Among the entire range of plumbing equipment, toilet cisterns are the most problematic. Due to continuous operation, the products often fail, which entails disruption of the normal operation of the entire bathroom. When choosing such an important and vital element, you need to navigate the range of products, taking into account the advantages and disadvantages of each option.

Content [Hide]

- 1 Components of the toilet cistern

- 2 The optimal size of toilet bowls with a cistern

- 3 Toilet cistern: device for draining water

- 4 Methods for connecting plumbing fittings: features of each option

- 5 Types of toilets with a cistern, depending on the location

- 6 Materials for the manufacture of toilet cisterns: characteristics of each option

- 7 Varieties of toilets with a cistern according to the variant of the flush mechanism

- 8 Possible problems with the toilet cistern and methods for their elimination

- 9 Elimination of external leaks and rust control

- 10 Toilet cisterns: useful recommendations for choosing products

- 11 Recommendations for installing a toilet cistern

- 12 Are toilet cisterns sold separately: an overview of popular models

- 13 Popular variants of toilet bowls-compact with a cistern

- 14 Purchase of spare parts for the toilet bowl

Components of the toilet cistern

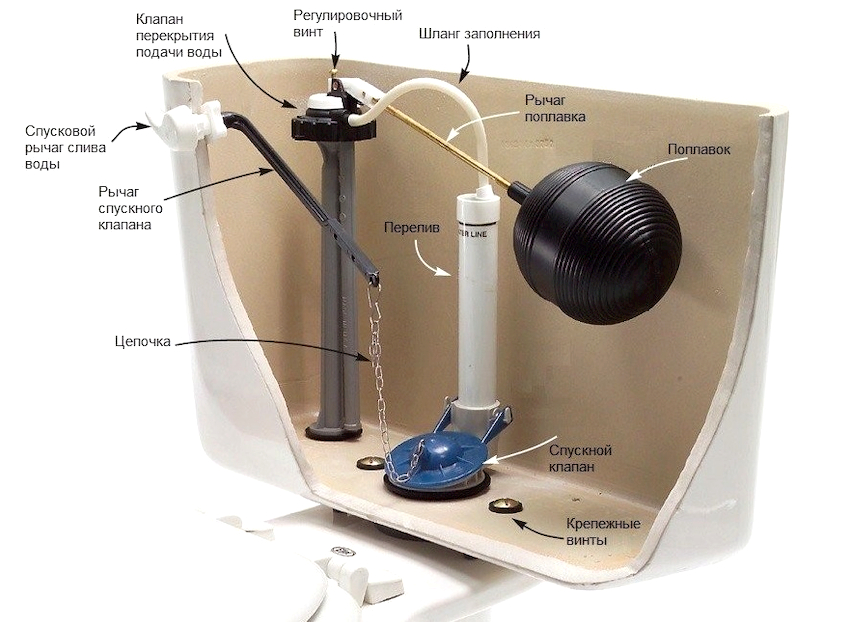

The structure of the toilet bowl is represented by a body made of a certain material, a lid, an element for starting the drainage of water in the form of a button, lever or rod, and internal fittings. The latter consists of a float mechanism and a drain system.

Cistern fittings consists of a float mechanism and a drain system

The float is in most cases made of plastic. Such a water seal with an internal cavity containing air rises together with water. When a certain level is reached, the liquid blocks its supply using a system of levers. The float is not adversely affected. Most often, connecting elements fail.

The so-called pear opens and closes the drain hole in the toilet cistern. When the water is drained, this element rises. During the emptying of the tank and filling it with water, it sinks to the bottom and is firmly pressed against the saddle. The pear moves thanks to a vertical guide, which looks like a plastic tube, inside of which there is air that pushes the pear upward. This element often undergoes deformation, cracks, and therefore needs to be replaced.

A cuff is used to ensure a secure connection between the tank and the toilet bowl. It helps to create a tightness of the system and eliminate water leaks.

