |

| Number of heat exchangers, pieces | 1 |

| Temperature regulator | Mechanical |

| Water temperature (maximum), ° С | 90 |

| Daily energy losses, kW | 2 |

| Weight, kg | 90 |

Characteristics of Dražice indirect heating boiler

If you want to buy an indirect heating boiler 200 liters floor-standing, it is recommended to consider the DRAZICE OKC 200 NTRR model from the Czech manufacturer. This company has been producing such equipment for over 60 years, constantly improving its functionality and design.

The model range includes units that provide significant energy savings. The advantage is the relatively affordable price of an indirect heating boiler 200 liters Drazhice - about 33 thousand rubles, and not to the detriment of the high quality of work and durability. Another plus concerns the question of how to connect the Drazhice indirect heating boiler. There are two options here: to the heating system or to the electricity network.

Technical characteristics of the boiler DRAZICE OKC 200 NTRR:

| Volume, l | 200 |

| The form | Cylindrical |

| Type of allocation | Outdoor |

| Number of heat exchangers | 2 |

| Temperature regulator | Mechanical |

| Water temperature (maximum), ° С | 110 |

| Weight, kg | 108 |

Technical characteristics of the ACV indirect heating boiler

A series of water heaters offered by the Belgian company ACV are durable, reliable, durable, spacious and modern units. To minimize the level of heat losses, the manufacturer paid great attention to thermal insulation. It is made of polyurethane foam - a completely environmentally friendly material, characterized by excellent sound-absorbing properties and a very long service life. The convenience of use is added by the large tank capacity. We are talking about the possibility of purchasing a 300-liter indirect heating boiler from this manufacturer.

Technical characteristics of the ACV SMART SLE 300 unit are presented below:

| Total volume, l | 293 |

| Heat input, kW | 68 |

| Heating time up to 80 ° С, minutes | 22 |

| Productivity when heated to a temperature of 40 ° C, liter / hour | 2100 |

| Empty boiler weight, kg | 87,0 |

The ACV SMART SLE 300 boiler is installed in a dry room with a temperature above zero. In this case, it is necessary to choose the right location for the water heater.

The SMART SLE 300 boiler model from ACV is equipped with high-quality thermal insulation, which reduces heat loss during operation.

Helpful advice! When installing, it is necessary to minimize the length of engineering communications. So, in addition to saving money on the purchase of piping label elements, you can further reduce the level of heat loss. That is, having already figured out how to connect an indirect heating boiler of this model, make sure that the distance of hot water consumption points from the unit is as small as possible.

Water heater Gorenje GBK80ORRNB6

If you are looking for a compact model of a storage water heater capable of supplying hot water to a house where 1-2 people live, experts recommend paying attention to this product from the Slovenian manufacturer Gorenje.

The compact GBK80ORRNB6 boiler has two tubular heat exchangers. Its volume is enough to service two points of water intake. The unit is equipped with an electronic control unit. The DHW temperature varies in the range 15-75 ° C.

The indirect heating boiler from GBK80ORRNB6 has a convenient control panel that allows you to control the water temperature

The function of an additional heater is performed by two "dry" heating elements. Several types of protection are implemented in the model: from heating without water and overheating, from corrosion (a magnesium anode is installed), from freezing (high-quality thermal insulation is implemented).

Another significant advantage of this unit is the presence of the function of controlling legionellosis (a common pulmonary disease, the habitat of pathogens of which is hot water). In general, today it is one of the best solutions in terms of price and quality.

Technical characteristics of the Gorenje GBK80ORRNB6 water heater:

