Cold smoking of meat involves prolonged fumigation of products with smoke, which occurs at a low temperature. A smoke generator is used to provide traction within the structure, which contributes to the uninterrupted flow of smoke into the main chamber. This device can be assembled by yourself at home. The cold smoking smoke generator greatly simplifies the process of preparing delicacies at home.

When making a smoke generator with your own hands, it is allowed to use any available materials, components and containers

Content [Hide]

- 1 What is a smoke generator for smoking: functions and features

- 2 Do-it-yourself smoke generator: structural elements

- 3 Smoke generator for cold smoking: dimensions

- 4 Do-it-yourself smoke generator: the principle of operation of the device

- 5 Smoke generator for cold smoking with your own hands: drawing

- 6 How to assemble a smoke generator for cold smoking with your own hands: instructions

- 7 Rules for using a smoke generator: photo and operational features

- 8 How to regulate the draft in a homemade smoke generator?

- 9 How to make a smoke generator for cold smoking with your own hands: additional elements

- 10 Do-it-yourself stove with a smoke generator for cold smoking: video and photo

- 11 Do-it-yourself smoke generator from a fire extinguisher: a simple and reliable option

What is a smoke generator for smoking: functions and features

Cold smoking takes quite a long period of time. Products obtained in this way have a more subtle, refined aroma and taste. During the cooking procedure, pathogenic bacteria are destroyed. The shelf life of products cooked in cold-type units can be up to a year, which is a serious advantage of the design.

Features of this process require the use of special equipment. The most important role in this case is played by the smoke generator for smoking. Certain requirements are imposed on this device. It should help generate sufficient smoke and regulate its intensity. The autonomous device greatly simplifies the process of cooking smoked meats.

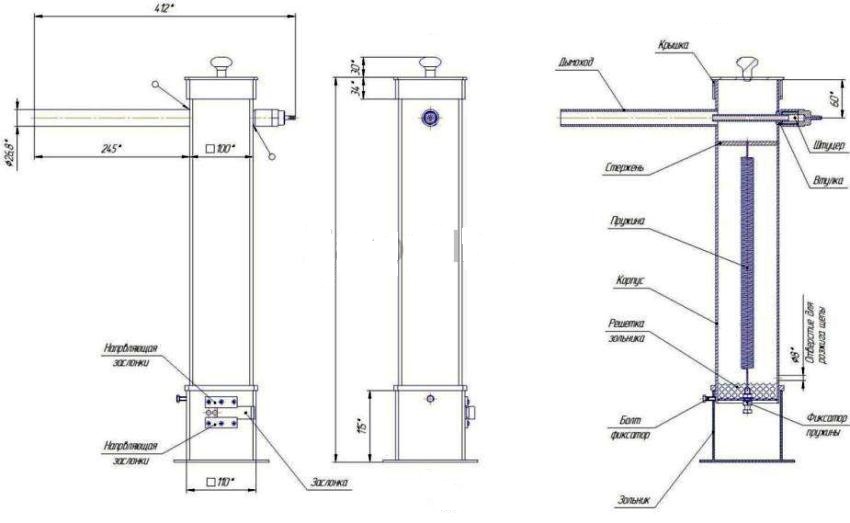

In order to assemble this device, you need to draw up a preliminary drawing. The diagram includes a drawing of the future device, the required dimensions and designations.

Helpful information! It is important to note that cold smoking temperatures do not rise above 50 ° C. In turn, the minimum value is only 30 ° C.The duration of such an operation varies depending on the quality of the product itself and can reach several days.

Specific smoke is formed due to the slow burning of wood raw materials, as well as other waste: from alder, pear, beech and apple

Do-it-yourself smoke generator: structural elements

Self-production of such a device will not take much time. The design of the smoke generator includes several basic elements that must be prepared before starting assembly. Let's consider them in more detail.

First of all, you need a tube (metal). Its shape can be round or square. The first option is preferable. This is due to the fact that the circular cross-section increases the throughput of the smoke and does not impede its transportation. The smoke generator tube for the smokehouse should have a diameter of 100 to 140 mm. It is the main structural element where smoke is generated and moved.

Next, you need to prepare the tubes for assembling the ejector. In this case, products of a smaller diameter are selected. Another important design element is the spring. It is placed inside the chamber. This part helps to raise smoke from the lower layers of chips upward.

