From this article you can find out what features the beds made of polymer-coated metal have: the purpose and characteristics of products, the advantages and specifics of operation, recommendations for choosing structures and self-assembly, rating of manufacturers. A comparative characteristic of metal beds with structures made of other materials will also be presented.

To protect it from the external environment, the frame of the metal row is covered with a special polymer coating

Content [Hide]

Beds made of polymer-coated metal: product characteristics

Many owners of summer cottages have already been able to appreciate the effectiveness and practicality of raised beds. Most often, for the manufacture of structures, gardeners and gardeners use improvised materials that remain after repair or construction. However, ready-made options for metal products are in many ways superior to the beds that you can create yourself.

Manufacturers offer the following types of metal products:

- beds made of galvanized steel;

- structures made of galvanized steel with polymer spraying;

- beds made of galvanized steel with polyurethane spraying.

Note! Do not give up buying steel beds due to their high cost. If we take into account the costs of maintaining such a garden and the terms of its operation, then the actual price of the products is not more than that of beds made of less durable materials.

Advantages of ready-made galvanized and polymer-coated metal beds

The use of ready-made metal structures at the summer cottage has its advantages:

- there is no need to dig up the soil in the garden. Organic farming is largely justified. To facilitate the maintenance of the beds, it is recommended to mulch the bulk soil and it is advisable to add EM preparations;

- the optimal dimensions of the structures allow for convenient access to the landings. You can freely approach the garden from either side;

- the consumption of water spent on watering plants is significantly reduced. This became possible due to the fact that moisture accumulates locally, exactly where it is needed;

- the possibility of saving fertilizers. The dosage is calculated only taking into account the area of the garden, and not the entire garden;

- the structure, depending on the type of protective coating, can be successfully operated for 20-30 years. Polymer, zinc and polyurethane coating will prevent corrosion and premature deterioration of the material;

The protective cover of the metal bed can be of any color, which allows you to fit the structure into the overall design of the site

- simple installation system and the ability to move the garden to another place;

- the structure of the structures allows the installation of additional sections to increase the size of the beds in height or length;

- arches for organizing a greenhouse can be easily fixed on a metal bed;

- the possibility of creating a neat and decorative garden on the site.

Features of galvanized metal products

Metal beds are suitable for growing vegetables in a greenhouse or outdoors. The products are made of solid steel. The thickness of the sheet material is usually 0.5-0.55 mm. The surface is covered with a thin layer of zinc or polymer.

The installation process for such beds is very simple. The side parts of the product are bent inward, thereby eliminating the likelihood that a person will be injured during the installation of the structure and its further operation. For the manufacture of modern metal fences for beds, special machines are used, therefore the edge line of the parts does not have irregularities and burrs that can injure a person.

It is better to immediately choose the optimal place for placing the garden, since it is often undesirable to disassemble and assemble the structure

Important! Despite the fact that the process of dismantling and installing the beds is very simple, it is not recommended to remove galvanized products every year after the summer season ends.

Regardless of the quality of the product and the manufacturer, the frequent assembly and disassembly of the structure leads to the appearance of deformational changes on the parts. Each time the docking between the elements of the bed will deteriorate. There is also a possibility that the surface of the profile will be damaged and the protective coating will be broken, which will lead to corrosion. The most optimal solution will be a competent choice of location and a stationary type of placement, only in this case the beds will last for many years.