Important! If the cuff is replaced, it should be sealed with silicone or sealant to ensure reliability.

An O-ring is responsible for ensuring tightness and reliable pumping of water into the sewer in the drain and overflow system, the condition of which should be constantly monitored.

The optimal size of toilet bowls with a cistern

The dimensions of the toilet bowl with the cistern (in terms of optimality) are selected based on the dimensions of the room. For a large room, long standard models are suitable, and for a small room it is best to choose compact options. These cast-shelf toilets are 340 mm wide, 605 mm long and 800 mm high. Products with a separate tank are characterized by dimensions of 460x360x815 mm. Corner toilets have the following dimensions: width - 340-370 mm, depth - 720-790 mm, height with a cistern - 815 mm, seat height - 370-430 mm.

Monoblocks are presented in a single design, which includes a toilet bowl and a cistern. The width of the product can reach 360-375 mm, depth - 685-700 mm, height - 390-775 mm.

The depth of the toilet bowl with the cistern is selected based on the need to maintain a distance of at least 60 cm between the device and the front door. Otherwise, it will be uncomfortable to sit on such a product due to the inability to position the knees properly when sitting.

The height of the device above the floor level is selected based on the height of the person. The toilet should be comfortable to sit with your leg muscles relaxed. For a tall person, it is better to choose suspension systems with an installation that can be adjusted in height.

Important! The smallest version of the tank is 275 mm wide.

The volume of the cistern can be 4-13 liters. Imported devices are designed for 4-6 liters. Dual-mode tanks have a capacity of 3 and 6 liters. Standard products that are hung on the wall or installed on the toilet have the following dimensions: width - 150-200 mm, length - 300-360 mm, height with a lid - 350-400 mm.

Toilet cistern: device for draining water

The modern toilet flush system consists of a shut-off device, a filling valve and a system that prevents overflow of water. Such a complex of elements can be represented as a solid structure or consist of separate parts.

The modern toilet flush system consists of a shut-off device, a filling valve and a system that prevents overflow of water

Controlling the drainage of water and preventing it from flowing unnecessarily is carried out by shut-off or drain fittings, which include a valve with a plug that blocks the hole that goes into the toilet bowl. The valve completely closes the outlet under pressure of the fluid in the tank.

Important! If there is a constant continuous movement of water in the toilet, the drain fitting is in a malfunctioning state.

The filling valve for the toilet cistern performs the functions of passing water from the water supply system to the cistern and closing it when the container is filled. The element is represented by a brass rod connected to a float. The latter, rising along with the water level, upon reaching a certain position, blocks the supply of liquid from the outside. In old tanks, such a valve was located on the side, and the float was in a horizontal position. In new devices, the filling valve is located at the bottom, and the float is located vertically.

The overflow system, which includes special hoses, is designed to prevent water from leaking to the floor in the room in case of a malfunction of the drain mechanism, and also to ensure its flow into the sewer.

If there is a constant continuous movement of water in the toilet, the drain fitting is in a malfunctioning state

Options for locking valves for the toilet cistern

The locking device for the toilet bowl can be represented by a piston, membrane or croydon valve.

The Croydon valve consists of a body, piston axles, float arm and seat. The piston is driven in a vertical direction by acting on the float arm. This option is typical for old-style tanks.

In a piston valve, the axis of the float arm is mounted in a split pin, which is split in two. When moving, the lever acts on the piston, which begins to oscillate horizontally. It periodically comes into contact with the seat, which allows you to regulate the flow of water in the tank. At the end of the piston there is a gasket for the toilet bowl, which, at the moment the piston acts on the seat, blocks the water flow. This mechanism is very popular in modern models.

The diaphragm valve is one of the latest advances in toilet cisterns. Instead of a piston gasket, a silicone or rubber membrane is mounted in it. Under the influence of the lever, the plastic piston moves the membrane, which blocks the water flow. Thanks to this mechanism, the tank is quickly and silently filled. However, membranes are very sensitive to cleanliness and can quickly fail.

