Traditionally, the cellar is used as a storage for vegetables, fruits and various types of preservation. A plastic cellar, also called a caisson, is an interesting alternative to the traditional storage facility dug in the ground and has a number of characteristics. In addition, the plastic cellar has its own installation features, which should also be taken into account. Ready-made storage models can vary in size and price.

Content [Hide]

Advantages and disadvantages of a plastic cellar

If you do not have the time and opportunity to independently equip a storage for products in a suburban area, then purchasing a ready-made plastic cellar may be an excellent solution. You can buy it directly from the manufacturer or through intermediaries, and the product itself boasts the following advantages:

- the placement of a plastic cellar for a summer cottage from the manufacturer is not affected by such factors as the type of soil, the level of groundwater, the degree of soil freezing and other parameters that can significantly complicate the construction of a traditional cellar with your own hands;

Cellar made of plastic - a ready-made solution for giving

- it is equally easy to install the structure, both in open space and under a residential or utility building;

- plastic caissons for a cellar tolerate negative environmental influences well, for example, temperature drops, high humidity, etc. In addition, with properly equipped ventilation, the quality of food storage in such a cellar will be an order of magnitude higher than in a traditional one;

- when buying a Tingard plastic cellar or another model, you save yourself the need to carry out a large amount of work. For example, no additional finishing of walls and floors is required, insulation of the structure, etc.;

- a ready-made plastic cellar does not absorb odors, reliably protects products from insects, rodents and mold. At the same time, the plastic walls of the structure are very easy to clean, unlike brick or concrete;

- with proper care and proper use, a plastic structure can last about 50 years, which is a very solid period for a cellar.

However, judging by the reviews, plastic cellars are not without drawbacks. The main one is the high cost. Do-it-yourself construction from simpler materials will cost 50% less, but it will take much longer, so in this case you have to choose what is more important to you - time or finances.

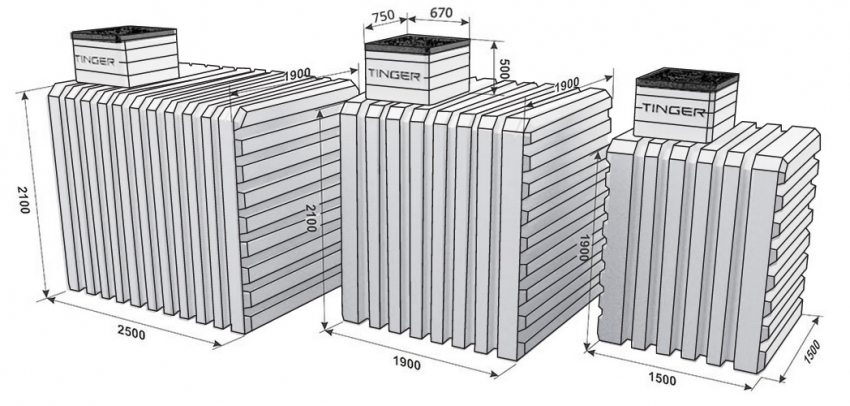

The second notable drawback of plastic storage is its typical size. Choosing a ready-made cellar, you can buy one of several standard options, and the design does not provide for the possibility of increasing the storage volume. Of course, it is always possible to purchase and install several adjacent structures, but this will cost much more than building one large storage facility.

Despite the rather high price of plastic cellars, they are very popular and are mounted on sites of various types.

Note! It is believed that you can use ready-made cellars for high groundwater. In fact, with elevated water levels in the soil, the plastic cellar can squeeze out of the ground. Therefore, in this case, it is better to give preference to the traditional storage or to fix the plastic in a special way.

Turnkey cellar at the dacha: model prices and selection parameters

The price of a plastic cellar for a summer residence depends on parameters such as its size and volume. For example, a cylindrical structure with a volume of 3.5 m³ will cost you about 60-80 thousand rubles, but a cellar with a volume of 9 m³ - 150 thousand. A large rectangular cellar with a volume of 16 cubic meters. will cost about 200-250 thousand rubles. Here it is worthwhile to understand that the price largely depends on the manufacturer, and the cost may also include installation work. By ordering a ready-made version immediately with installation, you significantly save your time and effort.

Also, the price of a plastic caisson for the cellar and the container itself depends on the quality of the materials from which it is made. It is on this parameter that you should first of all pay attention when buying. If you purchase a storage directly from the manufacturer, then it must be accompanied by quality certificates and documents proving that it is absolutely safe to use the cellar. The same documents must be provided by an intermediary when selling a plastic cellar. You will have to buy such a structure at a high price, so you should not neglect this moment.