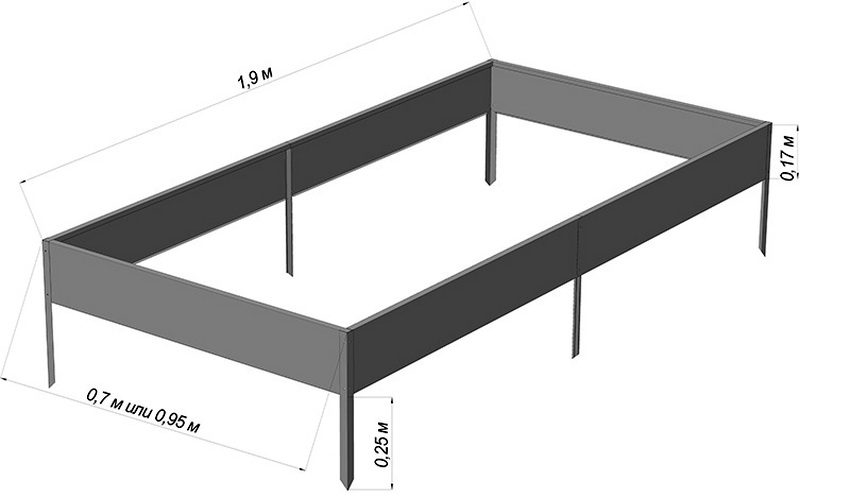

Varieties and dimensional parameters of metal fences for garden beds

The classification of galvanized beds with a protective coating can be based on various criteria:

- type of coating;

- type of construction;

- polymer coloring;

- dimensional parameters;

- metal thickness;

- method of fixing parts, etc.

Some modifications have special legs. These elements prevent the structure from moving during backfilling or weeding of plantations. The legs are buried in the ground, so that the bed is well fixed. The polymer coating can have various colors, due to which the buyer has the opportunity to choose almost any color scheme that will fit well into the surrounding landscape.

On sale there are high and low structures made of galvanized steel. The most popular among land owners are the beds with a height of 15-18 cm and 36 cm.In addition, products with a height of 50 cm are popular.

Note! For greenhouse houses of non-standard sizes, very narrow or, on the contrary, wide modifications may be required.If you buy beds directly from the manufacturer, you can order designs with any parameters, which the market for standard products cannot offer.

The designs may differ from each other and in length. In some modifications, it is possible to install an extension and lengthen the beds by purchasing additional elements.

What is better to buy metal beds: recommendations for choosing and rating of manufacturers

Manufacturers bring to the market models of metal beds with various parameters and characteristics. These factors have a direct impact on the life of the products as well as their cost.

The main criteria for choosing optimal designs:

- steel thickness;

- zinc coating thickness;

- the presence of polymer spraying and its features;

- production technology used to make the beds;

- quality level of parts for installation;

- the presence of stiffeners with a central type of placement.

When choosing a metal bed, you need to pay attention to the technical characteristics of the material

Recommendations for choosing beds based on material quality

Structures with a zinc coating exceeding 25 microns are considered optimal. It is easy to damage the zinc layer in the beds of smaller thickness, as a result of which the process of gradual destruction of the metal under the influence of corrosion will start. A protective coating in the form of a polymer significantly increases the service life of products. This type of spraying performs two functions at once:

- provides protection of galvanized steel from destruction due to contact with moisture, fertilizers and soil;

- eliminates the possibility of mechanical damage to the zinc coating during soil cultivation with a garden tool.

Metal thickness is one of the most important criteria for product quality. On sale there are configurations with a steel thickness in the range of 0.35-1 mm. For arranging a vegetable garden inside a greenhouse house, structures made of metal with a thickness of 0.5 mm are suitable. Outdoor beds should be more durable and reliable, therefore, for these purposes, it is better to take products with a steel thickness within 0.7-1 mm. The same applies to the construction of high beds (over 35 cm), which are subject to increased strength requirements.

One rule should be remembered: the higher the height of the beds, the thicker the sheets of metal should be

Interesting fact! For comparison, you can compare the parameter of the beds with the indicators of the metal from which the car body is made. The thickness of the latter is 1-1.2 mm.

Recommendations for choosing beds based on the quality of the structure

Manufacturers of finished steel structures use special technologies for the manufacture of beds:

- film coating;

- padding;

- powder coated;

- phosphating.

Related article:

High beds in the country with their own hands: photo and manufacturing technology

Photo and step-by-step description of the technology for manufacturing structures for growing crops at their summer cottage, interesting design options.

