Today, a wide selection of flooring is available in hardware stores. Porcelain stoneware, parquet, tiles, linoleum, carpet, laminate - a wide variety of options for every taste and budget, to embody the most bizarre design idea. The emergence of a new type of coating made it much easier for buyers to choose. New to vinyl flooring, the pros and cons of many other types of floor finishes come together.

Content [Hide]

The structure and manufacturing technology of vinyl floors

The advantages of vinyl floors are due to the peculiarity of their structure. They represent a multilayer material, the main components of which are polyvinyl chloride and mineral (most often, quartz) chips. Also, the composition of vinyl floors includes stabilizers, inert fillers, resins and plasticizers. These components are hot pressed into a new material with a multilayer structure.

The base consists of PVC and quartz chips, which gives the floors the necessary elasticity and strength. It is because of the presence of quartz that such floors are called quartz vinyl... Some models have one more bottom layer - a self-adhesive backing with a protective film.

Above is a colored decorative layer. A pattern is applied to it that imitates a tile, board, parquet, cork, stone, pebble, a strict geometric or bright abstract pattern. To protect the design from abrasion, a special polyurethane film is applied on top.

The topmost transparent layer protects the quartz vinyl coating from the harmful effects of ultraviolet radiation.

The top decorative layer of vinyl covering can imitate stone, wood, tiles, laminate or any other pattern

This complex structure makes it possible to achieve incredible strength and wear resistance of the material. It does not lose its appearance for decades.

Interesting fact! Vinyl floors combine the benefits of many types of flooring. By their flexibility they remind linoleum, strength - stone, ease of installation and shape - laminate. Only, unlike the latter, vinyl tiles do not have a locking system. It is replaced by special hollow sinuses, smeared with glue. Another difference lies in the thickness of the coating - it is twice as thin as laminate.

Vinyl flooring: the pros and cons of using flooring in residential areas

Vinyl flooring appeared in the second half of the last century. Over the years, it has significantly changed and gradually acquired those unique characteristics that guaranteed its popularity today. They are used in offices, industrial facilities, and apartments. More and more people prefer this type of flooring. What are the pros and cons of vinyl floors, according to these people, have been identified during their operation?

Benefits of vinyl floors

One of the main advantages of quartz vinyl flooring is its amazing strength and durability. It serves for decades without losing its original appearance. Thanks to its mineral crumb, it is almost not subject to abrasion, and a special protective film layer prevents it from fading from intense exposure to sunlight or aggressive detergents. True, this is only true for expensive vinyl floor coverings (reviews can be found on specialized forums).

The vinyl covering is also characterized by increased wear resistance, is not afraid of scratches and cracks, and dents from furniture legs do not form on it, as is the case with cork floors.

Among other advantages of the finishing material, it is worth mentioning water resistance. It allows vinyl flooring to be laid on the floor in rooms with high humidity and significant temperature changes, such as bathrooms or outdoor areas. The coating will provide a sufficient level of waterproofing for many years, as it is not afraid of water and does not deform due to exposure to steam or heat.

Based on numerous reviews of vinyl floors on the internet, they are not moldy or mildewy. And the fact that small pests such as mice and rats do not find it attractive to themselves allows this type of coating to be used in private houses.

In specialized stores, there is a large selection of quartz vinyl coating of all kinds of colors and textures. The assortment is so varied that it is often difficult to understand when looking at vinyl floors what it is - wood, stone or leather. Photos of quartz vinyl floors on the Internet clearly demonstrate how easily and very believably they imitate any natural and synthetic materials.

If desired, you can find vinyl tiles that resemble expensive woods, pebbles, natural or artificial stone, as well as bright abstractions or unusual patterns. This will allow you to decorate the interior in any style from classic to hi-tech and at minimal cost. The aesthetics of the material are not limited to a wide range of colors. This coating has no visible seams or joints.

If you compare the cost of vinyl tiles and other types of flooring, it turns out that it is roughly the same as ceramic tiles and less than parquet or cork flooring.