Compressor is an obligatory element of a smoke generator for cold smoking. This device is needed to supply air to the ejector. A thermometer is not considered a prerequisite. However, experts still recommend equipping a homemade device with a thermometer. This will allow you to monitor the change in temperature inside the smoke-producing chamber and avoid overheating.

All of the above parts can be purchased at hardware and hardware stores. To assemble a smoke generator, you must also purchase tools such as a grinder, a welding device.

Smoke generator for cold smoking: dimensions

The dimensions of the device used to produce the smoke vary. Purchased models are usually sold together with technical documents that indicate their characteristics. From them, you can also learn about which smoking cabinet this device will be optimal for.

Note! When assembling a smoke generator for a smokehouse with your own hands, it is recommended to calculate its power in advance. This indicator is determined depending on the volume of the smoking tank. It will not be possible to smoke food in the overall chamber if the power of this device is too small.

Home-assembled devices are difficult to classify. In order for the dimensions of the tank and the power of the smoke generator to coincide, it is often necessary to carry out test runs. The most common size of the smoking tank today is 0.3 m³. This design allows you to cook a sufficient number of home-made dishes by cold smoking. With your own hands, a smoke generator can be made from a variety of improvised means.

It is important to remember that the dimensions of the device itself are not so important. They depend primarily on what materials will be used in its assembly. The main parameter in any case is the power of the device, which affects the performance of the smoke generator.

Do-it-yourself smoke generator: how the device works

In order to assemble a functioning device, it is recommended to understand its design and understand how it works. All smoke generators have the same operating principle. All of them are used to produce smoke and help transport it in the right direction.

The fuel used to produce smoke can be represented by both wood and wood chips (sawdust). Let's consider the principle of operation of a smoke generator for cold smoking in more detail. When fuel is burned, smoke is emitted and enters the inlet of this appliance. Then it (under the influence of the compressor) is sent to another part of the device, as a result of which it enters the smoking tank.

The compressor plays a very important role, as it supplies air to the smoke generator with its own hands, which has an increased pressure. Many experts note that these devices have a very high efficiency.

In order to assemble the smoke generator chamber, in which the smoke will be distilled, you can use any suitable container. Most often, containers are used in this case:

- fire extinguisher body;

- aluminum milk can;

- thermos.

The most advisable is to use a metal tube. It can be used to make a smoke generator for cold and hot smoking. It is important to remember that its length should not exceed 1 m. If you make the device longer, then the efficiency of the device will decrease. Smoke passing through a pipe that is too long will lose its speed as well as its temperature.

Smoke generator for cold smoking with your own hands: drawing

Drawing up a drawing is a necessary preparatory stage that allows you to perform the appropriate calculations and mark them on paper. In the diagram, the body of the smoke generator is necessarily indicated, which can have a round or square shape.

Helpful information! The service life of the device depends on the choice of the material from which the case will be made. Masters recommend paying attention to two options - stainless steel or galvanized steel. This is due to the fact that such materials have the highest fire resistance, and are also resistant to corrosive effects.

The body of a homemade smoke generator is used as a chamber that is filled with fuel. The walls of the device must be of good tightness. Otherwise, the smoke generated by smoldering sawdust will dissipate into the surrounding space.

The devices for smoking products themselves are divided into varieties depending on design features and purpose. Today you can find large stationary devices or, conversely, more compact, portable ones. A damper may be present in the design of the smokehouse. This element allows you to increase the flow of air into the chamber, which contains fuel.

A homemade cold-smoked smokehouse can have two fireboxes. This design is aimed at increasing the thrust in the system. Smoke generators are used in both hot and cold smokehouses. The drawing indicates all the constituent elements of the device. It is imperative to include the ejector and its dimensions, as well as the compressor, in the circuit.