| Volume, l | 72,6 |

| A heating element | 2 coils |

| Accommodation option | Wall |

| Water pressure (maximum), MPa | 0,6 |

| Weight, kg | 51 |

| Overall dimensions, mm | 507×500×803 |

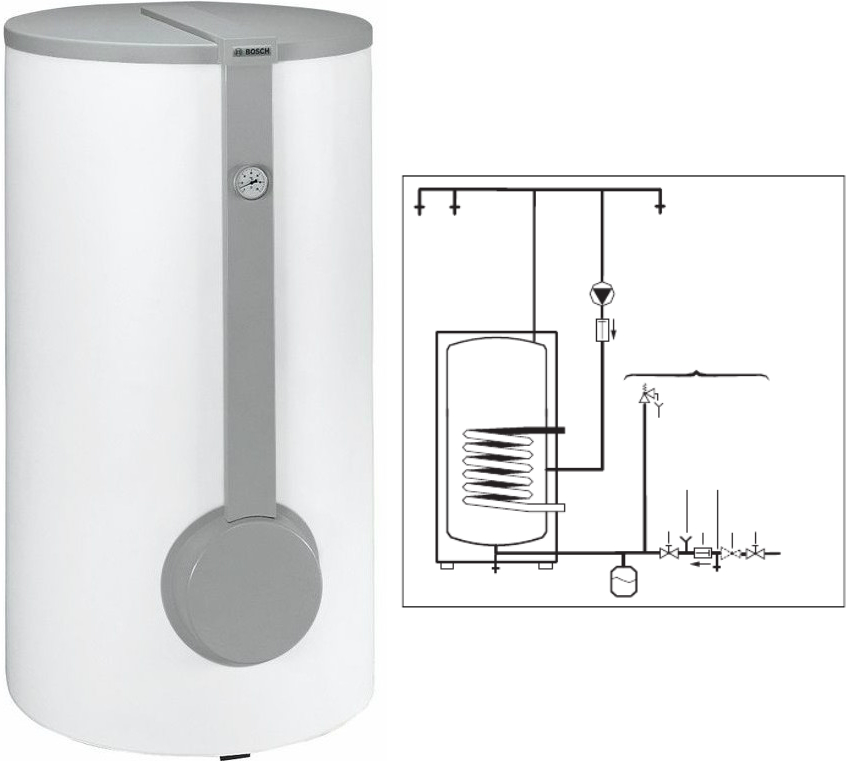

Features of the water heater Bosch SK 400-3 ZB

The results of monitoring the modern market demonstrate the fact that the range of indirect heating boilers produced by the German concern Bosch contains a very limited number of items. Therefore, this model deserves special attention. It is distinguished by its simplicity of design solution.

The Bosch SK 400-3 ZB is an enamelled tank with a stainless steel coil. The use of a magnesium anode for corrosion protection is not surprising either: this method of combating this phenomenon is very often used in equipment of this type. Serviceability is ensured by built-in thermometer and flange.

It is also possible to fine-tune the operation of this model of the water heater by connecting heated water recirculation with subsequent synchronization with the heating boiler. Thermal insulation is made of rigid foam, not polyurethane foam, which, given the same thickness, provides less reliable protection against heat loss.

Technical characteristics of the Bosch SK 400-3 ZB unit:

| power, kWt | 60 |

| Volume, l | 388 |

| Productivity (maximum) in flow mode, l / min., ΔT = 25 ° С | 24,2 |

| A heating element | 1 coil |

| Accommodation option | Floor |

| Water pressure (maximum), MPa | 1 |

| Weight, kg | 150 |

| dimensions | 710×1681 |

| Heating element connection | Impossible |

Features of the BOSCH WSTB 160 model

It is worth thinking about purchasing this water heater if a gas boiler is installed in the home. Although there is no possibility to connect the heating element here, the recirculation system is functioning.

This model is adapted to work in harsh operating conditions in the post-Soviet countries. In addition, the BOSCH WSTB 160 unit is suitable for working with hard water.To protect the steel from corrosion, the surface of the tank is covered with a glass-ceramic compound. In order to reduce heat loss, a polyurethane foam fur coat is used. The lining of the unit is soft, made of polyvinyl chloride. Connection type - front, it is possible to use a temperature sensor. The water is heated to 45 ° C in 37 minutes.

Technical characteristics of the boiler of this model:

| power, kWt | 20,8 |

| Volume, l | 160 |

| Accommodation option | Wall |

| A heating element | 1 coil |

| Water pressure (maximum), MPa | 1 |

| Dimensions, mm | 1193×550 |

| Weight, kg | 42 |

Features of the indirect heating boiler Baxi

Often, the owners of country houses choose a boiler, taking into account, first of all, the heating rate, and not its volume. In this case, you should take a closer look at the product from the BAXI GROUP holding (England), the Premier plus 300 model.

Helpful advice! If the material of manufacture of this unit - enameled steel or stainless steel - is critical for you, pay attention to its series. In the first case, it will be denoted by the sequence of characters "UB", and in the second - "INOX".

The key feature of this water heater is that the heat exchanger has a specific design - “coil within coil”. And it should also be noted that the Baksi indirect heating boiler is compatible with boilers of any type. In addition, this unit is well protected against corrosion. The rather compact dimensions and low weight of this water heater did not become an obstacle to equipping it with an accurate thermal pump.

Another important plus is the versatility of placement. The design of this model makes it possible to use a recirculation loop. In addition, it is possible to connect a heating element (optimal power 2.7 kW).

Technical characteristics of the Premier plus 300 water heater model from BAXI:

| power, kWt | 30 |

| Volume, l | 300 |

| Heating element design | Coil-in-coil |

| Water pressure (maximum), MPa | 0,7 |

| Accommodation options | Floor and wall |

| Heating element connection | maybe |

| Dimensions, mm | 2040×552 |

| Weight, kg | 60 |

Features of the Hajdu STA 400 C indirect heating boiler

A potential buyer may be interested in this model by the possibility of more precise adjustment in the presence of a heat exchanger. For example, at a negative temperature outside, this unit can be rebuilt to work together with the boiler, and in the summer it can be connected to solar collector (when necessary, the heating element is connected).

The tank and the heat exchanger are protected from corrosion by enamel and an installed magnesium anode. The polyurethane foam insulation is protected, in turn, by a plastic casing. A DHW recirculation system can be connected.

Characteristics of the STA 400 C model:

| power, kWt | 69 |

| Volume, l | 400 |

| Productivity (maximum) in flow mode, l / min., ΔT = 35 ° С | 28,3 |

| A heating element | 1 coil |

| Accommodation option | Floor |

| Ode pressure (maximum) | MPa 1 |

| Weight, kg | 145 |

| Dimensions, mm | 1832×670 |

In conclusion, it must be said that the choice and installation of a combined boiler for the home is a responsible and difficult task, which can be solved by reading the connection diagrams, advice and opinion of specialists, as well as feedback from users of such systems.