The reliability and durability of the filling fittings will be affected by the presence of a filter for water purification from mechanical impurities

Models are available with a floatless bottom or top valve. In this case, the water flow is blocked when filling the tank due to the presence of a special chamber, which has the shape of an inverted glass. The principle of operation of the device is based on the action of the Archimedean force, which changes depending on the filling of the tank.

Important! The reliability and durability of the filling fittings will be affected by the presence of a filter for water purification from mechanical impurities.

Methods for connecting plumbing fittings: features of each option

After flushing the water, the tank can be filled with a certain volume of water through the side or bottom inlet. In the first case, filling occurs with noise. However, some models of cisterns are supplemented with a soft plastic tube, which directs the stream of water to the lower area of the container. This method of filling the tank is used in most modern models related to the budget and middle price segment. It is characterized by simple and easy installation, availability of adjustment and repair work.

The side water connection mechanism consists of a shut-off valve, a control lever, a float and a filling tube. The lever can be plastic or brass. The float is represented by a plastic container or a foam product.

The bottom inlet provides a silent water supply, it is not visible, which leaves free space on the sides

The principle of operation of the filling mechanism for a toilet bowl, in which the control device is located horizontally, is as follows. When flushing water, which entails a decrease in the level of liquid in the tank, the float device of the toilet bowl is lowered, attracting a bar that opens the shut-off valve. Water begins to fill the container, gradually raising the control mechanism.

Important! If a piston rod valve is used, the water flow decreases gradually and the diaphragm valve shuts it off immediately when a certain level is reached.

The bottom inlet ensures a quiet water supply. It is not visible, which leaves free space on the sides. Such a device is the most difficult to repair. To fill it, an intense water pressure is required.

The stop valves for a toilet cistern with a bottom liner include a float, a guide, a glass where the float is lowered during water flushing, a draft, which is attached to the float on one side and to the shut-off device on the other, and a diaphragm valve.

The shut-off valve for a toilet cistern with a lower connection includes a float, a guide, a glass, a draft and a diaphragm valve

The principle of operation of the device is as follows. During emptying of the container, the float is lowered along the guide. The diaphragm valve opens, which is influenced by the draft. Water begins to fill the tank. The valve closes at the moment the float chamber reaches the required level, which is determined by the size of the control rod.

Types of toilets with a cistern, depending on the location

An unremarkable sanitary ware in the form of a toilet cistern is presented in a wide variety of species.

The toilet cistern can have a one-piece body. This monoblock is easy to install. It is enough to install the design of the cistern with a toilet bowl and connect the pipes for the supply and drainage of water. The product can be floor-standing or suspended. If one of the components of the tank fails, it needs to be completely replaced, which will lead to disharmony in the design of the monoblock.

The traditional version is represented by a separate cistern for the toilet, which makes it possible to combine different models of the constituent elements of a single system. In the case of purchasing a toilet tank separately, there are three options for installing the structure. The cistern can be wall-mounted, built-in or positioned on the toilet.

The traditional version is represented by a separate cistern for the toilet, which makes it possible to combine different models of the constituent elements of a single system

A hanging toilet cistern implies both high and low placement of the element. In the first case, the tank is located at a certain height and is connected to the toilet using a long pipe. This old-fashioned arrangement is characterized by the creation of optimal pressure and high rinsing rates. However, there is a high noise level during the discharge of the water. The flushing device of the old-style cistern is represented by a lever with a chain located on the side.

Low cistern placement is very popular. The element is attached to the wall and connected to the toilet with a short tube. The water from the tank is drained by pressing a button on the device body.

Related article:

How to choose a toilet: the main criteria and features of various models

Overview of the 5 most popular manufacturers and models. Common breakdowns and how to fix them.