How to make a smoke generator with your own hands: making the ejector

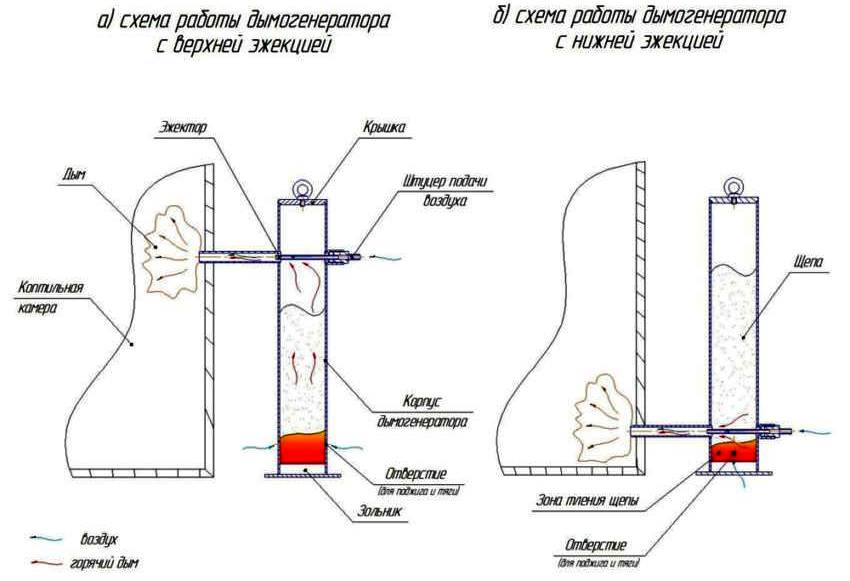

An ejector is a device that is a tube and is used to create the required draft in the smoke generator. This appliance is classified by location. Depending on this factor, two types of ejectors can be distinguished:

- lower;

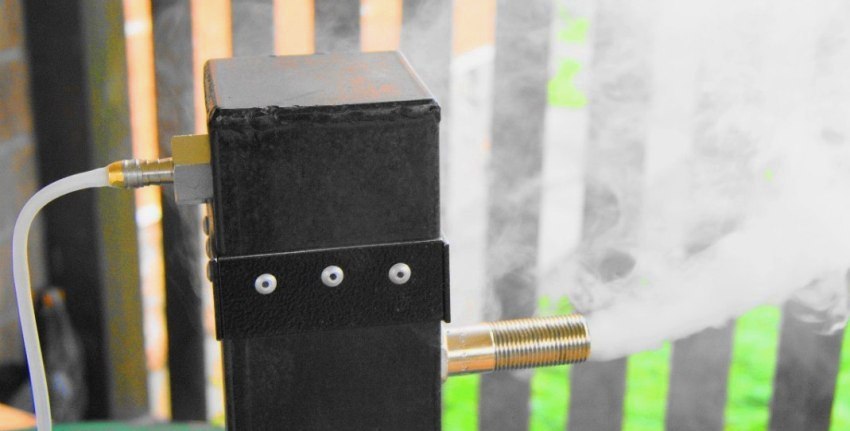

Any smoke generator for a cold smoking smokehouse consists of a container, a pump (compressor) and an ejector

- upper.

The first option is not recommended by experts for self-made smokehouses.This is due to the fact that such placement prevents air flow, which, accordingly, is reflected in the thrust in the structure. Tubes installed at the bottom require constant monitoring, which is not very convenient. When drawing up a drawing of a smoke generator, it is necessary to think over the location of this tube in advance and fix it in the figure.

Traction problems are easy to avoid. All that is required is to place the ejector in the upper half of the smoke generator. This move has several advantages. Installing an ejector in the upper part increases the volume of the combustion zone. The fuel located inside the chamber smolders more slowly in this case, and the likelihood that it will go out is also reduced.

This is how the ejector for the smoke generator is assembled with your own hands. A drawing, a photo and step-by-step instructions - all this allows you to perform a competent assembly of this product.

Note! An important advantage of the ejector installed at the top of the smoke generator is that it has a longer service life. This is due to the fact that the device is located at a considerable distance from the heated area of the chamber.

What to make a compressor for a smoke generator with your own hands?

The compressor is considered one of the most important parts of the appliance, which generates smoke for smoking products. It can be purchased separately and then attached to the structure. But most often for these purposes, various scrap materials are used that can be found in every apartment or house.

Related article:

Do-it-yourself cold smoked smokehouse: delicious dishes at home

Features of the cold-type smokehouse. Device and types. Assembly stages. Preparation of products for cold smoking.