For this reason, it is recommended to purchase plant beds with proven quality. The durability of a structure can also be affected by the quality of the elements it consists of. Mounting pegs and fixing parts will affect the result of the assembly and subsequent installation of the fence. If these parts are not long enough for deepening, then the structure may warp over time. The risk of such an outcome especially increases when arranging a vegetable garden on the slopes. In such areas, the soil is constantly slipping.

The recommended depth of pegs in a greenhouse house is 25 cm; for a garden in an open area, this indicator should be increased to 35-40 cm.If the height of the bed exceeds 20 cm, and its length is more than 200 cm, it is desirable that the structure includes jumpers between the joints, which are located parallel to each other.

Central stiffening ribs are designed to increase the strength and reliability of the structure; they significantly strengthen the frame part of the product. If it is planned to install structures of small height on the site inside the greenhouse, you can do without the presence of stiffeners in the configuration of the bed. However, for long-term use of fences in the open air, they will definitely be required.

Note! Some manufacturers may issue bends that are present along the edge line of the profile as stiffeners. However, this nuance does not reinforce the design.

Rating of manufacturers of polymer-coated beds

The table shows the differences between the beds New summer residents, GreenBox and other brands that were recognized by consumers as the best. Among them, you can choose structures for different purposes and for any size of the site.

Rating of the best producers of beds:

| Brand name | disadvantages | Advantages | price, rub. |

| New summer residents | Limited choice of shapes (exclusively rectangular beds) | Large selection of dimensional parameters | From 915 (set) |

| Four colors | |||

| Service life 20-30 years | |||

| GreenBox | Not seen | Suitable for outdoor use and greenhouse use | From 620 (set 65x100 cm) |

| Wide range of colors | |||

| Funny | General standard height - 15 cm | Variable width of structures | From 460 (lm) |

| Wide range of colors | |||

| Siberian beds | Relatively high cost | Simple assembly of the box by fixing its elements with bolted connections | From 720 (set 100x200 cm) |

| Large palette of colors (about 200 shades) | |||

| Possibility to order any size | |||

| In addition to rectangular structures, the range also includes hexagonal modifications. | |||

| Novoladozhsky plant | Standard width - 50 cm | Several colors: green, yellow, brown | From 2400 (set 2x05 m) |

| Height - 38 and 19 cm |

Note! If the height of the box exceeds 30 cm, such structures can be effectively used not only for growing vegetables, but also as flower beds, where large perennial plants can be planted. And the modification of the "honeycomb" is in itself a decoration for the site.

