It takes a lot of effort to grow healthy and organic vegetables, as well as create a favorable environment for them. An excellent solution to this problem is to grow some crops on your own in a greenhouse throughout the year. This article will discuss how to make a practical greenhouse from polypropylene pipes with your own hands without significant financial investments.

A greenhouse made of PVC pipes is a budget solution for summer residents, which can be built independently without large financial investments

Content [Hide]

- 1 DIY greenhouse made of polypropylene pipes: design features

- 2 DIY greenhouse made of polypropylene pipes: characteristics

- 3 DIY greenhouse made of plastic pipes: design features

- 4 DIY greenhouse made of polypropylene pipes: photo instruction

- 5 How to assemble a greenhouse frame from plastic pipes with your own hands

- 6 What covering material for greenhouses is better: fastening features

- 7 DIY greenhouse made of polypropylene pipes: video instruction

DIY greenhouse made of polypropylene pipes: design features

If the decision is made to make a greenhouse from plastic pipes with your own hands, and not to purchase a ready-made structure, you should decide on the type of the future greenhouse. Depending on the shape of the frame, the following types of frames are distinguished:

- arched;

An example of a neat building greenhouse from arcs arched type using a special covering material - agrospana

- rectangular, which, in turn, are divided into two types: for a single-pitched and a gable roof;

- combined: consisting of several sections;

- rectangular structures with an arched roof.

For a better understanding of the varieties of designs, it is recommended to see a photo of PVC pipe greenhouses with your own hands. You should also read the reviews of experienced summer residents who use different types of greenhouses to learn about the advantages and disadvantages of a particular design.

Which of the options to give preference depends solely on your desires and preferences. There are also some expert recommendations on this issue. So, for personal use (in the event that you do not plan to grow vegetables for sale in large quantities), it is recommended to install small or medium greenhouses, the length of which is in the range of 4-12 m, the width is not more than 3 m, and the height is about 2 -2.4 m.

Useful advice!Each bed should be allocated between 80 and 100 cm to provide the plants with enough space for comfortable growth, as well as the ability to conveniently care for them. It is necessary to focus on this indicator in the process of making calculations.

In order for the greenhouse to have the necessary rigidity and not lose its shape under the external influence of the wind, it is worth using high-quality pipes with an aluminum interlayer

As for the materials suitable for creating a greenhouse frame from plastic pipes, the best are PVC water pipes, the diameter of which ranges from 16-110 mm. Any pipe can be used in length, usually from 2 to 5 m.

Sometimes you can find on sale plastic pipes that have a fiberglass layer with polypropylene or aluminum. Their strength index is much higher, although the cost of such pipes is quite high. You can find the statement that such investments are not justified, so this choice should be made from taking into account your own financial capabilities.

For various parts of the structure, it is preferable to use pipes of different diameters: from 25 to 32 mm for arched elements, 50 mm and more for elements that perform a supporting function, especially when it comes to rectangular structures.

DIY greenhouse made of polypropylene pipes: characteristics

Plastic pipes, despite their lightness and relatively low cost, have a lot of positive characteristics. The ease of installation and the resistance of the material to external factors makes it popular among gardeners. Let's consider some of the advantages of using it:

- high wear resistance: the service life of PVC pipes can reach up to 10 years;

- are not affected by moisture and decay processes;

- fire resistant;

- environmentally friendly, do not emit hazardous substances;

- do not deform even under severe mechanical stress, withstand strong winds;

- resistant to chemical and biological influences.

- due to the flexibility of the material, it can be easily given any shape by bending into an arc of the desired radius.

These characteristics make the use of plastic pipes in the independent construction of greenhouses convenient and justified. If you correctly make all the preliminary calculations and purchase the material according to your needs, you can avoid unnecessary waste, as well as create a high-quality and reliable greenhouse with minimal financial investment.

Plastic pipes can be used to build not only the frame of the greenhouse, but also shelves, doors or vents for ventilation

DIY greenhouse made of plastic pipes: design features

In order to make a greenhouse from PVC pipes with your own hands, you will need a drawing, or at least a sketch. The easiest way to find a suitable scheme on the Internet, however, many people prefer to draw it on their own, creating the necessary structure, ideally suited in size and location in the garden or local area.

Having decided to prepare a drawing of a greenhouse made of polypropylene pipes with your own hands, you need to think in advance what the shape of the frame will be, what size the structure should be, and most importantly - how many connecting nodes it will have. This is important because they are more expensive than all other items. Other important aspects that need to be thought out before starting the construction of a greenhouse from HDPE pipes with your own hands include:

- the type of foundation you want to use as the foundation;

- selection of materials that are planned to be used for the construction and covering of the greenhouse;

- placement and shape of the main nodes;

- the distance at which the supporting elements of the structure are located;

- a method of fastening parts to each other and joining them.

Useful advice!To connect plastic pipes to each other, you can use several different methods, for example, you can fasten them with self-tapping screws, glue, solder, or use special connecting fittings.