The compact version is a design where the cistern is located on the toilet. Despite the fact that it is similar in appearance to a candy bar, such a tandem consists of two separate elements. There is a special shelf on the toilet, on which the cistern is installed, followed by reliable fixation on it. The advantages of the design are compact size and ease of maintenance.

Quite common is the corner cistern for the toilet, which has a triangular or trapezoidal shape, so that it is convenient to place the structure in the corner of the room if it is small.

The built-in toilet cistern (in the wall) is hidden in a special closed niche. Only a button for draining water is brought out, through the hole in which a preventive inspection and repair of the device is carried out. Choosing a hidden toilet cistern contributes to the aesthetic design of the bathroom interior. In this case, the toilet will be close to the wall, which will make the room more spacious and neat. There is also a wall-hung version of the product with a built-in waste tank.

Materials for the manufacture of toilet cisterns: characteristics of each option

The most common option is ceramic. The material is characterized by high strength, ease of care, a large number of colors and attractive appearance, which is facilitated by the glossy shine of the product.

Porcelain structures of the toilet bowl with a cistern have a smooth, glossy surface without pores, which is easy to clean. In matters of strength, the product is inferior to ceramics. Porcelain devices are presented in a wide variety of performance designs, which makes them presentable and original. The disadvantage of porcelain tanks is their high cost.

Metal products are superior to ceramics in lightness and strength. Cast iron and steel are used for their manufacture. In the first case, the tanks are heavy and fragile. More reliable products are steel elements. The cisterns with their characteristic dark sheen look stylish and modern.

Porcelain structures of the cistern toilet have a smooth, glossy surface without pores, which is easy to clean

Important! The cistern and the toilet bowl must be compatible with each other in terms of material of manufacture and color.

Reinforced acrylic is widely used for the manufacture of plumbing fixtures. The material has a smooth, non-porous structure, making it easy to clean. Acrylic cisterns are characterized by hygiene, high strength and low weight.

Products belonging to the elite class are made of glass, natural or artificial stone. Such tanks have a stylish and original appearance, fragile and high cost.

Elements built into a wall niche are often represented by plastic toilet cisterns. The products are quite reliable, but do not have an attractive appearance.

Varieties of toilets with a cistern according to the variant of the flush mechanism

The flushing device of the toilet bowl can be operated by means of a pulling or pushing mechanism. In the first case, the main element is the lever, which is located in the upper part of the body. The water is drained by lifting the handle up. Such a mechanism has already lost its popularity and is extremely rare in modern products.

Most models are represented by a toilet cistern with a button. The water is drained by means of a button recessed in the device body. The drain valve is opened with a lever system. In turn, the push mechanism can be one-button or two-button. In the first case, one button is installed on the lid for the toilet cistern, as a result of pressing which, the entire contents of the device are dumped into the tank. The two-mode cisterns have a button for the toilet cistern, which consists of two parts. One half is responsible for dumping half of the volume of the tank, the second for completely emptying it.

Helpful advice! Some modern models are equipped with a stop-function button, which, when pressed for the first time, helps to start draining the water, and when it is pressed again, closes the drain hole of the tank.

Possible problems with the toilet cistern and methods for their elimination

Any mechanism tends to fail after a while. Most often, water flows from the cistern to the toilet. This can happen for several reasons. Sometimes a float is knocked down on the stop valves, which leads to overflow of water after filling a certain level. To correct the problem, adjust the float height. If the element has lost its tightness, it must be replaced with a new one.

Sometimes a float gets knocked off the stop valves, which leads to overflow of water after filling a certain level

In case of displacement of the regulator responsible for the height of the button, a gap is formed between the water drain valve and the hole in the toilet sink. The problem can be rectified by adjusting the height of the button.Water can enter the toilet sink by loosening the nut at the base of the overflow tube. To do this, it must be tightened.

Water leakage into the toilet sink may occur if the valve on the shut-off valve is faulty. You can check this by pressing the lever that goes to the float. If the water does not stop flowing, the valve is faulty. It will be necessary to replace the shut-off valves.