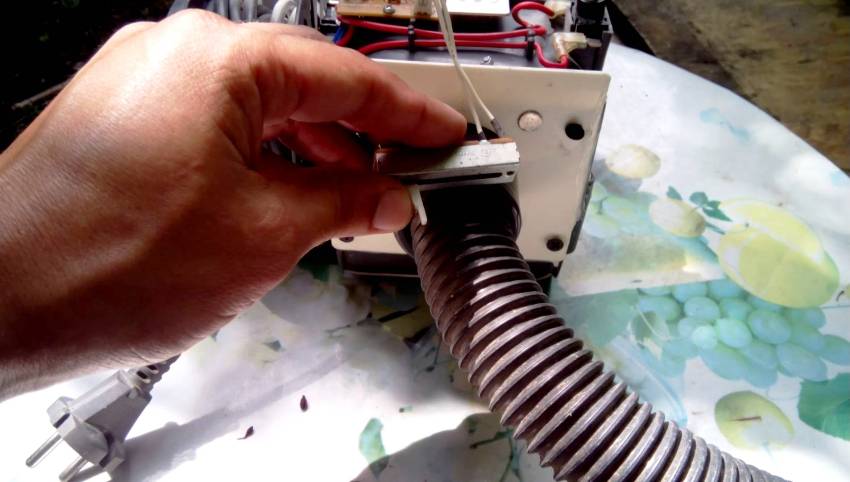

A do-it-yourself air blower can be made from an old cooler. This computer part is perfect for increasing the air flow into the structure. It is necessary to follow the procedure for transforming the cooler into a compressor.

First of all, you need to take a plastic bottle and cut off its top. Next, use glue to attach the fan to the inside of the cut plastic element. On the other side (to the neck), a hose is connected. The second outlet of the tube is connected to the smoke generator. This design does an excellent job of its function. Its only drawback is its unpresentable appearance.

A compressor for a smoke generator with your own hands can be made from an old computer part - a cooler

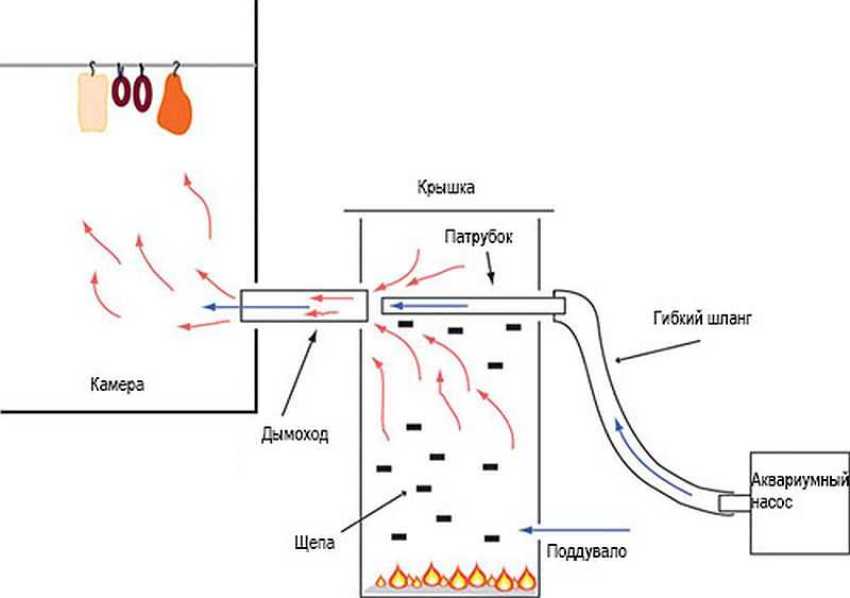

Another common option is to buy an aquarium compressor for your smoke generator. Many people find that a smoke generating device can work without a compressor. But the efficiency of such an installation is lower, since air enters it naturally.

Therefore, it is recommended to assemble the compressor to increase performance. Moreover, it is not necessary that it has a complex design. A simple fan for a smoke generator with your own hands greatly simplifies smoking, and it takes no more than an hour to produce it.

How to assemble a smoke generator for cold smoking with your own hands: instructions

When assembling the smoke generator yourself, it is recommended not only to pay attention to photographic materials, but also to watch training videos on this topic. The design of the device is quite simple. Therefore, anyone without special technical knowledge will be able to assemble this unit.

For the manufacture of a smoke generator, no special equipment and materials are needed, you can assemble it from available tools

There is a certain sequence of actions that should be followed. Any deviation from the instructions can lead to errors that affect the functionality of the device when using it.It is necessary to familiarize yourself with the assembly of the smoke generator in stages.

After drawing up a drawing of a smoke generator for cold smoking, the direct layout of the device begins. First of all, you need to complete the body of the device. To do this, you need to prepare a square or round piece of pipe. The length of the product should not exceed 1 m, otherwise, when using it, there will be problems with the thrust indicator.