For the construction of a greenhouse of a more complex shape made of PVC pipes, it is necessary to have a design diagram and adhere to accurate calculations

The simplest and most affordable option for making a greenhouse yourself is an arched frame made of polypropylene pipes, as a covering material for which a film is used. Rectangular structures are more difficult to erect and require the most accurate calculations, as well as the presence of additional ribs for the rigidity of the structure.

Another important aspect that should definitely be taken into account before giving preference to one or another type of structure is the number of docking points that weaken the structure. The more there are, the less resistant the greenhouse is to various influences, including atmospheric loads.

DIY greenhouse made of polypropylene pipes: photo instruction

The complete installation of a greenhouse structure made of polypropylene pipes takes only a few hours and can even be done by one person. Although, working together is much easier and more convenient. It is necessary to carry out the assembly on a pre-prepared, level area.

Preparing the area for the installation of a greenhouse includes clearing the area from grass and debris, as well as laying the foundation. Perfect for a greenhouse strip foundation, but you can also lay out the site with bricks, stones or blocks. It is even easier to use for this purpose a timber or boards measuring 50 × 100 mm or 50 × 150 mm, depending on the size of the greenhouse.

Before starting the construction of a greenhouse, it is necessary to prepare a flat and solid foundation.

To create a complete foundation, you should adhere to the following algorithm:

- The site is marked out according to the drawing.

- Pegs are hammered in the corners, and a rope is pulled along the perimeter of the site.

- It is best to remove the topsoil. It will be enough to remove about 30-50 cm of soil.

- It is advisable to dig a trench along the perimeter, the depth of which will be 30-70 cm, and the width - 30-40 cm.

- It is necessary to level the bottom as much as possible and fill the crushed stone into the trench with a layer of 10-20 cm and on top of the sandstone - 10-20 cm. Further, the layers must be tamped.

- After that, one, or preferably two, layers of roofing material are laid.

- The timber or boards that are planned to be used must be treated with an antiseptic impregnation and smeared with liquid bitumen.

- Once dry, they can be laid out in a trench. At this stage, it is worth checking the geometry so that the diagonals and angles are equal;

- Finally, galvanized corners are attached and secured with long screws.

Useful advice!If it is necessary to strengthen the base, then you can saw down the end parts of the timber in half and put one into the other. To fix it, it is enough to drill through both beams and tighten them with bolts.

A box for a greenhouse can be made of boards or slate and reinforced with self-tapping screws or reinforcing bars

To provide additional waterproofing, roofing material is laid at the top and along the side parts of the foundation. Only after that you can proceed to backfilling the soil.

Useful advice! For a better understanding of the construction process, it is useful to look at the step-by-step instructions with a photo of greenhouses made of plastic pipes with your own hands. In addition, many visual tips can be obtained by watching a video of do-it-yourself PVC pipe greenhouses.

How to assemble a greenhouse frame from plastic pipes with your own hands

To make the frame of the greenhouse, you will need to cut the pre-prepared pipes according to the dimensions, as indicated in the drawing. For this purpose, you can use a grinder or a hacksaw for metal. In this case, the ends must be cleaned with a file.

It's worth starting with assembling the fronts. It is most convenient to do this on the ground, and then install and fasten ready-made elements to the foundation.

With the help of special fasteners, it is necessary to securely fasten the plastic pipes at an equal distance from each other.

Particular attention should be paid to doors, as its convenience is directly related to the comfort of your use.In order to assemble the doors, you need 2 vertical and 3 horizontal parts, as well as 4 corners and 2 tees, which will serve to connect all the elements.

Two vertical posts, approximately 2-2.1 m high, will be used to create an opening with hinges on one side. At this stage, you will also need one of the cross members, 50-70 cm wide.

Then we take a PVC pipe, the length of which corresponds to the length of the arch, and put all the existing tees on it so that the distance between them corresponds to the width of the opening. We fix the opening on the tees.

Useful advice!Using tees, you can significantly strengthen the strength of the structure. To do this, it is enough to put 2-3 pieces on the frontal arch and attach additional horizontal stiffeners to them.

In order to prevent the covering material from sagging between the pipes, you can stretch a wire or plastic mesh and secure it with ties

In order for the greenhouse to stand firmly, reinforcing rods are driven into the ground, the thickness of which is 8-12 mm. This should be done from the outside of the foundation, hammering them to a depth of 30 to 70 cm. At the same time, at least 50-80 cm of the rod should remain outside. The distance that should be observed in this case should not exceed 1 m. Usually it is from 60 to 90 cm.

Related article:

Greenhouse Bread box: functional design for growing vegetables

Design advantages and disadvantages. How to make and sheathe a frame with your own hands. Prices and features of finished structures.

Having cut all the pipes to a suitable size, we put one of its ends on the rod and bend it so that the other end can be put on the second rod located on the opposite side of the foundation. On the second side, this procedure must be repeated.

Useful advice! To ensure the strength of the fastening, you can use wide polymer clamps or special galvanized brackets that will help to securely attach the arcs to the foundation. The same method can be used to attach the greenhouse gables.

