Among the many materials that exist today for the finishing of premises, decorative plastic panels for the ceiling and walls stand out. Plastic panels are affordable, reliable in operation, easy to install. Produced by domestic and foreign industry in dozens of different types and sizes, colors and shades, shapes and textures, they are able to provide the embodiment of almost any design idea in interior decoration and have been used in finishing and renovation work for more than 15 years.

Content [Hide]

Plastic panels for ceiling decoration - what are the advantages?

The main criteria for choosing the type of finishing for any premises, both residential and public use, are:

- ease of installation and assembly;

- safety and reliability in operation;

- resistance to adverse factors (moisture, high temperature, pollution);

- convenience in maintaining cleanliness;

- ease of dismantling to eliminate the consequences of emergency situations;

- affordable cost, both of the finishing material itself, and the tools and fasteners necessary for its installation;

- the ability to create a variety of decorative compositions based on a limited number of standard sizes of material and methods of its installation.

The decoration of walls and ceilings made of plastic panels in the kitchen and in the bathrooms meets these criteria as much as possible, due to the properties of their material and design features. Plastic panels are hollow PVC “boards” reinforced with internal stiffeners. Manufacturers produce panels of the following sizes:

- length 2.7-3.0 or 6.0 meters;

- width 25 or 50 centimeters;

- thickness 5-10 mm.

Helpful advice! The plates for the ceiling are lighter and thinner than those for the walls. Accordingly, care must be taken when assembling the ceiling from plastic panels: it is as easy to damage them with your own hands as with a tool.

Through PVC panels, can be trimmed not only ceilings in the kitchen, but also walls that are easy to keep clean

The surfaces assembled from plastic panels for the ceiling and walls are easy to install, practical to use, resistant to prolonged exposure to hot vapors, dirt and moisture. They are able to withstand extreme stress, i.e. in the event of an accident (breakthrough of water-carrying communications, gulfs, etc.), they can hold a large volume of water and withstand heating up to 70-80 ° C.At the same time, the material from which the panels for the ceiling (PVC) are made does not deteriorate and does not lose its properties. To repair the structure, it is enough to remove it from the ceiling, dry it and then restore it in place.

Installation of plastic panels on the ceiling

The entire range of works on the installation of a ceiling made of plastic panels (video and photo instructions are very useful in this case) can be divided into the following stages:

- Selection and calculation of material.

- Determination of the distance between false and base ceilings.

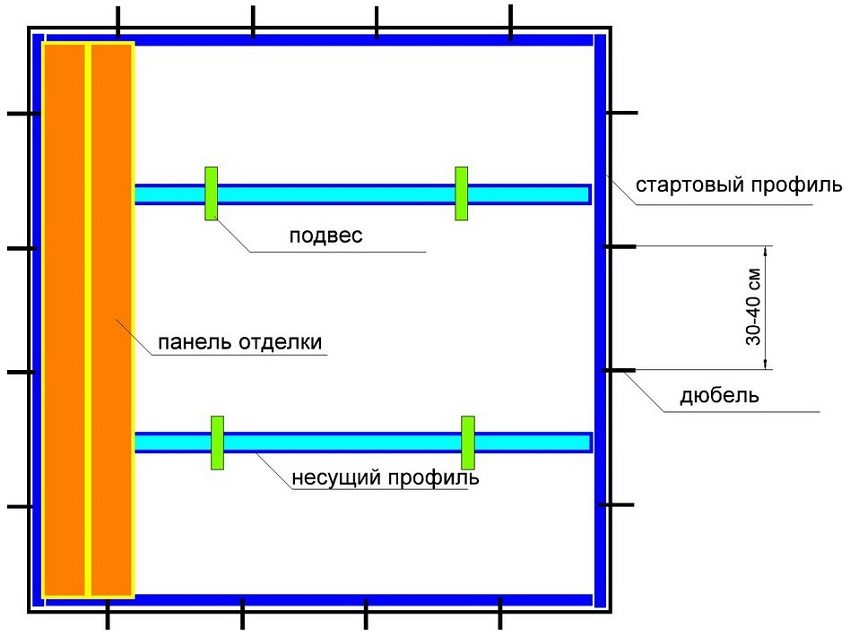

- Installation of the suspended ceiling frame.

- Device electrical wiring.

- Installation of plastic panels.

Selection and calculation of material

The range of plastic ceiling panels on the market for finishing materials is unusually wide. In accordance with the chosen method of finishing walls and ceilings, plastic panels can be selected with highlighted or hidden seams. Also available are panels of various colors, with and without a pattern, matte, glossy and mirror, as well as creating an imitation of natural surfaces: wood, stone, metal, etc. The most popular among the consumer are plastic panels with dimensions of 2.7-3.0 meters by 25 cm white, which easily fit into any interior. At the same time, glossy plastic panels are preferable for a bathroom or for a kitchen: they visually enlarge a small interior.

Helpful advice! For a room that is more than 2.70 meters high, panels of any color are suitable, but it is better to use pastel, neutral colors. It is advisable to decorate low ceilings with plates of mirrored or light colors in order to visually expand the volume of the room.

Plastic ceiling panels only need to support their own weight, so they are thinner and less durable than similar wall products.