Helpful information! As a rule, when making a smoke generator independently, it is customary to use a pipe section, the length of which is 70-80 cm.

A cover must be made at the top of such a tube. It is needed for free access to the smoke generator chamber. This will allow you to easily fill the sawdust inside the device, as well as clean it. In turn, a special container should be provided below, which will collect the ash formed after fuel processing.

A cold-smoked smokehouse with a smoke generator is highly functional if its design has been worked out correctly. The simplest options for smoke generators are made from a tube to which the bottom is tightly welded. Such devices do not provide for the presence of an ash pan, and their cleaning is very simple: the accumulated ash is simply shaken out of the device.

More technologically advanced designs are equipped with a removable bottom. Below its level, a grate is placed on which wood combustion products fall. Through it, they enter the ash pan. Regardless of which design option was chosen, they all provide for a hole in the lower half of the body. It is necessary in order to provide air supply to the smoldering wood. The diameter of such a hole should not be more than 6 mm, otherwise the sawdust can simply catch fire, which will harm the smoking process.

How to make a smoke generator: arrangement of the chimney and ejector

The chimney is necessary for the delivery of smoldering wood chips to the chamber of the smoking unit. The chimney is located at the top of the smoke generating device. It is important to remember that it is not performed in the lid, but approximately 8 cm below the edge of the case (top).

It is better to make a chimney element for a smoke generator from steel, which has a higher thermal conductivity

To do this, a hole should be made in the wall of the smoke generator, which should correspond to the diameter of the tube. It is then welded to the device using welding equipment. It is necessary that the length of the metal tube is of sufficient size so that a plastic tube can be thrown over it, through which the smoke moves into the smokehouse. The recommended length of this element is 7-8 cm. The chimney must be shown without fail in the drawing of the smoke generator with your own hands.

Note! A plastic tube is optional. Dimensional models of smoke ovens, which are of a stationary type, provide for docking with a smoke generator without this element. In this case, the device is simply fixed to the wall of the smoking tank.

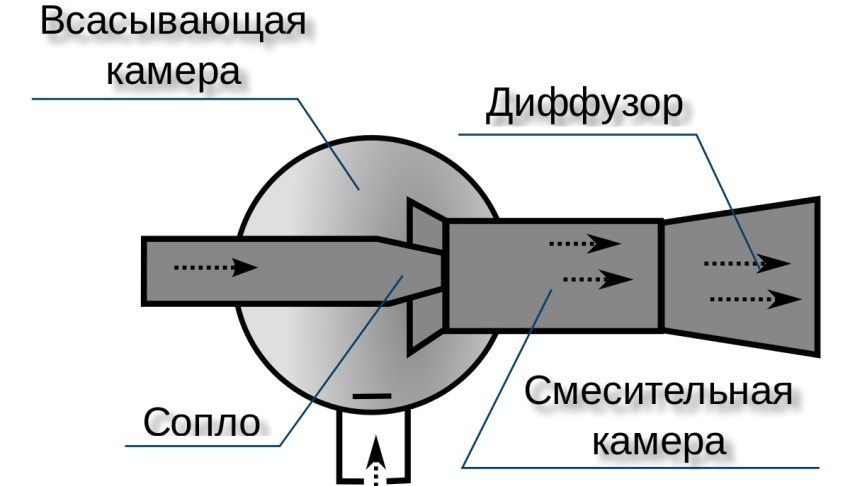

The next step is to assemble an ejector for a smoke generator with your own hands. A cold smoker will generate enough smoke if this attachment is assembled correctly.

Ready-made drawings of smoke generators will help to understand the features of installing an ejector. They can be easily found on the Internet. This device is associated with a compressor that builds up pressure inside it. The moving air creates a vacuum zone in this element. As a result, the smoke from the ejector passes into the chimney.

If you place the ejector at the bottom of the device, then there will be no natural air draft in the device, since the product chamber and the sawdust bin will be on the same level

Rules for using a smoke generator: photo and operational features

After completing the installation of the smoke generator, you need to check its effectiveness. Using this device is quite simple. Consider how to properly operate a home-made smoke generator.