For convenience, a low greenhouse can be made with an opening top by securing the two parts with rope and chain

After that, it remains only to give the frame a solid shape, fastening it with the help of transverse elements. To do this, PVC pipes are cut so that their size corresponds to the length of the greenhouse, and then they are fixed with plastic clamps. It is imperative that one such arc is located in the central, uppermost part of the arc. Also, additional side bars on each side will not be superfluous.

According to the same principle by which the doors were made, they also make vents intended for ventilation. After that, it remains only to cover the frame of the greenhouse from HDPE pipes with a film or sheathe it with polycarbonate.

What covering material for greenhouses is better: fastening features

Either plastic wrap or polycarbonate can be used as a covering material for greenhouses and greenhouses. These two materials differ significantly from each other in characteristics, fastening methods and service life. However, each of them occupies its own niche in modern greenhouse construction, and has some advantages. Consider how to choose a covering material for a greenhouse.

Which film is best for a greenhouse, and how to attach it to the frame

There are several ways of attaching a plastic film to the frame of a greenhouse, among which the simplest and most convenient one should be noted: the film is cut into pieces, 5-10 cm in size, and a quarter is cut along the length to make staples. The film is pulled over the greenhouse, and with the help of the obtained brackets is fixed to the longitudinal and vertical racks.

Other options for attaching the film include fixing with ropes, a net throughout the frame, using double-sided tape, and even ordinary self-tapping screws.For the latter method, small pieces of linoleum are required, which will protect the film from damage. You can buy clips for the film on the greenhouse, which are sold in specialized stores and not only provide reliable fastening of the cover, but also greatly simplify the work.

The main advantage of this method is the low price of film for greenhouses and greenhouses. Such a coating does not last longer than one or two seasons, however, there are no problems with its replacement. By purchasing a roll of film for a greenhouse 6 meters wide, you can be sure that it will last for several seasons of use.

Anchor covering material on the greenhouse, you can use stationery binders, double-sided tape or pipe clips

Useful advice! In order not to encounter drafts in the greenhouse during operation, it is recommended to make the film longer than the frame so that about 10-20 cm remains on the ground. In this case, the edges can be sprinkled with earth or put on top of the board to ensure the structure is more tight.

Most often, acrylic film for greenhouses is used as a covering material. Its strength indicator is higher than that of polyethylene, and therefore its service life will be noticeably longer. Although, it is worth noting that the price of acrylic film for a greenhouse is slightly higher.

How to choose polycarbonate for a greenhouse: mounting methods

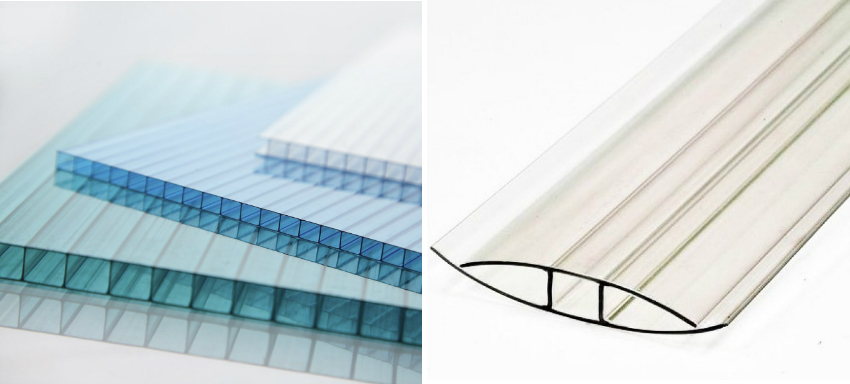

Polycarbonate is another covering material for a greenhouse, which you can buy at any hardware store. Before buying, you need to think about which sheets are needed, and how to properly fit the materials together. For example, in order to attach polycarbonate to the frame, the frame must be made of polypropylene pipes with a diameter of at least 32 mm.

It is believed that cellular polycarbonate, whose thickness is in the range of 4-6 mm, has ideal technical characteristics for covering a greenhouse. It makes no sense to purchase a coating thinner, since it will not be able to cope with external loads.

Polycarbonate is attached to a greenhouse made of PVC pipes as follows:

- Using self-tapping screws and washers 3.2 × 25 mm, the material is attached to the frame.

- With a sharp knife, the excess is cut off in an arc.

- Each next sheet is attached with an overlap of 100 mm to the previous one.

- To strengthen the structure, a special detachable docking profile is used, which is attached with self-tapping screws. Polycarbonate sheets are inserted into it.

- The joints are closed with plugs.

You can make a hinge for a greenhouse made of PVC pipes with your own hands. To do this, two pieces of 10 mm are cut from a pipe of larger diameters and connected to each other with glue. Polycarbonate sheets are inserted into them and fixed with the same screws. This is very convenient for creating vents and door elements.

You can create a durable greenhouse with your own hands by combining plastic and HDPE pipes for strength

DIY greenhouse made of polypropylene pipes: video instruction

It is quite simple to make a greenhouse from polypropylene pipes on your own. By adhering to all the recommendations and instructions, you can create a solid and beautiful structure that will be an excellent addition to the site and will allow you to grow seedlings, vegetables and herbs. The main thing is to choose the right materials and ensure their reliable fastening to each other.