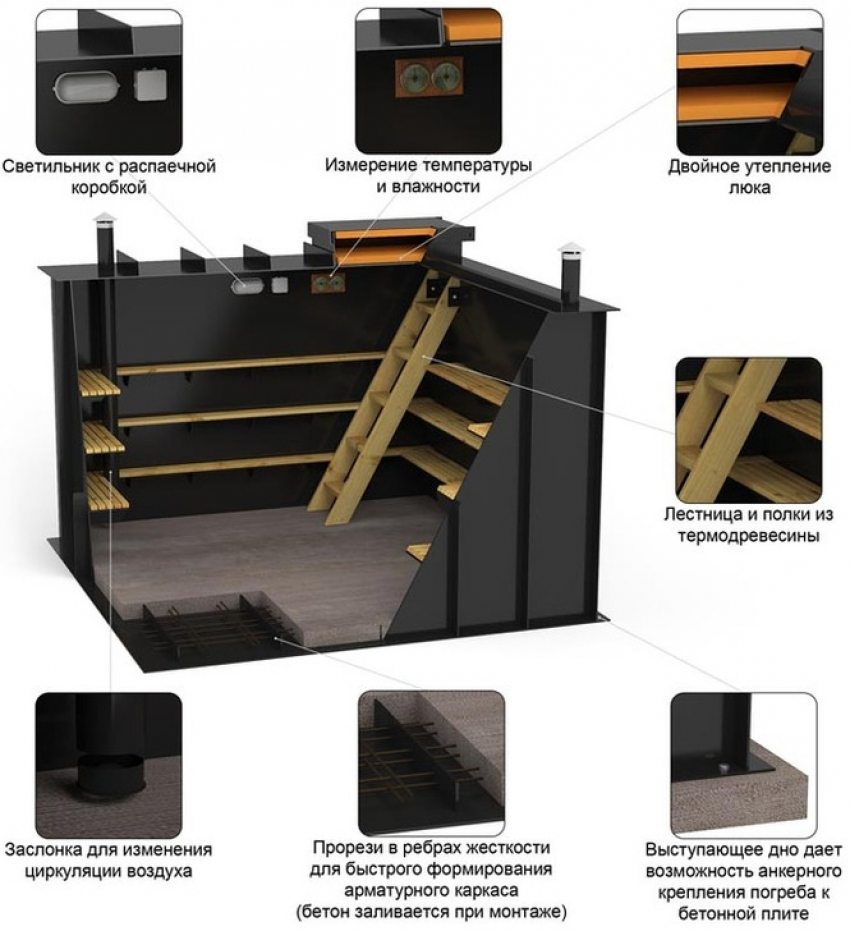

The second important nuance that you need to pay attention to when buying a structure is the ventilation system. It should be a series of pipes and holes that can be modified taking into account the nuances of operation. In most ready-made plastic cellars, in which fresh food is supposed to be stored, a forced ventilation system will have to be made, since the built-in one will not cope with the moisture released.

When buying a ready-made cellar for a summer residence, it is imperative to clarify whether the supplier company is installing the product. This is very important, since the price of a ready-made plastic cellar can be much higher if it includes an installation. It is not so difficult to install the structure with your own hands, but it will take you more time than when specialists will do it.

Installation of a plastic cellar: the price of work and self-installation

If you order the construction of a turnkey cellar, prices can vary in a fairly wide range. It all depends on the complexity of the installation, the size of the storage and the need for additional work. Usually, the price of installing a plastic cellar for a summer residence from the manufacturer starts from 30 thousand rubles, and the installation of a large cellar with a volume of 16 m³ will cost about 150 thousand rubles.

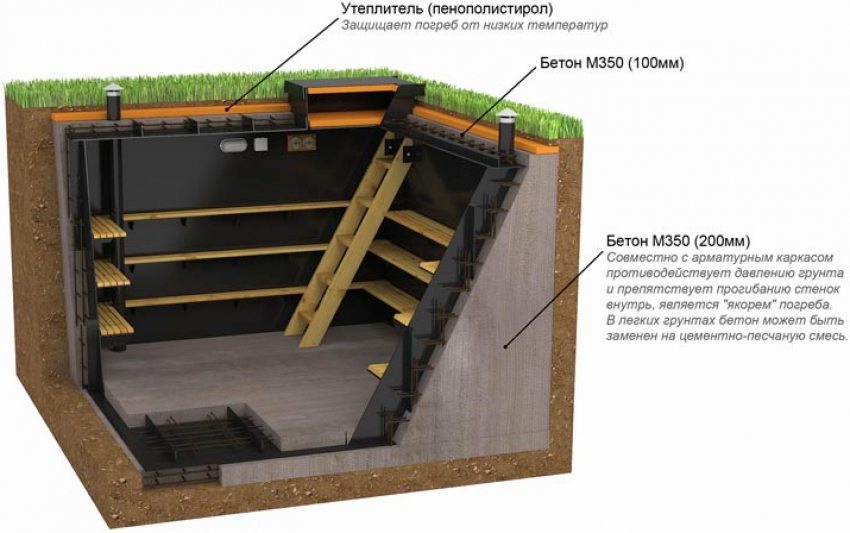

Additional work includes the installation of stairs to the basement, wall insulation or the organization of a groundwater drainage system. In order not to order wall insulation after installation, you can buy a cellar made of plastic with insulation, it will cost a little less.