First, you need to load chips into the structure. The amount of fuel can vary. As a rule, its total weight is about 0.7-0.8 kg. An important point is the choice of the type of wood used to obtain the smoke required for smoking. It is categorically impossible to use coniferous trees, as they emit resins when heated, which will spoil the food loaded into the smoking machine. For smoking, it is recommended to select firewood and sawdust made from deciduous and fruit trees (for example, oak, maple or apple).

The technology for using this unit is explained in detail in the related videos. After filling with sawdust, the smoke generator must be closed, and then the chimney pipe must be connected to the smoking tank. The device can be attached directly to the camera. In this case, it is simply installed in its place - close to the wall of the smokehouse.

After completing the installation of all the necessary components of the smoke generator, you need to check its performance

In order to set fire to the sawdust, you need to open the side door. After they are fired up, a compressor is turned on, distilling air. After completing all the above manipulations, the smoking process begins. It remains only to wait for the right time, which will be required in order to cook food in the smokehouse.

How to regulate the draft in a homemade smoke generator?

The design, the assembly of which was described above, is quite efficient. However, it also has one serious drawback. When using such a smoke generator, it is difficult to adjust the combustion intensity. The only way to do this is to change the capacity of the air blower (compressor).

This problem can be overcome by equipping the device with an additional element - a blower. For the manufacture of this part, you need a metal tube with a length of 10 to 15 cm. It must be welded into the lower part of the body the smoke of the machine. It is not very difficult to make a blower with your own hands, but you should take this work seriously.

After the pipe is welded, two holes should be made in it, parallel to each other. Then you need to prepare a metal rod. The size of its section must be such that it can be easily passed through these holes. The next step is to cut a circle out of a metal sheet.

Equipping the smoke generator with a blower, it will be possible to regulate the draft in a homemade unit

Note! The diameter of the circle should be 1-2 mm smaller than the inner section of the tube.

The organization of the blower can significantly increase the efficiency of the devices. This solution is also suitable for smoke generators without a compressor. It is very simple to assemble such a damper with your own hands. The main thing is to observe the geometric parameters and the sequence of actions.

Then the end of the rod is bent, which allows you to make a kind of handle. Finishing the shutter manufacturing involves pulling the handle through the hole made in the tube and welding the metal circle to the bar. The simplicity of the design does not in any way affect its effectiveness. Adjusting the size of the lumen of the tube allows you to adjust the amount of air entering the smoke generator.

How to make a smoke generator for cold smoking with your own hands: additional elements

In simple devices, the products of smoldering chips accumulate at the bottom. Such smoke generators need regular preventive cleaning.In order to avoid this, the design can be improved by equipping it with an ash pan - a reservoir in which wood combustion products are collected.

The ash pan is located below the level of the bottom of the smoke generator. To make it, you will need to prepare a metal pipe, the diameter of which should be higher than the cross-sectional index of the device body. Photos will help you understand all the nuances of the device of smoke generators for cold smoking. It is not difficult to assemble an ash pan with your own hands. To do this, you must clearly adhere to the instructions.

First of all, it is necessary to weld a metal strip (along the perimeter) to the body. Its thickness should not be too large. A metal bottom must be connected to the pipe, which is the body of the ash pan, using welding equipment. At the final stage of assembly, the body of the smoke generator is inserted into the ash pan.

Such a device can serve for a long time. It does not need constant removal of combustion products from the body. If necessary, you can buy a ready-made device equipped with this container. The price of the smoke generator ranges from 4 to 12 thousand rubles. depending on its design features.

Another important point that you need to focus on when making a smoke generator is the accumulation of condensate. During cold smoking, a reaction occurs, as a result of which drops of moisture settle on the walls of the structure. A collection is used to eliminate them. You can do it yourself. To do this, you need to familiarize yourself with the sequence of steps in the manufacture of the device.

First, you need to lower the exhaust pipe of the smoke generator down. Next, you need to prepare a tank in which condensate will accumulate. Two tubes are connected to it with the help of welding equipment (parallel to each other). Then the branch pipe returns to its original position. Such a system will allow to collect most of the condensate that occurs during the smoking process.

It will not be difficult to make a collector for accumulating condensate on your own from improvised means

Do-it-yourself stove with a smoke generator for cold smoking: video and photo

In some cases, the dimensions of standard devices may not be enough. If you want to assemble a structure that is more efficient, then you can make a smoking oven and equip it with a smoke generator.

Note! The main element of such a furnace is the body. It can be made from a wide metal pipe or welded from pieces of metal. In the second case, the structure should have a rectangular shape, which is the most efficient.