Related article:

|

Cons of vinyl floors

Despite the undeniable advantages of this coating, the disadvantages of vinyl laminate are well known.

Given the composition of the vinyl flooring, it is impossible to consider it environmentally friendly. This entails several problems at once. Firstly, this composite material is non-degradable and therefore cannot be recycled.Second, the new vinyl flooring releases toxins for a while. They will not harm an adult, but it is better not to use it in children's rooms. It is not suitable for asthmatics, allergy sufferers, people with weakened immunity, since the substances secreted by it can irritate the mucous membranes and provoke the development of respiratory diseases.

Useful advice! It is worth asking for a hygiene certificate before purchasing vinyl flooring. Its presence guarantees the safety of using the finishing material in the apartment.

It is not recommended to use fire-hazardous vinyl in the kitchen, since the possibility of fire cannot be excluded in this room, and the material emits toxic substances when burning.

Vinyl tiles are tough, durable and airtight. But due to these qualities, the dismantling of the floor covering is associated with difficulties. Even if only a small area of the floor is damaged, it cannot be replaced. All vinyl will have to be removed.

Vinyl flooring is resistant to mechanical stress and aggressive chemical attack. However, there are substances and materials, contact with which will negatively affect the appearance and quality of vinyl tiles. One of these unsuitable materials is rubber. Vinyl will discolor and tarnish on contact with it. For this reason, you should not buy rubber mats for vinyl bathrooms.

Due to the thinness of the coating, it is impossible to warm the vinyl floor. The floor will definitely have to be additionally insulated, which will lead to an increase in the cost of repairs.

The main types of vinyl flooring

There are several classifications of vinyl flooring.

Depending on the technological characteristics, the following varieties are distinguished:

- universal tile on an adhesive basis (the easiest option to install, the adhesive already applied to the bottom of the tile provides perfect adhesion to any clean surface);

- a covering with a lock joint (the glue is applied not to the back side, but to the edge of a single-strip vinyl laminate (with or without bevel), thus, the floor seems to "float", an excellent option for places with increased traffic and the topcoat of a warm floor);

- adhesive coating (the most affordable option in terms of price, it is laid with vinyl tile adhesive).

Depending on the size, the following types of coverage can be distinguished:

- vinyl tiles (PVC tiles) 300 × 600 mm in size with lockless and lock connection;

- quartz vinyl laminate with dimensions of 180 × 920 cm and 100 × 920 mm;

- in the form of rolls (2000 × 25000 mm), resembling linoleum.

Depending on the level of wear resistance, vinyl flooring is used in apartments and offices, airports, schools, shops. Dividing the coverage into several classes allows you to choose the right option correctly:

- Average level of use, wear resistance class 23-31. It is used in residential premises with low traffic. The service life of this 2 mm thick coating is not long (only 6 years), but it is represented by a huge assortment of colors and textures.

- Intensive level, class 32-42, coating thickness 2.5 mm. It is used in public and commercial buildings - offices, schools, shopping centers, etc. It can last up to 15 years, and in apartments up to 30 years.

- Maximum level, class 43, thickness 3 mm. It was created specifically for premises with high traffic and high mechanical stress - in production, gyms, airports, garages.Its distinctive characteristics are high elasticity, good anti-static and anti-slip properties.

DIY vinyl flooring tips

Before you start laying vinyl floors (the video can be found on the Internet), you must thoroughly clean the floor of any debris and dry it. Otherwise, even small particles can spoil the soft bottom layer and lead to deformation and rupture of the coating during its further operation.

The surface on which you plan to lay vinyl tiles must be perfectly flat. Since the floor differences should not exceed 3 mm, the concrete floor must be leveled with a self-leveling screed, and then treated with a primer. The wooden base is also suitable for gluing tiles, but it is pre-leveled with thin plywood. Particleboard can be used instead of plywood, but they are not suitable for glued laminate installation due to their rough and uneven surface.

Useful advice! To facilitate the work with the finishing material, after purchase, vinyl must be left indoors for some time without removing it from the package. If the temperature outside during the transportation of the tiles was below +100C, then this time should be at least two days.