If you decide to save money and do self-installation, then for this you will need to complete the work described below.

Digging a pit. This can be done manually or using specialized equipment, for example, an excavator. The pit should be slightly larger than the finished product. If, as a result of a high level of groundwater, water begins to accumulate at the bottom of the pit, then this problem can be solved by digging a hole up to 0.5 m deep in its center. The water will drain into the hole, and you can safely continue working.

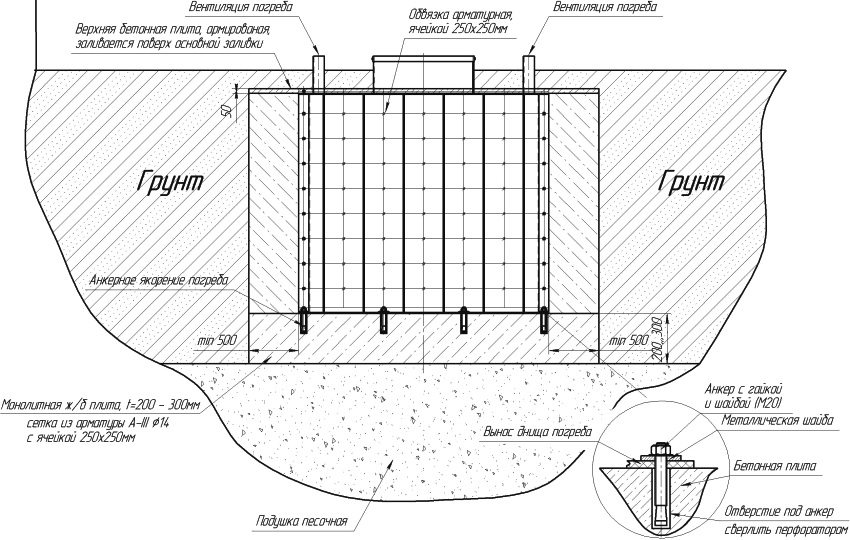

Foundation concreting. When installing a seamless plastic cellar, the bottom can be filled with concrete, or a reinforced plate can be installed. This is done to level the base and also to protect it from moisture. The stove will also have to be installed using specialized equipment, for example, a winch or a crane.

For additional reliability, the concrete base should be installed on a sandy cushion 8-10 cm thick, on top of which roofing material can be laid or a layer of bitumen can be poured. This is done for the purpose of additional waterproofing and provides good protection of the bottom of the cellar from groundwater.

Thanks to the one-piece sealed element, the plastic cellar can be installed and assembled in the most suitable and convenient place

Installation of the structure and its fixation. Continuing the installation, the plastic cellar must be fixed to the base using special slings. A caisson is installed under the bottom of the cellar, which can be plastic or metal. In the caisson, the cellar body is also fixed in the way provided by the manufacturer of the product.

Backfilling the cellar. The structure is covered with soil and a mixture of sand and cement. The soil layer around the cellar must be carefully compacted.

If in your area groundwater comes too close to the surface, then it is recommended to make a concrete floor inside the cellar itself, and when installing a structure under a residential building, the walls of the pit should be concreted. This is done to reduce the pressure of the soil on the wall of the storage facility, which can lead to their premature deformation.

Helpful advice! If you plan to install turnkey cellars, under a house or other building, then this should be done at the construction stage, when the state of the structure allows the plastic container to be carried inside.

The advantage of installing a plastic cellar with your own hands is that you significantly save money, and also get the opportunity to install the structure at any convenient time and anywhere. But here it is worth understanding that an incorrect installation can lead to disastrous consequences. For example, with a high level of groundwater, the base of the structure must be additionally reinforced and reinforced with concrete so that it becomes as heavy as possible. Otherwise, there is a risk that the container will simply be squeezed out.

In addition, if desired, you can increase the thermal insulation characteristics of the vegetable storage cellar. You can buy thermal insulation materials in any specialized store, and their installation is carried out in the same way as when insulating any other structures. Even if you buy a cellar made of fiberglass, which is characterized by increased thermal insulation characteristics, insulation may still be needed.

The installation of a plastic cellar at a summer cottage should be carried out taking into account its total area, as well as the specifics of the relief and type of soil

Cellars Tingard, Triton and other popular brands

There are several popular manufacturers of plastic structures that are in great demand in the domestic market. For example, cellars made of polypropylene from the Triton company. They are manufactured using extrusion welding technology, are of high quality, but also at a fairly high price.Seamless plastic cellars from the company can be of the following types:

- semi-underground - with a part protruding above the ground;

- completely underground;

- drilling;

- ground;

- glacial.