If no water is drawn into the drain tank, this indicates a float stuck in the stem or a clogged valve. In the first case, the float should be adjusted. The second option requires cleaning the valve. If the procedure did not give positive results, you will need to replace the shut-off valves.

If there is a decrease in the force of the drain flow when the tank is completely filled, this indicates a clogged drain hole. This problem can occur as a result of a jumped hose being installed to lower the water level. You can eliminate the malfunction by dismantling the tank and cleaning it.

If there is a decrease in the force of the drain flow when the tank is completely filled, this indicates a clogged drain hole

Elimination of external leaks and rust control

The appearance of water under the plumbing fixture indicates the leakage of the toilet tank at the place of its connection with the device. This option is possible if the tank is incorrectly installed or the gasket is aging. In this case, the drain container will have to be removed, cleaned and dried. The tank can then be refitted using a new, uniform gasket. For secure attachment, a layer of silicone glue is applied to the gasket on both sides.

If the toilet tank leaks at the water inlet, it is necessary to shut off the water, remove the hose, wind the fum tape around the thread and screw the connection again. If the fastening bolts are leaking water, the cause is dry out of the gum of the seal or improper installation. First, the connection is untwisted and the gaskets are changed. Next, you should carefully tighten the bolts so as not to skew.

Helpful advice! It is recommended to use tapered spacers under the fasteners.

Water on the floor does not necessarily mean that the cistern is leaking. Condensation may form on it and drip down. This may be due to the high humidity in the room. To eliminate the problem, it is necessary to install forced ventilation. The reason may also lie in the constant flow of water into the toilet sink. It will be possible to remove condensate after eliminating the malfunction of the drain system.

The drain mechanism often fails due to the accumulation of dirt and rust. To exclude such a problem, regular prophylaxis should be performed. The container is completely emptied, after which it is treated with special agents against plaque and rust. Then, the tank is rinsed with water several times and put into operation.

You can pour Sanox gel and half a liter of vinegar into the toilet bowl. This mixture is left to act for several hours, after which the tank is rinsed several times with water.

Toilet cisterns: useful recommendations for choosing products

For small bathrooms, monoblocks or compact models should be preferred. A sensible solution is to install a corner toilet with a cistern, which saves additional space in the room.

When decorating a bathroom in a modern style with the use of new-fashioned finishing materials and accessories, a floor device with a hanging cistern for a toilet built into a niche will look most organic.

Choosing a specific model, you should study the structure and quality of all constituent elements, the capabilities of the device

To create an original room design, you can combine separate models of the toilet and cistern, showing a creative approach to organizing a unique setting in the room.

Choosing a specific model, you should study the structure and quality of all the constituent elements, the capabilities of the device. Practicality, reliability, uninterrupted operation and durability of the drain element will depend on this. Numerous reviews of models on the Internet will help you make the right decision.

Important! The key to choosing a high-quality and reliable device is its involvement in a well-known brand with a worldwide reputation.

Double-button cisterns allow you to reduce water consumption during operation, which is a real result of savings.

The key to choosing a high-quality and reliable device is its involvement in a well-known brand with a worldwide reputation.

Recommendations for installing a toilet cistern

A toilet with a cistern is installed in a specially designated place, which must be pre-leveled. When installing products, a horizontal level check is performed.

If you purchase a separate hanging cistern for the toilet and the plumbing device itself, prepare a place for the container. For this, the supporting beams are securely mounted to the wall. As fasteners for the toilet cistern, you need to choose metal brackets, which are fixed with anchors or screws with dowels. It is important to ensure a rigid and reliable fastening here, since the container filled with water has a significant weight.

All connecting elements in the joint places should be treated with sealant or silicone to ensure reliable sealing.