To calculate how many plastic panels are needed for the ceiling, the dimensions of the ceiling (its area) are divided by the area of one panel, which is indicated on the package. The resulting value is rounded up and another 15-20% is added for cuts and filling of gaps.

Helpful advice! The required number of plastic panels should be correctly calculated based on the area of the room. In this case, ceiling sheathing will take the minimum possible amount of time.

In addition to the plastic panels themselves, for the false ceiling you will need:

- metal profiles for the frame;

- U-shaped elements for fixing them to the ceiling;

- start profile;

- UD profile 28 mm;

- ceiling plinth;

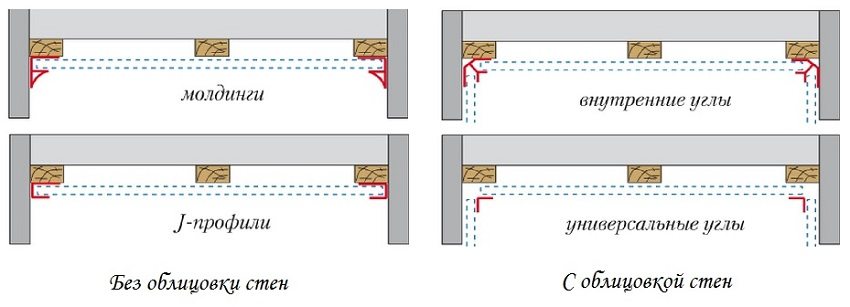

- F-profile and / or external and internal corners to eliminate gaps in the corners;

- H-shaped connecting molding (if the length or width of the ceiling is greater than the length of the panel);

- screws and dowels;

- glue or "liquid nails".

For work, you will need the following tools and accessories:

- drill or hammer drill;

- measuring instruments: tape measure, rulers;

- water level;

- a knife with a replaceable blade;

- scissors for metal;

- a hacksaw for wood or plaster;

- screwdriver;

- masking tape;

- pencil.

Laser level very convenient to use when marking the ceiling height

Preparing the ceiling for finishing with plastic panels

One of the advantages of using PVC panels is that there is no need for complex surface preparation work. The panels themselves will perfectly hide the unevenness of the ceiling, its small cracks and defects. It is enough to clean the crumbling whitewash, if any. After that, it is necessary to clean the surface and treat it with a special composition from fungus and mold.

Helpful advice! It is possible to use wooden blocks to make the ceiling frame from plastic panels in the room. A photo or video of the details of the installation of such a frame can be easily found on network resources dedicated to repair and construction.

Before starting installation work, the panels should be laid out on a clean, dry and level surface so that they lie down. This will make the process much easier.

Related article:

|

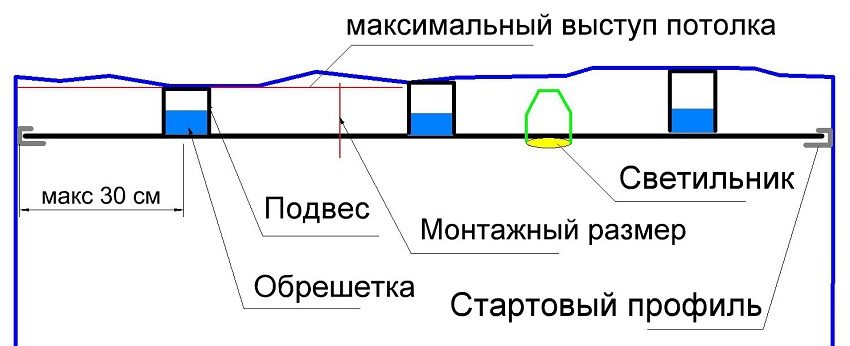

Frame installation

To determine the lowest point of the base ceiling, it is necessary to take into account the presence of irregularities, protrusions and beams, communications, hidden wiring and the size of lighting fixtures. From this point, they begin to mark the plane of the frame, making an indent from the ceiling at the required distance. Usually, a gap of 6-7 cm is made between the suspended and base ceilings. Having determined the position of the frame, on the walls perpendicular to the one where the entrance door is located, mark places for support guides and lines for other profiles or U-shaped elements.

Helpful advice! Walls and ceilings must be checked for hidden wiring. This is done using a special detector or a specialist is invited.

The profiles are mounted with a step of 60-100 cm, adjusting the level.

If electrical wiring or ventilation pipes are to be laid between the base and false ceilings, they should be fixed between the frame elements before installing the plastic panels.

It is convenient to hide the wiring of communications in the frame of the suspended ceiling made of PVC panels

Ceiling decoration with plastic panels

Videos and photos give much more insight into how to make a ceiling from plastic panels than verbal descriptions of the process.

Helpful advice! It is preferable to place the ceiling panels parallel to the wall where the entrance door is located.

You should pay attention to the main points:

- plastic panels must be prepared in advance;

- cutting off the plates is supposed to be 5 mm less than the length of the room;

- to get even cuts, they must be cleaned with sandpaper;

- taking care not to damage the panel, make holes for lighting fixtures with a knife or a drill with a special nozzle;

- Before installation, remove the plastic film from the panels.

So, one of the main advantages of using plastic ceiling panels is the unique ease of assembly provided by their design features. Butt locks on the sidewalls make it possible to install the ceiling from plastic panels with your own hands. Videos and photos, along with instructions that can be found on the Internet, clearly demonstrate the entire workflow.