Be sure to apply markings on the floor if you have to work with an adhesive coating. The room should be divided into 4 sectors relative to the center. Installation of tiles begins from the site that is located farthest from the door and is carried out from the center to the corners of the room. The glue itself is applied to the concrete screed for a quarter of an hour, after which the tiles are laid and pressed with a rubber roller or flat plate. It is necessary to completely remove the film from under it, otherwise the surface will be uneven. Apply the glue with a very fine-toothed comb.

Installation of the lock connection is the same as the installation of a conventional laminate. A protective strip is located along the protruding edge of the cover to cover the adhesive edge. Remove it, insert the ledge into the groove of the laid laminate and tap with a rubber mallet to join the edges.

When laying the tiles on a self-adhesive backing, the film is removed and pressed to the floor. It is important to do this the first time, because if you glue the tile several times and tear it off, then you will not be able to glue it well. To avoid this, you must first remove the narrow edge of the protective film and apply the vinyl covering to the already installed tile. Then remove all the film and press it firmly to the floor. It is important to trim the edges and adjust the tiles before removing the adhesive film.

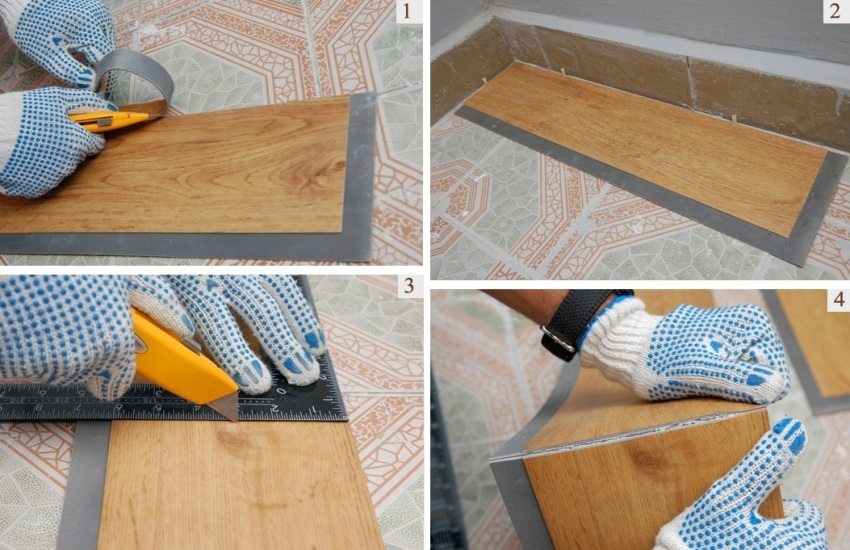

Step 1: trimming the lock from the panels adjacent to the wall; step 2: laying the first panel; steps 3 and 4: trim and fit panels to size

Important! During installation, the quartz vinyl covering must be moved over the already laid laminate. This is primarily due to the need to maintain the ideal cleanliness of the surface to be coated.

Immediately after installation, it is necessary to check the quality of the installation so that there are no hollows or bulges. The corners and joints must be smooth and neat.

You can remove excess glue with a cloth dampened with alcohol or soapy water. You can wash the floor one day after laying the floor, and arrange the furniture after two days.

Proper care of quartz vinyl flooring

Caring for quartz vinyl floors, according to reviews on the Internet, is not difficult. They can be vacuumed, including with a vacuum cleaner for wet cleaning of premises, swept, washed with a damp cloth. They will be given shine by special means for linoleum (various solutions and mastics).

Despite the excellent durability and strength of vinyl floors (photos are presented in this article), they cannot be washed with aggressive abrasive detergents and industrial cleaners. They can not only lead to discoloration of the coating, but also deform it. If such a product does spill, it must be removed immediately.

Although the vinyl floor is not afraid of harsh mechanical stress, it is still worth using special suede foot pads or plywood sheets when moving furniture.

These simple rules will keep your vinyl floor in top condition for many years.