Consider the sequence of steps for assembling a do-it-yourself smoke generator furnace. Video and photo materials that allow you to understand the intricacies of the process can be easily found on the Internet at specialized forums.

As mentioned above, the structure body is first assembled. Next, you need to cut a rectangular door in it. The chimney in such a device is located at a certain slope. This is necessary to maintain traction within the system. The inner space of the furnace, welded from stainless steel sheets, should be divided into two parts. For this, a metal sheet is also used. The bottom should occupy approximately 60% of the chamber volume. A fire is ignited in this area. In turn, the upper zone is needed to accommodate chips.

It is best to draw up a drawing of a smoke generator for this type of smokehouse with your own hands. This oven has a high performance. However, assembling such a structure requires more time, effort and resources.In any case, the type of smokehouse is selected based on its purpose and individual preferences of the owner.

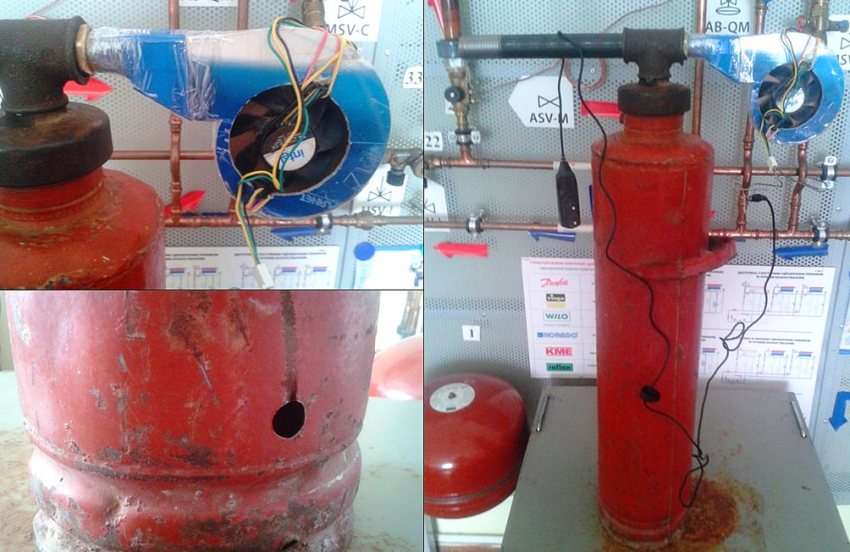

Do-it-yourself smoke generator from a fire extinguisher: simple and reliable option

This design is perhaps the simplest. To assemble it you need an old fire extinguisher. The body of this device must be metal. It is important to remember that the fire extinguisher should not have rusty walls. If there is still content in the device, it is necessary to empty it and rinse thoroughly before starting work.

An old fire extinguisher can be used to make a smoke generator for cold smoking. Videos on this topic can be found using the search box of your browser. A correct and clear sequence of actions will allow you to perform a high-quality transformation of a fire extinguisher into a smoke generator.

In order to make a smoke generator, a fire extinguisher with a diameter of about 100 mm and a length of 500 mm is taken

First you need to cut the fire extinguisher. An incision is made in the upper part (5 cm below the neckline). The result is a simple lid that does not need any further modification. Next, you need to make two holes in the bottom of the fire extinguisher. It is desirable that they are located 5-6 cm below the cut made in the upper part. The optimal diameter in this case should be 2.5 mm.

Note! Before assembly, it is recommended to complete a detailed drawing of a cold smoking smoke generator with your own hands. The video will also help simplify the manufacturing process of this device.

After organizing the holes, you can proceed to the next stage - welding pipes to them. The length of the products should not exceed 7-8 cm. One tube will serve as a chimney, and the second is necessary for air supply. This design takes into account the upper location of the ejector, and the air intake hole will be located at the bottom of the device.

A smoke generator made from an old fire extinguisher is able to function smoothly for about 7 hours. Thus, the simplest smoke injection device is assembled.

From the fire extinguisher, smoke enters the smoking chamber through an inch pipe 150-250 mm long screwed into a tee

The smoke generator can greatly simplify the smoking process. For self-assembly of this device, it is necessary to draw up a preliminary drawing. It must indicate the size of the individual components. This device is manufactured in accordance with the instructions. If you are not confident in your own abilities, then the best solution would be to purchase a ready-made smoke generator.