When choosing a compact toilet bowl with a cistern, the elements are securely attached. To do this, use the bolts that are included in the kit. Rubber gaskets are installed in the joints. All supply and output pipelines, hoses and corrugations must be tightened to the stop, which will ensure a reliable seal.

All connecting elements in butt joints should be treated with sealant or silicone to ensure reliable sealing.

Are toilet cisterns sold separately: an overview of popular models

Flush cisterns are purchased mainly with a toilet bowl. In the event of a breakdown of individual parts, original components are selected, which will have identical dimensions. In this case, there will be no installation problems.

High-quality earthenware plumbing fixtures are offered by the global manufacturer Roca. The company manufactures a wide range of products. The Roca Victoria model is very popular. The design has an elegant oval shape with a pleasant white glossy shade. The product is a device with a bottom water supply.

Colombo toilet cisterns are no less in demand. The manufacturer offers earthenware products with an attractive design. The models have smooth lines and are characterized by compact dimensions. Among the wide range of products, the Colombo Orhideya double flush toilet cistern deserves attention. The cost of products is 2.4 thousand rubles.

They are characterized by two modes, involving the release of water in a volume of 3 liters and 6 liters. The drain mechanism is controlled by pressing a double metal button. The cistern for the toilet has dimensions of 185x370x390 mm. The product warranty is 10 years. The price of a cistern for a toilet is 2.7 thousand rubles.

For floor-standing toilets Verona, Keramin and Cesaro, you should choose the Keramin Grand porcelain drain systems. Products have a trapezoidal shape, tapered at the bottom. Such tanks are characterized by high quality workmanship, reliability and durability of internal fittings. The size of the bowl is 380x385x170 mm. You can buy the product for 4.5 thousand rubles.

Another interesting model is the Roca Gap toilet cistern. The product has dimensions 365х365х150 mm. The cistern is made of white faience. Differs in a rectangular shape with smooth corners.Equipped with a two-mode control, providing a flush of water with a volume of 3-4.5 liters. You can buy the product for 7.5 thousand rubles.

The clean and simple design features the Laufen Pro floor-standing cistern with side water supply. The volume of the container is 4.5 liters. Has a dual mode of water drainage - 3 and 4.5 liters. The price of a cistern for a toilet is 8.5 thousand rubles.

Original in configuration and design is the Villeroy & Boch Hommage toilet cistern, made of porcelain. The water supply is from the side on the right. The product is equipped with a double button for complete drainage and has a volume of 3 liters. The cost of the tank is 10 thousand rubles.

Popular variants of toilet bowls-compact with a cistern

An interesting and popular model is the Cersanit Best compact toilet with bottom water supply. The product is made of sanitary ware and has an oval shape. The dimensions of the device are 360x655x815 mm. The volume of the tank is 5 liters. The drain mechanism is activated by pressing one button. The cost of the product reaches 3.5 thousand rubles.

Cersanit Olimpia cisterns with internal flush fittings are a good solution for floor-standing compact toilets. Products are made of high quality faience. They are characterized by a rectangular outline with smooth corners. The water is supplied from the bottom. The dimensions of the toilet bowl with the cistern are 360x375x170 mm. The drain mechanism is equipped with a dual mode with a water outlet of 3 and 6 liters. The cost of the product is 3.7 thousand rubles.

Noteworthy is the white floor-standing toilet-compact Orion made of sanitary ware. It has a double flush mechanism for 3 and 6 liters. Product dimensions are 350x635x810 mm. You can buy such a toilet for 4.5 thousand rubles.

The Sanita Luxe Best compact toilet with bottom water supply is in demand among consumers. Product dimensions - 340x640x770 mm. The Sanita toilet tank, like the device itself, is made of sanitary ware. The volume of the tank is 6 liters. The product is equipped with a Geberit bi-mode fitting. The device has a 5-year warranty. You can buy a toilet bowl with a cistern for 6 thousand rubles.