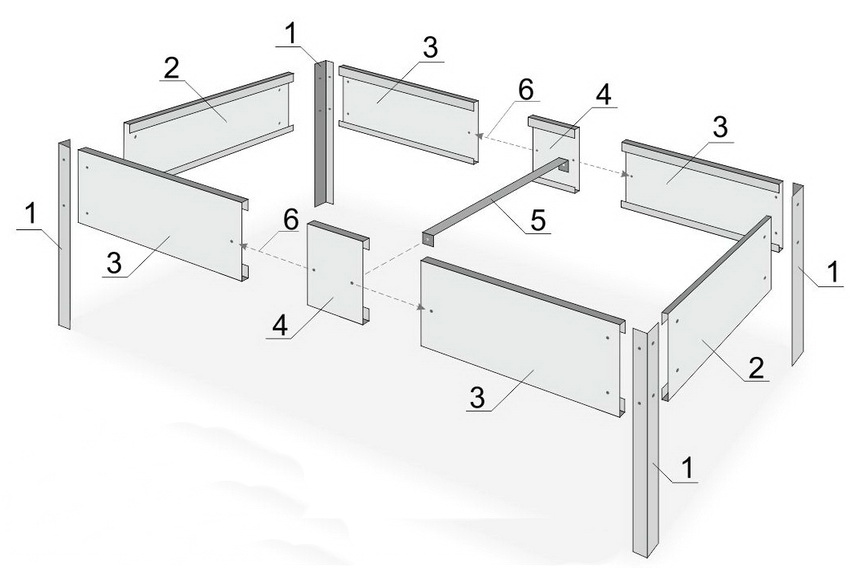

Assembly and self-production of structures

It is very easy to assemble and install a polymer-coated metal bed. Anyone can handle this task. Depending on the modification, the manufacturer can provide various types of connection units. Most often, the groove / tenon method is used to assemble the product. In addition, additional fasteners in the form of self-tapping screws will be required.

Most summer residents use a bolted type of connection. This method is considered to be more reliable. To carry out the assembly of the structure with this method, it is necessary to bend the sides located at the upper edge line on the metal strips. The width of these elements is about 1.5-2 cm. You will need to make holes in them. There are also French beds. To assemble these expensive structures, you only need to connect the elements by snapping.

Bed assembly diagram: 1 - corner, 2 - transverse element, 3 - longitudinal element, 4 - connecting profile, 5 - tie, 6 - junction of the profiles of the longitudinal element and tie

Self-manufacturing technology of metal beds

If you intend to make the structure yourself, it is very important to choose high-quality material. Even corrugated metal will do.

Step-by-step manufacturing technology:

- According to the markings, it is necessary to dig 4 boards into the ground. They should have a strictly vertical position, because it is in this place that the corners of the beds will be located.

- The upper and lower parts of the supports should be nailed onto a wooden frame made of planks.

- Fix galvanized steel breakages on the resulting structure. It is recommended to use electric shears for cutting the material. The metal parts are secured with a slight offset from the edge of the frame using bolted connections.

Useful advice! As an alternative to polymer coating, powder dye can be used.

Manufacturing technology of beds with a fence in the form of gabions

Gabions look as aesthetically pleasing as the beds made of stone. However, unlike masonry, such structures are much easier to assemble and much cheaper. This is due to the fact that the construction of gabions does not imply fixing the filler. The frame part of the bed is simply filled with stones or other types of material. The metal mesh is capable of withstanding severe loads. Due to this, natural stone with a large fraction can be used as a filler.

Instructions for assembling a gabion garden bed:

- The base for construction is cleared of debris and leveled.

- Racks are being installed. For this, pillars are used, equipped with flanges at the bottom. For these purposes, it is recommended to take a rod, the diameter of which is 0.8-1 cm. In this case, you need to install 8 supports so that 2 rectangles are formed: large and small. The smaller rectangle should be equally spaced inside the larger one.

- To form the lattice, a galvanized rod is used, the recommended diameter is 0.5-0.6 cm. The size of the cell is selected taking into account the size of the bulk material so that it does not spill out, and voids do not form inside the product.

- If large bulk material is used, it is worth taking care of the stiffeners. You can use double rods for this.

- The pillars should be fixed as rigidly as possible, since they bear the main load.

The frame part is fixed on the supports. The result should be 2 mesh boxes. The space between them is filled with stone or brick. The inside of the small frame is filled with soil where the plants are planted. Some manufacturers offer ready-made designs to order, which greatly simplifies the gabion assembly process.

How to decorate the structures of metal beds on the site

Steel beds are a great way to create a beautiful and neat vegetable garden on your site. To decorate such structures, you can use not only a colored coating, but also other means. For example, cover the bed with spunbond. Agrofibre in various shades can be found on sale. Canvases in white colors are recommended for use in the garden. Such a surface reflects the sun's rays well, excluding excessive overheating. For woody compositions and flower beds, you can choose any shade, the main thing is that it matches the landscape.

Metal structures braided with a vine look quite decorative. Using this method allows you to get a natural and beautiful garden design on the outside and a durable metal base on the inside. There are other design options as well. The design of the garden depends solely on the imagination and budgetary possibilities of the owner of the site.