Plastic cellars Triton are also characterized by the fact that they can easily tolerate high humidity, low temperatures and other negative environmental influences. There are many models on the market that differ in volume, shape and a number of other characteristics. The kit may include electrical wiring and various optional accessories.

The second popular manufacturer of cellar containers and caissons, which you can buy online or directly from the manufacturer, is the Tingard trademark. The structures of this company are manufactured using rotational molding technology and are somewhat more expensive than those of the previous company. When buying a Tingard seamless plastic cellar, you get a wide choice of design dimensions, as well as a high level of quality and reliability.

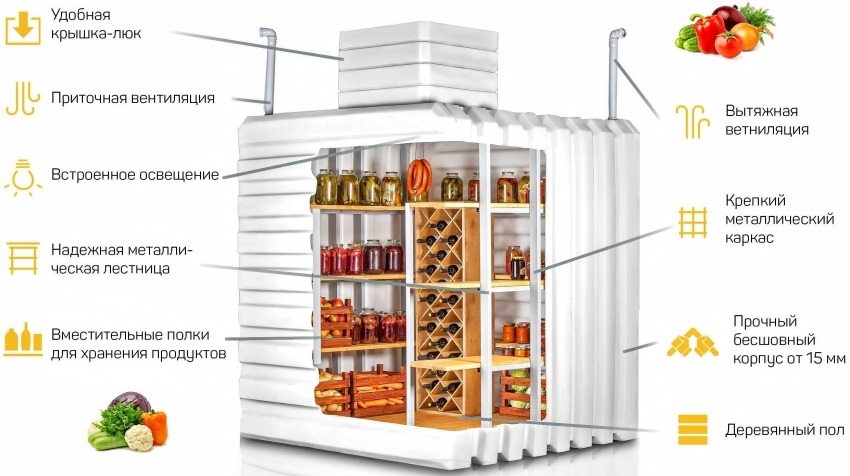

According to reviews, the Tingard cellar is one of the most popular among domestic buyers, and the container itself usually comes with a folding metal ladder, wooden shelves, regular or insulated Luke and a lamp for lighting.

The price of a Tingard plastic cellar can vary from 100 to 250 thousand rubles, depending on the storage volume. If you order additional work, for example, installation of a cellar, then the price will be an order of magnitude higher.

Among all brands of plastic food storage facilities, Titan storage stands out. Firstly, these are plastic cellars with a side entrance. This is very convenient if you do not need an underground, but a ground or semi-underground basement. Secondly, the company produces storages of various shapes and sizes, well suited for any need. In such a cellar there may be an enlarged or insulated hatch, temperature and humidity sensors. The latter is especially true for wine cellars or storage facilities where products need a special temperature regime.

Helpful advice! When choosing a brand of plastic storage for a suburban area, pay attention to reviews of the owners of plastic cellars from the company whose products you are going to purchase.

In addition to the above brands, there are also domestically produced Vityaz plastic cellars. They are characterized by a relatively low cost with good performance characteristics. The company's products have a hatch located on top, shelves are made of plastic inside.

Plastic cellar: pros and cons

If we consider the features of this design in comparison with a conventional basement, it becomes clear that the main parameter thanks to which plastic cellars are very popular is saving time for construction. In addition, such a cellar is usually sealed, complete with a ladder and shelves, so the amount of work you need is minimized. And if we consider a photo of a plastic cellar of a ground or semi-underground type, it becomes clear that he does not need external finishing work either.

On the other hand, the plastic construction costs much more than even the most expensive DIY basement option. In addition, you cannot add storage capacity, deeper or wider at will. The installation of a plastic caisson is also associated with certain nuances. Although both the number and the complexity of earthworks in this case are less than with an independent arrangement of the cellar: the structure will have to be installed with the help of specialized construction equipment, since it is put into the pit immediately assembled.

If you plan to make a cellar under the house when the construction is already finished, then the option with a plastic cellar will be difficult to implement. In order to place a volumetric container under the floor of an already finished building, you will need to disassemble part of the walls or the roof, and this is associated with additional difficulties and costs.

Many buyers point out such factors as "for", such as ease of use and lack of need for care. Indeed, when purchasing a plastic cellar from a well-known manufacturer, you do not need to additionally manufacture shelves, spend time arranging ventilation and conducting electric lighting. The structure can be used immediately after the completion of installation work. And plastic walls do not have to be regularly patched up, cleaned of mold and repaired - even without maintenance they will last for several decades.

From all that has been said, it follows that the main disadvantage of a plastic basement is its price. All other characteristics are at a high level and allow you to use the storage with great comfort.