Another popular model is the Classic Soft Close toilet bowl with double flush, high-quality Swiss Geberit fittings. The dimensions of the device are 345x590x760 mm. You can buy a compact toilet for 7.3 thousand rubles.

Toilet bowl-compact Santek Alkor is equipped with two-mode fittings Uklad. The product is made of oval earthenware. Has a smooth, glossy snow-white surface that is easy to clean. The water is supplied from below. Product dimensions - 365x765x670 mm. The cost of a toilet bowl with a cistern is 7 thousand rubles.

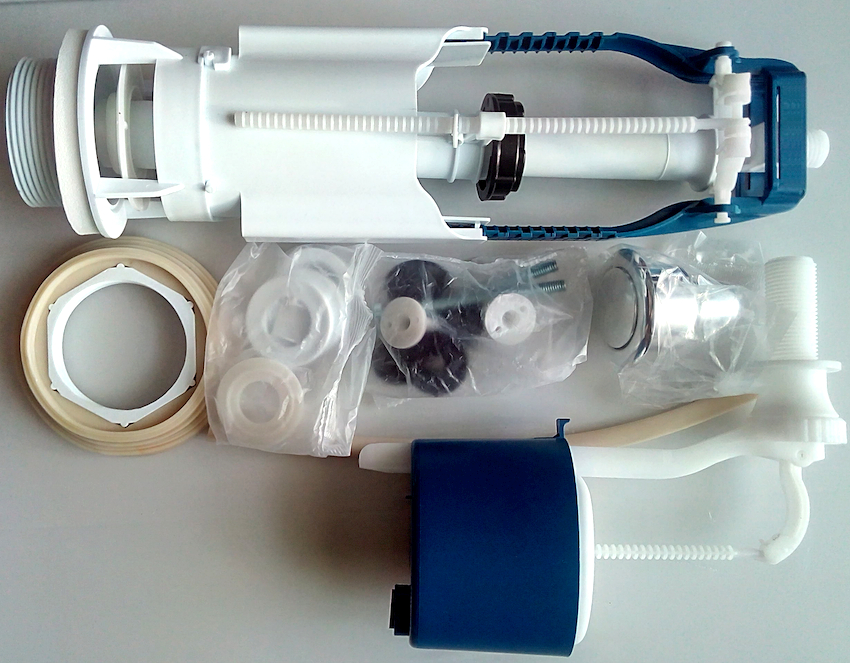

Purchase of spare parts for the toilet bowl

A set of internal fittings from the Polish manufacturer Cercanit is distinguished by a good price-quality ratio. It includes an outlet valve, floor valve, O-ring, plastic connection Bas 24, metal sleeve and button. The cost of the set is 650 rubles.

The Vidima drain device will cost 1.2 thousand rubles. This manufacturer provides the opportunity to separately order a membrane inlet valve for the toilet cistern, which will cost about 300 rubles. The cost of internal fittings for the Hybner tank is 1.8 thousand rubles.

A set of internal fittings from the Polish manufacturer Cercanit is distinguished by a good price-quality ratio.

High quality and reliable fittings are offered by the Jika trademark. The locking mechanism can be presented in two versions - with a short or increased button height. These fittings can be used for Jika and Roca cisterns. The cost of the set is 2.8 thousand rubles.

The cheapest option is domestic fittings offered by Uklad. It is made of high quality virgin polypropylene. The shut-off valves are made using natural rubber.The cost of the kit is in the range of 250-360 rubles.

Quality products are produced by RBM company. Internal fittings are equipped with one of the valve types: diaphragm, direct-acting or backpressure mechanism. The elements can be used in tanks with both bottom and side water supply. The cost of such sets starts at 200 rubles. There are models with a push-button and rod trigger mechanism, which can be purchased from 100 rubles.

A toilet cistern is a must-have for every bathroom. Thanks to modern innovative technologies, the product is constantly being improved, which has a beneficial effect on the operational and aesthetic functions of the device.